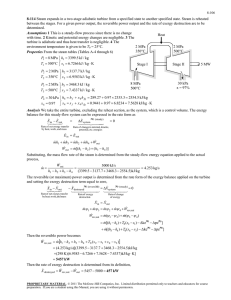

DESALINATION Desalination 201 (2006) 224-240 www.elsevier.com/locate/desal Exergy and thermoeconomic evaluation of MSF process using a new visual package A. S. Nafeya*, H. E. S. Fathb, A. A. Mabrouka aFaculty of Petroleum & Mining Engineering, Suez, Suez Canal University Egypt; email: asnafey31@yahoo.com, abdul_naser70@yahoo.com, bFaculty of Engineering, Alexandria University, Egypt; email: h_elbanna_f@yahoo.com Received 7 January 2005; accepted 26 September 2005 Abstract This paper presents a methodology of exergy and thermoeconomic analysis for performance of the Multi-Stage Flash (MSF) process using the developed package. This methodology gets insight on details not available by the first law analysis. The main target of these analyses is to improve the MSF process as well as to determine the unit product cost of the distilled water. Using the developed VDS package, the energy analysis of the considered MSF plant in the rating mode (performance), the gain ratio (GR) is calculated as 7.91. The exergy input, E⭈F, to the MSF plant is calculated as 10.7 MW which represents the exergy of the heating steam, exergy associated to the sea water feed, and electrical pumping power minus the exergy of the brine heater condensate. Only 0.2 MW of an elevated exergy in the distilled stream is produced. The exergy associated with blow down and rejection of cooling streams is 4.04 MW which nominated as an exergy loss. The remainder part of E⭈ D = 6.46 MW is destroyed internally in the plant components as a result the exergetic efficiency of the considered MSF plant, ηII 1.87%. The unit product cost of the MSF desalination plant is calculated as 2.63 $/m3 by two different ways. The first one by calculating the capital and running costs which invested at the boundary of the MSF plant (input streams); the second way is based on mathematical model (thermoeconomics) by which the outlet streams cost is calculated and charged their value to the desalted water. Thermoeconomic analysis shows that the overall cost of the desalination plant will be obtained if the exergy destruction rate of the desuperheater, the distiller train is reduced. The monetary cost of the streams indicated that any modifications in the first stages will cause more effect other than the last stages. Different partial load conditions for the real data of Eoun Mousa MSF plant are depicted and recorded by Data Control System (DCS). These data are fed to the developed VDS software to investigate the performance of the MSF plant. The distillate product varies from 104 (50%) m3/h to 208 (100%) m3/h as well as the top brine temperature varies from 86 to 110°C. The heating steam consumption varies from 12 to 26 m3/h. Thermoeconomic analysis of MSF plant under different partial load conditions showed that the unit product cost increases to 21% when the load decreases to 50% of its design value. Keywords: Visual package, design and simulation MSF plant, Exergy, Thermoeconomics. *Corresponding author 0011-9164/06/$– See front matter © 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.desal.2005.09.043 225 A.S. Nafey et al. / Desalination 201 (2006) 224–240 1. Introduction The conservative nature of the MSF desalination plant owner, their large number of operation and maintenance (O&M) experience, as well as the strategic characteristics of the product, makes the MSF process favored over the other competitive thermal desalination methods [2]. Competing desalination processes such as reverse osmosis (RO) or vapor compression (VC) which get their exergy from electricity are nowadays having some market successes based on better economics and thermodynamic performance, but some doubts arise from the lack of operating experience and fouling problems [3]. On the other hand, more development and innovations by better exergy utilization are required in the MSF plants. Exergy analysis is a method that uses the conservation of mass and energy principles together with the second law of thermodynamics for the analysis, design and improvement of energy systems. Exergy analysis of major recirculation multi-stage flash desalting plants in Saudi Arabia is conducted via a simple scheme [5]. The obtained results show that the MSF desalting plants are highly irreversible with exergetic efficiency (the sum of all rates of exergy outflows/the sum of all rates of exergy inflows) ranging from 1.12–10.38%. Frederick [3] outlined an exergy analysis for the MSF desalination plant (947 m3/h) of 1970s design, which showed that the second law efficiency (exergy of distillate stream/the sum of exergy of inflows) of the MSF desalination is calculated as 4%. Since exergy destruction measures the true thermodynamic value of irreversibility effect on the system, it is meaningful to use exergy as a basis for assigning costs in thermal systems, which is called thermoeconomics, Bejan et al. [6]. Thermoeconomics is an effective tool to reveal opportunities for higher efficiency and lower cost of a system of energy conversion devices [6,7]. Thermoeconomic analysis provides information about the cost formation process and the flow of costs in the system. Costing analysis of a com- bined power (60 MW of electricity) and MSF desalination plant (18,000 m3/day) was performed based on the exergy concept by Gaggioli et al. [7]. In that work, the exergetic efficiency (elevated exergy of distillate stream/ exergy of inflows streams) of the MSF is calculated as 5% in summer operation. The mathematical model considers the money balance for each hardware component (boiler, turbine, pump etc.) and several different set of auxiliary equations. However, the model did not consider the distillation plant. Here, in this regard, the interaction between cost and efficiency still needs to be investigated for MSF process. So, this paper presents energy, exergy and thermoeconomic analysis for MSF desalination process at different partial loads. The main target of these analyses is to pinpoint the locations of the improvement of MSF process as well as to determine the unit product cost of the desalinated water. 