Engineering Structures 24 (2002) 227–237

www.elsevier.com/locate/engstruct

Moment–rotation model of semi-rigid connections with angles

Sang-Sup Lee, Tae-Sup Moon

*

Division of Architectural Engineering, Hanyang University, Seoul 133-791, South Korea

Received 15 December 2000; received in revised form 26 June 2001; accepted 26 June 2001

Abstract

A 2-parameter log model to describe the non-linear M–q relationship of semi-rigid connections is proposed. The proposed model

accurately describes the moment–rotation behavior of nearly all connections by controlling shape parameters a and n. To overcome

the disadvantage that the shape parameters have very little physical meaning, the semi-analytic approach that optimum values of

a and n, agreeing rather well with experimental curves, are derived in terms of initial stiffness (ki) and plastic stiffness (kp) from

statistical regression analysis is applied to this paper. The analytic formulations of ki and kp are developed for double web angle

connection and top and seat angle connection respectively. 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Moment–rotation model; Semi-rigid connection; Angle connection

1. Introduction

For conventional analysis and design of a steel-framed

structure, the actual behavior of beam-to-column connections is simplified to the two idealized extremes of

either rigid-joint or pinned-joint behavior. However most

connections used in steel frames actually exhibit semirigid deformation behavior that can contribute substantially to overall force distribution in the members [1].

As such steel frame connections should be treated as

being a ‘semi-rigid frame’ for the purpose of proper

analysis and design. Accurate modeling of their

moment–rotation (M–q) relationship is necessary if the

effects of connections are to be considered in structural

analysis [2].

Because it would be prohibitively expensive to obtain

the moment–rotation relationships for all practical connection types by full-scale tests, an attractive solution is

to derive a single standardized model for each connection type. Many models have been proposed and are generally composed of parameters depending on the

strength, stiffness and ductility for a given connection

and shape parameters treated as a curve-fitting parameter. As these parameters are mainly expressed in

* Corresponding author. Tel.: +82-02-2290-0312; fax: 82-022296-4145.

E-mail address: bluemoon@email.hanyang.ac.kr (T.-S. Moon).

terms of the geometric variable, the expressions prove

to be accurate only for the limited range of data used in

regression analysis. The problem can be solved by using

the many test data, or by theoretical parametric study.

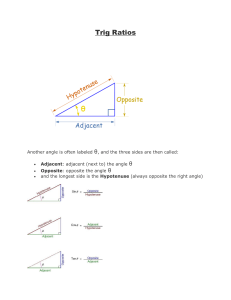

The purpose of this paper is to propose a practical

model regarding semi-rigid connections with angles that

predicts the moment–rotation characteristics by

determining two shape parameters, and to develop the

analytic formulations for evaluating the two shape parameters for double web angle connection and top and seat

angle connection as shown in Fig. 1.

2. Modeling of connection

2.1. Connection model [3]

2.1.1. Linear model

The first attempt at using mathematical expression to

define the M–q curve dates back to Rathbun (1936). A

single tangential line to the initial slope of the M–q curve

was defined as the semi-rigid connection factor Z.

Z⫽q/M

(1)

Tarpy and Cardinal (1981), Melchers and Kaur

(1982), Lui and Chen (1983) also proposed the bilinear

models in which the initial slope of the moment–rotation

line is replaced by a shallower line at a certain transition

0141-0296/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 1 - 0 2 9 6 ( 0 1 ) 0 0 0 6 6 - 9

228

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

Fig. 1.

Semi-rigid connections with angle. (a) Double web angle connection; (b) top and seat angle connection.

moment. Razzaq (1983) used the sophisticated piecewise

linear models represented by a series of straight line segments. Even though these linear models are easy to use,

the inaccuracies and sudden jump in stiffness at the transition points make their practical use difficult.

2.1.2. Polynomial model

A polynomial function model was proposed by

Sommer (1969) used has also been used to express

rotation in terms of moment.

q⫽C1(KM)1⫹C2(KM)3⫹C3(KM)5

(2)

where K is the standardization factor dependent upon the

connection type and geometry and C1, C2 and C3 are

curve-fitting constants. This model represents the M–q

behavior reasonably well. The main drawback is that the

nature of a polynomial is to peak and trough within a

certain range. The connection stiffness may become

negative at some values of M. This negative stiffness

may cause numerical difficulties in the analysis of frame

structures if the tangent stiffness formulation is used.

