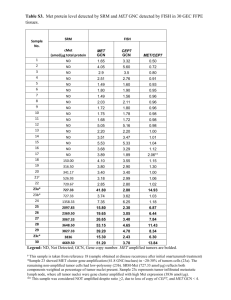

Journal of Energy Storage 32 (2020) 101840 Contents lists available at ScienceDirect Journal of Energy Storage journal homepage: www.elsevier.com/locate/est A review on Graphitic Carbon Nitride based binary nanocomposites as supercapacitors T M.G. Ashritha, K. Hareesh ⁎ School of Applied Sciences (Physics), REVA University, Bengaluru560064, India ARTICLE INFO ABSTRACT Keywords: Supercapacitors Graphitic carbon nitride Transition metal oxide Metal sulfides Conducting polymer Graphitic carbon nitride (GCN): a structural analogous of graphite with aromatic tri-s-triazine units has attracted and opened a new arena in energy storage and conversion of supercapacitors owing to its nitrogen rich framework, metal-free characteristic, earth abundance and environmental friendliness in the current decade. Nevertheless, the supercapacitance performance of GCN can be enhanced by coupling with transition metal oxide/hydroxides, metal sulfides or conducting polymers, which increases the surface area, number of active sites and easy diffusion of inserted/de-inserted ions at the electrode-electrolyte interface further facilitating the faradaic reaction. Therefore, the present review discusses the different GCN based electrode materials with enhanced supercapacitor performance. Furthermore, the historical development, future prospects and opportunities in supercapacitors are elaborately addressed. 1. Introduction With ceaseless depletion of fossil fuels, dramatically varying climate changes, uneven distribution of energy and global concern towards environmental pollution, there has always been a necessity to develop cleaner, renewable and reliable energy sources to cope up with ever growing energy need of human race. To stand up with such indispensable energy demands, it is must to develop more efficient, affordable, alternative energy storage devices to easily harvest energy from intermittent renewable sources like solar, wind and tidal energies and to store them effectively [1–4]. Electrochemical energy storage/conversion system is one such technology. Electrochemical capacitors also termed as supercapacitors or ultracapacitors, gained prominence due to their unique properties like, they possess higher power densities than conventional batteries additionally store ten to hundredfold of more energy delivered in a short interval time than capacitors. They tend to have thousands of continuous charge discharge cycles which make them distinctive from other storage devices like batteries and capacitors [5–9]. In present scenario supercapacitors are widely used where quick charge/discharging is required like regenerative braking in hybrid electric vehicles (HEVs). They also used in portable electronics, LEDs, power back up, power grids and flashlights etc [10,11]. Researchers are working to improve the efficiency of supercapacitors by using different electrode materials such as carbon, transition metal oxides, sulfides, ⁎ Mxene or different combination of them depending upon their applications [12–16]. Among these, carbonaceous materials due to their promising properties towards supercapacitor application like high surface area, remarkable chemical and mechanical stability, ease of synthesis, availability of precursors due to natural abundance of carbon based materials and bipolarity leading to continuous charge/discharge cycles making them a potential material for supercapacitors [7,17,18]. Performance of those carbon-based materials can be enhanced by doping with heteroatoms which increases the pseudocapacitance of the system. Heteroatoms like O, N, B, S and P through surface faradaic reactions, changes acceptor-donor characteristics leading to an increase in capacitance of system [19,20]. Nitrogen is one such widely incorporated atom into graphene network for supercapacitor application. Addition of nitrogen to carbonaceous material frame increases the wettability of electrode, electrical conductivity and hence enhance the capacitive performance. N doing increase the active surface sites and being a neighbour of carbon additionally provide an electron, which improve the stability of material. Moreover, it supplies pseudocapacitance by surface faradaic reactions [21]. Graphitic carbon nitride(GCN) a metal free semiconductor, an analogous to graphene in its layered structure have high nitrogen content with C:N ratio of 3:4 has emerged as a most desirable material in various fields because of its high thermal and chemical stability, wettability, abundance of raw material, ease of synthesis along with high nitrogen content makes it more viable in different fields like Corresponding author. E-mail address: appi.2907@gmail.com (K. Hareesh). https://doi.org/10.1016/j.est.2020.101840 Received 20 June 2020; Received in revised form 27 July 2020; Accepted 28 August 2020 2352-152X/ © 2020 Elsevier Ltd. All rights reserved. Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh photocatalysis, sensing, water splitting and as well as in supercapacitors [22,23]. In comparison to above investigated areas GCN utilization in supercapacitor electrodes are limited due to its comparatively lower surface area and low electronic conductivity [24]. Hence a continuous effort is going on scientific community to tackle this drawback of GCN. Although a number of review articles are presented on GCN in various applications, only a short note is presented on usage of GCN towards supercapacitors in most of the papers [23,25–29]. Therefore, a detailed study on usage of GCN is of great concern now. On the other hand, from the past three to five years only handful of reports are published outlining the drawbacks of GCN and various techniques used to get over it. Therefore, in this study our aim to insight a note on advances in usage of GCN and its hybrids which includes at least one GCN material along with different metal organic framework/carbonaceous material/ conductive polymers or by making appropriate modification in the frame work as electrode materials for supercapacitors. Considerable enhancement in electrochemical framework of system could be achieved in some cases. All these different combinations and significant electrochemical property changes are the main focus of this review. In conclusion and outlook, an advanced overview on different directions and prospects along with some research gaps in the field of GCN based supercapacitors are briefly discussed. tri-s-triazine/heptazine aromatic conjugated rings as demonstrated in Fig. 1. Among all these allotropes, it was proven that graphitic carbon nitrides is most stable phase in ambient condition [31]. Even though research in the field of utilization of GCN as a supercapacitive material is stepping its foot in present decade, it is becoming a new hot spot of research among scientific and production community. Graphitic carbon nitride is an n type semiconductor, with 2D structural analogous of graphene in its stacked layers with a nitrogen substituted framework which exhibits pi conjugation with sp2 hybridization of carbon and nitrogen atoms in each plane. More interestingly compared to graphite, interplanar distance between layers in GCN is decreased from 0.335nm to 0.315nm and this can be explained by altering localization of electrons by substituted nitrogen atom. This leads to more denser packing of GCN with stronger binding which results in enhanced perpendicular charge transfer between the layers of GCN which is fruitful for supercapacitors [32]. There are two isomers of GCN, one (Fig. 1a) is condensed s triazine unit and another (Fig. 1b) is tri-s-triazine unit which are obtained using different synthesis methods and with whole lots of nitrogen-based precursors. The latter has larger periodic carbon vacancies in the lattice compared to earlier. Further DFT calculations demonstrated that tri-striazine isomers are energetically more stable and favourable than other proposed s-triazine isomer [34]. Therefore, it is recognized as most productive tectonic unit of GCN frameworks. GCN is generally a yellow (pale yellow) coloured polymer in powder form with 0.75 of C:N ratio and that can be varied depending upon the different precursors and synthesis routes. Graphitic carbon nitride can be synthesized through various methods. One such most widely used easy, facile method is pyrolysis (thermal polymerization) of nitrogen rich precursors. An oxygen free and C-N core structured precursor like urea [35–40], cyanamide [41,42], thiourea [43,44], melamine [45,46], dicyandiamide [47,48], guanidinium chloride [49] or different mixture of them [50] heated at desired temperature to obtain polymeric GCN. 2. History, structure and properties of GCN Carbon nitride is regarded as one of the earlier developed polymers in scientific community. History of carbon nitride way back to early 1834 with the synthesis of polymeric tri-s-triazine material called ‘Melan’ by Berzelius [30]. Theoretically through first principle calculation it was found there were seven phases of carbon nitride. It includes alpha, beta, cubic, pseudocubic and graphitic structures (g-htriazine, g-o-triazine, and g-h-heptazine). It has been found that basic structural building block of all these allotropes are triazine (C3N3) and Fig. 1. The structure of a) s-triazine, (b) tri-s-triazine, (c) g-C3N4 based on s-triazine units, (d) g-C3N4 based on tri-s-triazine units. Reproduced from ref. [33] with the permission of Elsevier. 2 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh But these materials yielded a bulk GCN which possess low electronic conductivity due to stacking of layers which leads to lower surface area and fast electron hole recombination rates. Various exfoliation techniques were used to obtain GCN with higher surface area with numerous reaction sites and shorter diffusion pathways leading to increased conductivity of GCN which is most suitable for supercapacitor applications [16]. As mentioned earlier addition of nitrogen into carbonaceous materials improve their wettability and conductivity. Addition of nitrogen brings electrons to delocalized pi electron cloud of carbon materials thus increases the conductivity. Graphitic carbon nitride is chemically stable that it cannot dissolve in any acidic, alkali or other organic solvents which makes it a powerful material for electrochemical applications. On the other hand due to high contact resistance, low surface area and large recombination rate it faces serious conductivity issues affecting storage of supercapacitors [51]. Nevertheless from the view of non-polar carbons, substitution of nitrogen in graphitic carbon nitride leads to more heterogenous atoms owing to increased wettability. Injection of electrons increases the density of states near fermi energy level leading to enhanced quantum capacitance in GCN. Most importantly added heteroatom enriches GCN towards reverse redox faradaic reaction (pseducapacitance) which causes them to possess hundreds of magnitudes of specific capacitance than EDLCs along with maintaining its cycle life. As shown in Fig. 2, GCN generally consists of pyrrolic, pyridinic/ pyridone N, quaternary N and oxidized pyridine-N, N rich functional groups. Pyrrolic N and pyridinic N are present at the edges of GCN plane whereas quaternary N atoms groups are present inside the plane. Pyrrolic N and pyridinic N are bonded to two carbon atoms and act as electron donors and quaternary N are bonded to three carbon atoms respectively. Quaternary N significantly enhance the electron transfer property and hence electrical conductivity. Table 1 Comparison of characteristics of different energy storage devices. Reproduced from ref. [56] with the permission of Elsevier. Performance Battery Electrostatic capacitor Supercapacitor Charge time Discharge time Energy density (Wh/kg) Power density(W/kg) Charge- discharge efficiency Cycle life 1-5 h 0.3-3 h 1-100 5-200 0.7-0.85 10−3s to 10−6 s 10−3 to 10−6 s <0.1 >10000 ~1 0.3-30 s 0.3-30 s 1-10 ~1000 0.85-0.98 500-2000 >50000 >10000 the fields where we have to store a higher amount of energy for long term use, nevertheless they lack when it comes to higher power delivery [5,52]. Both these batteries and capacitors uses are limited when it comes to high energy density along with high power capability application. In the view of solving this need, supercapacitors gained profound interest because of its proficiency in high power densities with decent energy densities along with remarkable cycle life [53,54]. They manage to supply higher amount of power than battery but they aren't able to store as much as energy a battery can store in a same volume. They have advantages of unlimited cycle life without considerable capacitance loss, with low ESR responsible for high power delivery and quick charging. As well they work efficiently and safely in low temperatures. They even possess some limitations like fraction of energy storage with shorter voltage window in comparison to batteries and cost per Watt is high compared to capacitors. They also possess high self-discharge rate. A table of various characteristics of different energy storage devices are listed in Table 1. Nevertheless, supercapacitor differs from regular capacitor or battery in its charge storage mechanism also. Supercapacitor can store charge either electrostatically like capacitor but with higher amount of capacity (EDLC) or through faradaic charge transfer like batteries but with no phase change leading to a mechanism called pseudocapacitance or by combining these two mechanism leading to a hybrid supercapacitor [53]. There are three different classes in hybrid supercapacitor. 