2. Overview on the VDS package Using the developed Visual Design & Simulation (VDS) package, different types and configurations of thermal desalination plants can be manipulated [8]. The object oriented programming technique is used to build a friendly user-interface. Different types of calculations such as energy, exergy, and thermoeconomics can be performed by the developed VDS package. Modifications in existing plants can be evaluated. Desalination plant components (units), such as heat exchangers, flash chambers, evaporators, pumps, pipes, etc. are stored as icons in a visual library. Using this visual library, different configurations can be constructed by just clicking the mouse over the required units (icons). Fig. 1 shows the brine circulation MSF-BR plant. To construct such configuration, the designer needs to drag the required units from visual library and drop it in the panel. Then these icons (units) are visually arranged similar to the real plant. A menu bar is created and located at the top A.S. Nafey et al. / Desalination 201 (2006) 224–240 226 Fig. 1. Panel of process flowsheet of MSF-BR desalination plant. of a panel which associated with drop-down submenus. The developed menu bar contains the following five submenus: 1. Calculations Mode menu: this menu is linked with a drop-down sub-menu of (simulation, design, and optimization). 2. Connections menu: this menu is associated with buttons that enable the user to connect all units, and plant pipes. 3. Start Calculations menu: enables the user to select the required type of calculations such as energy, exergy, cost, and thermoeconomics analysis. 4. Display Results menu: allows the user to display the results in the same panel or another window in both table and chart forms. 5. Print menu: to print the oriented form. After all units and pipes are connected with each others the scenario between the user and the computer is stopped to start the numerical calcu- lations phase which occurs at the behind of the panel. The user can change the operating conditions of the desalination plant during run-time. The desalination process configuration composes of collective icons (units and pipes) which should be seen mathematically as a large matrix that assembled from sub matrices. Composing different configurations means that the location of the icon (real unit) can change. Mathematically, this means that the sub matrix elements position will sequentially change. Therefore, the developed program has the following features: 1. It is a robust code modulates upon the unit position and type changes. 2. It has a powerful graphic interface to build up different configurations for different types easily. 3. It has a reliable code based on the sparse matrices for technique. The details of the package construction and verification are reported and illustrated in [8]. 227 A.S. Nafey et al. / Desalination 201 (2006) 224–240 3. Exergy analysis The specific exergy of a fluid stream with negligible kinetic and potential energies is given by e = h – h0 – T0(s – s0). Since the saline water is a mixture of pure water and salt, the properties of salt must be taken into account along with pure water properties. The molar specific enthalpy and specific entropy of a solution can be expressed as h = xw hw + xs hs and s = xw sw + xs ss – Ru (xw ln xw + xs ln xs). The enthalpy and the entropy values for pure water and the salt in the above relations are obtained from thermodynamic relations [11]. The reference state for water is T0 = sea water temperature, K, P0 =100 kPa and the state of salt at 0 is taken as reference state. So the exergy point of certain saline stream is calculated as follows [4]: e = eph + ech (1a) e ph = (Npure + Nsalt)[xw(hw – hw,0) + xs(hw – hs,0) – T0 (xw(sw – sw,0) + xs(ss – ss,0))] or – (T – T ) + x C – e ph = Nm[xwC p,w w w,0 s p,s (Ts – Ts,0) – T p – p0 – ln — T0(xw (C – ——— — — —) + p,f T0 T0 * –ρf f T p – p0 xsCp,s ln — – ——— — — —) T0 T0 * –ρf ⭈ = [N ⭈ ⭈ ) and T = T = T let N +N m pure salt f s Then the above relation becomes: – – ⭈ [x C e ph = N m w p,w + xsCp,s (T – T0) – T – – T0[xw (Cp,w + xsCp,s (ln —) – T0 p – p0 p – p0 (xw + xs )(——— — — + ——— — — —)]] T0 * –ρs T0 * –ρf T e ph = Cp,m (T – T0) – T0[Cp,m(ln —) T0 p – po – ——— — —] To * –ρm (1b) – +xC – where Cpm = N⭈ m(xwC p,m s p,s ) is mean specific heat of saline water and –ρ + –ρ ⭈ (— w— s is the density of saline ρm = N — — — — — — —) m ρf * –ρs water, and (xw + xs ) = 1. The chemical exergy is calculated with respect the sea water composition as follows: e ch = – N⭈ m RuT0 [(xw ln xw + xs ln xs)↓brine] (1c) Substituting Eqs. (1b) and (1c) into equation (1a) the following equation is obtained ⭈ [e ph + e ch] E⭈ b = M b (1) By similarly the exergy of the distilled water can be written as follows: T ⭈ (C (T – T ) – T (C (ln —) E⭈ d = M – d p,d 0 0 p,d T0 p – p0 — — — — — — — —)) + Md (ΔG)P,T T0 ρd (2) The first term on the right side of the above equation is related to thermal and mechanical exergy which calculated from equation 1 by substitute xs = 0 and xw = 1. The second term is function of the minimum power required for sea water separation. The minimum power of a material stream is Gibbs free energy (ΔG)P,T of its composition change. The minimum work forms a basis for comparison of actual distillation processes, and