2.1.3. Power model

Richard and Abbott (1975) proposed primarily to represent the stress–strain relationship, which expresses

moment in terms of rotation as follows:

M⫽

(ki−kp)q

n

(ki−kp)q

1+

M0

冉|

|冊

⫹kpq

(1/n)

(3)

where:

ki

kp

M0

n

is

is

is

is

the

the

the

the

initial slope of connection

strain hardening slope of connection

reference moment

shape parameter

One advantage of the Richard–Abbott function over the

Ramberg–Osgood function is that whereas the former

permits positive, zero, and negative values of kp, the latter permits only a zero value.

Ang and Morris (1984) followed the same procedure

but used the Ramberg–Osgood (1943) function to

express the standardized moment–rotation behavior in

the following form:

再 冋 册 冎

q (KM)

KM

⫽

1⫹

q0 (KM)0

(KM)0

(n−1)

(4)

where q0, (KM)0, n are constants that define shape of

function, K is the standardization constant dependent on

the connection type and geometry. Depending upon the

value of n, the shape of the curve changes, allowing one

to model a sharp ‘knee’-type M–q curve or one with a

long, gradual decreasing slope. The Ramberg–Osgood

function has the advantage that its derivative, hence the

slope of the M–q curve, does not fluctuate in value contrary to the inherent oscillatory nature of polynomials.

2.1.4. Exponential model

Lui and Chen (1986) proposed the multi-parameter

exponential model.

冘冋

m

冉 冊册

|q|

Cj 1⫺exp ⫺

2ja

j⫽1

M⫽

⫹M0⫹Rkf|q|

(5)

where M0 is the starting value of the connection moment

to which the curve is fitted, Rkf is the strain-hardening

stiffness of the connection, a is a scaling factor, and Cj is

a curve-fitting constant obtained from a linear regression

analysis. This model gives as good a curve-fitting to test

data as that of the cubic B-spline model. However, if

there is a sharp change in slope in the M–q curve, this

model cannot represent it adequately.

Kishi and Chen (1986) refined the Lui and Chen

exponential model to accommodate any sharp change in

slope in the M–q curve as follows

冘冋

m

冉 冊册 冘

|q|

Cj 1⫺exp ⫺

2ja

j⫽1

M⫽M0⫹

n

⫹

Dk(q⫺qk)H[q

(6)

k⫽1

⫺qk]

where M0 and a are defined as in Eq. (5) and Dk is a

constant parameter for the linear portion of the curve, qk

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

is the starting rotation of the linear component of the

curve, H[q] is Heaviside’s step function (unity for qⱖ

0, zero for q⬍0) and Cj and Dk and curve-fitting constants obtained from a linear regression analysis.

Although this model can deal with connection loading

and unloading for the full range of relative rotation in a

second-order structural analysis with secant connection

stiffness, it is not manageable.

2.2. Modeling of M–q curve

Using the two shape parameters a and n, the model

to represent the moment–rotation relationship of semirigid connections is proposed as follows

M⫽aln(n·103·q⫹1)n

Fig. 2.

moment and the shape parameter n governs an the entire

shape of a curve.

Hence, this log model is found suitable and adjustable

for the representation of the various connection

behaviors connection. As can be observed in Fig. 3, the

proposed model gives a good curve-fitting with test data

selected in the database (SCDB; The Steel Connection

Data Bank program) by Kishi and Chen (1986) [3]. And

this model can be easily applied to the second-order

frame analysis with semi-rigid connection because the

tangent stiffness (kt) can be determined directly from Eq.

(8) without iteration.

dM

n·103

(8)

kt⫽ ⫽n·a[ln(n·103·q⫹1)]n−1·

dq

n·103+1

(7)

where a and n are shape parameter which are determined

by using the method of least squares for differences

between the predicted moments and the experimental

test data.