1) Asymmetric supercapacitor-where two different electrodes with differentiating EDLC (carbon based) and Pseudocapacitor (metal oxides or conducting polymers) are combined to form a cell. 2) Battery type supercapacitor- two different electrode with one battery type and another 3. Supercapacitors With increase in energy consumption among human trace, as important it is to develop clean, environment friendly energy portfolio it is also crucial how we efficiently store energy. Supercapacitor is one such energy storage devices along with commonly used batteries and capacitors. Capacitors are well known for their higher power density and are generally used in the application where there is need to deliver energy quickly within seconds which can be termed in other way as, where there is a need for high power. Whereas the batteries are applicable in Fig. 2. Schematic of the types of N-doping of GCN. 3 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Table 2 List of GCN materials for supercapacitors. Material Carbon nitride source and synthesis method Electrolyte and potential window in Volt Specific capacitance in F/g (at *Cd in A/g) Cycle number, capacitance retention Ref. g-C3N4 nanofibers Tubular g-C3N4 Activated carbon nitride (ACN) Melamine, Melamine Melamine, pyrolysis/activation 263.75 (0.1) 233 (0.2) 185(0.5) 2000, 93.6% 1000, No obvious loss 5000 87.2% 69 70 72 Exfoliated g-C3N4 Urea, pyrolysis 113.7 (0.2) 5000 89.3% 73 Mesoporous graphitic carbon nitride (MGCN) g-C3N4@G Melamine, carbonization Na2SO4, (0.1-0.7) KOH(-0.2 to 1) [BMIm]BF4/acetonitrile, (-1.3 to 1.3) LiClO4 (0.2 to 0.8) H2SO4 (-0.2 to 0.8) LiClO4 (0 to 1) H2SO4(-0.8 to 0) KOH(-1 to 0) KOH(-0.5 to 0.5) H2SO4(-0.2 to 0.8) 244 (0.5) 5000 100% 74 264 (0.4) 10000, No obvious loss 75 265 (1) 288 (0.5) 379.7 (0.25 403.6 (0.1) 5000, 94% 10000, 85% 5000, 100% 21 76 77 61 Melamine, hydrothermal GOOCN rGO/carbon nitride C-C3N4@rGO g-C3N4/nitrogen-enriched carbon spheres g-C3N4/ mesoporous carbon sphere Carbon cloth@GCN (CC@GCN) g-C3N4 Assembly with graphene oxide g-C3N4/Ni(OH)2 Melamine, solution based method Dicyandiamide, hydrothermal Melamine, solvothermal method Urea, thermal decomposition Melamine, Urea, glucose annealing Urea, pyrolysis Melamine, hydrothermal method KOH(-0.2 to 0.6) H2SO4(0 to 1) 352.44 (5 mV/s) 499 (1) 3000, 88.44% 10000,113% 78 79 H2SO4(0 to 0.8) KOH (-0.1 to 0.5) 936 mF/cm2 (936 mF/cm2) 505.6 (0.5) 1000, No obvious loss 1000, 71.5% 80 85 g-C3N4/NiAl-LDH Urea, In situ self-assembly KOH (-0.2 to 0.6) 714 (0.5) 10000, 82% 86 CNRG/Ni(OH)2 KOH (0 to 0.5) 1785 (2) 5000, 71.3% 87 Carbon-doped g-C3N4/MnO2 (CCNM) Melamine, Hyper acoustic treatment, oil bath Melamine, Hydrothermal method Na2SO4(-0.2 to 0.8) 324 (0.2) 1000, 80.2% 88 K doped g-C3N4/MnO2 (KCNM) Thiourea, hydrothermal method Na2SO4(-0.2 to 0.6) 373.5 (0.2) 1000, 95.2% 89 Na doped g-C3N4/MnO2 (Na-CNM) Thiourea, hydrothermal method Na2SO4(-0.2 to 0.6) 294.7 (0.2) 1000, 93.7% 89 MnO2/ g-C3N4 NC Melamine, chemical route Na2SO4(-0.2 to 0.8) 211 (1) 1000, 100% 90 Nanoneedle-assembled NiCo2O4// gC3N4 Nanosheet assembled NiCo2O4/gC3N4 CN/Ni g-C3N4/α-Fe2O3 thiourea, Hydrothermal treatment, calcination thiourea, oil bath treatment, calcination Sonication, heat treatment Melamine, pyrolysis KOH(0 to 0.6) 274.8 (1) 1000, 89.4% 91 KOH(0 to 0.6) 118.2 (1) 1000 101% 91 KOH(0 to 0.5) KOH(0 to 0.5) 1768.7 (7) 580 (1) 4000, 84% 1000, 96% 92 93 Carbon/CuO nanosphere@ g-C3N4 Thiourea, co pyrolysis decomposition Melamine, co-precipitation NaOH(-0.6 to 0.6) 247.2 (1) 6000, 92.1% 94 KOH (0 to 0.5) 780 (1.25) 1000, 80% 95 Melamine, hydrothermal and lyophilization Dicynamide, hydrothermal, heat treatment Thiourea, hydrothermal Thiourea, oxidation reduction reaction Thiourea, chemical reduction method Melamine, hydrothermal Melamine, thermal decomposition Melamine, in situ method Melamine, hydrothermal KOH(-1.2 to 0) 704.3 (0.5) 2000, 98% 96 KOH(0 to 0.5) 125.1 (1) 1000, 100% 97 KOH(0 to 1.0) KOH(0 to 1.0) 79.62 (1) 174 (1) 9000, 92% 6000, 85% 98 99 KOH(0 to 1.0) 64 (1) 6000, 87% 99 KOH(0 to 0.5) 243(1) 1000,81% 100 KOH(0.2 to 0.6) KOH(0 to 0.6) KOH(0 to 0.6) 3000(3) 1998(2) 1557 (1) 1000,95.6% 5000 95.2% 10000, 92.6% 101 102 108 Thiourea, Melamine, solvothermal Melamine, solvothermal KOH (-0.1 to 0.5) KOH (-0.1 to 0.5) Na2SO4(0 to 0.5) 506C/g (1) 834 (0.5) 210.30 (0.5) 1500 99% 5000 98% 1500 84% 109 16 65 g-C3N4 /MoS2 Thiourea, sonication Na2SO4-pva(0 to 0.4) 45.5 (0.5) 100 98% 110 PEDOT/ g-C3N4 PEDOT/ g-C3N4 PANI/ g-C3N4 Polypyrrole/ g-C3N4@G Cellulose /polypyrrole /tubular gC3N4 Melamine, layer-by-layer assembly Melamine, layer-by-layer assembly Urea, oxidative polymerization Melamine, hydrothermal Melamine, polymerization followed by self-assembly. H2SO4(-0.2 to 0.8) Na2SO4(-0.6 to 0.6) H2SO4(-0.2 to 1.2) KOH(-1.0 to 0.2) KCl(0 to 0.5) 137 (2) 200 (2) 584.3 (1) 260.4 (1) 2.53 F/cm2 (5 mA) 1000, 1000, 1000, 2000, 2000, 114 114 115 116 117 MnS / g-C3N4 Melamine, sol-gel Na2SO4(-0.2 to 1.0) 403.36 (0.005) 2000, 98.6% Mesoporous Co3O4/ g-C3N4 RuO2/ g-C3N4@rGO TiO2/ g-C3N4 TiO2/ g-C3N4 g-C3N4/MnO2 g-C3N4/SnO2 Fe2O3 nanospheres /GCN GCN/(OZCN) Ov-NiCo2O4 /ND-g-C3N4 C self-repairing GCN/NiCo2S4 (CPCNNSs/NCS-NPs) NiCo2S4/p- g-C3N4 nanosheets Cobalt sulfide/ g-C3N4 (CN/CS) SnS2– g-C3N4 89% 96.5% 82% 80% 54.9% 67 (continued on next page) 4 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Table 2 (continued) Material Carbon nitride source and synthesis method Electrolyte and potential window in Volt Specific capacitance in F/g (at *Cd in A/g) Cycle number, capacitance retention Ref. Red phosphorus g-C3N4 GCN/ZSO Melamine, mechanical ball milling Melamine, ultra-sonication assisted Na2SO4(0 to 0.4) Na2SO4(-0.6 to 0.6) 465 (1) 244.7(1) 1000, 90% No obvious loss 118 119 *Cd- Current density supercapacitor type are combined. Most important one is 3) Composite supercapacitor-on a single electrode both chemical (pseudocapacitance) and a static (EDLC) are combined to utilize the advantageous of both mechanisms to yield both higher energy with power capability through a single electrode [57,58]. In the following review we mainly discuss different hybrid composite electrode and their performance. Specific capacitance (Cs in F/g) of asymmetric supercapacitor is calculated from GCD data using the formula [59] Cs = I× t ma × V = 4. Perspectives of GCN Like aforementioned graphitic carbon nitride being an analogous of graphite with high nitrogen content(non-graphitic), redox active materials, its application when accessed as a material for electrochemical electrode is hindered because of its large band gap(2.67eV), low conductivity and low surface area. As though a simple GCN with high nitrogen content can be easily produced by pyrolysis of melamine at 550°C, but it doesn't exhibit a notable energy storage in supercapacitors. Hence, it is important to resolve this problem by altering its electronic and textural properties of GCN. A various approach has been put forward including morphological control by varying precursors and synthesis condition, doping with other atoms, compositing with other metal organic framework or with conducting polymer materials or even by combining some of these approaches. Interestingly, GCN have the potential to integrates the uniqueness of carbon material like low cast, availability of abundant sources with advantages of nitrogen doping like surface redox reaction and improved surface wettability along with benefits from energy storage of supercapacitor. In the following review we mainly concern on advancements in the field of pristine GCN, GCN/ transition metal oxide/sulfides and GCN/conducting polymer composites for energy storage enhancement in supercapacitors. where I is applied current (A), Δt is discharge time (s), ma is mass of active material, ΔV is voltage window (V). The specific energy (Ed in Wh/kg) and specific power (Pd in W/kg) [58] can be calculated as follows. 1 Cs ( V )2 2 (2) Pd = Ed t (3) The specific capacitance (Cs) of symmetric supercapacitor is calculated using [60,61], Cs = 4I × t ma × V (4) The corresponding specific energy (Ed) and specific power (Pd) of symmetric supercapacitor are given by [60,61], Ed = Pd = 1 C( 8 s V )2 4.1. Synthesis of GCN based binary nanocomposites (5) 3.6 Ed t (7) where td and tc are time taken for charging and discharging taken from GCD curves. (1) Ed = td × 100 tc There are different synthesis methods used for the synthesis of GCN binary nanocomposites. Some of them are briefly discussed as follows Hydrothermal/solvothermal methods: It is the most widely used synthesis process in any nanoparticle or composite preparation. It is described as a synthesis methods where the chemical reaction takes place inside a closed Teflon autoclave under high pressure and high temperature condition [62]. It is admired because there is a control over different morphology of nanoparticles along with their size, high purity, and controlled crystallinity. Nevertheless, it lacks control over particle aggregation. If other solvents instead of water is used in the pressure vessel(autoclave) it is termed as solvothermal method. Various (6) Eddefines how efficiently a device can store energy and thus a device with higher Ed can store and supply an electronic load for longer than one with a lower Ed.Pd describes how quickly the device can deliver the stored energy with respect to time. It is equivalent to the maximum current you can draw from a device of a given mass/volume A Ragone plot effectively describe specific energy versus specific power at different current densities. Also, coulombic efficiency (ɳ) is calculated using [59–61], Table 3 List of GCN materials and structure for various nanocomposites. Materials Structure Property Enhancement of Cs Ref. Mesoporous GCN g-C3N4@G Ni(OH)2/ g-C3N4 g-C3N4/NiAl-(LDH) MnO2/ g-C3N4 GCN/Ni Co3O4/ g-C3N4 TiO2/ g-C3N4 g-C3N4/MnO2 g-C3N4/ SnO2 MoS2- g-C3N4 PEDOT/g-C3N4 Nanoflakes Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nanosheet Nitrogen content Specific surface area Morphology conversion (nanoplates to nanoflowers) Surface area and pore size Surface area Surface area and pore size Surface are and pore volume Surface are and pore size Surface are and pore size Surface are and pore size high surface area, increased mass transfer high surface area, increased mass transfer 3.4-fold higher than bulk GCN