the determination of the second-law efficiency. The pure water, in terms of irreversibility, is expensively obtained as the minimum work required is 0.936 kWh/m3 relative to Gulf sea water [3]. In another literature [4], the minimum work input requirement for distillation process is accounted by 0.575 kWh/m3 based on driven relation. Another value is reported by El-Sayed [15], for sea water at 25°C and 45 g/l salt TDS and rejected brine as 65 g/l, of 1.345 kWh/m3. A.S. Nafey et al. / Desalination 201 (2006) 224–240 228 The exergy rate of the heating steam is determined from the following equation: ⭈ (h – h – T (s – s ) E⭈ = M (2) v v 0 0 0 The thermophysical properties are calculated based on the relations illustrated in [11]. Based on Eqs. 1, and 2, the exergy rate of all the process streams are calculated. Exergy balance analysis of each unit in the considered process is performed based on the following equation:E⭈ = E⭈ + E⭈ + E⭈ (3) F P D L The rate of exergy product E⭈ P represents the desired result produced by the unit. The rate of fuel exergy (E⭈ P) represents the resources expended to generate the product. The difference between the fuel and product is mainly due to exergy destruction into the system (E⭈ D) and the exergy loss out of the process (E⭈ L) Bejan et al. [6]. Because of the space limitation, only a flash chamber unit is illustrated her to show how exergy balance equations are applied. To understand the exergy analysis of the flash chamber unit, it may be divided into three subunits; splitter, mixer and condenser which are operating in parallel as shown in Fig. 2. Applying equation 4 the following equation are obtained: (i) Splitter (brine pool) of the flash chamber: E⭈ b,1 = E⭈ vapor + E⭈ b,2 + E⭈ D,spliter (4) (ii) Heat exchanger of the flash chamber: E⭈ – E⭈ = E⭈ – E⭈ + E⭈ cw,5 cw,6 vapor, in condensate D,exchanger (5) (iii) Mixer (distillate tray) of the flash chamber: E⭈ + E⭈ = E⭈ + E⭈ (6) d,3 condensate d,4 D,mixer By summing (4), (5), and (6), the exergy destruction in the flash chamber is obtained as: E⭈ = E⭈ + E⭈ + E⭈ + E⭈ + E⭈ + E⭈ (7) D b,1 b,2 d,3 d,4 cw,5 cw,6 The exergetic efficiency of the flash unit is: Fig. 2. Schematic diagram of the flash chamber. ( E⭈ d,4 – E⭈ d,3) + ( E⭈ cw,5 – E⭈ cw,6 ) ———— ————————— ηII = —— E⭈ b,1 – E⭈ b,2 (8) 4. Thermoeconomic analysis 4.1. Mathematical modeling The cost balance of the unit relates the rate of the expenditures made to generate the product. The general cost balance equation is written as follows [6,7]: C⭈ = C⭈ + Z⭈ CI+OM (9) P F The above equation shows that the cost rate associated with the product stream equals the total rate expenditures C⭈ F and the cost rates associated with capital investment and operation and maintenance Z⭈ CI+OM. On this basis, it can be deduced that the cost balance equations for the flash chamber are: (i) Splitter (pool brine): Since the inlet brine is partly vaporized and the remaining brine leaves the pool with higher salt concentration; C⭈ = C⭈ – C⭈ + Z⭈ (CI+OM) (10) flashed vapor b,in b,out sp (ii) Mixer (distillate tray): The condensate of the flashed vapor is mixed with distilled water of previous stage, so 229 A.S. Nafey et al. / Desalination 201 (2006) 224–240 (CI+OM) C⭈ d,out = C⭈ d,in – C⭈ condensate + Z⭈ mix (11) (iii) Preheater/condenser: The incoming cooling water temperature is increased at the expense of the condensation of the flashed vapor. C⭈ – C⭈ = C⭈ – C⭈ + Z⭈ (CI+OM) cw,out cw,in flashed vapor condensate hx (12) Summing up Eqs. (10), (11) and (12); the following equation is obtained for the overall cost balance of flash chamber; – C⭈ b,in + C⭈ b,out + C⭈ cw,out – C⭈ cw,in + C⭈ d,out – C⭈ = Z⭈ (CI+OM) (13) d,in As there are three outlet streams from each flash chamber, two additional auxiliary equations are required. The first auxiliary equation states the equality of the average cost of the inlet and exit brine. C⭈ b,in C⭈ b,out — — —–— — — —=0 (14) E⭈ E⭈ b,in b,out The second auxiliary equation states the equal average cost of the flashed vapor and its condensate; i.e C⭈ flashed vapor C⭈ condensate — — —— —— — —–— — ——— — —=0 (15) E⭈ E⭈ flashed vapor b,out (i) Capital cost Purchased equipment cost (PEC) = $7.7 × 106 Working capital investment (WCI) = $530 × 103. Intake system, [9] = 300$/(m3/day) × 5000 = 1.5 × 106 $ The total capital investment TCI = 9.73 × 106 $ Annual capital investment = TCI × CRF Table 1 Operating conditions for Aoun Mousa MSF desalination plant [12] condensate By substituting equations 10, 11 and 12 into equation 15 thus; C⭈ b,in – C⭈ b,out C⭈ d,out – C⭈ d,in — — —— —— —— — – —⭈— — —— —— —— = 0 (16) E⭈ – E⭈ E – E⭈ b,in the sum of the fixed capital cost depreciation rate (FCCDR) per year and the annual operation and maintenance (O&M) cost. The FCCDR is estimated from the sum of individual capital items costs divided by the effective life period. The annual O&M cost is the sum of individual annual costs necessary for operation of the desalination plant. The annual operating and maintenance cost expenses (OMC) include the operating Electricity, labor, maintenance labor, maintenance materials, chemicals, and the cost of the consumed steam. A recent tender of 5000 m3/day of MSF desalination plant [12], is used to calculate the unit product cost as shown in Tables 1, 2 and 3. d,out d,in Following the same sequence, three equations similar to Eqs. (13), (14) and (16) are generated by VDS program according to the stages number. 