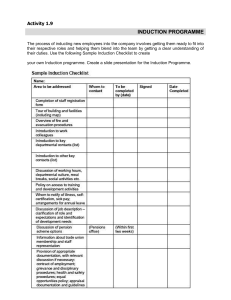

Proceedings of the 35th Chinese Control Conference July 27-29, 2016, Chengdu, China A new speed control method of induction motor NIU Ming-zhe, WANG Tao, ZHANG Qian, HE Xiang, ZHAO Ming-liang School of Electrical Engineering, Southwest Jiaotong University, Chengdu 610031 E-mail: 1101396623@qq.com Abstract: In recent years, the control of induction motor has become an important research topic and a variety of control methods have been born.This paper proposes a new motor speed control approach based on methods of synergetic control thoery, which combines the traditional speed closed-loop control and synergetic control. The new method gets rid of PI regulators compared to the traditional conrtrol methods and the algorithm is very simple. The result of simulation shows that this control system has good dynamic and static performance. Key Words: induction motor, speed control, synergetic control 1 Introduction From a control point of view, the induction motors are nonlinear, high-order dynamic systems of considerable complexity. They are amenable to a formal mathematical analysis. However, it is not a trivial matter to comprehend the principles of their operation in an imaginative way, especially under transient conditions. Conversely, induction motors are widely used in practical systems because of their simple construction, low maintenance requirements, and lower cost compared with other types of motors,such as brushless DC motors.Therefore, it is a great significance to investigate the control problems of induction motors [1]. With the development of power electronic technology, control technology and control theory, a variety of general and high performance control strategies have been born and become more and more mature, some representative control strategies of the induction motor are as follows: speed opened-loop constant V/f control, field oriented vector control (FOC), direct torque control (DTC), feedback linearization control, sliding mode control(SMC), intelligent control, etc. [2]. These strategies have different advantages and disadvantages, hence, these strategies must be selected appropriately according to the specific requirements in practice. regulation. In section Ċof this paper,the model of the induction motor is presented. In section ċthe new speed control method is introduced which includes the basics of synergetic control synthesis , hysteresis current control and the algorithm used in the new control method. Finally, in section ČMATLAB is used in the simulation experiment, and the results demonstrate the ability of the proposed control method to improve the static performance and dynamic performance. 2 Model of the induction motor According to the state representation of the induction motor, with consideration of the stator current isd , isq , and rotor flux UG, UT as the state vectors, we define x1=¹U , x2= UG , x3= UT , x4= isd, x5= isq, for notation convenience. Then the induction motor is described by the following system of equations are given by [10]: Traditional vector control methods depend on PI regulator and the parameters of the regulator are difficult to regulate. Though some new methods have good dynamic and static performance but their algorithms are complex and have many parameters to regulate. Introduced in the last decades, synergetic control has rapidly gained acceptance not only by the robust control but also by the industrial partners as illustrated by its implementation in power electronics field [3-9]. The good robustness of the new control theory provides a new train of thoughts of motor speed control. This paper proposes a new control strategy combines traditional vector control and synergetic control, which can not only simplify the algorithm but also eliminate the PI regulators compared with the traditional methods. What’s more, this new control strategy can reduce the number of parameters to be debugged and get good dynamic and static performance just through a simple process of parameter x1 P 2 Lm P (x2 x5 x3 x4 ) TL JLr J x2 x3 Zs x2 x4 (Zs x1 ) x5 x5 E x1 x2 (Zs x1 ) x4 L 1 x2 Zs x3 m x4 Tr Tr L 1 x3 m x5 Tr Tr E Tr x2 J x4 Where Rs : stator resistance LS : stator self inductance Lm : mutual inductance Zs :slip angle frequency TL : load torque, and L L , L2m T = r E = m V =1 Ls Lr r Rr (1) V Ls Lr E Tr 1 V Ls usd x3 J x5 1 V Ls usq Rr : rotor resistance Lr : rotor self inductance T2 : rotor time constant Zr : rotor frequency , J L2 1 ( Rs m2 Rr ) Lr V Ls For a rotor-flux orientation we get * This work is supported by National Natural Science Foundation (NNSF) of China under Grant 51477146. 