Twice high than pristine graphene 2.2-fold than Ni(OH)2 1.6 fold than pure LDH and 25 fold than GCN 2 fold than MnO2 4.2 fold higher than Ni(OH)2 1.8 fold higher than Co3O4 1.1 fold higher than TiO2 2.6 fold higher than MnO2 1.2 fold higher than SnO2 5 fold higher than MoS2 1.1 fold higher than PEDOT 74 75 85 86 90 92 95 97 99 99 110 114 5 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh GCN based supercapacitor electrodes are successfully synthesized such as Cobalt sulfide/graphitic carbon nitride[16], GCN/Ni2CoS4 nanocomposites [63], heterostructure SnO2/GCN [64], 3D flower-like SnS2 on g-C3N4 [65] by hydrothermal method. Co-precipitation method: It is moderately used synthesis method when it comes for large scale production. Here for the precipitation to takes place, high temperature is required. It has advantages like high purity, ease and low cost of synthesis. It disadvantages lies in its uncontrollable morphology because of high rate precipitate formation [66]. Sol-gel method: It is a method to get uniform particle size with high purity. Here the sol (particles in a solution) agglomerate and form a gel. Colloidal and polymeric are the two different methods which differ by precursor used in solvent. The solvent is usually water and alcohol in respective colloidal and polymeric method. precursor is activated either by using an acid or base, then with appropriate temperature and reaction time it forms a network of gel. Materials with different morphologies can be easily synthesized using this method with high surface area [67]. In-situ polymerization: Here through sonication, monomers are effectively dispersed in solution and with addition of oxidising reagents polymerization starts in the solution. These polymerized nanoparticles are then washed and filtered from the aqueous solution. With modification in synthesis parameters different morphologies of nanoparticles are effectively reported with better chemical properties. Chemical vapour deposition (CVD): This technique is performed in vapour phase where porosity of synthesized material is of concern. Initial vapour material subjected to form even morphology nanomaterial under an 800-1000°C of temperature. For an example synthesis of graphene using CVD compared to other synthesis route yielded better crystal domain with less defects and with uniformity [68] Direct coating: It's a commonly employed fabrication methods when the synthesized nanoparticles are effectively in the form of slurry. These slurries are directly applied on the substrate. Generally activated carbon or carbon black is introduced to enhance electrical conductivity along with polyvinylidene fluoride (PVDF) as a binder and NMP as a solvent in different electrode preparation process for supercapacitors. Tahir et al. [69] synthesized nanofibers of GCN(GCNNFs) using a melamine. SEM images showed that these fabricated GCNNFs have an average diameter of 10nm and length 20µm as shown in Fig. 5A. Compared to bulk GCN surface area (4m2/g), GCNNFs possessed a higher surface area(165m2/g). In aqueous Na2SO4 solution they delivered a specific capacitance (Cs) of 263.73F/g and the cycling life of GCNNFs was found to be 93.6% when assessed in 1 A/g of current density by 2000 GCD measurement. The same research group synthesized a tubular GCN using melamine as a precursor which was pretreated with HNO3 and ethylene glycol [70]. With a mean diameter of 0.8 µm of tubular structure, formation of GCN is clearly presented in Fig. 4. Different classes of supercapacitors. Fig. 3B. At a discharge current of 0.2 A/g it achieved a specific capacitance of 233 F/g in KOH solution. It exhibited only 10% capacitance attenuation after 1000 charge/discharge cycles. This difference in Cs of these structures compared to bulk GCN evidently revealed that structural optimization is one of the effective methods for enhancement in supercapacitor energy storage. Zhang et al. [71] synthesised a set of GCN nanosheets using thermal and chemical oxidation methods with different concentration of H2SO4 and with different temperature. Values found for Cs of GCN is higher than both GCN (127.7 F/g) synthesized at 550 °C using melamine and GCN (133.6 F/g) after chemical oxidation with 12 M sulfuric acid at a discharge value of 0.5 A/g. Further, 580 °C CN exhibited energy density of 3.740 Wh/kg at 99.46 W/kg of power output. Shen et al. [72] synthesized a porous activated carbon nitride (ACN) via a facile pyrolysis/activation method. A series of ACN is synthesized by varying the pyrolysis temperature of the precursor melamine and citric acid, as these precursors can effective form a porous framework. The yielded ACN at 700°C (ACN-700) exhibited optimal nitrogen content (15.6 at%) with high surface area (716.3 m2/g) [calculated using BET]. Intense quaternary N group(Q-N) represented in XPS spectra of ACN-700 predicted the enhanced the specific capacitance of porous ACN. When the synthesized material used as an electrode it delivered 185 F/g of Cs at the discharge current of 0.5 A/g and offered almost 87.2% of initial capacitance after 5000 GCD cycles. When ACN-700 is accessed in symmetric cells it delivered 16.9Wh/kg of Pd in an ionic M [BMIm]BF4/acetonitrile solution and 6.2Wh/kg in KOH solution. The achieved performance is attributed to pseudo−capacitance of N group and enhanced surface area after KOH activation. As well the electrochemical properties of pristine GCN is reported by Gonçalves et al. [73]. They used a simple pyrolysis of melamine and exfoliated using ultrasonication using water/isopropanol (2: 1) solution. GCN when accessed exhibited a Cs of 113.7 F/g in LiClO4 acetonitrile solution. It exhibited only 10.7% of capacitance fading after continuous 5000 GCD measurements indicating its charge/discharge stability. Furthermore, it delivered an Ed of 76.5 Wh/kg at a power capability of 11.9 W/kg. Idris et al. [74] is synthesized mesoporous graphitic carbon nitride (MGCN) using a facile carbonization method. The methylolated surfactant-polymer composite (reaction between melamine and glutaraldehyde, in presence of P123, a surfactant) is used as a precursor to develop MGCN and bulk GCN (BGCN) is developed without the surfactant in under the same condition. MGCN and BGCN are tested for electrochemical performance both in acidic (H2SO4) and alkaline (KOH) electrolyte. Both bulk and mesoporous showed inverted Fig. 3. Ragone chart: Power density vs energy density for various energy devices. Reproduced from ref. [55] with the permission of Elsevier. 6 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 5.1. A. (a, b) Low-magnification SEM images of GCNNF and (c, d) high-magnification SEM images of GCNNF. 5.1. B.(a) 1st, 1000th, and 2000th charging−discharging curves for current density 0.5 A/gof GCNNF. (b) 1st, 1000th, and 2000th charging−discharging curves for current density 1.0 A/g of GCNNF. Reproduced from ref. [69] with the permission of American Chemical Society. ‘V-shape GCD curves. MGCN delivered a higher Cs (244, 56 F/g in acid and alkaline respectively) in acid medium and compared to BGCN (71 F/g in acid and 27 F/g in alkaline) it is because of the high surface area and more accessible mesopores possessed by MGCN and being intrinsically basic provides less accessible sites for chemical reaction in alkaline than in acid medium. Fig. 6: depicts the GCD of BGCN and MGCN in a) 1 M H2SO4 and (b) 6 M KOH electrolytes. At a power density of 125 W/kg MGCN exhibited three folds the higher value of energy density (38.74 Wh/kg) than BGCN (11.39 Wh/kg). Furthermore, MGCN exhibits no attenuation of Cs after 5000 GCD measurements. The enhanced electrochemical performance was attributed to uniform mesoporous structure and high accessible surface area of MGCN and different nitrogen groups increased surface redox reactions leading to high Cs. Aforementioned few results highlighted electrochemical performance and inherent properties of GCN which are important to develop composites with other materials to enhance the specific capacitance along with long lifespan and energy density. 4.2. GCN composite with carbon nanomaterials Considering the effective stability and high conductivity and ease of availability carbon material, it is a potential material in supercapacitors. Some of the research groups utilized these properties of Carbon materials to synthesize composite with GCN to enhance the conductivity and to yield high specific capacitance of GCN. Graphene, a class of carbon with two-dimensional hexagonal lattice of carbon atoms. They stand out in their performance by their large accessible surface area, thermal as well as electrical properties [75]. As both GCN and graphene possess similar electronic structure expect GCN having high nitrogen content, it was found advantageous to modify graphene with GCN to enhance the performance of composite towards 7 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 5.2. A. (a & b) SEM images, (c & d) TEM images of the tubular g-C3N4;B. (a)First five charging discharging curves (b) Last five charging - discharging curve in a potential window of -0.2–1.0V for current density 0.2 A/g and 0.5A/g of tubular g-C3N4. Reproduced from ref. [70] with the permission of Royal Society of Chemistry. supercapacitor electrode application than using bare components. Chen et al. synthesized a 3D functionalized graphene/GCN binary nanocomposites using a facile hydrothermal process as shown in Fig. 7. Similar to that of graphene, GCN have been successfully formed on graphene layers with loosely formed 3D structure. Even though both gC3N4@G and graphene possess almost same conductivity values (0.38 S/m and 0.35 S/m respectively), g-C3N4@G composite when used as an electrode material delivered a Cs of 264 F/g which is considerably greater than pristine graphene (152 F/g). The increase in capacitance values of almost about 75% is attributed to addition of GCN to graphene framework. GCN addition was found advantageous because it decreased the aggregation of graphene sheets and enhanced the capacity along with cycling stability of composite. At 4 A/g, g-C3N4@G showed no obvious capacitance decrease even after evaluating over 10000 cycles.Thus, the results demonstrated that synthesized g-C3N4@G composite can be efficiently used as an electrode for electrochemical 8 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 6. A.CV of BGCN and MGCN recorded at a scan rate of 5 mV/s 1 in (a) 1 M H2SO4 and (b) 6 M KOH electrolytes; B. Galvanostatic charge-discharge cycles of BGCN and MGCN recorded at a current density of 0.5 A/g in (a) 1 M H2SO4 and (b) 6 M KOH electrolytes. Reproduced from ref. [74] with the permission of John Wiley and Sons. supercapacitors. Edge nitrogen atoms mainly contribute to pseudo-capacitance of the system. But a large molecule lacks in number of edge nitrogen. Hence n number of research groups are working develop a facile GCN with increased number of nitrogen atoms. Hence Lin et al. [21] demonstrated a facile route by combining graphene with pre-oxidized GCN (GOOCN). When g-C3N4 treated with HNO3 (oxidizing agent) it cuts the larger molecule of GCN into smaller pieces, as a results number of edge heteroatoms increases thus, the pseudocapacitance of the system. The composite in acid and alkaline medium of electrolyte resulted in 265.6 and 243.8 F/g of specific capacitance respectively. With the same conditions but without pre oxidization of GCN, the composites yielded 40% and 55% decrease in capacitance values in respective acid and alkaline electrolyte medium. The composite exhibited an excellent cycling life of 94% over 5000 GCD cycles. As shown in Fig. 8c, the surface capacitive effects are found to take over the major part of Cs of the composite with surface capacitive effects being 86.6% and diffusioncontrolled processes being 13.4% of total capacitance of electrode. It is proved that the oxidation of g-C3N4 leads to higher electron conductivity and enhance ion diffusion of the composite by developing a uniform