4.2. Estimation of unit cost of the desalted water The annualized cost expenses for production of fresh water per year are simply based on both Variables Design data Sea water feed, m3/h TBT, °C Make up, m3/h Brine circulation flow, m3/h Sea water temperature, °C Heating steam, °C Heating steam pressure, bar Recycle splitter ratio, α1 Blow down splitter ratio, α2 Brine heater surface area, m2 Area of heat recovery section Area of heat rejection section 1370 110 660 1847 27 205 7 0.724 0.482 780 17 × 488 3 × 357 A.S. Nafey et al. / Desalination 201 (2006) 224–240 230 Table 2 Chemical cost and dosing rate [13] Chemical Unit cost ($/kg) Dosing rate (g/ton) of make up Cost rate $/h Sulfuric acid Caustic soda Anti-scalant Chlorine Total 0.504 0.701 1.9 0.48 — 24.2 14 4 4 — 24.2 × 660/1000 × 0.504 = 7.92 14 × 660/1000 × 0.701 = 6.47 4 × 660/1000 × 1.9 = 6.27 4 × 660/1000 × 0.482 = 1.2 21.93 Table 3 Capital cost of the MSF-BR desalination plant (5000 m3/day) [ 12] Item Cost, $ Capital cost Lump sum price for designing, furnishing, fabricating, testing, and demisters, delivery including evaporator trains with ejectors, strainers, heat exchangers, condensers, pumps and motors, chemical feed systems, electrical equipments and control systems, chemicals for normal operation and control room. 7.7 × 106 Salaries and wages during start up, payroll taxes, insurance and plant overhead, air travel. 103,112 Lump sum price for off-shore training of owner’s personnel. 12,684 Lump sum price for job site training of owner’s personnel. 19,054 Provisional sum 398,290 Total purchased order price 8.23 × Intake cost, $ 1.5 × 106 Sub total, $ 9.73 × 106 Grand total 11.68 × 106 Hourly depreciated cost, $/h 119 where the capital recovery factor (CRF) is given by: i × (1 + i)n 0.05 × (1 + 0.05)20 CRF = — — — — — — — — — — — — — — —=— — — — — — — — — — — — — — — — — — — — — — — — — — — — — = 0.08 (1 + 0.05)20 – 1 (1 + i)n – 1 (18) Interest rate, i = 5% Amortization year, n = 20 years The annual capital cost rate = 9.73 × 106 × 0.08 = 778,400 $/year. Multiplying this figure by a cost index of 1.2 [17], the annual capital cost in the time of evaluation is calculated as: 106 The total annual of depreciation capital cost, FCCDR = 934,080 $/year. (ii) Annual operation and maintenance cost (OMC) Cost of extracted steam to MSF process = 347/26 = 13.36 $/m3, see appendix A. The cost of extracted steam =13.4 ($/ton) × 26.5 (ton/h) × 24 × 365 × 0.9 = 2,799,608 $/year Specific cost of electricity = 33,423/ (320,000) = 0.1 $/kWh, see appendix A Electricity cost = 0.1 ($/kWh × Power × 24 × 365 × plant factor = 0.1 × 590 × 24 × 365 × 0.9 = 465,165 $/year The reminder item of OMC per year of operation can be calculated as follows: 231 A.S. Nafey et al. / Desalination 201 (2006) 224–240 The performance of a distillation plant depends mainly on the overall heat transfer coefficient of the evaporators and brine heater. The overall heat transfer coefficient is affected by the fouling on the tube surface. Therefore scale prevention is one of the indispensable techniques in distillation processes. The distillation plant with high temperature additive treatment for feed make up sea water is designed to have the maximum brine temperature of 110°C and recirculating brine circulation of 63,000 ppm as shown in Table 1. The injection Belgard EV is recommended to make up flow rate for the reduction of bicarbonate ion in sea water flow rate. The formation of alkaline scale of calcium carbonate and magnesium hydroxide over a long period of operation can be prevented by the use of acid cleaning. The chemical consumption and dosing rate and their cost are given in Table 2. The rate of chemical consumption and cost is shown in Table 2. Chemicals cost = 22 ($/h) × 24 × 365 × 0.9 = 173,448 $/year The total annual operation and maintenance cost = 3,438,221 $/year The total annual cost = 934,080 +3,438,221 = 4,372,230 $/year The unit product cost = 4,372,230/(5000 × 365 × 0.9) = 2.63 $/m3. 5. Thermoeconomic variables Following the above analysis, the developed VDS program is utilized to calculate the plant streams cost flow rate. The cost flow rate of the plant streams give an idea about the cost distribution, however, it does not help to take a decision. So these results are processed in calculating the thermoeconomics variables ηII cp, cF, CD, Z CI+OM, r, f. For the sake of demonstration, the flash chamber is considered to define thermoeconomic variables as follows: • Cost of the unit heating surface area, (Z⭈ CI+OM, $/h) The capital investment and operation and maintenance terms Z⭈ CI+OM is calculated for flash evaporator as follows: The purchased cost of the pumps can be calculated from the following equation [14]: PEC = 32000 × 0.000435 × M 0.65 × ηp ΔP 0.55 × ——— — 1 – ηp 冢 冣 (20) where M is the brine mass flow rate (kg/s), in kPa, is the pump efficiency. Based on this equation the purchased cost of the feed pump, brine circulation pump, distillate, and blow down pump are calculated as Purchased equipment cost (PEC) = $264,660 Working capital (WC) = 0.2 × 264,660 = $52,932 The total annual cost of the pumps = $317,592 The hourly cost = 317,292 × 0.13/(365 × 24 × 0.9) = 5.2 $/h. By excluding the cost of intake and the cost of pumps, the cost of heating surface area is calculated as = 119 – (15 + 5.2) = 98.8 $/h. The cost per unit surface area is calculated as follows: 98.8 Z⭈ CI+OM = —— —— × heating surface area (m2) 10147 $/(hr.m2) • Average cost per exergy unit of fuel (cF, $/GJ). This variable represents the average cost at which each exergy unit of fuel is supplied to the flash chamber. This can be expressed as follows: C⭈ f C⭈ b,in – C⭈ b,out + C⭈ d,in 1000 cF = —⭈— = — — — —— —— — — —— —— —— × — —— — — (21) ⭈ ⭈ ⭈ E E –E +E 3600 F b,in d,out d,in • Average unit cost of product, (cP). This represents the average cost at which each exergy unit of the product of the flash chamber is generated. C⭈ C⭈ – C⭈ + C⭈ 1000 P cw,out cw,out d,out A.S. Nafey et