This log model has the properties that the larger the

index n, the more linear the curve, and the smaller, the

flatter as shown in Fig. 2(a)–(c). For example, the curve

is nearly akin to the linear behavior in that n equals 3.0

and shows the general M–q behavior in the case of

n=1.0. Otherwise, if n is 0.1, the curve is characterized

by bilinear behavior. For constant values of a, the plotting of Eq. (7) for different values of n is shown in Fig.

2(d). Consequently, it can be argued that the shape parameter a has an effect upon initial stiffness and ultimate

229

Fig. 3. Comparison of curve-fitting curves and test curves.

Characteristic of shape parameters. (a) n=3; (b) n=1; (c) n=0.01; (d) sensitivity of n

230

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

2.3. Study of model parameters

⫽0.91)

As described above, it can be seen that the proposed

model represents a close fit with the experimental tests

by controlling a and n only. While other models are

expressed in terms of stiffness, strength, and standardization factor etc, the proposed model has no such parameters. This fact could be a demerit that the parameters

a and n in this log model have very little physical meaning. On the other hand, it can be offset by simplicity and

accuracy that this model requires only two parameters

and can provide a good fit with various connection M–

q curves.

Some parameters of most models have a form of function derived theoretically, and the others are determined

by using the statistical analysis for experimental test

data. The accuracy of those models is under the influence

of the number of data used, and the availability has the

limited type of connection M–q curve.

To overcome these disadvantages, the approach that

the optimum values of a and n, agreeing rather well with

experimental curves, are derived in terms of initial stiffness (ki) and plastic stiffness (kp) from statistical

regression analysis is applied to this paper.

a⫽f(ki,kp)

(9a)

n⫽f(ki,kp)

(9b)

The ultimate moment is excluded from Eqs. (9a) and

(9b), because most M–q curves of top and seat angle

connections and double web angle connections exhibit

elastic-plastic hardening characteristics and do not flatten out near the final state of loading.

To express a and n as a function of ki and kp, a total

of 75 experimental data were used for the derivation of

Eqs. (10a, 10b, 11a) and (11b). A set of 50 double web

angle connections and a set of 25 top and seat angle

connections are employed. These experimental data were

selected from database collected by Kishi and Chen. A

simple statistical regression analysis on shape parameters is carried out along with ki and kp. The

expressions of a and n, representing double web angle

connections, are statistically analyzed and regressed to

a plane equation are shown in Fig. 4.

a⫽1.499E⫺03·ki⫹1.449E⫺03·kp⫹0.704 (R2

(10a)

⫽0.83)

n⫽⫺3.594E⫺05·ki⫺3.496E⫺05·kp⫹1.170 (R2

(10b)

⫽0.80)

Similarly, the expressions of shape parameters of top

and seat angle connections are statistically analyzed and

plotted in Fig. 5. The a and n can be expressed as

a⫽9.689E⫺0.4·ki⫹9.562E⫺04·kp⫹3.850 (R2

(11a)

n⫽4.500E⫺06·ki⫹4.400E⫺06·kp⫹0.601 (R2

(11b)

⫽0.92)

where R2 is correlation factor and the unit of ki (kp) is

kN·m.

3. Behavior of angle segment

If the initial stiffness and the plastic stiffness could

be determined analytically, the prediction of the M–q

relationship from the proposed model can be made independent of experiment. In order to determine ki and kp,

the load–deformation (P–⌬) the behavior of angle segment in tension needs to be examined first of all.

The behavior of angle segment will be analyzed for

the two states as follows

1. Elastic state

2. Plastic state in which the collapse mechanism is

developed

The basic assumptions for analyzing are as follows.