dispersion of oxidized GCN on graphene. When GCN is treated with strong oxidizing agents, it breaks the polymeric structures and give rise to higher amount of edge N along with O doping of GOOCN which leads to higher pseudocapacitance hence the conductivity. Wen et al. [76] synthesized graphene/GCN composites with various ratios of GCN in the composite using a one-step hydrothermal method. In 6M KOH electrolyte the as synthesized RGO/GCN is used as a negative electrode and Ni-MOF/CNT as positive electrode for calculating the Cs of the system. For RGO/GCN -X (X¼ 2, 3, 4, 5) is an abbreviation used all over the paper where X stands for concentration of GCN in composite. Pristine rGO was also prepared without the addition of GCN nanosheets for comparison. at the same scan rate, rGO/GCN delivered a higher current compared to the pristine rGO, indicating the higher specific capacitance. This is because the added nitrogen in the GCN, enhanced electron transfer of the composite and also increased the wettability of electrode. The incorporated nitrogen atoms induced the pseudocapacitance, which is in well agreement with the CV curve and its shape. Higher values of g-C3N4 (from 4 mg to 5 mg of doping) induced smaller electrical double-layer contribution thus a decreased power density compared to bare rGO. All the galvanostatic charge/ discharge curves exhibited a symmetrical triangular shape with a slight deflection at 0.1 A/g of current density as shown in the following Fig. 9. Symmetrical curve represented a good reversibility and linearity interpreted the good capacitive properties of electrode material. It is observed that specific capacitance of rGO/GCN composite increased from 212F/g to 288 F/g with the decrease in discharge current from 10 A/g to 0.1 A/g. It offered over 95% retention rate of Cs after 5000 GCD cycles. A porous structure of nitrogen-rich carbon material is synthesized and reported by Ding et al. from carbon self-repairing GCN (C–C3N4) assembled with 2D graphene oxide [77]. They developed a facile route for the fabrication of porous nitrogen- rich carbon through a colloidal solution of self-assembly of (C–C3N4) and GO. at 0.25A/g of current density synthesized material exhibited a high Cs of 379.7 F/g. Energy densities are calculated and represented in Ragone plots using GCD tests and it was found to be 52.7 W h/kg at 0.25 A/g. At 10 A/g of constant discharge current, stability tests showed that the material retained almost 85% of its initial specific capacitance even after 9 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 7. A. (a) Schematic of synthesis of g-C3N4@G; (b) photograph of g-C3N4@G; (c) SEM image of g-C3N4@G; B. (b) CV curves with different scan rates and (c) galvanostatic charge-discharge curves for g-C3N4@G at different discharge current densities. Reproduced from ref. [75] with the permission of Royal Society of Chemistry. continuous 10,000 charge–discharge cycles. Pristine rGO was also used as electrode material and it exhibited only 195.1 F/g of specific capacitance. These specific capacitances values when compared illustrated the role of GCN in enhancement of performance. The enhanced capacitance is due to the improved electrical conductivity, which attributed from expanding of delocalized π-electron cloud by insertion of GCN through the formation of substitutional C configuration and also by the larger specific surface area, enhanced contact between rGO and C– C3N4 of hybrid material. Nitrogen doped carbon spheres are successively introduced into interlayers of GCN to form g-CN/NCS composite using co-calcination of precursors [61] as shown in Fig. 10. Synthesized hierarchical porous structure in turn possess high nitrogen content (along with added NCS) which is making them ideal for supercapacitor material. Introduction of NCS expanded interlayers of GCN and thus, more area was available for conductivity which was proved by BET results of composite (448m2/g). When used as an electrode material the as prepared composite exhibited 403.6 F/g of specific capacitance in 1M H2SO4 electrolyte solution. It also exhibited excellent cycling stability of almost zero % capacitance loss even after 5000 cycles. The notable improved performance of composite is ascribed to its high nitrogen doping, improved specific surface area (electro active sites) and also because of enhanced conductivity which imparts efficient pathways for electron and ion transportation in the conductive network of GCN by introduction of NCS. As a result, g-CN/NCS material can be efficiently utilized as a material for supercapacitor electrodes owing to the synergistic effects. Oh et al. [78] successfully dispersed mesoporous carbon spheres (MPCS) on GCN to synthesis g-C3N4 /MPCS composites via a three- step carbonization method. In this report they highlighted the effect of dispersed MPCS on the electrochemical performance of electrode material. It was shown in the paper that only a proper ratio or amount (1:2 by weight) of MPCS can enhance the capacitive behaviour by increasing surface area but a higher amount of MPCS in composite hinders the electrolyte towards accessing GCN thus, decreasing the performance. A Cs of 352.4 F/g was exhibited at a potential sweep of 5 mV/s by the GCN/MPCS composites. Almost 89% of Cs retention was found after 3000 cycles. Zhu et al. [79] synthesised a carbon cloth (CC) supported GCN nanosheet electrode for supercapacitor. Zhu et al. coated GCN synthesized using urea and glucose on CC through annealing treatment at a temperature of 900°C. taking advantage from binder free character, favourable, ease of coupling and high N content of GCN, CC@GCN-900 delivered 499 F/g of Cs in discharge value of 1 A/g. moreover a symmetric supercapacitor exhibited moderate energy storage of about 10.1 Wh/kg at a high power output of 10000 W/kg. zero capacitance loss was found even after 10000 GCD cycles. Thus, it showed potential to become a binder free electrode for supercapacitors. Graphitic carbon nitride in its bulk structure possess low conductivity may be because of its high nitrogen level (greater than 50%) or by failure of thickness control which is leading to agglomeration (because of some conventional synthesis methods). There are n numbers of works are going in this field to increase the conductivity of GCN. Lu et al. [80] synthesized an assembly of graphene-templated, conductive graphitic carbon nitride using epitaxial strategy. The reported assembly exhibited a large specific surface area of about 724.9 m2/g with moderate nitrogen doping of 18% along with 12.2 S/cm of high conductivity compared to bulk GCN (1 S/m). The as prepared assembly delivered a specific capacitance of 936 mF/cm2. They exhibited excellent charge discharge cycling stability of over 10000 cycles. In the synthesized assembly graphene acted as a current collector and the structure provided more active sites along with many channels for storing and transport. This report promotes the use of GCN as an efficient material in energy storage in supercapacitors. 4.3. Carbon nitride composite with transition metal oxides and hydroxides Transition-metal oxides such as manganese dioxide (MnO2),Fe3O4, 10 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 8. (a) Synthetic route of GOOCN composites; (b) schematic illustration of predicted g-C3N4 before and after oxidation (c) kinetic analysis of the GOOCN24 electrode from CV curves. Reproduced from ref. [21] Published by The Royal Society of Chemistry. This article is licensed under a Creative Commons Attribution 3.0 Unported Licence. nickel oxides (NiO), ruthenium oxide (RuO2) and cobalt oxide (Co3O4) have been studied as a pseudocapacitive material for energy storage applications in supercapacitors because of its multiple oxidation sates [81–83]. Inherently they possess pseudocapacitive nature. They can be used to improve specific capacitance of g-C3N4 by developing a binary nanocomposite within appropriate potential window. Hence they endows a great potential to yield high capacitance supercapacitors and are discussed as follows [84]. Shi et al. [85] reported g-C3N4/Ni(OH)2 composite by a facile single step hydrothermal method. Two sets of gC3N4/ Ni (OH)2 were prepared by adding different quantity of nickel acetate (0.5 and 1 g) to GCN to form composites. Added GCN successfully convert nanoplates like morphology of Ni(OH)2 into flower like g-C3N4/Ni(OH)2 composite proved by TEM images. Synthesized composited when used as an electrode material exhibited notable enhancement in specific capacitance (505.6F/g) compared to pristine Ni (OH)2 (228F/g) in 6M KOH electrode solution. Here flower like Ni (OH)2 enhanced the electron diffusion and ion transport in the composite hence exhibited an improved performance. It also showed about 71% of capacitance retention over 1000 cycles. It 17.56Wh/kg of energy density along with 125.43W/kg of power density. Thus, the synthesized composite can be used as an electrode material. A g-C3N4/ NiAl-layered double hydroxide (LDH) composites are synthesized Fig. 9. Electrochemical performances. (a and b) CV and GCD of rGO/GCN composites with different contents of g-C3N4, respectively. (c) Specific capacitance as a function of current density. Reproduced from ref. [76] with the permission of Royal Society of Chemistry. 11 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 10. A. Schematic illustration of the preparation process of the g-CN/NCS; B. (a) CV (b) GCD of g-CN/NCS-2. Reproduced from ref. [61] with the permission of Royal Society of Chemistry. through a in situ method, where of NiAl-LDH were successfully grown on GCN. Mixture of Al(NO3)3 9H2O and Ni(NO3)2 6H2O along with gC3N4 nanosheets and urea was refluxed to form the composite. Bare LDH possess platelets stack like structure and the prepared nanocomposite exhibits a porous structure with curved nanosheets as shown in TEM Fig. 11. Different amounts of GCN are added LDH to form composites. g-C3N4 in composite improve the dispersibility of the LDH and the formation of mesoporous structures which enhance the supercapacitor performance. When the composite is used as an electrode it showed 714 F /g of specific capacitance which is considerably greater than LDH 446 F /g at a discharge current of 0.5 A/g. After 10000 GCD evaluations the composite exhibited only 18% of capacitance fading indicating its higher stability. Excellent Cs demonstrated that prepared nanocomposite can be used as a potential electrochemical electrode material [86]. Li et al. [87] synthesized CNRG/Ni(OH)2 via a facile hydrothermal method. Porous GCN/rGO was synthesized with the aid of glucose molecules and Ni(OH)2 nanosheets are successively grown on GCN/rGO assembly as clearly illustrated in the Fig. 12. It is clearly indicated that g-C3N4 layers are uniformly coated on both sides of the rGO, to form a sandwich structure upon which Ni(OH)2 are successively deposited. Here GCN avoid agglomeration Ni(OH)2 and also leads to high dispersity of the composite. The as prepared hybrid when accessed as an electrode exhibited excellent Cs of 1785F/g in KOH solution. At 3 A/g they delivered only 71% of cycling capacitance lifespan after assessing over 5000 GCD measurement. It retained almost 900 F/g of specific capacitance when the current density increased from 2A/g to 20A/g owing to its excellent rate stability. Such enhanced electrochemical performance signifies that this hybrid could be a prominent electrode for supercapacitors. Carbon-doped g-C3N4/MnO2 (CCNM) was reported using facile hydrothermal synthesis route to investigate the advantages of using 2D architectures. Carbon is doped into GCN network by calcination of porous melamine in presence of thiourea. Then it is mixed with KMnO4 solution and through hydrothermal reaction, carbon-doped g-C3N4/ MnO2 composite was prepared. Series of composites are prepared by varying temperatures during hydrothermal process (CCNM 1- 120°C, CCNM 2- 140°C, CCNM 2-180°C). The specific capacitance of carbon doped