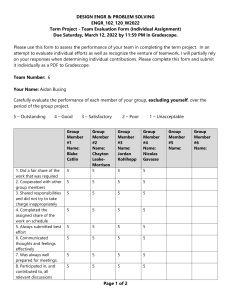

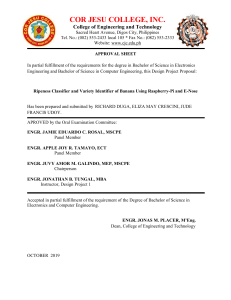

NanoFit Inc. Vision A life-giving organization striving for optimum therapeutic methods in accordance to technological advancements. Committed to provide high quality, accessible, and exceptional medication for the wellness of the community. Mission NanoFit's mission is to provide quality healthcare services to our customers. To provide hope, care, and cure. Company Nature NanoFit introduces a breakthrough in the world of technology and medicine, aiming to develop the procedure of medicinal care to make it safer and faster with the help of nanotechnology. In layman’s terms, the process of scrutinizing with the use of “microchip” is simply ingesting it, and it will begin to do work on its own, but under the surveillance of professionals. An essential component of medicine is life. Thus, NanoFit is collaborating to offer clients technology that is both lasting and of an exceptional quality, while also highlighting the need for continued research and study into more ecologically friendly and sustainable business methods in the region. Our main areas of focus include the development, design, and production of several technologies that will make consumers' lives better and easier. In appreciation to the people who believed and funded the development of the project, the first projects developed were named according to our primary stakeholders. They were also the pioneer beneficiaries of these, which they not only believed but thoroughly trusted throughout, demonstrated by the long line of achievements of our products, with the aid of great corroboration among the team. The business is now operational in several areas even outside Batangas, but our headquarters stay in the vicinity of where we picked up ourselves and made the difference. Company History NanoFit Incorporation is a company that has overcome several challenges and obstacles to the way of dedication and a commitment to excellence. Through Engr. Kathleen Capalaran and her colleagues' determination in the face of numerous failures, the previously underachieving company was reborn and transformed into one of the most reputable providers of quality healthcare services in the Philippines. Engr. Capalaran, who had the idea to start this company because of the influence of her family of doctors and nurses, as well as her knowledge of engineering, approached Engr. Lagus about collaborating and exchanging ideas. They created a company, but due to a lack of successful projects and bankruptcy, it was unable to make a consistent impact on the industry over time. The company failed due to bankruptcy and several unpaid debts because it was unable to generate a consistent income from its operations. So, they carefully devised a concrete plan to build a successful company. Initially, they struggled to come up with an innovative idea for an existing product, so Engr. Capalaran uses her family's connections to contact someone in the medical industry who might have ideas or insights into their proposed product. They also attend seminars and meetings on business management. Engr. Lagus continues to research and expand his knowledge of hardware and nanotechnology; he is in charge of it. NanoFit Inc. After months of planning and research, they decided to hire colleagues to assist them in their business. They struggled at first to find colleagues who would trust and help them expand their knowledge, but Engr. Capalaran was able to utilize the company's teams and even persuade some of her former college classmates to work alongside her in managing the company's key sectors. Engr. Kathleen Capalaran and Engr. John Ramsey Lagus worked with five more engineers to create a plan proposing the desired incorporation. To avoid bankruptcy in the upcoming future, Engr. Capalaran hired Engr. John Zelwyn Esguerra to be the company’s financial analyst. Engr. Esguerra was tasked to make the financial plans of the NanoFit Incorporation. On the other hand, Engr. Lagus referred to Engr. Cassandra Vallejo to lead the company's research and development department to guarantee that the NanoFit Incorporation is continuously suited to the industry's needs. Former college classmate of Engr. Capalaran hired Engr. Brylla-Jane Montero as a Sales and Marketing Manager, she will manage the marketing and sales teams as well as perform managerial duties to help the company fulfill its operational goals. Engr. Capalaran hired Engr. Anthony Reynes as a Human Resources Manager entrusted to oversee the screening, interviewing, and placement of workers or applicants, as well as the protection of the company from workplace issues. And with the help of Engr. Christine Arquez as a Human Resources Assistant she’s the one answering phone calls, conducting research to find potential job candidates, compiling materials, and maintaining employee database records in order to find quality employees. Every position in the company