1. Deformation of connection is small.

2. Deformation of beam and column is negligible compared with the deformation of connection.

3. The slip deformation is negligible.

3.1. Pe–⌬e relationship in elastic state

The assembly angles of connection can be simplified

as shown in Fig. 6(a). It is assumed that the fasteners

hold the angle legs fixed at points A and C. Point C

moves downward only because of symmetry, and the

rotation at B is the same in both legs as a result of continuity. If the angle is temporarily free to translate and

rotate at C in Fig. 6(c), the moment (Me) and the horizontal load (He) contribute to the deformation of point

C: (1) vertical displacement (⌬v); (2) horizontal displacement (⌬h); (3) rotation (q). As the situation of point C

is actually a fixed restraint, there is no horizontal displacement or rotation. Therefore, the boundary conditions are

⌺⌬h⫽⌬h(Pe)⫹⌬h(He)⫹⌬h(Me)⫽0

(12a)

⌺qr⫽qr(Pe)⫹qr(He)⫹qr(Me)⫽0

(12b)

⌺⌬v⫽⌬v(Pe)⫹⌬v(He)⫹⌬v(Me)⫽⌬e

(12c)

As the angles shown in Fig. 6(b) are pulled out in an

initial elastic state, it is assumed that the fixed support

at point A is the first fastener-nut edge in the leg adjacent

to the column face and the concentrated load Pe acts at

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

Fig. 6.

Fig. 4.

Statistical regression analysis on double web angle connections.

Fig. 5.

Statistical regression analysis on top and seat angle connections.

Angle segment in elastic state. (a) Double angle segment; (b) modeling; (c) free body diagram.

the center of fastener holes in the leg adjacent to the

beam web face because of the higher restraint caused by

clamping action [4].

Based on these assumptions and using various elastic

theories, boundary conditions with respect to material

and geometrical properties can be rewritten

冉

231

冊 冉

冊

He

g32 Me

g22

Pe

g1g22⫹ ⫺

g1g2⫹ ⫽0

⫺ (g21g2)⫹

EI

EI

3

EI

2

(12aa)

冉冊

冉冊 冉 冊 冉冊

Pe g21 He

Me

⫺ (g1g2⫹g22)⫹ (g1⫹g2)⫽0

EI 2

EI

EI

(12bb)

Pe g21 He g21g2 Me g21

⫺

⫹

⫽⌬e

EI 3

EI 2

EI 2

(12cc)

where:

g1

distance from the leg’s center line to the first

fastener-nut edge in leg adjacent to the column

232

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

Fig. 7.

g2

EI

Angle segment in elastic state. (a) Mechanism of double angles; (b) location of plastic hinges; (c) deformed configuration.

distance from the leg’s center line to the center

of fastener holes in leg adjacent to the beam

bending stiffness of angle segment per unit

length.

Solving the simultaneous equation Eqs. (12aa, 12bb)

makes it possible to determine the relative magnitude of

He and Me. Substituting He and Me solved for Pe into

Eqs. (12cc), the load–deformation (Pe–⌬e) of angle segment in elastic state can be obtained as

冉 冊

12EI g1+g2

·⌬

Pe⫽ 3

g1 g1+4g2 e

(13)

3.2. Pp–dp relationship in plastic state

The comprehensive experiments showed that there was

a significant difference in behavior of angles with different mechanisms.

In this state, the geometrical changes of angles are

large compared to the restrained lengths of the angle

legs. Therefore, it is necessary that the deformed shape

of angles be known or at least closely approximated so

that the locations of hinges can be determined. Figs. 8

and 9 shows the deformed configuration of angle consistent with vertical deformation ⌬p. It is assumed that the

angle segment behaves in the following manner.

1. As the plastic hinge at point B is formed, the A–B

part rotates as a rigid body around the base at A.

2. As the plastic hinge at point C is formed, the C–D

part rotates as a rigid body around the base at D.

3. The heel of angle (fillet) does not deform.

As observed in Fig. 3, the behavior of connections has

a transition between the elastic state and plastic state [5].

The load–deformation relationship in transition state is

not treated here because kp is necessary to be determined

in plastic state in which the collapse mechanism is

developed. As the angles are pulled out still more, the

plastic hinges will be formed at point A primarily, and

then point B and point C simultaneously. Usually, point

A is the edge of the first fastener-nut in the leg adjacent

to the column face and the points B and C are in the

vicinity of the two intersections of the fillet and the angle

legs as shown in Fig. 7. However, point A has a

migration toward the angle’s toe that is caused by a snug

tight fastener and relatively thicker angle (Fig. 8) [6].

Fig. 8.

Migration of plastic hinge. (a) Mode 1; (b) Mode 2.

Fig. 9.