g-C3N4/MnO2 (CCNM 2) composite delivered a Cs of 324 F/ g in a Na2SO4 electrolyte which is found to be much higher in comparison to the specific capacitance exhibited by undoped g-C3N4/MnO2 (89 F/g). At a discharge current of 0.2 A /g, a retention rate of almost 80% was found over 1000 cycles. Results indicated doping is an alternative way of increasing the surface area and charge transfer in GCN and the GCN improves the wettability thus enhances the specific capacitance of the composite [88]. K or Na doped g-C3N4/MnO2 composite was synthesized by Shen et al. [89] using thiourea and KBr/NaBr by thermal treatment. As prepared K/Na doped g-C3N4 hydrothermally treated in presence KMnO4 solution to from composite material containing K/Na doped g-C3N4/MnO2 as shown in Fig. 13. All electrochemical characterization was done for the samples with and without doping. GCD results showed better specific capacitance for the materials with metal doping. Specific capacitance evaluated from GCD at various current densities represented improved performance of doped composite than the bare g-C3N4/MnO2 composite. The structure of self-assembled Na and/or K doped g- g-C3N4/MnO2 improved electron and ion transportation as well as utilization of MnO2 towards specific capacitance of electrode. Both K doped g-C3N4/MnO2 and Na doped g-C3N4/MnO2 exhibits Cs of 373.5 F/g and 294.7 F/g respectively in Na2SO4 electrolyte solution at 0.2A/g of current density. Higher value of specific capacitance in K doped g-C3N4/MnO2 is because of K doping which is intercalated into the layers of GCN, provided numerous delivery channels thus improve charge transfer. Results exhibited (Fig. 13) doping is an efficient way to improve the energy storage of electrode materials. Chang et al. [90] fabricated graphitic carbon nitride/MnO2 nanocomposite, by sandwiching MnO2 nanorods (NRs) on upper and lower surfaces of GCN layers via chemical route. GCN layered sheets provided numerous sites towards chemical reaction (nucleation) for growth of the MnO2 nanorods on both sides to form a sandwich like structure of the composite g-C3N4/MnO2 NCs. To study the effect of 12 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 11. (A) SEM image of LDH, (B) SEM image CL10 (g-C3N4/NiAl-LDH10), (C) TEM images of LDH and (D) CL10, (E) Cyclic voltammograms of LDH, g-C3N4 and C3N4/LDH composites (CL5, CL10, CL20) at scan rate of 10 mV/s, (F) GCD of LDH, g-C3N4 and C3N4/LDH composites (CL5, CL10, CL20) at 1 A/g. Reproduced from ref. [86] with the permission of Elsevier. sandwiching on the composite performance, a bare MnO2 and one more composite of MnO2 but with graphene oxide (MnO2/GO NC) was prepared under same condition. When the synthesized material is used an electrode material the MnO2/g-C3N4 NC (211 F/g) composite exhibited a specific capacitance much higher than other two compounds. Enhanced specific capacitance of MnO2/ g-C3N4 NC compared to MnO2 /GO NC is attributed to the unique 2D sandwich like structure on gC3N4 sheets and the presence of heteroatom of g-C3N4. This work clearly demonstrated that improvement in the performance of MnO2 as well as other transition metal oxides can be found using GCN than the commonly used GO sheets. Future more to study the dependence of structure of nanocomposite on performance of electrode material Guan et al. [91] fabricated nanoneedle and nanosheets of NiCO2O4 on GCN. g-C3N4 prepared via thermal decomposition of thiourea. Nanosheet and nanoneedle NiCO2O4/ g-C3N4 (NNC) are synthesized using oil bath (NNC-I) and hydrothermal method (NNC-II) respectively which are 13 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 12. (A) Schematic illustration of the preparation of CNRG/Ni(OH)2 composite;(B) (a) Cyclic voltammograms of CNRG/Ni(OH)2 electrodes measured at scan rates from 2–50 mV/s, (b) charge-discharge curves of CNRG/Ni(OH)2 measured at various discharge current. Reproduced from ref. [87] of Nature. This work is licensed under a Creative Commons CC BY license. followed by a calcination process. NNC-I exhibited nanosheets like structure which staggered on the GCN, whereas NNC-II exhibited uniform nanoneedles structure on GCN substrate as shown in Fig. 14. The surface area and pore distribution values of nanosheet and nanoneedle like morphologies of NNC are calculated to be 77.5 m2/g, 5nm and 105.7 m2/g, 8nm respectively. At a discharge current of 1 A/g, NNC-II composite exhibited a higher Cs of (274.8 F/g) than NNC-I (118.2 F/g) in 1 M KOH solution. Results are accredited to the higher surface area and availability of more redox sites provided by nanoneedle structure. It also improved wettability (electrode- electrolyte contact) and space between synthesized nanoneedles improved the diffusion kinetics of electrode material. Nanosheet-assembly of NiCO2O4/ g-C3N4 exhibited no capacitance loss even after continuous 1000 GCD cycles. Thus, this report successfully demonstrated the dependence of specific capacitance on structure of electrode material. A g-C3N4/Ni(OH)2 [CN/NI] material was synthesized by dong et al. [92] as they exhibit high theoretical specific capacitance. Via a GCN template the composite was synthesized using nickel nitrate as a main precursor in oil bath treatment. The yielded nanocomposite possessed honeycomb structure comprising of Ni(OH)2 nanosheets on GCN template. TEM image showed the successful formation of Ni(OH)2 nanosheets connected to GCN sheets with 20 nm thickness. CN/NI when used as an electrode materials showed excellent specific capacitance of 1768.7 F/g which is much higher than bare Ni(OH)2 (968.9 F/ g) and GCN (416.5 F/g) respectively in aqueous electrolyte at a current density of 7 A/g. CN/NI also showed a very high 2667 F/g of specific capacitance at a scan rate of 3 mV/s in three electrode system. In 6M KOH, two electrode supercapacitor was fabricated using graphene as negative and CN/NI as positive electrode. Typical CV curves with a variation in scan rate from 0 to 1.3V of CN/Ni//G asymmetric supercapacitor. They exhibited a moderate Cs of 51 F/g along with almost 72% of its initial capacitance retention after 8000 charge/discharges kinetics. Furthermore, they achieved a high Ed of 43.1Wh/kg and power capability of 9126W/kg in a two-electrode configuration. The notable performance of the CN/NI hybrid could be used as an excellent electrode for supercapacitor. Liu et al. [93] synthesized graphitic carbon nitride/iron oxide(GCN/ α-Fe2O3) hybrid by simple one step pyrolysis using Prussian blue (PB) and melamine as precursors at 550C. Here α-Fe2O3 which has successfully anchored on GCN prevents it from agglomeration and expanding. In this report the synthesized composite was accessed for supercapacitors and also for sensing application of non-enzymatic glucose. When used as supercapacitor electrode material 14 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 13. (A)(a) Schematic representation of the preparation of K-CNM and Na-CNM (b) SEM images of K-CNM and Na-CNM; (B). (a) CV curves at the scan rate of 100 mV/s; (b) GCD curves at 0.5 A/g of K-CNM and Na-CNM. Reproduced from ref. [89] with the permission of Elsevier. they exhibited 580 F/g of specific capacitance in 1M KOH at 1 A/g. With increase in current density (1 A/g to 4A/g) only a fractional amount of capacitance loss was found owing to its rate capability property of composite. At a discharge current of 2 A/g they exhibited a nominal cycle life up to 1000 cycles. Vattikuti et al. [94] synthesized carbon (C) and copper oxide (CuO) nanospheres on GCN nanosheets to form a hybrid C/CuO@GCN assembly through co-pyrolysis method. A precursor mixture of CuSO4, D-glucose and thiourea was heated in a muffle furnace at 550o (10°C/min), to yield a yellow coloured product of C/CuO@GCN. C/CuO@ g-C3N4 was found to have higher specific surface area than bare GCN owing to more reaction sites of hybrid for electrochemical reaction. Higher specific capacitance of hybrid is 15 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 14. (A). (a) Low and high (the inset) magnification SEM images of the g-C3N4; (b) low and high (the inset) magnification SEM images of NNC-I; (c) Low and (d) high magnification SEM images of NNC-II.(B). (a, b) CV curves, (c, d) charge-discharge curves of NNC-I and NNC-II. Reproduced from ref. [91] with the permission of Elsevier. 16 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 15. (A). SEM images of (a) pure Co3O4 (b) g-C3N4 and (c) Co3O4/g-C3N4; (B). (a) CV curves of the Co3O4/g-C3N4 in 2M KOH. (b) Charge-discharge curves of gC3N4, Co3O4 and Co3O4/g-C3N4 composites with current density of 1.25 A/g (c) GCD curves of Co3O4/g-C3N4 composites at different current densities. Reproduced from ref. [95] with the permission of Elsevier. attributed to anchoring of C/CuO nanospheres on GCN surface. When this novel nanocomposite is used as an electrode material in 0.5 M aqueous NaOH electrolyte for supercapacitor exhibited 247.2 F/g of Cs at 1 A/g of current density. They delivered 92% of the initial Cs after 6000 cycles determining the long-term stability of the nanocomposite electrode. Co3O4 on graphitic carbon nitride (GCN) was successfully anchored by Zhu et al. [95] using a co-precipitation method. Precursors of Co3O4 and GCN are heated at 400°C in muffle furnace to form Co3O4/ g-C3N4 powder. Fig. 15 presents the SEM images of GCN, Co3O4 and Co3O4/g-C3N4. GCN showed an aggregated layered structure and Co3O4 exhibited polyhedral aggregation with 10-200nm. Co3O4/g-C3N4 clearly indicated the physical interaction between Co3O4 and g-C3N4 structures. Specific surface area of Co3O4/g-C3N4 and bare Co3O4 nanoparticles are calculated using Brunauer-Emmett-Teller theory. It demonstrated that Co3O4/g-C3N4 composite possessed a higher surface area of 12.6m2/g with a pore volume of 0.05cm3/g compared to surface area of Co3O4(11.8 m2/g and pore volume is 0.03 cm3/g), which attributed to the enhanced electrochemical behaviour of composite electrode. Using GCD curve of synthesized nanocomposite, calculated specific capacitance was found to be 780 F/g in 2 M KOH electrolyte at 1.25 A/g of current density. There is 80% of initial capacitance retention after 1000 continuous cycles of charging and discharging. The Cs of the Co3O4 (419 F/g at 1.25 A /g) is much lower than Co3O4/g-C3N4 nanocomposite proofing the utilization of GCN in the nanocomposite. Zhang et al. fabricated a three-dimensional RuO2/g-C3N4@reduced graphene oxide aerogel composite (RCGA) through an electrostatic assembly of positively charged colloidal nanoparticles of RuO2, negatively charged graphene oxide and GCN [96]. These precursors are successfully transformed into a 3D RuO2/g-C3N4@reduced graphene oxide (rGO) aerogel (RCGA) composite through a facile hydrothermal and simple lyophilization processes. The fabricated RCGA composite showed 704.3F/g of specific capacitance which is a high value for the use of such electrode in supercapacitors at 0.5A/g of current density. Galvanostatic charge discharge curves of these nanocomposites also exhibited usual triangular charge/discharge kinetics demonstrating the reversibility of electrochemical process. Excellent cycling charge discharge stability of almost 98% of its initial specific capacitance was retained after 2000 cycles. This excellent electrochemical behaviour showed potential approach towards supercapacitor application. To study the practical application of composite an asymmetric SC was developed by using activated carbon as the second electrode in two electrode system. AS exhibits a the specific capacitances of 23.2 F/g at 0.5 A/g. They delivered a high energy and power characteristics of 80.64 Kw/h and 450 W/kg respectively. A new cost-effective nanocomposite was prepared using TiO2 nanoparticles. TiO2/g-C3N4 hybrid was synthesized via a simple, facile hydrothermal method. GCN layers are prepared by heating dicyanamide followed by a hydrothermal method to yield amorphous TiO2/gC3N4 composite upon heating leading to crystal form of the