Aspen Plus

Summary File Toolkit

Version: V14

Copyright (c) 2022 by Aspen Technology, Inc. All rights reserved.

Aspen Plus, aspenONE, the aspen leaf logo and Plantelligence and Enterprise Optimization are trademarks or

registered trademarks of Aspen Technology, Inc., Bedford, MA.

All other brand and product names are trademarks or registered trademarks of their respective companies.

NIST Standard Reference Data (SRD); © Copyright ©2022 by the U.S. Secretary of Commerce on behalf of the

United States of America. All rights reserved.

This document is intended as a guide to using AspenTech's software. This documentation contains AspenTech

proprietary and confidential information and may not be disclosed, used, or copied without the prior consent of

AspenTech or as set forth in the applicable license agreement. Users are solely responsible for the proper use of

the software and the application of the results obtained.

Although AspenTech has tested the software and reviewed the documentation, the sole warranty for the software

may be found in the applicable license agreement between AspenTech and the user. ASPENTECH MAKES NO

WARRANTY OR REPRESENTATION, EITHER EXPRESSED OR IMPLIED, WITH RESPECT TO THIS DOCUMENTATION,

ITS QUALITY, PERFORMANCE, MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE.

Aspen Technology, Inc.

20 Crosby Drive

Bedford, MA 01730

USA

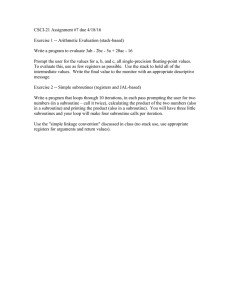

Phone: (1) (781) 221-6400

Toll Free: (1) (888) 996-7100

URL: http://www.aspentech.com

Contents

Who Should Read this Guide ...................................................................................1

Introducing Summary File Toolkit ...........................................................................3

Related Documentation ..................................................................................... 3

Technical Support ............................................................................................ 4

1 Getting Started ....................................................................................................5

The Summary File and Toolkit ............................................................................ 6

32-bit and 64-bit Code ...................................................................................... 6

Initializing the Toolkit ....................................................................................... 7

Accessing the Required Files .................................................................... 7

Getting the Summary File Name ........................................................................ 7

Getting Property and Units File Names ...................................................... 7

Defining Units of Measurement ................................................................ 8

Specifying a Value for Missing Results ....................................................... 8

Determining the Data Dimensions ...................................................................... 8

Retrieving Data for an Object............................................................................. 9

Using the Toolkit With a Hierarchical Aspen Plus Run .......................................... 11

Linking Toolkit Subroutines into Your Module ..................................................... 11

Creating a Toolkit Application for Windows ........................................................ 11

About the Windows Version ................................................................... 12

Linker Directive Commands for Windows ........................................................... 12

Calling Summary File Toolkit Routines .............................................................. 13

VBA Calling Fortran Example ................................................................. 14

Opening and Closing Files Using the Summary File Toolkit ......................... 14

Using Fortran to Call Routines ................................................................ 15

Changes in the Toolkit .................................................................................... 15

2 General Subroutines ..........................................................................................17

Initializing the Summary File Toolkit ................................................................. 18

Closing the Summary File Toolkit ..................................................................... 19

Opening and Closing Files................................................................................ 20

Retrieving Run Information ............................................................................. 21

Standard Run Information ..................................................................... 21

Run Titles ............................................................................................ 22

Accounting Information ......................................................................... 23

Retrieving Flowsheet Balance Results................................................................ 23

Units Conversion ............................................................................................ 24

Changing Units Sets ............................................................................. 24

Converting Units for Real Numbers ......................................................... 25

Determining Units Labels ...................................................................... 26

Component Information Retrieval ..................................................................... 26

Number of Components ........................................................................ 26

Contents

iii

Component IDs .................................................................................... 27

Component Alias Names ....................................................................... 27

Component CAS Numbers ..................................................................... 28

Component Properties .......................................................................... 28

Sensitivity Block Results ................................................................................. 28

Identifying Sensitivity Blocks ................................................................. 29

Determining Sensitivity Dimensions ........................................................ 29

Retrieving Sensitivity Results ................................................................. 30

3 Block Result Subroutines...................................................................................31

Block Identification ......................................................................................... 32

Block IDs ............................................................................................ 32

Next Block ........................................................................................... 32

Block Connectivity Information ........................................................................ 33

Number of Inlet and Outlet Streams ....................................................... 33

Stream Names and Types ..................................................................... 33

Additional Port Information .................................................................... 34

Standard Block Results ................................................................................... 36

Dimensions of Standard Scalar Results ................................................... 36

Standard Scalar Block Results ................................................................ 37

Compressor Results ........................................................................................ 38

Dimensions of Performance Results ........................................................ 38

Stage-by-Stage Performance Results ...................................................... 39

Dimensions of Wheel-by-Wheel Performance Results ................................ 40

Wheel-by-Wheel Performance Results ..................................................... 40

Compressor Profile Results .............................................................................. 41

Dimensions of MCompr Profile Results .................................................... 41

MCompr Profile Results ......................................................................... 41

MCompr Cooler Profile Results ............................................................... 42

Heat Exchanger Results .................................................................................. 42

Number of Detailed Results ................................................................... 43

Detailed Results ................................................................................... 43

Velocity and Pressure Results ................................................................ 44

Heat Exchanger Results Dimensions ....................................................... 44

Heat Exchanger Zone Results ................................................................ 45

Heat Exchanger Shell Results................................................................. 45

Heat Exchanger Tube Results................................................................. 46

Heat Exchanger Baffle Results ............................................................... 47

Heat Exchanger Nozzle Results .............................................................. 47

Heat Exchanger Profiles .................................................................................. 48

Heat Exchanger Profile Size ................................................................... 48

Heat Exchanger Profile Properties ........................................................... 49

Heat Exchanger Profile Results ............................................................... 49

Column Results .............................................................................................. 50

Number of Columns .............................................................................. 50

Column Profile Dimensions .................................................................... 51

Column Profile Properties ...................................................................... 51

Non-Component-Dependent Column Profiles ............................................ 52

Component-Dependent Column Profiles .................................................. 52

RadFrac Thermosiphon Reboiler Results .................................................. 53

Interconnecting Stream and Pumparound Results..................................... 54

Additional Data for PetroFrac Models................................................................. 56

iv

Contents

Dimensions of Additional Data ............................................................... 56

Additional Scalar Results Data ............................................................... 57

Additional PetroFrac Profile Properties ..................................................... 58

Additional Property Profiles .................................................................... 58

Furnace Data for PETROFRAC ................................................................ 59

Component-Dependent Properties for the PetroFrac Furnace ..................... 60

Pumparound Results for PetroFrac Columns ............................................. 60

Connectivity Data for PetroFrac Strippers ................................................ 61

Additional Data for RateFrac Models ....................................................... 62

Dimensions of Additional Scalar Data ...................................................... 62