Detail of angle configuration in plastic state.

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

By equating the moment at these points to the plastic

moment, the equilibrium equation is

冦

冧

g3(冑g23+⌬2p−g3)

g3·⌬p

⫹Mp⫹Hp· 2 2⫽

⫺Pp· g3⫺

2

2

冑g3+⌬p

冑g3+⌬p

冦冢 冣

g3

冑g +⌬

2

3

2

p

·g2−

冑

冑g +⌬

g3( g23+⌬2p−g3)

2

3

2

p

冧

(14)

4.1.1. Initial stiffness (ki)

Typical double web angle connection is shown in Fig.

1(a). In the initial elastic state, it is assumed that there

is no slip and that the leg of angle adjacent to the column

behaves linearly elastic, while the leg of angle adjacent

to the beam behaves as a rigid body [7]. Since the higher

restraint between the angle and the column face arises

from the clamping action of bolts, it is assumed that the

full length of the angle can resist the bending moment.

The center of rotation is close to the mid-length of the

connection [8]. Using the Pe–⌬e relationship of angle

segment in Eq. (13) and the load distribution as shown

in Fig. 10, the relationship between the moment M and

the rotation q is obtained as

+Mp

(at point C)

冦

冢 冣冧

g3

+Hp· g1−g3+⌬p+ 1−

冑g +⌬

2

3

2

p

·g2 =−Mp

M⫽2⫻

(15)

where:

g1

distance from the leg’s center line to the plastic

hinge (point A) in leg adjacent to the column

distance from the leg’s center line to the first

fastener-nut edge in leg adjacent to the beam

distance from the toe of fillet to the plastic hinge

(point A) in leg adjacent to the column

plastic moment (=t2a·sy/4 (ta: thickness of angle

and sy: yield strength of angle)

g2

g3

Mp

For the purpose of simplification, the higher-order

terms (⌬3p…) are neglected and the expression in Eq. (16)

is used.

冑g +⌬ ⬇g ·

2

3

2

p

3

冋 冉 冊册

1 ⌬p

1⫹

2 g3

4. Determination of initial stiffness and plastic

stiffness

4.1. Double web angle connection (all bolted)

⫺Mp (at point B)

−Pp· g1− 1−

233

2

(16)

冉

冊冉 冊 冉 冊

1

4

0.5la

·q

Pe·0.5la · ·0.5la ⫻

2

3

⌬e

(18)

where la: the length of angle

Consequently, initial stiffness ki is given by

冉 冊

2EI g1+g2 3

·l

ki⫽ 3

g1 g1+4g2 a

(19)

4.1.2. Plastic stiffness (kp)

According to experimental results reported by Lewitt

et al. [8], it can be seen that the plastification of angle

takes place perfectly at ⌬p=5.08 mm (0.2 in) and the

center of rotation has been assumed to be at 0.8 of the

length of angle. This actually varied with the value of

⌬p, the center of rotation is conservatively determined

to be at 0.8la in this paper. As the moment increases, the

load distribution in the length of angle has a tendency

to be concentrated on bolts [9]. Therefore it is assumed

that the total tension force in connection angle is the sum

of the product of the applied load(F1,…, Fn) and diameter of the nut(Dnut). Assuming the deformation of angle

is proportional to the distance from the center of rotation

Eliminating Hp from Eqs. (14) and (15) and then using

the Pp–⌬p relationship it can be shown that

Pp

⫽

再

再

1

2Mp (g1−g3)(g23+⌬2p)+ g2⌬2p

2

冉

冊 冉

冎

1

1

g3(g1−g3) g23+ ⌬2p +g3⌬p g2⌬p−g1g3+g23

2

2

(17)

冊冎

Fig. 10. Force distribution of double web angle in elastic state.

234

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

Fig. 11.