composite. When used as electrode it represented a high Cs of 125.1 F/g compared to bare TiO2 nanoparticles (106.7 F/g). As prepared TiO2/g-C3N4 showed no capacitance loss after 1000 cycles illustrating its stability as an electrode material in 2M KOH solution. It was found that improved electrochemical behaviour of electrode is related to its pore size (9.3 nm) and specific surface area (128 m2/g) of TiO2/GCN which was reported by Zhao et al. [97]. Kavil et al. also synthesized a TiO2 composite with GCN but with 1D nanotubes of TiO2 supported by two dimensional (2D) GCN nanosheets [98]. GCN layers are prepared by simple pyrolysis of thiourea followed by a hydrothermal treatment to yield TiO2/g-C3N4 assembly. The electrochemical electrode based on 1: 4 weight ratios of TiO2 and GCNexhibited an improved specific capacitance compared to bare TiO2 and GCN (79.62, 15.02 and 50.22 F/g respectively). BET surface area of TNT (TiO2 anatase phase) and TiO2/GCN respectively are 25 and 74 m2/g. The improved specific capacitance of composite is because of improved specific surface area of composite which can be attributed to the spacing effect of 1D nanotubes towards layered network of 2D GCN. Pseudocapacitive MnO2 and SnO2 anchored GCN nanosheets, are reported by Kavil et al. They are synthesized through a one-pot simple chemical reduction. The enhanced performance of gC3N4 /MnO2 is attributed to successful incorporation of MnO2 on bare GCN. The Cs delivered by g-C3N4, g-C3N4 /SnO2 and g-C3N4 /MnO2 are found to be 50.22, 64, and 174 F/g respectively which are obtained 17 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh from GCD curves of two electrode configurations. They respectively preserved 94%, 85% and 87% of Cs after 6000 cycles. Improved performance of g-C3N4 /MnO2 composite is accredited to enhanced surface area as a result of spacing effect exhibited by MnO2 between the layers of GCN consequently a greater charge transport at interfaces of electrode and electrolyte [99]. Through a facile hydrothermal synthesis method SnO2/g-C3N4 nanocomposite was synthesized and reported by Xu et al. [64]. This SnO2/g-C3N4 composite exhibited a flower like structure with an average of 15µm in diameter. When the prepared composite accessed as an electrode material, delivered a 488 F/g of Cs within 0 to 1 V potential range of 1M H2SO4 electrolyte solution at a discharge current of 1A/g. After a continuous 5000 GCD cycles, SnO2/ g-C3N4 composite represented 97.2% initial capacitance at 10 A/g and around 73.4% at 20A/g illustrating a good capacitive retention. Furthermore, in symmetric cell it showed 153F/g of Cs nevertheless, exhibited energy density of 2.8 Wh/kg at operating power density of 5684 W/kg. In the composite GCN reduces the agglomeration of SnO2 hence an enhanced performance is found compared to both bare GCN and SnO2. Zhang et al. [100] synthesised Fe2O3 /GCN by anchoring Fe2O3 nanospheres on GCN which are surface oxidised using HNO3 through one step hydrothermal method. The as prepared 10%OCN/ Fe2O3 (10%:1 weight ratio of oxidised GCN and Fe2O3) delivered a 243 F/g of Cs at 1A/g of current. A capacitive retention loss of almost 19% was exhibited by 10%OCN/ Fe2O3 composite after 1000 GCD cycles. OCN which was well dispersed on GCN effectively prevent the aggregation of nanospheres which lead to an enhanced specific capacitance. The maximum Ed of 25.7 7 Wh/kg is exhibited at power characteristic of 833.8 W/kg. One more TMO based GCN nanocomposite using ZnO has been prepared by shen et al. [101]. An oxygen vacancy rich zinc oxide with GCN is synthesized using a novel thermal decomposition method using melamine as a precursor for GCN and zeolitic imidazolate framework precursor for ZnO. Here this novel assembly exhibited an excellent Cs value of 3,000 F/g at 3 A/g of discharge current. The assembled asymmetric supercapacitor delivered 680 F/g of capacitance and retained almost 86.2% of its initial Cs at a discharge current of 3 A/ g after 1000 GCD cycles. They represent higher energy as well as power characteristics of 100.9Wh/kg and 3,466W/kg. This excellent value is accredited to enhanced ion exchange rate and carrier concentration between the assemblies of OZCN leading to an improved charge-discharge mechanism. Hou et al. [102] developed an oxygen-vacancy-rich NiCo2O4/ nitrogen-deficient GCN hybrids (Ov- NiCo2O4 /ND-g-C3N4) using a facile in-situ method using nickel and cobalt nitride. The as prepared hybrid delivered a high Cs of 1998F/g at 2A/g of current density. The fabricated asymmetric supercapacitor using Activated carbon as second electrode represented Ed and Pd of 70.22 Wh/kg and 800W/kg respectively. They also delivered 95.2 % of initial capacitance after 5000 GCD cycles. electrolyte solution. CPCN-NSs/ NCS-NPs deliver almost 93% retained Cs after 10000 cycles. CV curves represented pair of cathodic and anodic peaks corresponding to oxidation states of Ni and Co. the results clearly demonstrated incorporation of CPCN-NSs on the surface NCSNPs is an effective and viable way of improving the capacitive behavior of CPCN-NSs/ NCS-NPs composite [108]. A new electrode material prepared by compositing nickel cobalt sulfide (NiCo2S4) on GCN to form (NiCo2S4 NSs/P-g-C3N4) nanocomposite by LI et al. [109]. Here NiCo2S4 nanosheets are successfully grown on porous GCN sheets using hydrothermal method. Along with TEM, EDS mapping successfully proven the formation of hybrid material showing Ni, Co, and S elements of NiCo2S4 and C, N of porous GCN. For understanding the effect of GCN on the composite and for electrochemical behavior comparison, nickel sulfide, cobalt sulfide along with different cobalt, nickel and Sulphur stoichiometric (NixCoxSx) ratios of composite with GCN nanosheets were examined. Among all, NiCo2S4@ g-C3N4 delivered highest electrochemical performance. They composite delivered a Cs of2210 F/g at 1 A/g. The composite retained 100% capacitance even after 1500 GCD cycles exhibiting notable cycling stability. The excellent exhibited performance is attributed to shorting of electron and ion diffusion pathways owing to the presence of ‘sheet on sheet’ morphology. Two electrode configuration supercapacitor fabricated using activated carbon and the aforementioned composite delivered an Ed of 16.7 Wh /kg and Pd of 200 W/kg. It affords 99% capacitive retention even evaluating after 5000 cycles. Jiang et al. [16] synthesized a 2Dcobalt sulfide/graphitic carbon nitride (CN/CS) nanocomposite through a facile single step solvothermal method by successfully anchoring of cobalt sulfide nanosheet on GCN nanosheets. Fig. 17 illustrates the synthesis of CN/CS composite. Using GCD curves it is shown that with increase in GCN content Cs increased till 50% then after that a decrease in Cs is found because of high GCN content agglomerated CS and thus reduced the effective electron transfer and active sites. Calculated surface area of CN/CS (52.84 m2/g) using BET was found to more than bare GCN (41.12 m2/g) and CS (14.80 m2/g) attributed nanosheet architecture of CS on GCN sheets. Hybrid nanosheet architecture possessed larger surface area for electrochemical reaction hence exhibited a 668F/g of Cs at a discharge current of 2A/g. furthermore CN/CS showed no attenuation in Cs after 5000 cycles. These excellent electrochemical performances attributed to symbiotic nature of both cobalt sulfide and GCN nanosheets. CN/CS delivered an Ed of 18.5 Wh/kg and 99.8 W/kg of power capability according to a discharge current of 0.5 A/g. No absolute capacitance loss was found after 5000 GCD cycles. Kavil et al. [110] synthesized a TMS based g-C3N4/MoS2 binary nanocomposite using advantages of both electrostatic and electrochemical behavior of GCN and MoS2 respectively. When this 2D nanohybrid is employed as an electrode material, it delivered a Cs of 45.5 F/g which is greater than both pristine GCN (10F/g) and MoS2 (14 F/g). They also represented only 2% capacitance attenuation after only 100 cycles of GCD in Na2SO4 gel electrolyte solution. These performances are ascribed to synergist effect and also due to spacer act of MoS2 between GCN layers. Ansari et al. [65] reported a SnS2 TMS on GCN sheets to form a 3D SnS2/GCN binary composite using solvothermal route. SEM images represented flower like morphology of SnS2 and successful formation of these SnS2 on GCN sheets to form a 3D structure. SnS2/GCN delivered a Cs of 210.30 F/g at a discharge current of 1 A/g which is found to be higher than pristine GCN or the physical mixture of powders of GCN and SnS2 in Na2SO4 solution as shown in Fig. 18. The synthesized material exhibited almost around 16% capacitance loss after continuous 1500 GCD cycles represented its cycling stability. 4.4. GCN composites with transition metal sulfides Transition metal sulfides (TMSs) are other class materials which are used in place of TMO because of their high conductivity along with excellent mechanical stability in energy storage systems [103–105]. A nanocomposite of TMSs such as sulfides of Co, Mn, Ni or Cu (CoS, MO2S, NiS or CuS) [106,107] with GCN could be an ideal option to enhance the electrochemical behavior of pristine GCN. Some of the binary metal sulfide/ GCN hybrids are discussed as follows NiCo2S4 nanoparticle (NCS NPs) composite with porous GCN (PCN) nanosheets were synthesized using a hydrothermal route. Carbon selfrepairing PCN (CPCN) are prepared using solvothermal method followed by heat treatment to form the CPCN-NSs/ NCS-NPs hybrid as shown in Fig. 16. The successful anchoring of NCS nanoparticles on PCN and acted as a conductive linker are showed in TEM images in Fig. 16. By TEM images CPCN-NSs which are having a surface area of about 220.7 m2/g are showed a particle size of average 50 nm. The as synthesized nanocomposites delivered a Cs of 1557 F/g in NaOH 4.5. GCN composites with conductive polymer Conducting polymers (CP) are the materials which provide pseudocapacitance to the system (bulk of the material undergo redox 18 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 16. (A) (a) Schematic representation of the carbon self-repairing porous g-C3N4 nanosheet / NiCo2S4 nanoparticle (CPCN-NS/NCS-NP) hybrid composite, (b) TEM image of CPCN-NSs/NCS-NPs; (B) (a) Comparison of cyclic voltammogram (CV) curves of CPCN-NSs, pristine NCS-NPs, PCN-NSs/NCS-NPs and CPCN-NSs/NCSNPs at same scan rate of 10 mV/s; (b) Comparison of galvanostatic charge-discharge (CD) curves at a current density of 10 A g-1; (c) CV curves of CPCN-NSs/NCS-NPs at various scan rates; (d) GCD curves of CPCN-NSs/NCS-NPs at different current densities. Reproduced from ref. [108] with the permission of Elsevier. reaction). Till date, CP are standing as an attractive material in supercapacitor application because of their prominent properties such as superior conductivity, facile redox capability and also flexibility [111,112]. PANI, PPy and PTh are important CPs. Nonetheless, they face low power performance and also a short cycle life (cycling stability) to successfully use as a single component for electrode of supercapacitors because of its ion and charge transportation in conductive network of polymer is hindered during charge/discharge cycles. Furthermore, compositing with other carbon material will address this disadvantage towards improved performance of the electrode. In this section, we will review advancement in GCN based composite with different conducting polymers such as PANi, PPy or PTh and derivatives of them [113]. One such group Chen et al. [114] synthesized poly(3,4ethylenedioxythiophene) (PEDOT):poly(styrenesulfonate) and GCNnovel assembly. Here PEDOT was successfully deposited on GCN layers via an electrodepositing method on a glassy carbon nitride. When used as an electrode, the as prepared PEDOT/g-C3N4 composite in electrochemical cell exhibited excellent rate capability, cycling stability and electrochemical performance (energy and power density) in both Na2SO4 and H2SO4 electrolyte solution than bare PEDOT. At a