Additional Scalar Results Data ............................................................... 62

Dimensions of Component Split Fractions ................................................ 63

Component Split Fractions ..................................................................... 63

Number of Liquid Phases ....................................................................... 64

Tray Reports .................................................................................................. 64

Tray Report Dimensions ........................................................................ 64

Sequential Tray Report Properties .......................................................... 65

Specific Tray Report Properties .............................................................. 66

Tray/Packing Sizing and Rating ........................................................................ 66

Number of Columns .............................................................................. 67

Number of Column Sections .................................................................. 67

Column Section Types and Numbers ....................................................... 67

Size of a Column Section ....................................................................... 68

Scalar Results for a Column Section ....................................................... 69

Column Section Profile Properties ........................................................... 69

Column Section Profiles......................................................................... 70

Reactor Results .............................................................................................. 71

Number of Reactor Substreams.............................................................. 71

Reactor Profile Dimensions .................................................................... 71

Reactor Profile Properties ...................................................................... 72

Non-Component-Dependent Reactor Profiles............................................ 72

Component-Dependent Reactor Profiles .................................................. 73

Number of Components with Component Attribute Results ........................ 74

Number of Attributes for a Component .................................................... 74

Details of a Component Attribute ........................................................... 74

Component Attribute Results ................................................................. 75

Number of Continuous Feed Streams ...................................................... 75

Continuous Feed Stream Results ............................................................ 76

RBATCH Vent Accumulator Results ......................................................... 76

RBatch Vent Profile Results.................................................................... 79

Reaction Data ...................................................................................... 81

Reactor Property Reports ................................................................................ 84

Number of Reports for a Reactor Block.................................................... 84

Size of a Reactor Property Report ........................................................... 84

Sequential Reactor Report Properties ...................................................... 85

Specific Reactor Report Properties .......................................................... 86

Pipeline Results .............................................................................................. 86

Pipeline Results Dimensions ................................................................... 87

Non-Component-Dependent Pipeline Inlet and Outlet Conditions ................ 87

Component-Dependent Pipeline Inlet and Outlet Property Names ............... 88

Component-Dependent Pipeline Inlet and Outlet Conditions ....................... 89

Segment Data Property Names .............................................................. 89

Pipeline Segment Data .......................................................................... 90

Contents

v

Pipeline Node Property Names ............................................................... 90

Pipeline Node Results............................................................................ 91

Pipeline Profile Property Names .............................................................. 91

Pipeline Profile Results .......................................................................... 92

Pipe Results ................................................................................................... 92

Pipe Standard Profile Dimensions ........................................................... 93

Pipe Standard Profile Property Names ..................................................... 93

Pipe Standard Profile Properties ............................................................. 93

Pipe Property Reports ........................................................................... 94

Block VLE Results ........................................................................................... 96

Heating/Cooling Curves ................................................................................... 96

Number of Heating/Cooling Curves for a Block ......................................... 97

Heating/Cooling Curves for a Block ......................................................... 97

Size of a Heating/Cooling Curve ............................................................. 98

Standard Heating/Cooling Curve Results ................................................. 99

Sequential Heating/Cooling Curve Properties ........................................... 99

Specific Heating/Cooling Curve Properties ............................................. 100

Interconnecting Stream IDs ................................................................. 101

4 Stream Result Subroutines ..............................................................................103

Stream Identification .................................................................................... 103

Listing Stream IDs.............................................................................. 103

Determining the Next Stream .............................................................. 104

Material Stream Results ................................................................................ 104

Retrieving Basic Stream Information..................................................... 104

Listing Substream IDs......................................................................... 105

Retrieving Stream Results ................................................................... 105

Retrieving a Single Stream Property ..................................................... 106

Heat and Work Stream Results ...................................................................... 106

Component Attribute Results ......................................................................... 107

Determining the Number of Components with Attributes ......................... 107

Determining Number of Attributes for a Component ............................... 108

Determining Component Attribute Size ................................................. 108

Retrieving Component Attribute Values ................................................. 109

Substream Attribute Results .......................................................................... 109

Determining the Number of Substream Attributes .................................. 109

Determining Substream Attribute Size .................................................. 110

Retrieving Substream Attribute Values .................................................. 110

Stream Property Set Results .......................................................................... 111

Determining Dimensions of Stream Property Values ............................... 111

Retrieving Stream Property Results ...................................................... 111

5 Physical Property Table Results Subroutines ...................................................113

Property Table Identification .......................................................................... 114

Property and Flashcurve Table Results ............................................................ 114

Determining Property Table Dimensions ................................................ 114

Retrieving Sequential Properties in a Table ............................................ 115

Retrieving Specific Properties from a Table ............................................ 115

Pressure-Temperature Envelope Results.......................................................... 116

Determining Dimensions for Properties in the Envelope ........................... 116

Determining Envelope Dimensions ........................................................ 117

Retrieving Temperature and Pressure for Envelope Branch ...................... 117

vi

Contents

Retrieving Sequential Envelope Properties ............................................. 118

Retrieving Specific Envelope Properties ................................................. 119

6 Costing Results Subroutines ............................................................................121

Equipment Item Identification ........................................................................ 122

Determining Number of Equipment Items .............................................. 122

Listing Equipment Items ..................................................................... 122

Determining Next Equipment Item ....................................................... 122

Equipment Item Results ................................................................................ 123

Retrieving Equipment Item Costing Results ........................................... 123

Determining Equipment Item Sizing Results .......................................... 123

Retrieving Equipment Item Sizing Results ............................................. 124

7 Pressure Relief Subroutines ............................................................................125

Pressure Relief Block Identification ................................................................. 126

Determining the Number of Pressure Relief Blocks.................................. 126

Listing Pressure Relief Blocks ............................................................... 126

Determining the Next Pressure Relief Block ........................................... 127

Pressure Relief Results .................................................................................. 127

Determining the Number of Substreams................................................ 128

Determining Dimensions of Pressure Relief Arrays .................................. 128

Listing Profile Properties ...................................................................... 129

Retrieving Dynamic Scalar Results........................................................ 130

Retrieving Steady-State Scalar Results ................................................. 131

Retrieving Non-Component-Dependent Dynamic Profiles ......................... 131

Retrieving Dynamic Component-Dependent Profiles ................................ 132

Retrieving Steady-State Profiles ........................................................... 133

Determining Vent Accumulator Profile Dimensions .................................. 133

Listing Vent Accumulator Profile Properties ............................................ 134

Retrieving Non-Component-Dependent Vent Accumulator Profiles ............ 134

Retrieving Component-Dependent Vent Accumulator Profiles ................... 135

Determining Pressure Relief Vent Profile Dimensions .............................. 135

Listing Vent Profile Properties .............................................................. 136

Retrieving Position-Dependent Vent Profiles........................................... 136

Retrieving Component-Dependent Vent Profiles ..................................... 137

8 Examples .........................................................................................................139

Example 1: Stream Heat and Material Balance Table Generation ........................ 139