Force distribution of double web angle in plastic state.

as shown in Fig. 11, the relationship between the

moment M and the rotation q is obtained as

冉冘

冉 冊

M⫽2⫻

⫻

冊冉

li

⌺l

·Pp·Dmit ⫻

⫹0.1la

0.8l

⌺li

a

i⫽1

n

2

i

冊

(20)

0.8la

·q

⌬p

where:

li

Dnut

Distance from the center of rotation to the each

center of fastener

Diameter of the nut

Finally, plastic stiffness kp is given by

kp⫽

4Mp兵(g1−g3)(g23+⌬2p)+0.5g2⌬2p其·Dmit

·(⌺l2i

{g3(g1−g3)(g23+0.5⌬2p)+g3⌬p(0.5g2⌬p−g1g3+g23)}

(21)

1

⫹0.1la·⌺li)·

⌬p

where ⌬p=5.08 mm

because the dimension properties and material strength

are available.

The parameters used in each test and the comparison

of analytical and experimental initial stiffness is listed

in Table 1. As shown in Table 2, the prediction of plastic

stiffness is relatively accurate, and hence a good

relationship of M–q can be expected.

Finally, substituting ki and kp calculated from Eqs.

(19) and (21) into Eqs. (10a) and (10b), the shape parameters a and n can be easily obtained. Fig. 12 illustrates

that the proposed model gives a good curve-fitting with

test curve.

4.2. Top and seat angle connection (all riveted)

4.2.1. Initial stiffness (ki)

Typical top and seat angle connection is shown in Fig.

1(b). Based on previous assumptions that were made for

analyzing behavior of angles, the initial stiffness can be

obtained from simple elastic theory. The top angle provides resistance to the bending moment, in which the

fixed support is assumed to be in the vicinity of the rivethead edge in the leg adjacent to the column. Because

the clamping force of the rivet is lower than that of the

bolt, it is assumed that the effective length (diameter of

rivet-head×number of rivet) can resist the bending

moment. The center of rotation for the connection is

located at the leg adjacent to the compression-beam

flange at the end of the beam as shown in Fig. 13 [10].

Similarly, using these assumptions and the Pe–⌬e

relationship of angle segment in Eq. (13), the relationship between the moment M and the rotation q is

obtained as

M⫽(Pe·le)⫻(db⫹g1)⫻

4.1.3. Comparison of analytical and experimental

results

For the purpose of comparison of the analytical ki and

kp with the ki and kp measured from a test curve, the six

test data from SCDB are employed [3]. One bolted test

conducted by Lewitt, one bolted test conducted by Bose

and five bolted tests reported by Thompson are selected

冉冊

db

·q

⌬e

(22)

where:

le

db

Effective length of top angle.

Depth of beam

Table 1

Comparison of analytic and curve-fitting initial stiffness (double web angle connection)

Test ID

g1 (mm)

g2 (mm)

g3 (mm)

ta (mm)

Dnut (mm)

la (mm)

E (N/mm2)

ki(anal.)

(kN·m/rad)

ki(fitting)

(kN·m/rad)

ki(anal.)/ki

(fitting)

FK4AB-M

B-1

A1-2 ALT

B1-2 ALT

D1-2 ALT

E1-3 ALT

A2-3 ALT

38.32

52.95

44.93

42.55

25.88

39.37

44.93

84.14

82.50

37.31

34.93

37.31

34.93

37.31

20.83

31.87

29.85

25.08

10.80

21.91

29.85

9.53

15.00

7.94

12.70

7.94

12.70

7.94

31.75

31.75

31.75

31.75

31.75

31.75

31.75

292.10

400.00

292.10

292.10

292.10

292.10

292.10

2.06E+05

2.06E+05

2.06E+08

2.06E+05

2.06E+05

2.06E+05

2.06E+08

4293.03

17669.13

1996.21

9672.58

8909.51

11913.81

1998.26

5503.21

17349.86

2002.74

9768.32

8571.32

11563.58

2014.17

0.78

1.02

0.99

0.99

1.04

1.03

0.99

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

235

Table 2

Comparison of analytic and curve-fitting plastic stiffness (double web angle connection)

Test ID

g1 (mm)

g2 (mm)

g3 (mm)

Number db (mm)

of bolt

sy (N/mm2) ⌬p (mm)

kp(anal.)

