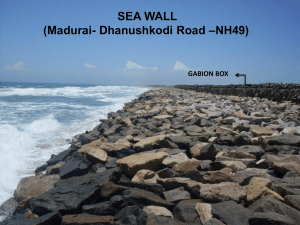

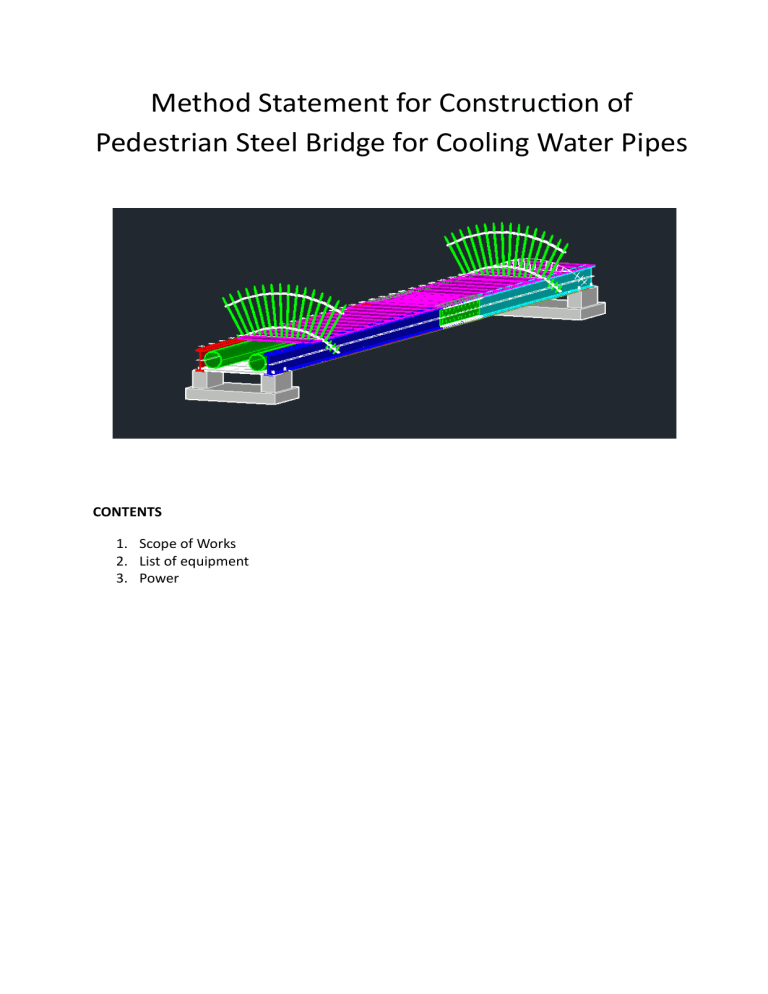

Method Statement for Construction of Pedestrian Steel Bridge for Cooling Water Pipes CONTENTS 1. Scope of Works 2. List of equipment 3. Power 1. Scope of work 1. Extend the existing gabion wall. 2. Construction the foundation base 3. Erect the steel bridge. Extend the existing gabion wall. For construct the bridge foundation, existing gabion wall should be extending the 4m towards the cannel. When extending the existing gabion wall, keep the existing gabion wall height and same structure. Place temporary sheet piling protection around the new gabion wall and bridge foundation area. To prevent Materials falling into the cannel. Keep the minimum 600 mm gap as the working space. Use the 9m sheet piles for the cannel side and 6m sheet piles for bridge foundation side. Excavate the depth using mini excavator and hand excavator for place the gabion baskets to minimize the soil falling down. Use submersible pumps for dewatering the working space. Level the ground level using 200mm thick ABC layer. Place the gabion baskets as per the drawing and refill the soil up to bridge foundation footing level. If excavated soils are weak, please use new soil for refilling. Use the vibrating poker and 1 ton roller for compact the soil. Construction the foundation base Place 50 mm concrete screed (Grade 15) for construct the footing. Set out footings as detailed drawing, ensure steel sheets are in place to prevent water ingress. Always have a submersible pump in attendance for use if required. Excavate to required depths using a combination of a mini excavator and hand excavation in no-dig areas. Check levels prior to concrete works. Concrete is to be supplied as per the specification. Place Shuttering outside to retain concrete. Place mesh as details. Concrete to level and vibrate as works proceed. Complete the gabion wall up to existing height. After complete concrete curing time, remove the shuttering of foundation. Fill the soil around concrete foundation & gabion wall and compact the soil using vibration poker & hand roller. Remove the temporary sheet piling protection. Erect the steel bridge. As per the bridge GAD drawing, place the main two I beam using mobile crane and should be anchor with foundation. After that install the connecting beams, plates, handrails. Complete the torque tightening of all bolts. Complete the welding as per the specification. Lay the HDPE pipes through the pipe bridge. 2. List of equipment 5-ton Excavator Vibration porker 1 Ton roller Submersible pumps Sheet piles (9m, 6m) Shoring sheets 25 Ton mobile crane Generators Hand tools 3. Power 220v Power or Generators will be required for these works.