al. / Desalination 201 (2006) 224–240 cP = —⭈— = — —— —— ——— — —— ——— —— × — —— — (21) EP E⭈cw,out – E⭈cw,out – E⭈d,out 3600 • Cost of exergy destruction (cD , $/h). The cost associated with the exergy destruction in a process is a hidden cost. It can be revealed only as follows: C⭈ D = cF × E⭈ D (23) • Relative cost difference, r. This variable expresses the relative increase in average cost per exergy unit between fuel and product of the component. This is expressed as: cP – cF r=— — — — — — — — — — cF Exergy input E⭈F Unit product cost, $/m 3, C⭈w = C⭈distilled + C⭈loss ($/h) C⭈disalted_water + C⭈L —— —— — —— — —— — —— —— = —— —— — —⭈— — —— — —— Distilled flow rate Md Brine circulation ratio, BCR = Brine recycle flow rate —— —— — —— —— — — —— ——— — —— —— Distilled output flow rate 6. Results and discussion 6.1. Design conditions (24) • Exergoeconomic factor. It expresses the contribution ratio of the non-exergy-related cost to the total cost increase: Z⭈ (CI+OM) f=— — —— — —— —— — —— —— — —— — — Z⭈ (CI+OM) + cF (ED + E⭈L) 232 (25) Eoun Mousa desalination plant is a brine circulation MSF-BR process as shown in Fig. 1. To perform the exergy and thermoeconomic analysis, the mass flow rate, temperature, pressure, entropy, and cost of the process streams are required. The VDS package is utilized to solve mass, pressure, and energy equations iteratively to obtain the mass, temperature and pressure of the state points in the MSF system, then the exergy flow rate of the streams is calculated. The cost balance equation model is solved to obtain the monetary cost flow rate of the streams. The following parameters are calculated for the overall plant performance analysis: ⭈ Distilled flow rate M d Gain ratio, GR = —— —— — —— —— — —— —–— = — — — ⭈ Steam flow rate Ms Exergy output E⭈P Exergetic efficiency, ηII = —— —— — —— —— —— = — — — The recycle brine splitter ratio α1 and the blow down brine splitter ratio α 2 are adjusted to set the make up flow rate by 660 m3/h as well as to set the brine circulation flow rate as 1847 m3/h. The VDS package results of stream mass balance, temperature, pressure, exergy, and monetary cost are illustrated in the panel as shown in Fig. 3. This panel also shows the main parameters such as gain ratio (GR), exergetic efficiency, ηII , surface area, and unit product cost. The energy analysis of the considered MSF plant in the rating mode (performance) shows that the gain ratio (GR) is calculated as 7.91 as shown in Fig. 3. The overall Exergy flow rate of the main variables is presented in Table 4. The exergy input, E⭈F, of 10.7 MW represents the exergy of the heating steam, exergy associated to the sea water feed, and electrical pumping power minus the exergy Table 4 Exergetic variables for MSF-BR process Exergy flow rate Calculated values ⭈ EF, MW ⭈ EL, MW ⭈ ED, MW ⭈ EP, MW ηII 10.7 4.04 6.46 0.2 1.87 233 A.S. Nafey et al. / Desalination 201 (2006) 224–240 Fig. 3. Energy, exergy, cost results of the developed VDS package. irreversibility’s, pressure drops in valves and tubes. The exergetic efficiency of the MSF, E⭈ P 0.2 — —— ——— = 0.0187. ηII = — E⭈ 10.7 F Fig. 4. Exergy analysis of the overall MSF desalination plant. of the brine heater condensate, see Fig. 4. Only 0.2 MW of an elevated exergy in the distilled stream is produced. The exergy associated with blow down and rejected of cooling streams is 4.04 MW which nominated as an exergy loss. The reminder part of E⭈D = 6.46 MW is destroyed internally in the plant components due to heat transfer The exergetic efficiency and the exergy destruction of MSF flash chambers are presented in Figs. 5a and 5b. These figures are in consistent to show that low exergetic efficiency of the first and last stages is mainly due to the exergy destruction in these stages. The exergetic efficiency and exergy destruction of the overall MSF plant units are given in the first two columns in Table 5. The results show that desuperheater, flash chambers, feed pump and recirculation pump have lower exergetic efficiency (ηII ). This table shows that most exergy destruction is occurred in the flash chambers. Based on the items of Tables 3 and 6, the unit cost of the product water for MSF-BR desalination A.S. Nafey et al. / Desalination 201 (2006) 224–240 234 b a Fig. 5. a. Exergy destruction in flash chambers. b. Exergy efficiency of flash chambers. Table 5 Thermoeconomic results of conventional MSF-BR Unit Desuperheated brine heater 0 Distilate pump Stage 1 Stage 2 Stage 3 Stage 4 Stage 5 Stage 6 Stage 7 Stage 8 Stage 9 Stage 10 Stage 11 Stage 12 Stage 13 Stage 14 Stage 15 Stage 16 Stage 17 Circu. pump Brine mixer 1 Stage 18 Stage 19 Stage 20 FEED pump B/D pump Exergy efficiency 0.77 0.72 0.70 0.82 0.87 0.87 0.88 0.88 0.88 0.89 0.89 0.88 0.88 0.87 0.87 0.85 0.83 0.81 0.78 0.73 0.82 1.00 0.80 0.80 0.80 0.78 0.67 Exergy destruction cf cp CD Z CD +Z MW $/GJ $/GJ $/h $/h $/h 1.55 1.08 0.01 0.37 0.24 0.21 0.19 0.17 0.16 0.15 0.13 0.12 0.12 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.08 0.02 0.17 0.17 0.17 0.03 0.01 14.90 18.13 31.66 57.77 64.79 68.36 71.97 75.65 79.45 83.41 87.62 92.16 97.13 102.67 108.97 116.26 124.87 135.26 148.08 164.32 32.79 33.53 68.93 68.93 68.93 22.10 27.78 19.44 25.97 44.93 71.95 75.67 79.39 83.19 87.12 91.26 95.72 100.61 106.09 112.37 119.71 128.52 139.33 152.98 170.79 194.55 229.47 39.94 33.64 84.03 84.03 84.03 43.06 47.60 83.05 70.52 1.53 77.93 54.98 52.99 49.85 47.48 45.36 43.50 42.25 41.40 41.13 41.52 42.67 44.70 47.79 52.15 58.15 66.38 8.92 2.72 41.64 41.64 41.64 2.20 1.47 0.00 10.26 0.64 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 6.42 7.62 0.00 4.69 4.69 4.69 2.53 0.68 83.05 80.77 2.17 84.35 61.40 58.81 56.27 53.90 51.78 50.01 48.66 47.82 47.55 