discharge current of 2A/g electrode delivered a Cs of 137 F/g and 200 F/g in H2SO4 and Na2SO4 solution respectively. As described in the Ragone plot with increase in current density, power density increased at different current densities. It is also observed that at higher current 19 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 17. (a) Preparation process of CN/CS nanocomposites (b) cycling performance and coulombic efficiency of the 50%-CN/CS electrode at 10 A/g. (b) CV curves of 50% CN/CS electrode at various scan rates (b) Galvanostatic discharge of 50%-CN/CS at various current densities. Reproduced from ref. [16] with the permission of Elsevier. density, energy density is decreased because of less accessibility towards pores and active sites. The equivalent series resistance PEDOT/gC3N4 is comparatively lower than bare PEDOT and is attributed to excellent interaction between PEDOT and GCN.Cycling stability of the composite electrode in H2SO4 and Na2SO4 solution are found to kept at 89% and 96.5% of its initial capacitance respectively. in H2SO4 electrolyte solution energy and power density are found to be 9.65 Wh/kg and 4000.8 W/kg respectively. At an Ed of 17.5 Wh/kg they represented an excellent power characteristic of 5000W/kg because of larger hole and accessibility towards ions in Na2SO4. Zhou et al. [115] synthesized a composite of polyaniline and GCN (PANI/g-C3N4) using oxidative polymerization of aniline along with GCN. SEM images of PANI showed a nanorod like morphology with 50nm diameter and 400nm length as shown in Fig. 19. GCN exhibited regular stacked layer structure, where as the synthesized nanocomposite showed a flower-like morphology. CV curves of composite exhibits a deviation from normal rectangular curves indicating its pseudocapacitive nature and area under CV increased with increase in scan rate with alike shapes illustration stability of electrochemical reactions. In 1M H2SO4 electrolyte solution at a current density of 1A/g PANI/GCN exhibited a Cs of 585.3 F/g. they exhibited a high power as well as energy density of 81.15 Wh/kg and 500.04 W/kg respectively. Furthermore, at a high-power density of 4998.28 W/kg, the Ed of composite remained at 51.94 Wh/kg, which illustrate an excellent range of power can be maintained even at moderate energy densities. At a current of 1A/g the synthesized composite exhibited almost 82% of capacitance retention after 1000 continuous GCD cycles which is notably higher than bare PANI when used as electrode (75.1%). There are also some researches reporting ternary composite by compositing GCN/ conducting polymer with other carbon-based materials towards enhancing the super capacitive performances. Two such composites like Conducting poly-pyrrole/g-C3N4@ graphene(PPy/g-C3N4@G) and cellulose/polypyrrole/tubular GCN are presented by Alshahrie et al. [116] and Li et al. [117] respectively. Conducting poly-pyrrole/g-C3N4@ graphene (PPy/g-C3N4@GN) ternary composite delivered a Cs of 260.4 F/g at 1 A/g and at 5mA/cm2 of current density, nano fibrillated cellulose/polypyrrole/GCN exhibited 2.53 F/cm2 of specific capacitance [116,117]. The below table summarizes the materials properties and structure for various GCN based nanocomposites. 20 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 18. A. (a and b) SEM of SnS2/GCN nanocomposite; (c) schematic illustration of the formation of 3D flower-like SnS2 on the surface of g-C3N4 sheets; B. CD curves for (a) g-C3N4-AP, SnS2-g-C3N4-St, and SnS2-g-C3N4-Pm heterostructure electrodes at a current load of 1 A/g, (b) g-C3N4-AP, (c) SnS2-g-C3N4-St heterostructure, (d) SnS2-g-C3N4-Pm heterostructure. Reproduced from ref. [65] with the permission of Royal Society of Chemistry. 21 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh Fig. 19. A.SEM images of (a) g-C3N4 (b) PANI, (c) PANI/ g-C3N4 (e) PANI, (f) PANI/ g-C3N4.B. (a) CV and (b) GCD curves of g-C3N4, PANI and PANI/ g-C3N4 at a current density of 1 A/g in 1 M H2SO4 solution. Reproduced from ref. [115] with the permission of Royal Society of Chemistry. 4.6. Some other GCN based composites 5. Outlook and conclusion Different materials other than transition metal oxide, conducting polymer and carbon based materials are also synthesized and used as electrode material for supercapacitors and they exhibited potential results. A short note on different GCN composites are briefly described. The research group Ragupathi et al. [67] fabricated g-C3N4 doped MnS nanoparticles through a sol-gel synthesis method. There is formation of spherical particles around 40nm revealed by SEM images. When synthesized material is evaluated it presented a Cs of 463.32 F/g at a very low discharge current of 0.005 A/g. an excellent stability (98.6%) over 2000 cycles is found and attributed to the existence of spherical nanoparticles and doping of GCN which enhance the electron transport. A red phosphorus GCN (RPh-g-C3N4) composited was synthesized by Ansari et al. [118] through simple ball milling. They exhibited a fair amount of Cs of 465 F/g at a 10 A/g with a decent 90% of cycling life was found after 1000 GCD measurement. Balasubramaniam et al. [119] reported a composite of GCN with zinc antimonate-ZnSb2O6 (ZSO) nanorods. Here ZSO nanorods are successfully integrated on GCN using ultrasonication-assisted method. A well-developed assembly of GCN/ ZSO exhibited a Cs of 557.5 F/g at 2.5 A/g of discharge current which is higher than GCN nanosheets synthesized using melamine precursor (244.7 F/g at 1 A/g of discharge current). They tend to possess no capacitance loss at 10 A/g of current density. Relatively higher Cs is attributed to synergistic effect of GCN and ZSO and also the presence of active sites on nanorod and nano porous structure of GCN and ZSO. The copper-manganese alloy nanoparticles decorated GCN was developed by Siwal et al. [120] which showed specific capacitance of 817.85 F/g with capacitance retention of 91% up to 1000 cycles attributed to the quicker diffusion extent of ions and higher surface area leading to enhanced electrochemical response. Talukdar et al. [121] have reported the enhanced the supercapacitance performance of GCN/FeNi3 heterostructure depicted a maximum areal capacitance of 19.21 mF/cm2 at 0.05 mA/cm2. They have also argued that the enhanced areal capacitance of developed heterostructure was due to the generation of the delocalized energy states, which consequently enriches the overlapping states in band structure near Fermi level, in turn providing the several electron channels for ion transfer within the system. Among the various challenges faced across the globe, energy crisis is undoubtedly the major problem which is affecting the modern society to a greater extent. Hence, there is a need for benign, low cost, efficient energy storage and conversion.Electrochemical energy storage is one such storage mechanism which have the potential to turn down energy outbreak. In the list of electrochemical devices, supercapacitor stands first because of its unique advantageous properties like desirable power density, fast charge/discharge rates, and long-life cycles which could effectively intermediate conventional battery and dielectric capacitor. Performance of ultracapacitors (supercapacitor) mainly depends on nature of electrode materials, electrolyte and voltage window of material used. n number of research studies in the field of supercapacitors are going on both in academic and industrial community to enhance supercapacitive performance. Development of new electrode materials is becoming a hotspot of research for enhancing the supercapacitive performance. Graphitic carbon nitride (g-C3N4) is one such material, a unique analogous of graphene with nitrogen as a heteroatom has gained attention as a novel material due to its prominent properties like ease of synthesis, unique electronic feature with 2D structure. Furthermore, with its high nitrogen content it increases wettability of electrode and also increases the number of active sites available for pseudocapacitive reaction, thereby, enhancing the efficiency of electrode. Even though bulk GCN is not efficiently used in supercapacitor applications on account of its shortcomings like low surface area along with low conductivity nevertheless, it exhibited excellent mechanical stability (withstand elastic deformation without damaging structure) and flexibility. Hence studies are carrying out to alleviate the above-mentioned disadvantages either by modifying the structural network of GCN or by coupling with other nanocomposites. Strategies like synthesizing a nanoscale hybrid material possessing high electrical conductivity has proved as an efficient way of upsizing the electrochemical performance of materials. A single layer GCN faced limited application in high power performance supercapacitors as a result of their inherent stacking due to van der Waals force. Hence development of a facile composite of GCN with pseudocapacitive material is of more importance. The combination of two different materials possessing two different storage 22 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh mechanism leads to an enhancement in the performance through the formation of a new material due to synergistic effect. Therefore, herein we discussed about GCN composites with different carbon materials, some of transition metal oxides and conducting polymers. The different GCN binary nanocomposites with their diverse configuration and synergistic effects between the individual components leading to enhancement in surface area, redox reaction at the electrode-electrolyte interface, non-dissolution of electrode material into electrolyte during chare-discharge processes, in turn enhancing electrochemical behaviour which can be effectively used in supercapacitor as a robust material of high performance. Adhering to their superior features like stability, hydrophobicity along with high amount of nitrogen, these GCN and their composites exhibits excellent supercapacitive performance. However, there is a broad spectrum which has been left for research studies towards use of SCs in practical applications. There aren't many reports on composite of GCN with metal phosphides which left a space for further exploration. It is also expected that these different combinations of GCN with TMO/hydroxides, CPs, carbon materials and some other functional groups to enhance of electrochemical performance of SCs. Additionally, a ternary composite by the combination of GCN with two different materials also started grounding its roots towards application of supercapacitors. Nevertheless, more information about optimized synthesis temperature, different exfoliation methods, different template approaches and electrical conductivity towards alleviating the shortcomings of GCN can be well explored. Future scope can be assigned to development a theoretical computation towards understanding different mechanisms of GCN and GCN composites required to understand relationship between different electrochemical variables such as composition, actives sites. There exist one more direction in extending the development of GCN with different C/N ratios of 3:5, 3:6 and also 3:7 which may exhibit improved electrochemical performance. From the future prospective GCN opens an array of opportunities either in academic and industrial fields. We hope this present review gives an essence about GCN and its nanocomposites which could be a beacon for next generation of researchers in the field of supercapacitors. [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] Declaration of Competing Interest [23] The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. [24] References [25] [1] G. Wang, L. Zhang, J. Zhang, A review of electrode materials for electrochemical supercapacitors, Chem. Soc. Rev. 41 (2012) 797–828 https://doi.org/10.1039/ c1cs15060j. [2] M.A. Scibioh, B. Viswanathan, Supercapacitor: an introduction, Mater. Supercapacitor Appl. (2020) 1–13 https://doi.org/10.1016/b978-0-12-819858-2. 