is interconnected, which is why the management team's performance and collaboration are related to the company's status. In 2010, NanoFit received its first investment to fund the initial model which was tested and proven to be efficient. NanoFit started as a small technology based-business located at Alangilan, Batangas, which focuses on the development of medicine. NanoFit offers their own brand of medicine that is created by our genius engineers and professionals in the medical fields. Engr. Lagus was the one who created the company’s name, “nano” means little or small and “fit” means suitable, it combines the microchip suitable and safe to ingest that provides medical services. This microchip-based technology is applied in medical sciences, especially by doctors. These microchips are directly embedded in the patient's body and doctors should monitor as well as control the drug release into their patients’ body remotely through wireless connections.As time goes by, NanoFit gained popularity through their innovative products that have a big contribution in curing people. They used advanced technology to create effective and budget-friendly products. NanoFit Incorporation is now recognized as the one of the notable corporations and prestigious group of explorers with outstanding goods and services. In a short period of time in business, the company has already surpassed its competitors while also addressing medical issues in the region. The company encouraged continuous research and development in the future in order to address or eventually achieve new advanced medical technology. From start to finish, the company maintained its pioneering spirit of toughness, creativity, and perseverance. NanoFit Inc. Organizational Structure Board of Directors Engr. Kathleen Capalaran Chief Executive Officer Engr. John Ramsey Lagus Chief Production Officer Engr. Anthony Reynes Jr. Financial Analyst Engr. Brylla-Jane Montero Sales and Marketing Manager Engr. Cassandra Ysabelle Vallejo Chief Research and Development Officer Engr. John Zelwyn Esguerra Human Resource Management Engr. Christine Ann Arquez Human Resources Assistant NanoFit Inc. Products/Services NanoFit Inc. focuses on producing harmless, high-quality, and effective microchips. To innovate our microprocessor and stay up with the quick advancement of technology, the company went through a comprehensive process. Developed the notion of generating computer-programmed microchips using medical technology developments from the United States. The company imports all the latest necessities required for creating and sustaining the chip's quality and efficacy. Computer-based chips are manufactured, developed, and studied thoroughly in our electronics manufacturing area, preparing for release on the market and benefiting from the field of technology and medicine. Moreover, the company's examination includes ongoing research and development of equipment and technologies that have served as accountable for product testing. Figure 1. Medical Technology Services Figure 2. Microchip Capsule Figure 3. NanoFit Factory Figure 4. NanoFit Main Factory NanoFit Inc. NanoFit Inc. also provides medical services to public and private hospitals and other companies. This product will be able to help them recover from their illness. Therefore, some other hospitals and companies will accept special services, especially for their fellow medical workers who have encountered problems with their patients. NanoFit Inc. supplies microchips and other medical technologies. Additionally, one significant movement the company is currently working on is being a part of "Future Medicines." Moreover, this collaboration lets NanoFit fulfill its mission of unlocking more caring ways of operating and running the medical technology industries for its people's better healthy lifestyles, the progress of the company, and keeping up with the challenges in the industry. NanoFit Inc. Projects Completed 1. Microchip – Nano Fit Inc. A capsule, which is resistant to stomach acids, is shaped like a medical pill, and can be orally taken in the same manner. This capsule includes a pair of plastic shells surrounding a circuit board, and, in an alternative embodiment, a microprocessor. The circuit board includes memory circuits for storing personal identification data, which is made available when needed, but which cannot be changed without a code number or word. A battery, an antenna for wireless access, and a metal disk supporting the location of the capsule with metal detectors may be added. Figure 5. Building Microchip 2. Acer Inc. The company has been a key supplier of microchips to Acer Incorporation, which are frequently utilized for the company's own stocks. The company's major products are the laptop and tablet, as it is involved in microchip product research, development, manufacturing, and sales. Figure 6. Nano Fit supplying Microchips products to Acer Inc. NanoFit Inc. Ongoing Projects 1. Microchip