47.94 49.09 51.12 54.20 58.57 64.57 72.72 16.54 2.72 46.34 46.34 46.34 4.72 2.15 r f 0.23 0.43 0.30 0.20 0.14 0.14 0.13 0.13 0.13 0.13 0.13 0.13 0.14 0.14 0.15 0.17 0.18 0.21 0.24 0.28 0.18 0.00 0.18 0.18 0.18 0.49 0.42 0.00 0.13 0.29 0.08 0.10 0.11 0.11 0.12 0.12 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.12 0.11 0.10 0.09 0.46 0.00 0.10 0.10 0.10 0.53 0.32 235 A.S. Nafey et al. / Desalination 201 (2006) 224–240 Table 6 Hourly operation and maintenance cost Items Value Chemical cost, $/h Steam cost, $/h (40 $/barrel) Electrical cost, $/h (40 $/barrel) Sub total, $/h 22 354 55 431 Table 7 Summarized cost data for the computer package The capital and O&M cost flow rate per m2 Specified cost of the inlet steam Electrical cost Cost of seawater feed (intake) 0.0097 $/h m2 13.4 $/ton 0.1 $/kWh 15 $/h plant of 208 m3/h, is calculated by another way as follows: The unit product cost = (capital cost ($/h) + running cost ($/h))/capacity (m 3/h) or Running cost, C⭈F = C⭈steam + C⭈electrical + C⭈chemical Capital cost, Z⭈ = 119 $/h = 354 + 55 + 22 = 431 $/h C⭈F + Z⭈ 431 + 119 Cost of disalted water = —— —— — — = —— — —— —— — — 208 208 = 2.63 $/m 3 thermoeconomic results shows that the cost flow rate of cooling water stream (feed + recycled) increases and reaches its maximum value at the inlet to the brine heater. Inversely, the cost flow rate of the brine stream decreases and reaches its minimum value at the exit of the last flash stage that is due to the exergy loss of the flashed vapor. These results also indicate that any modifications in the first stages will cause more effect other than the last stages. By using thermoeconomic mathematical model, the cost at the boundary of the MSF system is distributed on the internal streams. The over all stream costs of the MSF desalination plant of 5000 m3/day are shown in Fig. 6. The unit cost of the product is calculated based on the outlet streams. The cost of both the cooling water reject and the brine blow down streams are charged to the cost of the distillate stream. The cost of the brine blow down is obtained as 373 $/h as shown Fig. 6. The cost of desalted stream is obtained by 175 $/h. C⭈distilled_water = 175 $/h C⭈L = C⭈blowdown = 373 $/h C⭈distilled + C⭈ L Cost of disalted water = —— —— — —— —— — — 208 175 + 373 = —— —— —— — — = 2.63 $/m 3 208 The cost of the exergy destruction, C⭈D, inside the MSF is calculated as follows: C⭈ F 1000 431 1000 However, this method does not show how to minimize the unit cost. In other word, it gives no information about the monetary cost in the plant streams or how the expenditure cost is invested. Fortunately the thermoeconomics can. The summarized cost data of Table 7, are calculated by the VDS program and utilized to calculate the plant streams monetary cost flow rate. The Fig. 6. Cost analysis of the overall MSF desalination A.S. Nafey et al. / Desalination 201 (2006) 224–240 cF = —⭈— × — —— — — = ——— × — —— — — = 11.2 $/GJ EF 3600 10.71 3600 C⭈D = cF × E⭈D = 11.2 × 6.46 × 3.6 = 262 $/h Table 5 summarizes the thermoeconomic variables which are calculated for each component of the MSF system under the considered design conditions. These variables include the exergetic efficiency, rate of exergy destruction, average costs per unit fuel exergy cF, product exergy cp , cost rate of exergy destruction C⭈D, investment and O & M cost rate Z⭈ CI+OM, relative cost difference (r), and exergoeconomic factor ( f). This table shows that the distiller train generally has the highest values of the sum Z⭈ + C⭈D in the conventional MSF configuration especially the first stage, however the desuperheater and brine heater come in the next sequence. Therefore, these are the most important components to be considered for improvement from the thermoeconomics of point view. The zero value of the exergoeconomic factor ( f) for the desuperheater shows that the costs associated with the desuperheater are almost exclusively due to exergy destruction. The relatively high values of ( f) in the brine heater, circulation pump, feed pump, blow down pump, and distillate pump suggests a reduction in the investment costs of these components. The desuperheater, first, last stage, and brine recirculation pump have the lowest exergetic efficiency value and the highest relative cost difference (r) value. Thus it might be concluded that a decrease of the exergy destruction and capital cost in these components could be costly effective for the entire MSF plant. 6.2. Partial load analysis The MSF plant is adjusted to either partial load operation or shut down mode by controlling the rate of the heating steam source to count the distillate tank capacity limitation. Different partial load conditions for the real data of Eoun Mousa MSF plant are depicted and recorded by Data 236 Control System (DCS). These data are fed to the VDS software to investigate the performance of the MSF plant. The distillate product varies from 104 (50%) m3/h to 208 (100%) m3/h as well as the top brine temperature varies from 86 to 110°C. The heating steam consumption varies from 12 to 26 m3/h. The calculated results of energy analysis are given in Table 8, while the exergy analysis and thermoeconomic analysis are given in Tables 9 and 10 respectively. Table 8 shows that the gain ratio increases slightly with the decreasing the load and the brine circulation ratio (BCR) increases rapidly. This is mainly due to the decrease in the heating steam temperature at which the latent heat of evaporation is increased. As a result the steam consumption will decrease. Table 8 shows also that the top brine temperature (TBT) decrease with decreasing the load. This is due to the decrease of the heating steam temperature. Table 8 