Declaring Variables and Dimensioning ................................................... 139

Initializing the Toolkit ......................................................................... 140

Finding Number of Streams ................................................................. 141

Finding Component Molecular Weight ................................................... 141

Writing Stream Table .................................................................................... 142

Example 2: Interactive Heating/Cooling Curve Table Generation ........................ 145

Declaring Variables ............................................................................. 145

Initializing the Toolkit ......................................................................... 145

Finding Number of Blocks .................................................................... 145

Finding Blocks with Heating/Cooling Curves ........................................... 146

Prompting for Block Name ................................................................... 147

Finding Heating/Cooling Curves for Selected Block ................................. 147

Finding Dimensions of Heating/Cooling Curve ........................................ 148

Contents

vii

Retrieving Standard Heating/Cooling Curve Results ................................ 148

Retrieving Property Sets ..................................................................... 149

Example 3: Column Profile Results Written to Plot File ...................................... 152

Opening Files and Initializing Toolkit ..................................................... 152

Finding List of Blocks .......................................................................... 153

Finding List of Properties ..................................................................... 153

Retrieving Selected Property Profile ...................................................... 154

Closing the Application ........................................................................ 154

Example 4: Distillation Column Diagram Generation ......................................... 156

Initializing the Toolkit ......................................................................... 156

Retrieving Basic Block Results .............................................................. 156

Retrieving Inlet and Outlet Stream Flows .............................................. 157

Finding Inlet and Outlet Stream IDs ..................................................... 158

9 XML Summary File ...........................................................................................161

A Units ...............................................................................................................163

B Property Names ..............................................................................................165

Table B.1 - Standard Property Names ............................................................. 166

Table B.2 - Mixture Thermodynamic Properties ................................................ 179

Volume ............................................................................................. 179

Flow Rates, Fractions .......................................................................... 179

Enthalpy, Entropy, Gibbs Energy, Heat Capacity ..................................... 180

Other properties................................................................................. 180

Table B.3 - Thermodynamic Properties of Components in Mixtures ..................... 181

Table B.4 - Pure Component Thermodynamic Property Sets............................... 182

Table B.5 - Electrolyte Property Sets .............................................................. 183

Table B.6 - Transport Properties ..................................................................... 184

Mixture ............................................................................................. 184

Component in a Mixture ...................................................................... 184

Pure Components ............................................................................... 184

Table B.7 - Petroleum-Related Properties for Mixtures ...................................... 184

Distillation Curves .............................................................................. 185

Distillation Temperature ...................................................................... 185

Distillation Volume and Weight Percent ................................................. 186

Bulk Petroleum Property Values from Assay Curves ................................ 186

Petroleum Cuts .................................................................................. 187

Petroleum Property Curves .................................................................. 188

Table B.8 - Elemental Analysis of Mixtures ...................................................... 189

Table B.9 - Nonconventional Component Properties .......................................... 190

Table B.10 - Property Names for Costing Results .............................................. 190

Equipment Type: HEATX ..................................................................... 190

Equipment Type: AIRCOOL .................................................................. 190

Equipment Type: FIRED-HEATER .......................................................... 191

Equipment Type: PUMP ....................................................................... 191

Equipment Type: COMPR..................................................................... 192

Equipment Type: BLOWER................................................................... 192

Equipment Type: TRAY-TOWER ............................................................ 193

Equipment Type: TRAY-TOWER Section Results ..................................... 193

Equipment Type: USER ....................................................................... 193

Equipment Type: V-VESSEL ................................................................. 194

viii

Contents

Equipment Type: H-VESSEL................................................................. 194

Equipment Type: TANK ....................................................................... 195

Index ..................................................................................................................197

Contents

ix

x

Contents

Who Should Read this Guide

The intended audience for this toolkit is application developers who need to

get information from Aspen Plus simulations into their applications, and prefer

a file based data transfer to data transfer through OLE Automation.

Who Should Read this Guide

1

2

Who Should Read this Guide

Introducing Summary File

Toolkit

An Aspen Plus summary file is an ASCII file produced by Aspen Plus for every

simulation run, containing all the results for that run. The Summary File

Toolkit is a set of Fortran subroutines that you can use to build a program to

extract results from an Aspen Plus summary file.

This reference manual describes the Summary File Toolkit and how to build

programs using the toolkit.

The manual assumes that you are familiar with Fortran, Aspen Plus, and the

results of an Aspen Plus simulation.

There is also an XML Results file available from Aspen Plus which can be

processed by standard XML tools. See Chapter 9 for some information about

this file.

Related Documentation

Title

Content

Aspen Plus Getting Started Building and

Running a Process Model

Tutorials covering basic use of

Aspen Plus. A prerequisite for the

other Getting Started guides

Aspen Plus Getting Started Modeling

Processes with Solids

Tutorials covering the Aspen plus

features designed to handle solids

Aspen Plus Getting Started Modeling

Processes with Electrolytes

Tutorials covering the Aspen plus

features designed to handle

electrolytes

Aspen Plus Getting Started Using

Equation-Oriented Modeling

Tutorials covering the use of

equation-oriented models in

Aspen Plus

Aspen Plus Getting Started Customizing

Unit Operation Models

Tutorials covering the

development of custom unit

operation models in Aspen Plus

Aspen Plus Getting Started Modeling

Petroleum Processes

Tutorials covering the Aspen Plus

features designed to handle

petroleum

Aspen Plus User Guide

Procedures for using Aspen Plus

Introducing Summary File Toolkit

3

Title

Content

Aspen Plus Reference Manual Series

Detailed information about Aspen

Plus

Aspen Plus Application Examples

A suite of examples illustrating

capabilities of Aspen Plus

Aspen Engineering Suite Installation

Manual

Instructions for installing Aspen

Plus and other Aspen Engineering

Suite products

Technical Support

AspenTech customers with a valid license and software maintenance

agreement can register to access the online AspenTech Support Center at:

https://support.aspentech.com

This Web support site allows you to:

Access current product documentation

Search for tech tips, solutions and frequently asked questions (FAQs)

Search for and download application examples

Search for and download service packs and product updates

Submit and track technical issues

Send suggestions

Report product defects

Review lists of known deficiencies and defects

Registered users can also subscribe to our Technical Support e-Bulletins.

These e-Bulletins are used to alert users to important technical support

information such as:

Technical advisories

Product updates and releases

Customer support is also available by phone, fax, and email. The most up-todate contact information is available at the AspenTech Support Center at

https://support.aspentech.com.

4

Introducing Summary File Toolkit

1 Getting Started

This chapter describes how to build an application program using the Aspen

Plus Summary File Toolkit. It contains information on:

The summary file and toolkit.

Initializing the toolkit.

Determining data dimensions.

Retrieving data for an object.

Using the toolkit with a hierarchical Aspen Plus run.

Linking toolkit subroutines into your module.

Creating a toolkit application for Windows.

Transferring the toolkit to another computer.