Technology Expansion The possible expansion of Microchip would not be nearly as massive as the "megafabs" that Intel, Micron, Samsung, and others are creating in other regions of the country. However, that might be a vital hint that Oregon is still in the game. If Microchip chooses to develop elsewhere, it will raise new concerns about Oregon's viability as a destination for rising chipmakers. "Due to the complexity of this issue and the procedures governing the review of this case, there is nothing we can say publicly right now." Figure 7. Microchip Technology Expansion Future Projects 1. Edible Microchips Helius pills monitor patients’ reaction to treatments, and send the information to their mobile phone or computer. Helius contains a soluble microchip, which patients take alongside their usual medicine. It reacts with the stomach acid and gives off an electrical pulse, which is received by an adhesive patch on the patient’s body. Data about heart rate, respiration and temperature are then sent to the patient’s mobile phone or computer. Figure 8. Microchip NanoFit Inc. Background There are a lot of people who are facing different problems every day. One of the most common problems is health-related problems. With the health problem, it also comes with the financial problem. The majority of medicines and hospitals are expensive, especially when it is needed continuously. Here are the following objectives that will be addressed below: Creating a Budget-Friendly Product. Technology is a complex thing. You can do anything as long as you have the materials and you know what you want to do. NanoFit Inc. is working on creating a microchip that would contribute to the world of medicine and technology. The microchip would be made up of gelatin of a capsule. The gelatin of a capsule is affordable and that's what makes the product cheap yet effective Soluble and no adverse effects on the body. Most of the microchips we know are metals and have an effect on the body. NanoFit's microchip has its own special capability to dissolve. It is especially made with gelatin usually used in making capsule shells. Since it is made with gelatin, it has no harmful effect on the human body. It will be taken orally and work inside the body as its main purpose is to know the specific disease of a human. Create a product/ service that keeps up with the advancement in the medicaltechnology field. As time passes by, numerous advanced technologies are being produced in the world. One factor to consider is on how effective, advanced and convenient it is especially to those sick people who need to undergo countless tests. The microchip we knew are metals and made out of hard materials normally implanted in some specific part of the body. Through the emergence of high-tech machinery, our products have become more advanced and sufficient to provide the medicational advancement in our society. NanoFit Inc. Description To heal, care, and cure. NanoFit is driven by its ultimate goal of delivering high quality products to the masses by utilizing nanotechnology to develop medicine in the most efficient way possible. This microchip works like a capsule which is to be ingested by the person, then works its way inside the body to identify whatever there is need to be cured. Like a regular capsule, its parts are inside covered by a protective hard outer shell which will be broken down through digestion. The acids will activate the transmitter and microchip. With the right amount of solution and concentration, acids could produce electricity. To support this claim, a study conducted by Mcdonell in 2018 tried replicating a simple voltaic battery cell, but with the use of stomach acids. The researcher put copper and zinc electrodes on the ingestible sensor's surface to duplicate that method. The voltaic circuit is powered by the zinc, which also produces enough energy to run a 900megahertz transmitter and a commercial temperature sensor. The zinc discharges ions into the stomach acid to power the voltaic circuit. The voltaic cell produced enough energy while within the stomach to run a temperature sensor and wirelessly send data to a base station two meters away once every 12 seconds. The cell produced just 1/100 of what it did in the stomach once it was in the small intestine, which is less acidic than the stomach. Our capsule would work in the same manner, but with the integration of medicine and technology. With this, the possibilities our capsule could make becomes infinite in both worlds. Figure 9. Computer Programming Figure 10. Microchip Making / Machine NanoFit Inc. Detailed Budget Requirement for the Year 2022-2023 Cost BUDGET LINE ITEM 1 AMOUNT PROPOSED/ DESCRIPTION NEEDED SOURCES RESEARCH & DEVELOPMENT 1,500,000 Php NANOFIT INCORPORATION MATERIALS NEEDED 7,000,000 Php OCTA-GENE SYSTEMS, INCORPORATED 2 3 MEDICAL AND NANO TECHNOLOGICAL MACHINES TO MAKE THE PRODUCT 8,000,000 Php MEDICAL AND MICROCHIPS TECHNOLOGY (MMT) 4 PRODUCT TRIAL 