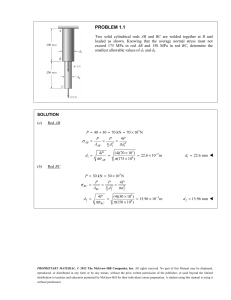

Solution 1.15 PROBLEM 1.15 Knowing that a force P of magnitude 50 kN is required to punch a hole of diameter d = 20 mm in an aluminum sheet of thickness t = 5 mm, determine the average shearing stress in the aluminum at failure. SOLUTION Area of failure in plate: A π= dt π ( 0.020 m )( 0.005 m ) = = 3.1416 × 10−4 m 2 Average shearing stress: τ avg = = P A 50 × 103 N 3.1416 × 10−4 m 2 τ avg = 159.2 MPa Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 1.18 PROBLEM 1.18 A load P is applied to a steel rod supported as shown by an aluminum plate into which a 12-mm-diameter hole has been drilled. Knowing that the shearing stress must not exceed 180 MPa in the steel rod and 70 MPa in the aluminum plate, determine the largest load P that can be applied to the rod. SOLUTION For steel: = A1 π= dt π (0.012 m)(0.010 m) = 376.99 × 10−6 m 2 τ1 = P ∴ P = A1τ1 = (376.99 × 10−6 m 2 )(180 × 106 Pa) A = 67.858 × 103 N = A2 π= dt π (0.040 m)(0.008 = m) 1.00531 × 10−3 m 2 For aluminum: τ2 = P ∴ P = A2τ 2 = (1.00531 × 10−3 m 2 )(70 × 106 Pa) = 70.372 × 103 N A2 Limiting value of P is the smaller value, so P = 67.9 kN Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 1.41 PROBLEM 1.41 In the truss shown, members AC and AD consist of rods made of the same metal alloy. Knowing that AC is of 25-mm diameter and that the ultimate load for that rod is 345 kN, determine (a) the factor of safety for AC, (b) the required diameter of AD if it is desired that both rods have the same factor of safety. SOLUTION Forces in AC and AD. Joint C: = ΣFy 0: Joint D: 1.5 0 F= AC − 48 kN 11.25 FAC = 107.331 kN T = ΣFy 0: PU FAC 345 kN 107.331 kN (a) Factor of safety for AC. (b) For the same factor of safety in AC and AD, σ AD = σ AC . F.S. = F.S. = 1.5 F= 0 AD − 48 kN 38.25 FAD = 197.909 kN T F.S. = 3.21 FAD F = AC AAD AAC AAD = Required diameter: FAD 197.909 kN π m) 2 9.0513 × 10−4 m 2 AAC = = (0.025 107.331 kN 4 FAC = d AD 4 AAD = π (4)(9.0513 × 10−4 m 2 ) π d AD = 33.9 mm Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 1.43 PROBLEM 1.43 Two wooden members are joined by plywood splice plates that are fully glued on the contact surfaces. Knowing that the clearance between the ends of the members is 6 mm and that the ultimate shearing stress in the glued joint is 2.5 MPa, determine the length L for which the factor of safety is 2.75 for the loading shown. SOLUTION = τ all 2.5 MPa = 0.90909 MPa 2.75 On one face of the upper contact surface, A= L − 0.006 m (0.125 m) 2 Since there are 2 contact surfaces, τ all = P 2A 16 × 103 0.90909 × 106 = ( L − 0.006)(0.125) L = 0.14680 m 146.8 mm Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 1.48 PROBLEM 1.48 For the support of Prob. 1.47, knowing that the diameter of the pin is d = 16 mm and that the magnitude of the load is P = 20 kN, determine (a) the factor of safety for the pin, (b) the required values of b and c if the factor of safety for the wooden members is the same as that found in part a for the pin. PROBLEM 1.47 A load P is supported as shown by a steel pin that has been inserted