10140 Authorized licensed use limited to: Universidad de Sonora. Downloaded on July 02,2023 at 00:50:19 UTC from IEEE Xplore. Restrictions apply. x2 \ rd 3 \r x3 0 Zs x5 Lm x2Tr (2) 3.2 Hysteresis current control Design of proposed synergetic controller In recent years, the synergetic control method has made a great influence in field of power electronics. The design process of synergetic control algorithm for an n-order nonlinear dynamic system described by the equation (1) is as follows [11]: 1. Select the macro variables defined in terms of eq. 3. These macro variables can be defined as linear combinations of state variables. <s Then we get the stator currents x4= isd and x5= isq which should be tracked. (x1 , x2 ......xn ) (3) The control will force the system to operate on the manifold: (4) <s 0 Nowadays, the hysteresis current control has rapidly gained acceptance because of its simple control mode, easy hardware implementation, reliable operation and quick dynamic response. For ac motors, a practical need is to make sure that the input current should be a sine wave, because only when the current in stator windings is three-phase symmetrical, the torque would be a constant value. If we can ensure the current’s sine waveform by using the hysteresis current control method, the system will clearly get good performance [12,13]. A common current closed-loop control method is CHBPWM (Current Hysteresis Band PWM) control, the current control principle of phase A is as shown in figure 1. 2. Set the dynamic evolution of macro-variables by the following equation (5): (5) Ts < s M (< s ) 0 where M is the function of Vto be selected, Ts defines the speed of convergence of macro-variables to manifolds s=0. To ensure the stability of the equation (5), the function M must satisfy following conditions: Ts < s < s (6) 0 Ms (0) 0,Ms (< s )< s ! 0 Load Fig. 1: The current control principle of phase A By setting hysteresis layer, we can control the output currents fluctuate around the given values of currents as shown in Fig. 2. (7) It’s obvious that the equation (5) will vary with function M and parameter Ts . In this paper, we select the function M which makes the equation (8) established: Ts < s < s 0 (8) Fig. 2: Current tracking use CHBPWM 3.3 Diagram of the control method 3.1 Application of synergetic speed control for IM Select the stator current x4= isd , x5= isq as the control variables, and select two macro variables as follows: <1 x1 x1ref (9) < 2 x2 x2 ref The resulting diagram of the synergetic control applied to an IM is given in Fig. 3. Zrref \ rref i*sd Synergetic Control i*sq Park 1 i *a i*b i *c CHB PWM Inverter IM From equation (8) and (9), we get˖ T1 <1 <1 T1 x1 (x1 x1ref ) 0 Zt (10) T2 < 2 < 2 T2 x2 (x2 x2ref ) 0 Combine equation (1), we obtain: P 2 Lm P T1 ( (x2 x5 x3 x4 ) TL ) x1 x1ref =0 JLr J T2 ( ª x1 º «x » ¬ 2¼ x5 x1ref x1 p JLr TL ) ( p 2 Lm x2 T1 Jr Zr Fig. 3: System configuration of the proposed control Solve the equation (11), the control variables are: Lr x2 ref x2 1 x2 ) ( Lm Rr T2 Tr isD isE (11) L 1 x2 Zs x3 m x4 ) x2 x2 ref =0 Tr Tr x4 Flux Observer Clark (12) The flux observer figures out amplitude and angle of the rotor flux online, the synergetic control algorithm figures out the given values of currents, the inverter produces pulse to make the input currents track the given values of stator currents. 4 MATLAB simulation Machine parameters has be shown in table 1. 10141 Authorized licensed use limited to: Universidad de Sonora. Downloaded on July 02,2023 at 00:50:19 UTC from IEEE Xplore. Restrictions apply. Table 1: Parameters of Induction Motor 4.85 Rr(oms) 3.8 Ls(mH) 274 Lr(mH) 274 Lm(mH) 258 P 2 J(kg.m²) 0.23 DC voltage˄V˅ 500 100 80 60 40 Te(Nm) Rs(ohm) 20 0 -20 -40 0 0.1 0.2 0.3 t(s) 0.4 0.5 0.6 Fig. 7: Electromagnetic torque The simulation uses ode45 algorithm, control algorithm (equation 11) is implemented by the S-function of MATLAB. The total time of the simulation is 0.6S, and T1= T2 =0.001, the load torque(Nm) jumps from 0 to 10 at 0.1Sˈ the given value of the flux jumps from 1 to 0.8 at 0.3s, the given value