1 Getting Started

5

The Summary File and Toolkit

The summary file is an ASCII file produced by Aspen Plus for every simulation

run. This file contains the summary of simulation results, such as block

results, stream values, tray profiles, heating/cooling curves, and property

tables. The information in a summary file is also contained within the Aspen

Plus backup file. Summary files are named according to the form runid.SUM.

Backup files are named according to the form runid.BKP.

The summary file toolkit is a set of Fortran subroutines that retrieve results

information from the Aspen Plus summary file and backup file. (Use the

backup file with results, in place of the summary file, in procedures

throughout this manual.)

The subroutines are organized around the logical structure of the data. You

can retrieve selected results. Or you can retrieve all the results of a

simulation or simulation object (such as unit operation blocks or streams).

The Fortran source code for the subroutines is provided so that you can build

applications on any computer.

The Fortran source code is delivered in a self-extracting zip archive named

toolkit.exe in the Engine\Utl directory of the Aspen Physical Property System

installation (typically C:\Program Files\APrSystem

<version>\Engine\Utl\toolkit.exe).

The DLL is stored in the Engine\xeq directory of the Aspen Physical Property

System installation (typically C:\Program Files\APrSystem

<version>\Engine\xeq\zetoolkit.dll).

To use the summary file toolkit, an application program must perform three

steps:

1

Initialize the toolkit for a summary file.

2

Get the dimensions of the data to be retrieved.

3

Retrieve the data.

These three steps are described in the following sections.

32-bit and 64-bit Code

The Summary File Toolkit DLL delivered with Aspen Plus is a 64-bit DLL which

works with 64-bit code which is commonly used on current platforms. It

works with VBA in 64-bit Microsoft Excel.

If you need to use the Summary File Toolkit with 32-bit code (including VBA

in 32-bit versions of Microsoft Excel), you can get it from article 000097276 in

the AspenTech Support knowledgebase.

6

1 Getting Started

Initializing the Toolkit

You must initialize the toolkit for a summary file before you can retrieve data.

The initialization process consists of:

1

Accessing the required files and setting up directories for fast data access.

2

Defining the units of measurement for all values retrieved from the toolkit.

3

Specifying a value to substitute for missing results.

Accessing the Required Files

You need to include file definitions for the following files during the

initialization process. The unit numbers for these files must match those

specified in the call to toolkit initialization routine TKINIT or TKINI2.

File

Description

Summary file

The summary file

Properties file

A file defining the names of results within the summary file

Units file

A file containing units conversion information

Scratch file

A temporary direct access file for fast access to summary file results

Defining the Summary File

To define the summary file, use the subroutine TKOPEN. See Chapter 2 for

more information.

Getting the Summary File Name

Because the summary file may be different each time the toolkit application is

executed, some input to the program is required to determine the summary

file name. If the application program has an existing method of passing

information into the program, use this method to pass the summary file name

to the program.

Otherwise, the three principal ways the program can get the file name are by:

1

Prompting the user at the terminal.

2

Reading the file name from the command line.

3

Reading the file name from a file.

Prompting the user is the easiest method for most operating systems. Fortran

READ and WRITE statements are used to get the file name.

Getting Property and Units File Names

The properties file, RCPROPNU.DAT, and the units file, RCUNITS.DAT, are

installed in the toolkit subdirectory of the Aspen Plus Simulation Engine

installation. The Engine directory should be set as the value of the %asptop%

environment variable.

1 Getting Started

7

Example of Environment Variable for Windows

When running in an Aspen simulation engine window, the environment

variable ASPTOP points to the top level supplementary directory for Aspen

Plus. The TOOLKIT directory is a subdirectory of this directory. You can use

the following code to expand the file specification:

USE IFPORT

CALL GETENV('ASPTOP', ASPTOP)

DO 50 I = 80, 1, -1

IF (ASPTOP(I:I) .NE. ' ') GO TO 55

50

CONTINUE

55

CONTINUE

RCPROP = ASPTOP(1:I) // '\TOOLKIT\RCPROPNU.DAT'

RCUNIT = ASPTOP(1:I) // '\TOOLKIT\RCUNITS.DAT'

Scratch File Units Number

The direct access file is used to provide fast access to data in the summary

file after initialization. The units number you specify for this file should not be

used by the application program.

Defining Units of Measurement

As part of the toolkit initialization process, you must specify a base units set

in which the results will be returned. The base units set defines the units of

measurement for each physical quantity (units type).

The base units sets available are SI, ENG, MET, and OUT. To customize a

units set to change the output units of measurement for one or more physical

quantities, or convert a result to another unit of measurement, use the

subroutines described in Chapter 2. See Appendix A for other conversion

options.

Specifying a Value for Missing Results

If you make calls to the toolkit to retrieve results, and a requested result is

missing, the toolkit returns a special value in place of the result. As part of

the toolkit initialization process, you specify this value by assigning it to the

argument RMISS in the call to routine TKINIT or TKINI2. Choose a value that

will not be mistaken for a real result. A very large value (greater than 1E20)

is recommended.

Determining the Data

Dimensions

The toolkit data retrieval routines require you to know the data dimensions

before a retrieval is done. With these dimensions in mind, you must allocate

space inside your application program for the data before retrieving it.

Determining data dimensions includes:

8

1 Getting Started

1

Querying the summary file for the existence of simulation objects and

data within an object.

2

Defining the size of the data for a simulation object.

The subroutine TKINFO returns the number of blocks, streams, property

tables, and sensitivity tables in the summary file.

Each type of simulation object has a subroutine to find the next object in

sequence. These subroutines are:

Object Type

Subroutine to Find Next Object

Blocks

TKNBLK

Streams

TKNSTR

Property tables

TKNPPT

Sensitivity tables

TKNEXT

Equipment item

TKNEQP

Pressure relief

TKNXPR

Each of these subroutines has a sequence number as an argument. The

sequence number identifies the position of the object within the summary file.

For example, a sequence number of five for TKNBLK indicates the fifth unit

operation block in the summary file. Except for sensitivity objects and

pressure relief, the subroutine also returns information about the type of

object: the unit operation model type for a block, the type of stream

(MATERIAL, HEAT, or WORK), or the type of property table.

The data available for an object are organized by the type of data. For

example, block data is organized into a standard results set, connectivity

information, heating/cooling curve data, profile data, and property set profile

data. Each type of data has a routine that returns the dimensions of the data.

Chapters 2 through 7 describe the toolkit routines for determining the

dimensions of data and retrieving it. If a type of data is not available for an

object, dimension values of zero are returned.

Retrieving Data for an Object

Once the dimensions for data are known, you can retrieve the data by calling

the appropriate routine. Each result returned is identified by a property name.

Appendix B contains a list of property names and their descriptions.

In addition to property names, some results have qualifiers to further identify

the data. For example, for an FSPLIT block, the split fractions for each outlet

stream are returned. The stream ID of the outlet stream is returned as a

qualifier for the result.