in a short wooden member hanging from the ceiling. The ultimate strength of the wood used is 60 MPa in tension and 7.5 MPa in shear, while the ultimate strength of the steel is 145 MPa in shear. Knowing that b = 40 mm, c = 55 mm, and d = 12 mm, determine the load P if an overall factor of safety of 3.2 is desired. SOLUTION = P 20 kN = 20 × 103 N (a) Pin: = A Double shear: = τ π = d2 4 π 4 P = τU 2A 2 (0.016) 2.01.06 × 10−6 m 2 = PU 2A PU = 2 Aτ U = (2)(201.16 × 10−6 )(145 × 106 ) = 58.336 × 103 N F= .S. (b) Tension in wood: PU = A PU w(b − d ) where = w 40 mm = 0.040 m PU 58.336 × 103 = 0.016 + = 40.3 × 10−3 m wσ U (0.040)(60 × 106 ) Shear in wood: b = 40.3 mm = PU 58.336 × 103 N for same F.S. Double shear: each area is A = wc = c F .S . = 2.92 = PU 58.336 × 103 N for same F.S. σ= U b= d + PU 58.336 × 103 = P 20 × 103 = τU PU = 2A PU 58.336 × 103 = = 97.2 × 10−3 m 6 2wτ U (2)(0.040)(7.5 × 10 ) PU 2wc c = 97.2 mm Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.9 PROBLEM 2.9 A 9-kN tensile load will be applied to a 50-m length of steel wire with E = 200 GPa. Determine the smallest diameter wire that can be used, knowing that the normal stress must not exceed 150 MPa and that the increase in length of the wire must not exceed 25 mm. SOLUTION Stress: Deformation: σ = P A = A P = σ δ = PL AE = A PL = Eδ The larger value of A governs: 9 × 103 N = 60 × 10−6 m 2 6 150 × 10 Pa (9 × 103 )(50) = 90 × 10−6 m 2 −3 9 (200 × 10 )(25 × 10 ) A = 90 mm 2 = A π 4 d 2= d 4A = π 4(90 mm 2 ) π d = 10.70 mm Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.14 PROBLEM 2.14 The 4-mm-diameter cable BC is made of a steel with E = 200 GPa. Knowing that the maximum stress in the cable must not exceed 190 MPa and that the elongation of the cable must not exceed 6 mm, find the maximum load P that can be applied as shown. SOLUTION LBC = 62 + 42 = 7.2111 m Use bar AB as a free body. 4 F= 3.5P − (6) BC 0 7.2111 P = 0.9509 FBC M A 0: Σ= Considering allowable stress, = σ 190 × 106 Pa π π 2 d2 = = (0.004) 12.566 × 10−6 m 2 4 4 FBC ∴ FBC =σ A =(190 × 106 )(12.566 × 10−6 ) =2.388 × 103 N σ= A A = Considering allowable elongation, δ = 6 × 10−3 m δ= FBC LBC AE ∴ FBC = AEδ (12.566 × 10−6 )(200 × 109 )(6 × 10−3 ) = = 2.091 × 103 N LBC 7.2111 Smaller value governs. = FBC 2.091 × 103 N P = 0.9509 FBC = (0.9509)(2.091 × 103 ) = 1.988 × 103 N P = 1.988 kN Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.17 PROBLEM 2.17 The specimen shown has been cut from a 5-mm-thick sheet of vinyl (E = 3.10 GPa) and is subjected to a 1.5-kN tensile load. Determine (a) the total deformation of the specimen, (b) the deformation of its central portion BC. SOLUTION = δ AB PLAB (1.5 × 103 N)(40 × 10−3 m) = = 154.839 × 10−6 m EAAB (3.1 × 109 N/m 2 )(25 × 10−3 m)(5 × 10−3 m) = δ BC PLBC (1.5 × 103 N)(50 × 10−3 m) = = 483.87 × 10−6 m −3 −3 9 2 EABC (3.1 × 10 N/m )(10 × 10 m)(5 × 10 m) δ= δ= 154.839 × 10−6 m CD AB (a) Total deformation: δ = δ AB + δ BC + δ CD = δ 793.55 × 10−6 m δ = 0.794 mm (b) Deformation of portion BC : δ BC = 0.484 mm Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.24 