2,000,000 Php ABESTOS TESTING LABORATORIES (ATL) 5 LOT FOR THE MANUFACTORY 3,000,000 Php ALANGILAN, BATANGAS 6 SHIPMENT 2,000,000 Php 2GO EXPRESS 7 EQUIPMENTS 6,000,000 Php GILEAD SCIENCE INC. 8 OTHER EXPENSES 1,000,000 Php NANOFIT INCORPORATION RETAINED EARNINGS NanoFit Inc. LABOR COST (ANNUALLY) 700,000 Php TOTAL COST 31,200,000 Php NanoFit Inc. Work Project Plan Time Table Phases of Activities Output/Target Person in Resources Charge needed To discuss the possible problems and what are the possible alternative ideas. Chief Executive Officer (CEO) Special Expertise, Resources Management 100,000 Php To find institutional investors tha t will help the business scale. Chief Executive Officer (CEO), Financial Analyst Manpower, Transportatio n 100,000 Php Look for the supplier on the needed materials. To find the right supplier of affordable but quality materials. Sales and Marketing Officer Manpower, Transportatio n 5,000,00 0 Php Hire production staff To find staff who are capable to maintain and make the machines work and check the quality products. Chief Production Officer, Human Resource Manager Human Resource Manager, Human Resource Assistant Cost the project (Date) February 2009 March 2009 May 2009 July 2009 Planning Find institutional investors an d partners. 500,000 Php NanoFit Inc. Septembe r 2009 November 2009 Proving one machine to check what are the possible problems to the machines and fix it Checking of product to identify the strengths and weaknesses. To begin trying to fix the problems to be able to manage in times of operating days. To evaluate whether the product is usable and efficient. Chief Production Officer, Manpower, Equipment, Research and Development Officer, Chief Production Officer Manpower, Transportatio n Research and Development Officer, Chief Productio n Officer Manpower, Transportatio n Chief Executive Officer, Sales and Marketing Manager Manpower 5,000,00 0 Php 2,000,00 0 Php To know if the product needs improvement s. January 2010 Finalizing the product and machines before launching the products. March 2010 Launch the product as well as the advertising and budget proposal that has been developed. To examine and final testing before publishing it To develop a comprehensive marketing and financial strategy that will certainly succeed. GRAND TOTAL 1,000,00 Php 3,000,00 0 Php Php 16,700,00 NanoFit Inc. Specification Figure 11. Microchip Process The first step in creating a microchip is typically to deposit thin films of materials onto the silicon wafer. These materials can be conductors, isolators or semiconductors. The second step is lithography, or photolithography, is the critical step in the computer chipmaking process. It involves coating the wafer with photosensitive material and exposing it with light inside an ASML lithography machine. The third step is to print a layer of a chip, the wafer is first coated with a light-sensitive layer called a ‘photoresist’, or ‘resist’, for short. It then enters the lithography machine. The fourth step is inside the lithography machine, light is projected onto the wafer through the reticle containing the blueprint of the pattern to be printed. The system’s optics shrink and focus the pattern onto the resist. Where light hits the resist, it causes chemical changes, recreating the pattern from the reticle in the resist. The fifth step is the reticle containing the pattern to be printed on the wafer sometimes needs to be optimized by intentionally deforming the pattern to compensate for physical and chemical effects that occur during lithography. ASML machines do this by combining algorithmic models with data from our machines and from test wafers. The sixth step is after leaving the lithography machine, the wafer is baked and developed to make those changes permanent, and some of the photoresist is washed away to create a pattern of open spaces in the resist. The seventh is materials such as gases are used to etch away material from the open spaces creating during the developing phase, leaving a 3D version of the pattern. The eighth step is metrology and inspection, throughout the chip production process, the wafer is measured and inspected for errors. These measurements are fed back to the systems and are used to optimize and stabilize the equipment. The ninth step is the wafer may also be bombarded with positive or negative ions to tune the semiconductor properties of parts of the pattern, before the remaining photoresist is removed. The tenth step is this whole process, from deposition to resist removal, is repeated until the wafer is covered in patterns, completing one layer of the wafer’s chips. To make an entire chip, this process can be repeated up to 100 times, laying patterns on top of patterns to create an integrated circuit. In the final step in production, the wafer is diced into individual chips, which are encapsulated in protective packages. The chip is now ready for your TV, tablet or other digital device! NanoFit Inc.