(kN·m/rad)

kp(fitting)

(kN·m/rad)

kp(anal.)/

kp(fitting)

FK4AB-M

B-1

A1-2 ALT

B1-2 ALT

D1-2 ALT

E1-3 ALT

A2-3 ALT

57.37

37.07

76.68

74.30

57.63

55.25

76.68

36.51

36.62

37.31

34.93

37.31

34.93

37.31

39.88

16.00

61.60

56.83

42.55

37.78

61.60

4

5

4

4

4

4

4

286.3644

344.2257

247.8415

247.8415

247.8415

247.8415

344.2257

327.05

6496.30

120.97

338.58

182.42

535.40

168.13

300.63

5843.02

129.29

322.51

174.56

482.83

172.98

1.09

1.11

0.94

1.05

1.05

1.11

0.97

456.95

456.95

533.15

533.15

533.15

533.15

533.15

5.08

5.08

5.08

5.08

5.08

5.08

5.08

Fig. 13. Force distribution of top and seat angle in elastic state.

Consequently, initial stiffness ki is given by

冉 冊

12EI g1+g2

·l ·(d ⫹g )

ki⫽ 3

g1 g1+4g2 e b 1

Fig. 12. Comparison of predicted results with experimental results

(DWA connection).

(23)

4.2.2. Plastic stiffness (kp)

As the moment increases, the plastic hinges are formed at the critical location of top angle. In cases the

angle is thick or the g3 is rather short compared to the

part of fillet, the plastic hinge of point A in Fig. 8 may

be developed at the rivet-head edge near the toe of the

angle. Therefore, it is necessary that the values of g1 and

Table 3

Comparison of analytic and curve-fitting initial stiffness (top and seat angle connection)

Test ID

g1 (mm)

g2 (mm)

g3 (mm)

ta (mm)

Hrivet (mm)

Number le (mm)

of rivet

db (mm) ki(anal.)

(kN·m/rad)

ki(fitting)

(kN·m/rad)

ki(anal.)/

ki(fitting)

No.2

No.5

No.9

No.10

No.20

No.22

No.24

41.24

42.83

41.24

39.65

41.24

41.24

38.91

58.76

60.35

58.76

57.18

58.76

58.76

60.31

20.60

23.78

20.60

17.43

20.60

20.60

18.28

15.88

12.70

15.88

19.05

15.88

15.88

15.88

28.65

28.65

28.65

28.65

28.65

28.65

33.30

2

2

2

2

2

2

2

310.39

458.72

458.72

458.72

355.09

406.65

458.72

25297.85

26572.30

53669.10

102450.24

34279.93

44229.51

76343.07

1.05

0.97

1.04

1.05

1.00

1.00

0.99

57.30

57.30

57.30

57.30

57.30

57.30

66.60

26594.90

25704.32

55885.75

107958.84

34293.39

44382.42

75297.11

236

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

meters a and n can be easily obtained. The proposed

model gives a good curve-fitting with test curve as

shown in Fig. 15.

5. Summary and conclusions

In this paper, a practical model is proposed to represent the moment–rotation relationship of semi-rigid

connection and the proposed model is simple to use and

accurately describes the moment–rotation behavior of

Fig. 14.

Force distribution of top and seat angle in plastic state.

g3 are adequately modified. In plastic state in Fig. 14,

the center of rotation keeps location in initial elastic

state. Again based on the Pp–⌬p relationship of angle

segment in Eq. (17), the relationship between the

moment M and the rotation q is derived as

M⫽(Pp·le)⫻(db⫹g1)⫻

冉冊

db

·q

⌬e

(24)

Finally, plastic stiffness kp is given by

kp⫽

2Mp{(g1−g3)(g23+⌬2p)+0.5g2⌬2p}

db

·l (d ⫹g )·

{g3(g1−g3)(g23+0.5⌬2p)+g3⌬p(0.5g2⌬p−g1g3+g23)} e b 1 ⌬p

(25)

where ⌬p=5.08 mm

4.2.3. Comparison of analytical and experimental

results

To compare the analytical ki and kp with the ki and kp

measured from a test curve, 12 riveted tests conducted

by Hechtman are selected in the present comparison

because the dimension properties and material strength

can be available from SCDB [3]. Similarly, the parameters used in each test and the comparison of analytical

and curve-fitting ki are listed in Table 3. The analytical

plastic stiffness agrees in general with the experimental

values as shown in Table 4.