You can use single subroutine calls to retrieve standard results for blocks,

streams, heating/cooling curves, and pressure-temperature envelopes.

Standard tray or reactor profiles are retrieved one profile at a time. You can

identify property set results by the property set qualifiers:

Qualifier

Description

PNAME

Property name. See Appendix B for a description.

SUBSID

Substream ID

1 Getting Started

9

Qualifier

Description

PHASE

Phase (VAPOR, LIQUID, LIQUID1, LIQUID2, TOTAL, SOLID)

COMPID

Component ID

WETDRY

Wet/dry basis (WET or DRY) †

BASIS

Unit basis for properties with multiple units ††

† Can be left unspecified.

†† Valid values for the basis are MOLE, MASS and FLOW. MOLE and MASS apply to

density (specifying mole density and mass density), entropy (specifying mole entropy

and mass entropy), and heat capacity (specifying mole heat capacity and mass heat

capacity). MOLE and FLOW apply to volume (specifying mole volume and volume

flow). MOLE, MASS and FLOW apply to enthalpy (specifying mole enthalpy, mass

enthalpy, and enthalpy flow).

Before calling a subroutine, make sure that all the qualifiers are set to the

desired values or unset. If you do not unset a qualifier from a previous value,

unexpected results may be returned.

All values with physical dimensions are returned in the units you specify

during the initialization process. The units label and the units type are usually

returned with the value. When the physical dimensions of a property are

always known, the units information may not be returned. You can call the

utility routine TKLABL to return the units label for a value not returned. In

addition, you can use the utility routine TKCNVT to convert a value from

default units to user-specified units.

Sometimes the retrieved data values are two-dimensional. For example, the

column profile routine TKPRO2 returns values for every stage and component

combination in a column. The dimension for the results then appears as two

dimensions multiplied together. This figure yields the total number of results

returned. It also shows the sequence of the results data in the array.

The results array is ordered so that the first dimension can scroll before the

second dimension. In the TKPRO2 example, the results are returned in

RVALS, which is dimensioned as NCP*NSTAGE (the number of components *

the number of stages). The values returned in the RVALS array are ordered

so that the results for every component on the first stage are given first,

followed by all the results for every component on the second stage, and so

on.

10

1 Getting Started

Using the Toolkit With a

Hierarchical Aspen Plus Run

Most Aspen Plus objects, including hierarchies, can exist within hierarchies. In

such cases it is not sufficient to reference an object by type and eight

character ID. The object’s ID must contain the full hierarchical path to the

object, with each hierarchy name separated by a period (.). For example, if a

run contains hierarchy H1, which contains hierarchy H2, which contains block

B1, refer to the block as H1.H2.B1.

All toolkit subroutines that accept or return an object ID declare the argument

as CHARACTER *(*). When passing such an argument, set up the dimension

large enough to hold the hierarchical ID. If referencing a non-hierarchical

problem, declaring the ID arguments as CHARACTER*8 is sufficient.

Note: The length must be larger for hierarchical problems. A declaration of

CHARACTER*128 is always sufficient.

The toolkit always returns IDs with full path name. For example, TKNBLK,

which lists the blocks in a run, cycles through all blocks in all hierarchy levels,

returning IDs with full path name.

Block, stream, pressure relief, property table, and sensitivity IDs are

hierarchical. Property name, substream, phase, and component IDs are not.

Note: It is not possible to cycle through all blocks in a single hierarchy level.

Linking Toolkit Subroutines into

Your Module

After you write or modify your application program to call the appropriate

toolkit subroutines to retrieve the data, you must build an executable module,

including the toolkit routines. The object code for the toolkit subroutines is

stored in a dynamic link library for Windows, which is delivered with Aspen

Plus.

To link to this library, include %asptop%\toolkit\zetoolkit.lib in the linker

directive, where %asptop% represents the Engine installation directory.

Creating a Toolkit Application

for Windows

The source code, in the form of a self-extracting executable, and dynamic link

library (DLL) for the summary file toolkit are located in the toolkit directory of

the Aspen Plus Simulation Engine installation.

1 Getting Started

11

About the Windows Version

The Windows version of the summary file toolkit consists of two files:

File Name

Description

zetoolkit.dll

The summary file toolkit dynamic-link library. This file is stored in the

Engine\xeq subfolder of the APrSystem installation, typically C:\Program

Files\APrSystem <version>\Engine\xeq\zetoolkit.dll

zetoolkit.lib

Import library. This file contains the external references to the summary

file toolkit routines in zetoolkit.dll. This file is stored in the Engine\toolkit

subfolder of the Aspen Plus installation, along with the Fortran source

files.

The DLL and LIB are compiled and linked with Intel Fortran 9.1.

If you are using the summary file toolkit as part of a full installation of Aspen

Plus, you can compile and link toolkit applications with the Fortran compiler

for your Operating System. Make sure you are set up for running Aspen Plus.

Aspen Plus provides procedures to help use the Aspen Plus Fortran utilities.

The following table summarizes these procedures:

To do this

Enter these commands

Compile a Fortran routine

ASPCOMP appname

Link an application executable

link @appname.opt

Run a previously linked executable

appname.exe

Where:

appname

=

The file name of the main Fortran application. Do not

include the file extension when specifying the file

name. ASPCOMP will accept Fortran files with the

extension .for.

appname.opt

=

Text file containing the linker directive commands. For

more information, see the following section, Linker

Directive Commands for Windows.

Linker Directive Commands for

Windows

The linker directive file contains a set of commands that control the

generation of the linked executable. Any object files or libraries you want to

be included in the linked executable must be listed in the linker directive file.

The standard set of commands required to link a toolkit application are shown

for a toolkit application named tkexampl.

Example of Linker Directive File

-entry:mainCRTStartup

msvcrt.lib

-nodefaultlib:libc.lib

libifcoremd.lib

-nodefaultlib:libifcore.lib

12

1 Getting Started

libifportmd.lib

-nodefaultlib:libifport.lib

libmmd.lib

-nodefaultlib:libm.lib

-nodefaultlib:libifcoremt.lib

-nodefaultlib:libmmt.lib

c:\Engine\toolkit\zetoolkit.lib

tkexample.obj

-out:tkexample.exe

Substitute c:\Engine with the appropriate drive and directory location where

the Aspen Plus Simulation Engine is installed. Replace tkexample with the

name of your application. Add any additional object files and libraries you

need to this directive file.

After creating the linker directive file for your application, you can use the link

and run commands to generate and run your application's executable

program.

Calling Summary File Toolkit

Routines

The files are compiled so that the summary file toolkit routines use the

default calling and naming conventions for the Fortran compiler. These are

similar to the stdcall convention, except:

All routine names are in uppercase.

All arguments are passed by reference.

All integer variables are 64-bit (VBA LongLong).

All real variables are 64-bit (VBA Double).

There is a hidden string length argument for each character string passed.