showed also, the salinity of the recycle stream (xrecycle) increases with the decrease of the load. This is mainly due to the increase of the brine circulation ratio (BCR). Table 9 shows the exergy analysis at different loads of MSF desalination plant based on the VDS results of energy analysis. This table shows that the exergy input to the MSF process decreases with the decrease of the load. This is due to the decrease in the steam consumption (slight increase of the gain ratio is obtained), as well as the decrease in pumping power. The exergy associated with the distilled stream also decrease with the decrease of the MSF capacity. This is mainly due to the decrease in the product flow rate as well as the distillate temperature (physical exergy). The exergetic efficiency, ηII, decreases with the decrease of the MSF capacity which indicates that under these conditions, the exergy output is the dominant. The exergy associated to both the rejected cooling water and the blow down brine increases with the decrease of the plant capacity. This is owing to 237 A.S. Nafey et al. / Desalination 201 (2006) 224–240 Table 8 Calculated results of partial load of MSF-BR desalination plant Load 100% 90% 75 % 63% 50% Mdistilled, m3/h GR Mfeed*, m3/h Mmake up, m3/h BCR xfeed*, g/1 xrecycle, g/1 xreject, g/l Tsteam*, °C Tfeed*, °C Tdesuperheater*, °C TBT, °C Tb,in*, °C α1 α2 208 7.91 1370 660 8.86 45 63 70 205 27 113 109 101 0.482 0.72 185 8.2 1636 469.5 9.3 45 66 74 191 27 107 104 96 0.287 0.81 158 8.1 1620 405 10 45 67 74 165 27 100 98.8 90 0.25 0.83 132 8.22 1645 345 12.4 45 66 73 193 27 93 91 85 0.21 0.84 104.8 8.5 1670 265 12 45 68 74 172 27 87 85.8 80 0.16 0.86 *Specified parameter Table 9 Exergy analysis at different partial load of MSF-BR plant ⭈ EF, MW ⭈ EL, MW ⭈ ED, MW ⭈ EP, MW ηII, % Table 10 Thermoeconomic analysis of MSF-BR at part load operation 100% 90% 75% 63% 50% Variable 100% 90% 75% 63% 50% 10.7 4 6.46 0.2 1.87 10.9 4.72 5.95 0.19 1.75 10 4.65 5.34 0.16 1.58 9 4.69 4.23 0.12 1.33 8.3 4.74 3.44 0.1 1.21 Expenditure, $/h Capital investment, Z, $/h Sub total, $/h Distillate product, m3/h Unit product cost, $/m3 431 387 327 275 119 550 208 2.63 119 506 185 2.74 119 446 158 2.82 119 394 132 2.98 the increase of the feed flow rate while decreasing of the distillate product. The decrease in the exergy destruction during the decrease of the capacity is 119 339 104 3.2 explained by the decrease of the irreversibility of heat transfer. Thermoeconomic analysis of partial loads for MSF is shown in Table 10. This table shows that A.S. Nafey et al. / Desalination 201 (2006) 224–240 the rate of the expenditure cost (C⭈F) decreases with the decreasing of the load. This is due to the decrease in steam consumption, chemicals cost and electrical requirements. The capital invest⭈ is fixed with the load variation, as there ment (Z) is no change in MSF configuration. As a results, the unit cost of the product increases with the decrease of the load. The unit product cost increases by 21% when the load decreases to 50% of its design value. This result indicated that the operation at partial load is not recommended from the cost point of view. It should be noted that the unit product cost increases while the exergetic efficiency (ηII) decreases. This result is in consistence with philosophy of the improvement which ascertains that the operation at part load is not preferable. lated and charged their value to the desalted water. Thermoeconomic analysis shows that the cost of the overall the desalination plant will be obtained if the exergy destruction rate of the desuperheater, the distiller train is reduced. The monetary cost of the streams indicated that any modifications in the first stages will cause more effect other than the last stages. Different partial load conditions for the real data of Eoun Mousa MSF plant are depicted and recorded by Data Control System (DCS). These data are fed to the developed VDS software to investigate the performance of the MSF plant. The distillate product varies from 104 (50%) m3/h to 208 (100%) m3/h as well as the top brine temperature varies from 86 to 110°C. The heating steam consumption varies from 12 to 26 m3/h. Thermoeconomic analysis of MSF plant under different partial load conditions showed that the unit product cost increases to 21% when the load decreases to 50% of its design value. 7. Conclusion Using the developed VDS package, the energy analysis of the considered MSF plant in the rating mode (performance), the gain ratio (GR) is calculated as 7.91. The exergy input, E⭈F, to the MSF plant is calculated as 10.7 MW which represents the exergy of the heating steam, exergy associated to the sea water feed, and electrical pumping power minus the exergy of the brine heater condensate. Only 0.2 MW of an elevated exergy in the distilled stream is produced. The exergy associated with blow down and rejected of cooling streams is 4.04 MW which nominated as an exergy loss. The reminder part of E⭈D = 6.46 MW is destroyed internally in the plant components as a result the exergetic efficiency of the considered MSF plant, ηII 1.87%. The unit product cost of the MSF desalination plant is calculated as 2.63 $/m3 by two different ways. The first one by calculating the capital and running costs which invested at the boundary of the MSF plant (input streams); the second way is based on mathematical model (thermoeconomics) by which the outlet streams cost is calcu- 238 Nomenclature C⭈ — cost flow rate, $/h c Cp E⭈ e f h P ⭈ M ⭈ Nm s T Ru r x ⭈ W ⭈ Z ρ –ρ — cost per unit exergy, $/GJ — Molar specific heat, J/kmol.k — Exergy flow rate, MW — Specific exergy, kJ/kg — Exergoeconomic factor — Specific enthalpy, kJ/kg — Pressure, kPa — Mass