PROBLEM 2.24 The steel frame ( E = 200 GPa) shown has a diagonal brace BD with an area of 1920 mm2. Determine the largest allowable load P if the change in length of member BD is not to exceed 1.6 mm. SOLUTION δ BD = 1.6 × 10−3 m, ABD = 1920 mm 2 = 1920 × 10−6 m 2 52 + 62 = 7.810 m, EBD = 200 × 109 Pa LBD = δ BD = FBD = FBD LBD EBD ABD EBD ABDδ BD (200 × 109 )(1920 × 10−6 )(1.6 × 10−3 ) = LBD 7.81 = 78.67 × 103 N Use joint B as a free body. ΣFx = 0: 5 FBD − P = 0 7.810 = P 5 = FBD 7.810 = 50.4 × 103 N (5)(78.67 × 103 ) 7.810 P = 50.4 kN Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.33 PROBLEM 2.33 An axial centric force of magnitude P = 450 kN is applied to the composite block shown by means of a rigid end plate. Knowing that h = 10 mm, determine the normal stress in (a) the brass core, (b) the aluminum plates. SOLUTION δ= δ= δ; P PA + PB = A B PA L PB L = δ = and δ E A AA EB AB δ δ Therefore, = PA (= E A AA ) ; PB ( EB AB ) L L δ Substituting, = PA ( E A AA + E B AB ) L δ P = ∈ = L ( E A AA + E B AB ) ∈= (450 × 103 N) (70 × 10 Pa)(2)(0.06 m)(0.01 m) + (105 × 109 Pa)(0.06 m)(0.04 m) 9 = ∈ 1.33929 × 10−3 σ = E∈ Now, (a) Brass-core: σB = (105 × 109 Pa)(1.33929 × 10−3 ) = 1.40625 × 108 Pa σ B = 140.6 MPa (b) Aluminum: σA = (70 × 109 Pa)(1.33929 × 10 −3 ) = 9.3750 × 107 Pa σ A = 93.8 MPa Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.48 PROBLEM 2.48 The brass shell (αb = 20.9 × 10–6/°C) is fully bonded to the steel core (αs = 11.7 × 10–6/°C). Determine the largest allowable increase in temperature if the stress in the steel core is not to exceed 55 MPa. SOLUTION Let Ps = axial force developed in the steel core. For equilibrium with zero total force, the compressive force in the brass shell is Ps . Ps ε s= + α s (∆T ) Strains: Es As P εb = − s + α b (∆T ) Eb Ab Matching: ε s = εb Ps P + α s (∆T ) = − s + α b (∆T ) Es As Eb Ab 1 1 + Ps = (α b − α s )(∆T ) Es As Eb Ab (1) Ab = (0.030)(0.030) − (0.020)(0.020) = 500 × 10−6 m 2 = As (0.020)(0.020) = 400 × 10−6 m 2 α b − α s = 9.2 × 10−6 / °C σ s As = (55 × 106 )(400 × 10−6 ) = 22 × 103 N Ps = 1 1 1 1 + = + = 31.548 × 10−9 N −1 −6 −6 9 9 Es As Eb Ab (200 × 10 )(400 × 10 ) (105 × 10 )(500 × 10 ) From (1), (31.548 × 10−9 )(22 × 103 ) = (9.2 × 10−6 )(∆T ) ∆T= 75.4 °C Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.51 PROBLEM 2.51 A rod consisting of two cylindrical portions AB and BC is restrained at both ends. Portion AB is made of steel ( Es = 200 GPa, α s =11.7 × 10−6 / °C) and portion BC is made of brass ( Eb = 105 GPa, α b = 20.9 × 10−6 / °C). Knowing that the rod is initially unstressed, determine the compressive force induced in ABC when there is a temperature rise of 50 °C. SOLUTION = AAB π π π π 2 = = d AB (30)2 706.86 = mm 2 706.86 × 10−6 m 2 4 4 2 = (50)2 = ABC = d BC 1.9635 × 103 mm 2 = 1.9635 × 10−3 m 2 4 4 Free thermal expansion: = δT LABα s (∆T ) + LBCα b (∆T ) = (0.250)(11.7 × 10−6 )(50) + (0.300)(20.9 × 10−6 )(50) = 459.75 × 10−6 m Shortening due to induced compressive force P: = δP = PL PL + Es AAB Eb ABC 0.250 P 0.300 P + (200 × 109 )(706.86 × 10−6 ) (105 × 109 )(1.9635 × 10−3 ) = 3.2235 × 10−9 P For zero net deflection, δ P = δT 3.2235 × 10−9 P = 459.75 × 10−6 = P 142.624 × 103 N P = 142.6 kN Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.60 PROBLEM 2.60 At room temperature (20°C) a 0.5-mm gap exists between the ends of the rods shown. At a later time when the temperature has reached 140°C, determine (a) the normal stress in the aluminum rod, (b) the change in length of the aluminum rod. SOLUTION ∆T = 140 − 20 = 120°C Free thermal expansion: Laα a (∆T ) + Lsα s (∆T ) δ= T = (0.300)(23 × 10−6 )(120) + (0.250)(17.3 × 10−6 )(120) = 1.347 × 10−3 m Shortening due to P to meet constraint: δ P= 1.347 × 10−3 − 0.5 × 10−3= 0.847 × 10−3 m PLa PLs La L + = + s P Ea Aa Es As Ea Aa Es As 0.300 0.250 = + P 9 9 −6 −6 (75 × 10 )(2000 × 10 ) (190 × 10 )(800 × 10 ) δP = = 3.6447 × 10−9 P 3.6447 × 10−9 P = 0.847 × 10−3 Equating, = P 232.39 × 103 N P Aa 232.39 × 103 = −116.2 × 106 Pa 2000 × 10−6 (a) σa = − = − (b) δ= Laα a (∆T ) − a σ a = −116.2 MPa PLa Ea Aa = (0.300)(23 × 10−6 )(120) − (232.39 × 103 )(0.300) = 363 × 10−6 m (75 × 109 )(2000 × 10−6 ) δ a = 0.363 mm Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.70 PROBLEM 2.70 The block shown is made of a magnesium alloy, for which E = 45 GPa and v = 0.35. Knowing that σ x = −180 MPa, determine (a) the magnitude of σ y for which the change in the height of the block will be zero, (b) the corresponding change in the area of the face ABCD, (c) the corresponding change in the volume of the block. SOLUTION (a)= δ y 0= ε y 0= σz 0 1 (σ x − vσ y − vσ z ) E σ y = vσ x = (0.35)(−180 × 106 ) ε y= = −63 × 106 Pa σ y = −63.0 MPa (0.35)(−243 × 106 ) = +1.890 × 10−3 45 × 109 σ x − vσ y 1 157.95 × 106 ε x =(σ x − vσ y − vσ Z ) = = − = −3.510 × 10−3 E E 45 × 109 1 E v E ε z =(σ z − vσ x − vσ y ) = − (σ x + σ y ) = − (b) A0 = Lx Lz A= Lx (1 + ε x ) Lz (1 + ε z )= Lx Lz (1 + ε x + ε z + ε xε z ) ∆ A = A − A0 = Lx Lz (ε x + ε z + ε xε z ) ≈ Lx Lz (ε x + ε z ) = ∆ A (100 mm)(25 mm)(−3.510 × 10−3 + 1.890 × 10−3 ) (c) ∆A= −4.05 mm 2 V0 = Lx Ly Lz V= Lx (1 + ε x ) Ly (1 + ε y ) Lz (1 + ε z ) = Lx Ly Lz (1 + ε x + ε y + ε z + ε xε y + ε y ε z + ε z ε x + ε xε y ε z ) ∆V = V − V0 = Lx Ly Lz (ε x + ε y + ε z + small terms) = ∆V (100)(40)(25)(−3.510 × 10−3 + 0 + 1.890 × 10−3 ) ∆V = −162.0 mm3 Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education. Solution 2.81 PROBLEM 2.81 Two blocks of rubber, each of width w = 60 mm, are bonded to rigid supports and to the movable plate AB. Knowing that a force of magnitude P = 19 kN causes a deflection δ = 3 mm of plate AB, determine the modulus of rigidity of the rubber used. SOLUTION Each block of rubber carries ½ of the applied force P. Thus the shearing stress is τ= 1 / 2P where A = 10.8 103 mm 2 =× 10.8 10−3 m 2 (180 mm )( 60 mm ) =× A 1 (19 × 103 N) 2 τ = = 0.87963 × 106 Pa 10.8 × 10−3 δ 3 mm = = 0.085714 γ = h 35 mm 0.87963 × 103 τ G = = = 10.26 × 106 Pa 0.085714 γ G = 10.26 MPa Copyright ©2020 McGraw-Hill Education. All rights reserved. No reproduction or distribution without the prior written consent of McGraw-Hill Education.