of the rotor speed jumps from 100 to 200 at 0.4s. The results of simulation are shown in fig. 4-7. To analyze the influence of T1 and T2 on the convergence process of macro variables, select three sets of parameters: T1 T2 k1 0.01 T1 T2 k2 0.001 T1 T2 k3 0.0001 The convergent waveforms of the two macro variables and are as follows: 120 250 k1 k2 k3 100 80 200 60 ǻwr(rad/s) wr(rad/s) 150 40 20 100 0 50 -20 0 0 0.1 0.2 0.3 t(s) 0.4 0.5 0 0.1 0.2 0.3 t(s) Fig. 8: 0.6 Fig. 4: Rotor speed 0.4 0.5 0.6 1 k1 k2 k3 2 1.8 0.5 ǻpsir(wb) 1.6 rotor flux(wb) 1.4 1.2 0 1 0.8 0.6 0.4 -0.5 0 0.1 0.2 0.2 0 0 0.1 0.2 0.3 t(s) 0.4 0.5 Fig. 5: Rotor flux ¹U 30 0.5 0 -10 K1 K2 K3 -20 0 0.1 0.2 0.3 t(s) 0.4 Fig. 6: Stator current of phase A 0.5 0.6 (\ rref \ r ) 100% \ rref Then we can get the table 2 and table 3. Table 2: Static Error of ¹r 10 isa(A) 0.4 From Fig. 8 and Fig. 9, if we define the static errors of and U as: (Zrref Zr ) 'Zr % 100% Zrref '\ r % 20 -30 Fig. 9: 0.6 40 0.3 t(s) 0.6 K1 K2 K3 0.1s-0.3s 0.3s-0.4s 0.603 0.606 0.068 0.061 0.04 0.038 Table3: Static Error of r 0.1s-0.3s 0.3s-0.4s -9.13 -9.19 -0.85 -0.85 -0.1 -0.1 0.4s-0.6s 0.304 0.031 0.02 0.4s-0.6s -9.2 -0.85 -0.1 10142 Authorized licensed use limited to: Universidad de Sonora. Downloaded on July 02,2023 at 00:50:19 UTC from IEEE Xplore. Restrictions apply. As we can see in the table 2 and 3, the smaller T1 and T2 are, the smaller static error will be. However, from the figure 9, we can see that transient time will be longer if T1 and T2 become bigger. 5 Conclusion We have proposed a new speed control method of induction motor which combines traditional vector control with synergetic control. This new method can reduce the complexity of algorithm and get rid of the PI regulators in traditional control methods. In addition, there are only two parameters need to be debugged. The results of simulation show that this new method has a good dynamic and static performance. References [1] [2] [3] [4] [5] V. I. Utkin, J. Guldner, and J. Shi, Sliding mode control in electromechanical systems, CRC Press, 2009:271-272. Xing Bing-suo, Summary of the control strategy for induction motor, Electric Drive Automation, 35(4):11-14, 2013. I. Kondratiev, R. Dougal, General synergetic control strategies for arbitrary number of paralleled buck converters feeding constant power load: Implementation of dynamic current sharing. IEEE ISIE, 1:257-261, 2006. Anatoly Kolesnikov, Gennady Veselov, Andy Popov, Alex Kolesnikov, Roger A.Dougal, Igor. Kondratiev, A synergetic approach to the modeling of power electronic systems, 7th Workshop on Computers in Power electronics, 2000. A. Kolesnikov,G. Veselov, A Monti, Synergetic synthesis of Dc-Dc boost converter controllers: Theory and experimental [6] [7] [8] [9] [10] [11] [12] [13] analysis, Applied Power Electronics Conference and Exposition, 1:409-415, 2002. A. Monti, R Dougal, E Santi, et al, Compensation for step-load variations when applying synergetic control, Applied Power Electronics Conference and Exposition, 1:334-340, 2003. A.Monti, E.Santi, K.Proddutur, R.Dougal, Synergetic control for DC-DC boost converter : implementation options, IEEE Trans. on Industry Applications,39(6):1803-1813,2003. Young-Dae Son,Tae-Won Heo,Santi, E.,Monti, A synergetic control approach for induction motor speed control, Industrial Electronics Society, 1:883-887,2004. Z. Jiang and R. Dougal, Synergetic control of power converters for pulse current charging of advanced batteries from a fuel cell power source, IEEE Trans. on Power Electronics, 19(4):1140-1150, 2004. Zhang Yong-chang, High performance control technology of induction motor without speed sensor, China Machine Press, 2015:45-50. M. Laribi, M.S. Ait Cheikh, C.Larbes, N.Essounbouli, A. Hamzaoui, A sliding mode and synergetic control approach applied to induction motor, Proceedings of the 3rd International Conference on Systems and Control, 2013. S. Sathiakuma, et al. Microprocessor-Based field-oriented control of a CSI fed induction motor drive, IEEE Trans. Indus. Electron., 33(3):39-43, 1986 . Kazmierkowski, M.P., Sulkowski, W. A novel vector control scheme for transistor PWM inverter-fed induction motor drive, IEEE Trans. Indus. Electron., 38(1):41-47, 1991. 10143 Authorized licensed use limited to: Universidad de Sonora. Downloaded on July 02,2023 at 00:50:19 UTC from IEEE Xplore. Restrictions apply.