These arguments are 32-bit integers (VBA Long) and they appear in the

same order as the string arguments but appended after all the normal

arguments.

For character arrays, the single character string passed is broken up into

individual elements based on the defined length of each element, which is

given by the hidden string length argument.

o

If the array is defined in the subroutine (see documentation for the

specific subroutine) with a fixed element length, such as

CHARACTER*8, then this length is what Aspen Plus uses and should be

given in the hidden argument.

o

If it is defined with a variable length as CHARACTER*(*), then the

hidden string length argument determines the length of each element;

in this case be sure to choose a length long enough to hold whatever

data you expect (such as hierarchical IDs).

Applications calling the DLL should use this convention. Please see your

compiler documentation about calling Fortran routines and hidden string

length arguments.

Fortran applications can call the routines in the Summary File Toolkit without

any code modifications. If you want to call the Summary File Toolkit from

1 Getting Started

13

another language, you will have to modify the code to work with the Fortran

conventions adopted, but this is not recommended. Instead, export an XML

summary file and use standard XML tools to process it.

VBA Calling Fortran Example

As an example, here is the argument list as described for Fortran for TKBRES

CALL TKBRES

(BLKID, NRES, NQUAL, PNAMES, QUALS, ITYPE, IVALS,

CVALS, RVALS, TYPES, LABELS)

Variable I/O † Type

Dimension

Description

BLKID

I

CHARACTER*(*) —

Block ID

NRES

I

INTEGER

—

Number of results

NQUAL

I

INTEGER

—

Maximum number of qualifiers ††

PNAMES

O

CHARACTER*12 NRES

QUALS

O

CHARACTER*8

NRES* NQUAL Qualifiers ††

ITYPE

O

INTEGER

NRES

Data type of results (1=Integer,

2=Real, 3=Character) †††

IVALS

O

INTEGER

NRES

Integer results †††

CVALS

O

CHARACTER*8

NRES

Character results †††

RVALS

O

REAL*8

NRES

Real results †††

TYPES

O

CHARACTER*12 NRES

Units types

LABELS

O

CHARACTER*16 NRES

Units labels

Property name. See Appendix B for

a description.

Here is the equivalent declaration in VBA:

Private Declare PtrSafe Sub TKBRES Lib _

"C:\Program Files\AspenTech\AprSystem V11.0\Engine\Xeq\zetoolkit.dll" _

(ByVal BLKID As String, NRES As LongLong, NQUAL As LongLong, _

ByVal PNAMES As String, ByVal quals As String, ITYPE As LongLong, _

IVALS As LongLong, ByVal CVALS As String, RVALS As Double, _

ByVal TYPES As String, ByVal LABELS As String, ByVal nBLKID As Long, _

ByVal nPNAMES As Long, ByVal nQUALS As Long, ByVal nCVALS As Long, _

ByVal nTYPES As Long, ByVal nLABELS As Long)

Opening and Closing Files Using the

Summary File Toolkit

You must be careful with file input and output when using the Summary File

Toolkit. You must observe the following practices:

14

Open and close the summary file with TKOPEN and TKCLFL.

Open and close the log file optionally used in TKINI2, with TKOPEN and

TKCLFL.

Close the toolkit with TKCLOS, at the end of each run.

Close the summary file and the log file with TKCLFL, at the end of each

run.

Do not use TKOPEN and TKCLFL for opening and closing the files your

application reads from or writes to.

1 Getting Started

Using Fortran to Call Routines

Use the Fortran default naming and calling conventions for calls to the

summary file toolkit shared library, when compiling code. You do not have to

carry out any special steps to call the summary file toolkit routines.

When linking the application, make sure a reference to the zetoolkit shared

library is included in the list of libraries, and that its pathname is included in

the list of library directories.

You must write your code and any setup procedures so that the zetoolkit

shared library is in your run time path.

Changes in the Toolkit

AspenTech tries to avoid changing the arguments to these routines but

occasionally changes are necessary. Sometimes these changes are made to

support changes in Aspen Plus; because of this, sometimes old versions of the

toolkit will not work with newer summary files. However, the latest version of

the toolkit should always work with all older Aspen Plus summary files.

The changes likely to affect users are listed here:

In version 11.1, all of the arguments holding stream IDs and block IDs

(including sensitivity blocks and the like) became variable length, changing

from CHARACTER*8 to CHARACTER*(*) to support hierarchy. See Using the

Toolkit With a Hierarchical Aspen Plus Run on page 11 for more info.

In version 12.1, the filename argument in TKOPEN changed from

CHARACTER*80 to CHARACTER*(*) to support using the toolkit with

summary files with long file paths, although the documentation was not

updated to reflect this change until version 2006. We recommend using a

CHARACTER of length 256 to hold this filename, as there may be other

problems with a longer file path.

1 Getting Started

15

16

1 Getting Started

2 General Subroutines

This chapter describes the purpose and use of subroutines in the Aspen Plus

Summary File Toolkit. Use the subroutines described in this chapter for:

Initializing the summary file toolkit.

Retrieving run information.

Retrieving flowsheet balance results.

Setting and changing units of measurement.

Retrieving component information.

Retrieving sensitivity results.

2 General Subroutines

17

Initializing the Summary File

Toolkit

Before you can retrieve any results from a summary file, you must call

subroutine TKINIT or TKINI2 to initialize the summary file toolkit.

TKINIT assigns Fortran unit numbers and unit names for files used by the

toolkit. See Initializing the Toolkit, Chapter 1, for information on identifying

the necessary files.

The scratch file is a direct access file used by the toolkit to store intermediate

data. You must supply a Fortran unit number for the scratch file.

To open the summary file and connect it to a unit number, you can:

Use a Fortran OPEN statement in your program.

Call TKOPEN routine (see Opening and Closing Files, this chapter), if using

the Windows DLL.

The property number file and the unit definition file are delivered with Aspen

Plus. The file names you specify to call TKINIT depend on the computer and

operating system you are using (see Getting Property and Units File Names,

Chapter 1).

TKINIT sets the default units set for all results data to the value of UNISET.

This can be one of four values: SI, ENG, MET, or OUT. The first three values

correspond to the Aspen Plus units sets with these names. OUT can be used

to retrieve the results from the summary file without any UOM conversion.

The data is retrieved in the same units as the Aspen Plus out units for the

run.

