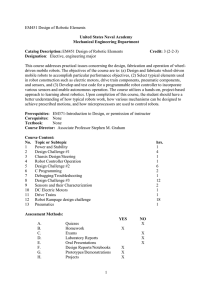

FACULTY OF ELECTRICAL ENGINEERING & TECHNOLOGY UNIVERSITI MALAYSIA PERLIS INTRODUCTION TO ROBOTICS EMJ37303 ROBOTIC SYSTEMS • • • • • • • • • • • Overview of robotics History of robots Classification of robots Robot components Robot Degree of Freedoms (DOF) Robot Joints Robot Coordinates and Frame Robot Workspace Resolution, accuracy and repeatability of robots Advantages and disadvantages of robots Robot applications EMJ37303 ROBOTIC SYSTEMS Contents 2 EMJ37303 ROBOTIC SYSTEMS Overview of Robotics What is Robot? Robot is “A machine capable of carrying out a complex series of actions automatically, especially one programmable by a computer”- Oxford Dictionary 3 EMJ37303 ROBOTIC SYSTEMS Overview of Robotics Then , what is Robotics? • The study of robots. • The branch of technology that deals with the design, construction, operation, and application of robots. - Oxford Dictionary 4 • International Organization for Standardization (ISO) EMJ37303 ROBOTIC SYSTEMS Definitions ISO8373:2021 Robot - programmed actuated mechanism with a degree of autonomy (ability to perform intended tasks based on current state and sensing, without human intervention) to perform locomotion, manipulation or positioning Robotics - science and practice of designing, manufacturing, and applying robots 5 • International Organization for Standardization (ISO) EMJ37303 ROBOTIC SYSTEMS Definitions ISO8373:2021 Industrial Robot - automatically controlled, reprogrammable multipurpose manipulator (mechanism consisting of an arrangement of segments, jointed or sliding relative to one another), programmable in three or more axes, which can be either fixed in place or fixed to a mobile platform (assembly of the components which enables locomotion) for use in automation applications in an industrial environment Industrial Robot System - machine comprising an industrial robot; end-effector(s); any end-effector sensors and equipment (e.g. vision systems, adhesive dispensing, weld controller) needed to support the intended task; and a task program 6 https://www.youtube.com/watch?v=2GxbXcPGhDg EMJ37303 ROBOTIC SYSTEMS Brief History of Robots 7 • 1922: Karel Čapek’s novel, Rossum’s Universal Robots, word “Robota” (worker) EMJ37303 ROBOTIC SYSTEMS Brief History of Robots • 1952: NC machine (MIT) • 1954: 1st Programmable Robot (George Devol) • 1955: Denavit-Hartenberg Homogeneous Transformation • 1962: First Robot by Unimation used by GM • 1967: Mark II (Unimation Inc.) • 1968: Shakey (SRI) - intelligent robot • 1973: T3 (Cincinnati Milacron Inc.) • 1978: PUMA (Unimation Inc.) • 1983: Robotics Courses in Academia • 21 C: Walking Robots, Mobile Robots, Humanoid Robots 8 EMJ37303 ROBOTIC SYSTEMS Industrial Revolution 9 EMJ37303 ROBOTIC SYSTEMS Industrial Revolution 4.0 10 EMJ37303 ROBOTIC SYSTEMS Industrial Robots Source: https://ifr.org/industrial-robots 11 Source: https://ifr.org/industrial-robots EMJ37303 ROBOTIC SYSTEMS Industrial Applications 12 EMJ37303 ROBOTIC SYSTEMS Classification of Robots (Mobility) Serial Robots Stationary Parallel Robots Industrial Robots Wheeled Robot Legged Mobile Swimming Flying Etc.. 13 Hybrid Serial-Parallel Mechanism EMJ37303 ROBOTIC SYSTEMS Industrial Robots Serial Kinematic Mechanism Parallel Kinematic Mechanism 14 • Power Source – electric (cheaper, cleaner, quieter), hydraulic (response, torque, noisy), pneumatic • Application Area – assembly and non-assembly robots (paint, welding, material handling etc). • Method of Control – servo (point-to-point, continuous path) and non-servo robots. • Geometry – Arrangement of