Eventually, substituting ki and kp calculated from Eqs.

(23) and (25) into Eqs. (11a) and (11b), the shape para-

Fig. 15. Comparison of predicted results with experimental results

(TSA connection).

Table 4

Comparison of analytic and curve-fitting plastic stiffness (top and seat angle connection)

Test ID

g1 (mm)

g2 (mm)

g3 (mm)

ta (mm)

le (mm)

db (mm)

sy

⌬p (mm) kp(anal.)

(kN·m/rad)

(N/mm2)

kp(fitting)

(kN·m/rad)

kp(anal.)/

kp(fitting)

No.2

No.5

No.9

No.10

No.20

No.22

No.24

65.11

66.70

65.11

63.53

65.11

65.11

66.66

39.66

41.25

39.66

38.08

39.66

39.66

38.11

44.48

47.65

44.48

41.30

44.48

44.48

46.03

15.88

12.70

15.88

19.05

15.88

15.88

15.88

57.30

57.30

57.30

57.30

57.30

57.30

66.60

310.39

458.72

458.72

458.72

355.09

406.65

458.72

258.22

258.22

258.22

258.22

258.22

258.22

258.22

1075.08

1417.89

2269.88

3076.13

1462.23

1816.87

2443.18

1.01

0.94

0.99

1.14

0.95

0.99

1.03

5.08

5.08

5.08

5.08

5.08

5.08

5.08

1087.37

1331.25

2241.86

3502.24

1392.07

1789.83

2514.84

S.-S. Lee, T.-S. Moon / Engineering Structures 24 (2002) 227–237

nearly all connections by controlling shape parameter a

and n. It introduces a semi-analytic procedure that the

optimum values of a and n, agreeing rather well with

experimental curves, are described as a function of initial

stiffness (ki) and plastic stiffness (kp) from statistical

regression analysis. Herein, the initial stiffness (ki) and

plastic stiffness (kp) of double web angle connection and

top and seat angle connection are derived analytically

and the analytical results agree in general with the

experimental values. It is difficult to apply Eqs. (10a,

10b, 11a) and (11b) to all angles used in practice because

not all the geometry and material properties of angles

are considered in this study. However, the proposed

model and semi-analytical procedure will be a very

effective tool for designers to execute the frame analysis

with semi-rigid connections.

Acknowledgements

The financial assistance of STRESS (advanced STructure RESearch Station) of KOSEF(KOrea Science and

Engineering Foundation), Hanyang University is

appreciated.

237

References

[1] Attiogbe E, Morris G. Moment–rotation functions for steel connections. J Struct Engng ASCE 1991;117(6):1703–18.

[2] Kishi N, Chen WF. Moment–rotation relations of semi-rigid connections with angles. J Struct Engng ASCE 1990;116(7):1813–

34.

[3] Chen WF, Toma S. Advanced analysis of steel frames. Boca

Raton (FL): CRC Press, 1994.

[4] Yee YE, Melchers RE. Moment–rotation curves for bolted connections. J Struct Engng ASCE 1986;112(3):615–35.

[5] Colson A, Louveau JM. Connections incidence on the inelastic

behavior of steel structures. Euromech Colloquium

1983;174(Oct).

[6] Fleischman RB, Chasten CP, Lu LW, Driscoll GC. Top and seat

angle connection and end-plate connections: snug vs. fully pretensioned bolts. Eng J AISC 1991;First quarter:18–28.

[7] Wu FH, Chen WF. A design model for semi-rigid connections.

Eng Struct 1990;12;12:88–97.

[8] Lewitt CW, Chesson E Jr, Munse W. Restraint characteristics of

flexible riveted and bolted beam to column connections. Bulletin

No.500, Urbana: Engineering Experiment Station, University of

Illinois, January, 1969.

[9] Sherbourne AN, Bahaari MR. Finite element prediction of end

plate bolted connection behavior. II: analytic formulation, J Struct

Eng ASCE 1997;123(2):269–81.

[10] Chen WF, Lui EM. Stability design of steel frames. Boca Raton

(FL): CRC Press, 1991.