Calling Sequence for TKINIT

CALL TKINIT (UNISET, IDIRAC, ISUMMF, IPROPN, RCPROP, IUNITS,

RCUNIT, RMISS, IERR)

Argument List Descriptions for TKINIT

18

Variable I/O † Type

Dimension Description

UNISET

I

CHARACTER*4

—

Units set for retrieved values (SI, ENG,

MET, or OUT)

IDIRAC

I

INTEGER

—

Fortran unit number for scratch file

ISUMMF

I

INTEGER

—

Fortran unit number for summary file

IPROPN

I

INTEGER

—

Fortran unit number for property

numbers file

RCPROP

I

CHARACTER*80 —

File name for property numbers file

IUNITS

I

INTEGER

Fortran unit number for units definition

file

RCUNIT

I

CHARACTER*80 —

RMISS

I

REAL*8

—

—

File name for units definition file

Real value flag for missing values

2 General Subroutines

Variable I/O † Type

Dimension Description

IERR

—

O

INTEGER

Error flag (0=No error)

† I = Input to subroutine, O = Output from subroutine

If you initialize the toolkit with TKINIT, Aspen Plus writes errors or warnings

from the toolkit run to the screen. TKINI2 works in the same way as TKINIT,

except that it allows you to specify a Fortran unit number for error and

warning messages. This is useful for applications where messages should not

be written directly to the screen. Like the summary file, this file should

already be opened before calling TKINI2. If you specify a negative unit

number for the error and warning messages, they are turned off.

Calling Sequence for TKINI2

CALL TKINI2 (UNISET, IDIRAC, ISUMMF, IPROPN, RCPROP, IUNITS,

RCUNIT, RMISS, IERR, ILOG)

Argument List Descriptions for TKINI2

Variable I/O

†

Type

Dimension

Description

UNISET

I

CHARACTER*4

—

Units set for retrieved values (SI,

ENG, MET or OUT)

IDIRAC

I

INTEGER

—

Fortran unit number for scratch file

ISUMMF

I

INTEGER

—

Fortran unit number for summary file

IPROPN

I

INTEGER

—

Fortran unit number for property

numbers file

RCPROP

I

CHARACTER*80 —

File name for property numbers file

IUNITS

I

INTEGER

Fortran unit number for units

definition file

RCUNIT

I

CHARACTER*80 —

RMISS

I

REAL*8

—

Real value flag for missing values

IERR

O

INTEGER

—

Error flag (0=No error)

ILOG

I

INTEGER

—

Fortran Unit number for log file.

Negative for no messages.

—

File name for units definition file

† I = Input to subroutine, O = Output from subroutine

Closing the Summary File

Toolkit

Call subroutine TKCLOS to close a summary file toolkit run. TKCLOS closes

files opened by TKINIT or TKINI2, so the argument list should use the

corresponding values passed to TKINIT or TKINI2. The summary file is not

closed by this routine, but is instead rewound to its first record. Use TKCLFL

to close it.

Calling Sequence for TKCLOS

CALL TKCLOS (ISUMMF, IDIRAC, IPROPN, IUNITS)

2 General Subroutines

19

Argument List Descriptions for TKCLOS

Variable I/O

†

Type

Dimension

Description

ISUMMF

I

INTEGER —

Fortran unit number for summary file

IDIRAC

I

INTEGER —

Fortran unit number for scratch file

IPROPN

I

INTEGER —

Fortran unit number for property numbers

file

IUNITS

I

INTEGER —

Fortran unit number for units definition file

† I = Input to subroutine, O = Output from subroutine

Opening and Closing Files

Two routines are provided to open and close files with a specified Fortran unit

number. If you are using a DLL version of the summary file toolkit, you must

use these routines to open and close the summary file, and any log file used

by TKINI2. Unless you do so, the summary file toolkit DLL will not recognize

the Fortran unit numbers you pass it for these files. When using the DLL, you

should not call these routines to open and close files your code accesses.

Call subroutine TKOPEN to open the file with the specified Fortran unit

number.

Calling Sequence for TKOPEN

CALL TKOPEN (IUNIT, FILNAM, ACCESS, FORM, IRECL, STATUS, MODE,

IERR)

Argument List Descriptions for TKOPEN

Variable

I/O

†

Type

Dimension

Description

—

Unit number of the file being opened

IUNIT

I

INTEGER

FILNAM

I

CHARACTER*(*) —

Name of file to open

ACCESS

I

CHARACTER*16 —

File access (SEQUENTIAL, DIRECT)

FORM

I

CHARACTER*16 —

I/O format (FORMATTED,

UNFORMATTED)

IRECL

I

INTEGER

Record length

STATUS

I

CHARACTER*16 —

File status (SCRATCH, OLD, NEW,

UNKNOWN)

MODE

I

CHARACTER*16 —

Open mode (READ, WRITE)

IERR

O

INTEGER

Error flag

(0=No error,

1=Invalid argument,

>0= IOSTAT error)

—

—

† I = Input to subroutine, O = Output from subroutine

Call subroutine TKCLFL to close the file with the specified Fortran unit

number.

Calling Sequence for TKCLFL

CALL TKCLFL (IUNIT, IERR)

20

2 General Subroutines

Argument List Descriptions for TKCLFL

Variable

I/O

IUNIT

I

INTEGER —

Unit number of the file being closed

IERR

O

INTEGER —

Error flag (0=No error)

†

Type

Dimension

Description

† I = Input to subroutine, O = Output from subroutine

Retrieving Run Information

Use the subroutines in this section to retrieve general information about the

run.

Call TKINFO to obtain standard information about a run.

Call TKTITL to obtain the run title.

Call TKACCT to obtain run accounting information.

Standard Run Information

Call subroutine TKINFO to retrieve the following standard information about a

run:

Aspen Plus release name.

Run ID of the Aspen Plus run.

Date of the run.

Input file name.

Input translator status.

Simulation program status.

Number of simulation objects (blocks, streams, property tables, sensitivity

tables).

Calling Sequence for TKINFO

CALL TKINFO (VERSN, RUNID, DATE, INFILE, ISSTAT, ISTAT, NBLOCK,

NSTRM, NTABLE, NSENS)

2 General Subroutines

21

Argument List Descriptions for TKINFO

Variable I/O

†

Type

Dimension

Description

VERSN

O

CHARACTER*20 —

Aspen Plus release name

RUNID

O

CHARACTER*8

DATE

O

CHARACTER*80 —

Date of Aspen Plus run

INFILE

O

CHARACTER*80 —

Aspen Plus input file name

ISSTAT

O

INTEGER

—

Input translator completion code

ISTATF

O

INTEGER

6

Simulation status flags for each

element. See ISTATF, below.

NBLOCK

O

INTEGER

—

Number of blocks

NSTRM

O

INTEGER

—

Number of streams

NTABLE

O

INTEGER

—

Number of property tables

NSENS

O

INTEGER

—

Number of sensitivity tables

—

Aspen Plus run ID

† I = Input to subroutine, O = Output from subroutine

ISTATF

The

0=

1=

2=

values are:

Completed without errors,

Completed with errors,

None in this simulation,

The elements represent:

ISTATF(1): Block status,

(2): Convergence status,

(3): Sensitivity status,

(4): Case study status,

(5): Stream calculation status,

(6): Fortran and transfer status

Run Titles

Call subroutine TKTITL to retrieve the run title.

Calling Sequence for TKTITL

CALL TKINFO (TITLE)

Argument List Descriptions for TKTITL

Variable

I/O

TITLE

O

†

Type

Dimension

Description

CHARACTER*64

—

Run title

† I = Input to subroutine, O = Output from subroutine

22

2 General Subroutines

Accounting Information

Call subroutine TKACCT to obtain accounting information for a run.