the kinematic chains (Serial – articulated, cylinder, spherical etc; Parallel – Stewart etc) EMJ37303 ROBOTIC SYSTEMS Classification of Industrial Manipulators 15 • Manipulators/ Rover EMJ37303 ROBOTIC SYSTEMS Robotic Systems • End Effector • Actuators • Sensors • Controller • Processor/ Computer • Software/ Programming 16 EMJ37303 ROBOTIC SYSTEMS Robot Manipulator Arm Wrist End-effector 17 EMJ37303 ROBOTIC SYSTEMS Robot Manipulator Joints Links 18 • The mechanical structure of a robot manipulator consists of EMJ37303 ROBOTIC SYSTEMS Robot Manipulator • a sequence of rigid bodies (links) interconnected by means of articulations (joints); • a manipulator is characterized by an arm that ensures mobility, a wrist that confers dexterity, and an end-effector that performs the task required of the robot. Open Kinematic Chain Closed Kinematic Chain 19 EMJ37303 ROBOTIC SYSTEMS Robot Joints (a) Prismatic (P) (b) Revolute (R) (d) Universal (U) (c) Revolute (R) (e) Spherical (U) 20 • Degrees of Freedom: Number of independent position variables which would has to be specified to locate all parts of a mechanism. • In most manipulators this is usually the number of joints. • In general, a task consisting of arbitrarily positioning and orienting an object in three-dimensional (3D) space, 6-DOFs are required (three for positioning a point on the object and three for orienting the object with respect to a reference coordinate frame). • If more DOFs than task variables are available, the manipulator is said to be redundant from a kinematic viewpoint. EMJ37303 ROBOTIC SYSTEMS Degrees of Freedom (DOF) 21 • Cartesian robot (rectangular robot, gantry robot): manipulator which has three prismatic joints, whose axes form a Cartesian coordinate system EMJ37303 ROBOTIC SYSTEMS Common Industrial Robots • SCARA robot: manipulator which has two parallel rotary joints to provide compliance in a selected plane • Articulated robot: manipulator which has three or more rotary joints • Parallel/Delta robot: manipulator whose arms have links which form a closed loop structure • Cylindrical robot: manipulator which has at least one rotary joint and at least one prismatic joint, whose axes form a cylindrical coordinate system • Polar robot (spherical robot): manipulator which has two rotary joints and one prismatic joint, whose axes form a polar coordinate system 22 EMJ37303 ROBOTIC SYSTEMS Types of Robotic Arm • Robot Manipulators R2P 3P 2RP 3R Selective Compliance Assembly Robot 23 EMJ37303 ROBOTIC SYSTEMS Joints and Links Representation 24 EMJ37303 ROBOTIC SYSTEMS Types of Robotic Arm 25 The workspace represents that portion of the environment the manipulator’s endeffector can access. Its shape and volume depend on the manipulator structure as well as on the presence of mechanical joint limits. EMJ37303 ROBOTIC SYSTEMS Workspaces 26 • Payload – The weight a robot can carry and still remain within its other specifications. • Reach – Maximum distance a robot can reach within its working envelope. • Precision (validity) – How accurately a specified point can be reached. • Repeatability (variability) – How accurately the same position can be reached if the motion is repeated many times. EMJ37303 ROBOTIC SYSTEMS Robot Characteristics 27 • Σ𝑤 : World reference frame 𝚺𝐣𝐢 EMJ37303 ROBOTIC SYSTEMS Robot Reference Frames • Σ𝑒 : End-effector reference frame 𝚺𝐞 • Σ𝑐 : Cylinder reference frame • Σ𝑏 : Box reference frame • Σ𝑗𝑖 : i-th joint reference frame 𝚺𝐛 𝚺𝐰 𝚺𝐜 28 EMJ37303 ROBOTIC SYSTEMS Find the Workspace 29 EMJ37303 ROBOTIC SYSTEMS Find the Workspace 30 EMJ37303 ROBOTIC SYSTEMS QR ATTENDANCE 31