flow rate, kg/s — Molar flow rate of saline water — Specific entropy, kJ/kg — Temperature, K — Universal gas constant, J/kmol.k — Relative cost difference — Mole fractions — Power, MW — Rate of the capital cost — Density, kg/m3 — Molar density, kmol/m3 239 A.S. Nafey et al. / Desalination 201 (2006) 224–240 ηII — Exergetic efficiency (second law efficacy) Superscripts CI — Capital investment OM— Operation and Maintenance Ph — physical Ch — chemical Subscripts 0 — Dead state b — Brine water cw — cooling water D — Destruction d — Distillate F — Fuel L — Loss m — Mixer of pure and salt water p — Product s — salt water v — Vapor w — Pure water [8] [9] [10] [11] [12] [13] [14] [15] [16] References [1] International Desalination Association (IDA) World Wide Desalting Plants Inventory, report No. 16 (2000). [2] A. Al-Shuaib, M. Al-Bahu, H. El-Dessouky and H. Ettouney, Progress of the Desalination Industry in Kuwait. IDA, 1999. [3] B. Frederick, Combined Power and Process: An Exergy Approach. Mechanical Engineering Publications Limited London, 1995. [4] C. Yunus, The minimum work required for distillation process. Exergy, 2 (2002) 15–23. [5] F. A. Al-Sulaimman and B. Ismail, Exergy analysis of major recirculating multi-stage flash desalting plants in Saudi Arbia. Desalination, 103 (1995) 265–270. [6] A. Bejan, G. Tsatsaronis and M. Moran, Thermal Design & Optimization. Wiley, 1996. [7] R. A. Gaggioli, Y. M. Elsayed, A. M. El Nashar and B. Kamaluddin, Second law efficiency and costing [17] analysis of a combined power and desalination plant. Journal of Energy Resources Technology, 1988. A. S. Nafey, H. S. Fath, A. A. Mabrouk and M. A. Elzzeky, A new visual computer package for simulation of thermal desalination processes: development and verification. Eight International Water Technology Conference, Alexandria, Egypt, 2004. H. N.Ali and H. A. Arafa, Effect of desalination plant performance on water cost in dual-purpose plant for production of water and electricity. Fifth International Water Technology Conference, Egypt, 2000. S. H. Fath, Desalination Technology. El dar Elgameia, Alexandia, 2000. A. S. Nafey, Design and simulation of seawater thermal desalination plants. Leeds University Ph. D., 1988. Babcock and Hitachi, Operation and Maintenance Manual of Eoun Mousa Desalination Plant. Egypt, 1998. H M. Ettouney, H. T. El-Dessouky, R. Faibish and P. Gowin, Evaluating the economics of desalination. CEP Magazine, 2002. Y. M. El-Sayed, Designing desalination systems for higher productivity. Desalination, 134 (2001) 129–158. Y. El-Sayed, The future of solar desalination. Fifth International Water Technology Conference, Alexandria, Egypt, 2000. M. A. Darwish, F. A.Youcef and N. M. Al-Najem, Energy consumption and costs with a multi-stage flashing (MSF) desalting system. Desalination, 109 (1997) 285–302. Cost index and depreciation schedules. North Carolina Department of Revenue Property Tax Division. 2003. Appendix (A) Fig. A.1. Design conditions of DDP boiler. A.S. Nafey et al. / Desalination 201 (2006) 224–240 Cost of heating steam and electricity The cost of heating steam is the main item of operating & maintenance cost of desalination plant. Eoun Mousa MSF desalination plant uses an extracted steam (7 bar and 205°C) of a power plant turbine. The generated steam at a high pressure (170 bar and 540°C) form the steam generator is utilized to produce work before its use as a heat source for the MSF process. The fuel used to produce this steam should be charged to two products (i.e. desalted water and power) according certain rules, Darwish et al. [16]. In this work a rational basis based on the exergy (available energy) method is utilized. The dual purpose plant (DPP) boiler is supplied with fuel energy, Qf , in order to raise the availability (exergy) of water steam flowing through the boiler. The design conditions of DDP boiler is 320 MW power and 5000 m3/day desalted water as shown in Fig. A.1. The specific enthalpy, entropy, and exergy flow rate for all inlet and exit streams are calculated by using VDS package. The exergy of the boiler product is calculated as follows: E⭈ = (E⭈ – E⭈ ) + (E⭈ – E⭈ ) = P,boiler 2 1 4 3 (446 – 780) + (414 – 312) = 470, MW (A.1) The exergy of the extracted steam is calculated as follows: E⭈ = 7 × [(2850 – 105) – 300 × ext,steam (6.9 – 0.35)] = 5.6 MW Based on the rational basis, the ratio of the fuel charged to the MSF process is calculated as follows: E⭈ ext,steam 5.63 —— — — = —— — —= Qf,MSF = Qf,boiler × —— ⭈ E 470 p,boiler 0.01198 × Qf,boiler Where, Qf,MSF is the fuel charged to the boiler and is calculated as follows: 240 M⭈ s × [(h2 – h1) + (h4 – h1)] —— — ———— — ———— — ———— — — Qf,boiler = —— ηb 302 × [(3394 – 1086) + (3560 – 2950)] = ———— — ——————— — ———— — ———— — ———— — — 0.92 = 958 MW Assuming the cost of a typical processed oil barrel is $40/barrel which produce 5.71 GJ of thermal energy when burning. Cost of fuel charged to the DDP boiler = (40/5.71) × 0.958 = 6.71 $/s. The cost of heating steam can be assumed to be 20% more than the consumed fuel to obtain that energy due to the use of boilers and running costs, [16]. So the cost of the fuel charged to the MSF process = 0.01198 × 6.71 × 1.2 = 0.0958 $/s. Cost of extracted steam to MSF process = 347/26=13.36 $/m3. The cost of energy added in electrical (or mechanical) form is considered equal to 40% more than the cost of fuel consumed in order to obtain that energy by the use of a power plant consisting of a boiler, turbine, generator, distribution lines, etc. [16]. Cost of the fuel charged to the power = (1 – 0.01198) × 6.71 × 1.4 = 9.28 $/s. Cost of electricity = 9.28 × 3600 = 33,413 $/h Specific cost of electricity = 33,423/(320,000) = 0.1 $/kWh