Accounting information is only available if requested in the Aspen Plus input.

Calling Sequence for TKACCT

CALL TKACCT (ACCNT, PROJID, PRNAME, USER, IERR)

Argument List Descriptions for TKACCT

Variable

I/O

Type

Dimension

Description

ACCNT

O

CHARACTER*8

—

Account number

PROJID

O

CHARACTER*8

—

Project ID

PRNAME

O

CHARACTER*32

—

Project name

USER

O

CHARACTER*20

—

User name

IERR

O

INTEGER

—

Error flag (0=No error)

†

† I = Input to subroutine, O = Output from subroutine

Retrieving Flowsheet Balance

Results

Call subroutine TKFLWB to retrieve the absolute and relative differences for:

Total mole balance.

Total mass balance.

Enthalpy balance.

Mole balance for each conventional component.

Mass balance for each nonconventional component.

Calling Sequence for TKFLWB

CALL TKFLWB (ABSMOL, RELMOL, ABSMAS, RELMAS, ABSENT, RELENT, NCC,

ABSCON, RELCON, NNCC, ABSNC, RELNC, IERR)

2 General Subroutines

23

Argument List Descriptions for TKFLWB

Variable

I/O

Type

Dimension

Description

ABSMOL

O

REAL*8

—

Absolute mole balance difference

(UNITS=MOLE-FLOW)

RELMOL

O

REAL*8

—

Relative mole balance difference

ABSMAS

O

REAL*8

—

Absolute mass balance difference

(UNITS=MASS-FLOW)

RELMAS

O

REAL*8

—

Relative mass balance difference

ABSENT

O

REAL*8

—

Absolute enthalpy balance difference

(UNITS=ENTHALPY-FLOW)

RELENT

O

REAL*8

—

Relative enthalpy balance difference

NCC

I

INTEGER —

Number of conventional components

ABSCON

O

REAL*8

NCC

Absolute mole balance difference for each

conventional component

(UNITS=MOLE-FLOW)

RELCON

O

REAL*8

NCC

Relative mole balance for each

conventional component

NNCC

I

INTEGER —

ABSNC

O

REAL*8

NNCC

Absolute mass balance difference for each

nonconventional component

(UNITS=MASS-FLOW)

RELNC

O

REAL*8

NNCC

Relative mass balance difference for each

nonconventional component

IERR

O

INTEGER —

†

Number of nonconventional components

Error flag (0=No error)

† I = Input to subroutine, O = Output from subroutine

Units Conversion

Use the subroutines in this section to:

Change the units set for results.

Convert units for individual results.

Find units labels for results.

Changing Units Sets

Values retrieved from the summary file are converted to the current units set.

The variable SETID takes the same values as UNISET does in TKINIT and

TKINI2. The units set is initially defined in the call to subroutine TKINIT or

TKINI2. You can change the units set at any point in your program, by calling

subroutine TKUNIT.

Use TKUNIT to define a new base units set and any units' options that should

override the units' options in the base set.

24

2 General Subroutines

Calling Sequence for TKUNIT

CALL TKUNIT (SETID, NTYPES, TYPES, LABELS, IERR)

Argument List Descriptions for TKUNIT

Variable

I/O

Type

Dimension

Description

SETID

I

CHARACTER*4

—

Base units set

(SI, ENG, MET, or OUT)

NTYPES

I

INTEGER

—

Number of units types to change

from the base set

TYPES

I

CHARACTER*12 NTYPES

List of units' types to change from

the base set. See Appendix A for a

list of valid units' types.

LABELS

I

CHARACTER*16 NTYPES

List of units labels for the units types

to change from the base set. See

Appendix A for a list of valid units'

labels. Note that units labels are

case-sensitive.

IERR

O

INTEGER

Error flag (0=No error)

†

—

† I = Input to subroutine, O = Output from subroutine

Converting Units for Real Numbers

Call subroutine TKCNVT to perform units conversion on a result or an array of

results. TKCNVT converts values from the current units set to units specified

by a unit's label. TKCNVT will not convert a result if the current units set is

OUT units. (There is no such thing as a current unit for a particular units type

with OUT units.)

Calling Sequence for TKCNVT

CALL TKCNVT (TYPE, LABEL, NVAL, RVALI, RVALO)

Argument List Descriptions for TKCNVT

Variable

I/O

TYPE

I

CHARACTER*12 —

Units type. Valid units' types are

shown in Appendix A.

LABEL

I

CHARACTER*16 —

Units label for output. See Appendix

A for a list of valid units' labels. Note

that units labels are case-sensitive.

NVAL

I

INTEGER

—

Number of values to convert

RVALI

I

REAL*8

NVAL

Array of values to be converted.

These values are assumed to be in

the current units set.

RVALO

O

REAL*8

NVAL

Array of converted values

†

Type

Dimension

Description

† I = Input to subroutine, O = Output from subroutine

2 General Subroutines

25

Determining Units Labels

Call subroutine TKLABL to determine the units' labels for a list of units' types

in the current units set. TKLABL will not retrieve a label for a type if the

current units set is OUT units. (There is no such thing as a current unit for a

particular units type with OUT units.)

Calling Sequence for TKLABL

CALL TKLABL (NTYPES, TYPES, LABELS)

Argument List Descriptions for TKLABL

Variable

I/O

Type

Dimension

Description

NTYPES

I

INTEGER

—

Number of units types

TYPES

I

CHARACTER*12 NTYPES

Units types. See Appendix A for a list

of valid units' types.

LABELS

O

CHARACTER*16 NTYPES

Units labels

†

† I = Input to subroutine, O = Output from subroutine

Component Information

Retrieval

Use the subroutines in this section to retrieve information about the

components in the simulation:

TKCOMP gets the number of components in the simulation.

TKCIDS gets the list of component IDs.

TKALIS gets lists of conventional components and their aliases.

TKCASN gets lists of components and their CAS numbers.

TKCPRP retrieves component properties, such as molecular weight, boiling

point, and standard volume.

Number of Components

Call subroutine TKCOMP to determine the number of components in a

simulation. TKCOMP returns the number of both conventional and

nonconventional components.

Calling Sequence for TKCOMP

CALL TKCOMP (NCC, NNCC)

26

2 General Subroutines

Argument List Descriptions for TKCOMP

Variable

I/O

Type

Dimension

Description

NCC

NNCC

O

INTEGER

—

Number of conventional components

O

INTEGER

—

Number of nonconventional components

†

† I = Input to subroutine, O = Output from subroutine

Component IDs

Call subroutine TKCIDS to retrieve the component IDs for conventional and

nonconventional components.

Calling Sequence for TKCIDS

CALL TKCIDS (NCC, NNCC, COMPID, COMPNC)

Argument List Descriptions for TKCIDS

Variable

I/O

Type

Dimension