00001-9. [3] K. Li, X. Lu, Y. Zhang, K. Liu, Y. Huang, H. Liu, Bi3TaO7/Ti3C2 heterojunctions for enhanced photocatalytic removal of water-borne contaminants, Environ. Res. 185 (2020) 109409https://doi.org/10.1016/j.envres.2020.109409. [4] E. Kim, S. Kim, Y.M. Choi, J.H. Park, H. Shin, Ultra-Thin Hematite on Mesoporous WO3 from Atomic Layer Deposition for Minimal Charge Recombination, ACS Sustainable Chem. Eng. (2020), https://doi.org/10.1021/acssuschemeng. 0c03579. [5] A. González, E. Goikolea, J.A. Barrena, R. Mysyk, Review on supercapacitors: Technologies and materials, Renew. Sustain. Energy Rev. 58 (2016) 1189–1206 https://doi.org/10.1016/j.rser.2015.12.249. [6] S. Najib, E. Erdem, Current progress achieved in novel materials for supercapacitor electrodes: Mini review, Nanoscale Adv. 1 (2019) 2817–2827 https://doi.org/10. 1039/c9na00345b. [7] X. Li, B. Wei, Supercapacitors based on nanostructured carbon, Nano Energy 2 (2013) 159–173 https://doi.org/10.1016/j.nanoen.2012.09.008. [8] Y. Huang, H. Yang, T. Xiong, D. Adekoya, W. Qiu, Z. Wang, S. Zhang, M.S. Balogun, Adsorption energy engineering of nickel oxide hybrid nanosheets for high areal capacity flexible lithium-ion batteries, Energy Storage Mater. 25 (2020) 41–51 https://doi.org/10.1016/j.ensm.2019.11.001. [9] T. Xiong, H. Su, F. Yang, Q. Tan, P.B.S. Appadurai, A.A. Afuwape, K. Guo, [26] [27] [28] [29] [30] [31] [32] [33] 23 Y. Huang, Z. Wang, M.S. Jie, T. Balogun, Harmonizing Self-Supportive VN/MoS2 Pseudocapacitance Core-Shell Electrodes for Boosting the Areal Capacity of Lithium Storage, Mater. Today Energy (2020) 100461https://doi.org/10.1016/j. mtener.2020.100461. J. Dai, K. Fu, R. Palanisamy, A. Gong, G. Pastel, R. Kornfeld, H. Zhu, M. Sanghadasa, E. Bekyarova, L. Hu, A solid state energy storage device with supercapacitor-battery hybrid design, J, Mater. Chem. A. 5 (2017) 15266–15272 https://doi.org/10.1039/c7ta02638b. D.P. Dubal, O. Ayyad, V. Ruiz, Hybrid energy storage: the merging of battery and supercapacitor chemistries, Chem. Soc. Rev. 44 (2015) 1777–1790 https://doi. org/10.1039/C4CS00266K. L.D. Chen, Y.Q. Zheng, H.L. Zhu, Manganese oxides derived from Mn(II)-based metal – organic framework as supercapacitor electrode materials, J. Mater. Sci. 53 (2017) 1346–1355 https://doi.org/10.1007/s10853-017-1575-7. Y.Z. Song, R.X. Zhao, K.K. Zhang, J.J. Ding, X.M. Lv, M. Chen, J.M. Xie, Facile synthesis of Mn3O4/double-walled carbon nanotube nanocomposites and its excellent supercapacitive behavior, Electrochim. Acta 230 (2017) 350–357 https:// doi.org/10.1016/j.electacta.2017.02.024. S.H. Kazemi, M.A. Kiani, M. Ghaemmaghami, H. Kazemi, Nano-architectured MnO2 Electrodeposited on the Cu-decorated Nickel Foam substrate as Supercapacitor Electrode with Excellent Areal Capacitance, Electrochim. Acta. 197 (2016) 107–116 https://doi.org/10.1016/j.electacta.2016.03.063. L. Yu, L. Hu, B. Anasori, Y.T. Liu, Q. Zhu, P. Zhang, Y. Gogotsi, B. Xu, MXeneBonded Activated Carbon as a Flexible Electrode for High-Performance Supercapacitors, ACS Energy Lett. 3 (2018) (2018) 1597–1603 https://doi.org/10. 1021/acsenergylett.8b00718. D. Jiang, Q. Xu, S. Meng, C. Xia, M. Chen, Construction of cobalt sulfide/graphitic carbon nitride hybrid nanosheet composites for high performance supercapacitor electrodes, J. Alloys Compd. 706 (2017) 41–47 https://doi.org/10.1016/j.jallcom. 2017.02.204. Z.S. Iro, C. Subramani, S.S. Dash, A brief review on electrode materials for supercapacitor, Int. J. Electrochem. Sci. 11 (2016) 10628–10643 https://doi.org/10. 20964/2016.12.50. A. Borenstein, O. Hanna, R. Attias, S. Luski, T. Brousse, D. Aurbach, Carbon-based composite materials for supercapacitor electrodes: A review, J. Mater. Chem. A 5 (2017) 12653–12672 https://doi.org/10.1039/c7ta00863e. C.H. Choi, S.H. Park, S.I. Woo, Binary and ternary doping of nitrogen, boron, and phosphorus into carbon for enhancing electrochemical oxygen reduction activity, ACS Nano 6 (2012) 7084–7091 https://doi.org/10.1021/nn3021234. Z.J. Han, C. Huang, S.S. Meysami, D. Piche, D.H. Seo, S. Pineda, A.T. Murdock, P.S. Bruce, P.S. Grant, N. Grobert, High-frequency supercapacitors based on doped carbon nanostructures, Carbon 126 (2018) 305–312 https://doi.org/10.1016/j. carbon.2017.10.014. R. Lin, Z. Li, D.I. Abou El Amaiem, B. Zhang, D.J.L. Brett, G. He, I.P. Parkin, A general method for boosting the supercapacitor performance of graphitic carbon nitride/graphene hybrids, J. Mater. Chem. A. 5 (2017) 25545–25554 https://doi. org/10.1039/c7ta09492b. W. Liu, Y. Li, F. Liu, W. Jiang, D. Zhang, J. Liang, Visible-light-driven photocatalytic degradation of diclofenac by carbon quantum dots modified porous gC3N4: Mechanisms, degradation pathway and DFT calculation, Water Res. 150 (2019) 431–441 https://doi.org/10.1016/j.watres.2018.12.001. N. Rono, J.K. Kibet, B.S. Martincigh, V.O. Nyamori, A review of the current status of graphitic carbon nitride, Crit. Rev. Solid State Mater. Sci. (2020) 1–29 https:// doi.org/10.1080/10408436.2019.1709414. Y. Luo, Y. Yan, S. Zheng, H. Xue, H. Pang, Graphitic carbon nitride based materials for electrochemical energy storage, J. Mater. Chem. A. 7 (2019) 901–924 https:// doi.org/10.1039/c8ta08464e. A. Wang, C. Wang, L. Fu, W. Wong-Ng, Y. Lan, Recent Advances of Graphitic Carbon Nitride-Based Structures and Applications in Catalyst, Sensing, Imaging, and LEDs, Nano-Micro Lett. 9 (2017) 47 https://doi.org/10.1007/s40820-0170148-2. Z. Zhou, Y. Zhang, Y. Shen, S. Liu, Y. Zhang, Molecular engineering of polymeric carbon nitride: Advancing applications from photocatalysis to biosensing and more, Chem. Soc. Rev. 47 (2018) 2298–2321 https://doi.org/10.1039/ c7cs00840f. L. Chen, J. Song, Tailored Graphitic Carbon Nitride Nanostructures: Synthesis, Modification, and Sensing Applications, Adv. Funct. Mater. 27 (2017) 1–15 https://doi.org/10.1002/adfm.201702695. Y. Yang, J. Chen, Z. Mao, N. An, D. Wang, B.D. Fahlman, Ultrathin g-C3N4 nanosheets with an extended visible-light-responsive range for significant enhancement of photocatalysis, RSC Adv. 7 (2017) 2333–2341 https://doi.org/10.1039/ c6ra26172h. Y. Zheng, J. Liu, J. Liang, M. Jaroniec, S.Z. Qiao, Graphitic carbon nitride materials: Controllable synthesis and applications in fuel cells and photocatalysis, Energy Environ. Sci. 5 (2012) 6717–6731 https://doi.org/10.1039/c2ee03479d. J. Zhu, P. Xiao, H. Li, S.A.C. Carabineiro, Graphitic carbon nitride: Synthesis, properties, and applications in catalysis, ACS Appl. Mater. Interfaces 6 (2014) 16449–16465 https://doi.org/10.1021/am502925j. D.M. Teter, R.J. Hemley, Low-compressibility carbon nitrides, Science 271 (1996) 53–55 https://doi.org/10.1126/science.271.5245.53. C. Merschjann, S. Tschierlei, T. Tyborski, K. Kailasam, S. Orthmann, D. Hollmann, T. Schedel-Niedrig, A. Thomas, S. Lochbrunner, Complementing Graphenes: 1D Interplanar Charge Transport in Polymeric Graphitic Carbon Nitrides, Adv. Mater. 27 (2015) 7993–7999 https://doi.org/10.1002/adma.201503448. K. Qi, S. yuan Liu, A. Zada, Graphitic carbon nitride, a polymer photocatalyst, J. Taiwan Inst. Chem. Eng. 109 (2020) 111–123 https://doi.org/10.1016/j.jtice. Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh 2020.02.012. [34] Y. Xu, S.P. Gao, Band gap of C3N4 in the GW approximation, Int. J. Hydrogen Energy 37 (2012) 11072–11080 https://doi.org/10.1016/j.ijhydene.2012.04.138. [35] J. Liu, T. Zhang, Z. Wang, G. Dawson, W. Chen, Simple pyrolysis of urea into graphitic carbon nitride with recyclable adsorption and photocatalytic activity, J, Mater. Chem. 21 (2011) 14398–14401 https://doi.org/10.1039/c1jm12620b. [36] J. Liu, W. Li, L. Duan, X. Li, L. Ji, Z. Geng, K. Huang, L. Lu, L. Zhou, Z. Liu, W. Chen, L. Liu, S. Feng, Y. Zhang, A Graphene-like Oxygenated Carbon Nitride Material for Improved Cycle-Life Lithium/Sulfur Batteries, Nano Lett. 15 (2015) 5137–5142 https://doi.org/10.1021/acs.nanolett.5b01919. [37] H.L. Guo, P. Su, X. Kang, S.K. Ning, Synthesis and characterization of nitrogendoped graphene hydrogels by hydrothermal route with urea as reducing-doping agents, J. Mater. Chem. A. 1 (2013) 2248–2255 https://doi.org/10.1039/ c2ta00887d. [38] H. Bin Fang, Y. Luo, Y.Z. Zheng, W. Ma, X. Tao, Facile Large-Scale Synthesis of Urea-Derived Porous Graphitic Carbon Nitride with Extraordinary Visible-Light Spectrum Photodegradation, Ind. Eng. Chem. Res. 55 (2016) 4506–4514 https:// doi.org/10.1021/acs.iecr.6b00041. [39] X.X. Zou, G.D. Li, Y.N. Wang, J. Zhao, C. Yan, M.Y. Guo, L. Li, J.S. Chen, Direct conversion of urea into graphitic carbon nitride over mesoporous TiO2 spheres under mild condition, Chem. Commun. 47 (2011) 1066–1068 https://doi.org/10. 1039/c0cc03530k. [40] L. Shi, L. Liang, F. Wang, M. Liu, K. Chen, K. Sun, N. Zhang, J. Sun, Higher Yield Urea-Derived Polymeric Graphitic Carbon Nitride with Mesoporous Structure and Superior Visible-Light-Responsive Activity, ACS Sustain. Chem. Eng. 3 (2015) 3412–3419 https://doi.org/10.1021/acssuschemeng.5b01139. [41] Z. Tong, D. Yang, Z. Li, Y. Nan, F. Ding, Y. Shen, Z. Jiang, Thylakoid-Inspired Multishell g-C3N4 Nanocapsules with Enhanced Visible-Light Harvesting and Electron Transfer Properties for High-Efficiency Photocatalysis, ACS Nano 11 (2017) 1103–1112 https://doi.org/10.1021/acsnano.6b08251. [42] Y. Shiraishi, S. Kanazawa, Y. Sugano, D. Tsukamoto, H. Sakamoto, S. Ichikawa, T. Hirai, Highly selective production of hydrogen peroxide on graphitic carbon nitride (g-C3N4) photocatalyst activated by visible light, ACS Catal. 4 (2014) 774–780 https://doi.org/10.1021/cs401208c. [43] J. Xiao, Y. Xie, F. Nawaz, Y. Wang, P. Du, H. Cao, Dramatic coupling of visible light with ozone on honeycomb-like porous g-C3N4 towards superior oxidation of water pollutants, Appl. Catal. B Environ. 183 (2016) 417–425 https://doi.org/10. 1016/j.apcatb.2015.11.010. [44] K. Wang, Q. Li, B. Liu, B. Cheng, W. Ho, J. Yu, Sulfur-doped g-C3N4 with enhanced photocatalytic CO2-reduction performance, Appl. Catal. B Environ. 176–177 (2015) 44–52 https://doi.org/10.1016/j.apcatb.2015.03.045. [45] L. Shi, T. Wang, H. Zhang, K. Chang, J. Ye, Electrostatic Self-Assembly of Nanosized Carbon Nitride Nanosheet onto a Zirconium Metal-Organic Framework for Enhanced Photocatalytic CO2 Reduction, Adv. Funct. Mater. 25 (2015) 5360–5367 https://doi.org/10.1002/adfm.201502253. [46] J. Fang, H. Fan, M. Li, C. Long, Nitrogen self-doped graphitic carbon nitride as efficient visible light photocatalyst for hydrogen evolution, J. Mater. Chem. A. 3 (2015) 13819–13826 https://doi.org/10.1039/c5ta02257f. [47] G. Liu, T. Wang, H. Zhang, X. Meng, D. Hao, K. Chang, P. Li, T. Kako, J. Ye, NatureInspired Environmental “Phosphorylation” Boosts Photocatalytic H2 Production over Carbon Nitride Nanosheets under Visible-Light Irradiation, Angew. Chemie. 127 (2015) 13765–13769 https://doi.org/10.1002/ange.201505802. [48] T.Y. Ma, Y. Tang, S. Dai, S.Z. Qiao, Proton-functionalized two-dimensional graphitic carbon nitride nanosheet: An excellent metal-/label-free biosensing platform, Small 10 (2014) 2382–2389 https://doi.org/10.1002/smll.201303827. [49] J. Xu, H.T. Wu, X. Wang, B. Xue, Y.X. Li, Y. Cao, A new and environmentally benign precursor for the synthesis of mesoporous g-C3N4 with tunable surface area, Phys. Chem. Chem. Phys. 15 (2013) 4510–4517 https://doi.org/10.1039/ c3cp44402c. [50] Y. Zhang, H. Gong, G. Li, H. Zeng, L. Zhong, K. Liu, H. Cao, H. Yan, Synthesis of graphitic carbon nitride by heating mixture of urea and thiourea for enhanced photocatalytic H2 production from water under visible light, Int. J. Hydrogen Energy 42 (2017) 143–151 https://doi.org/10.1016/j.ijhydene.2016.11.040. [51] Y. Zhao, J. Zhang, L. Qu, Graphitic Carbon Nitride/Graphene Hybrids as New Active Materials for Energy Conversion and Storage, ChemNanoMat 1 (2015) 298–318 https://doi.org/10.1002/cnma.201500060. [52] J. Libich, J. Máca, J. Vondrák, O. Čech, M. Sedlaříková, Supercapacitors: Properties and applications, J. Energy Storage 17 (2018) 224–227 https://doi.org/ 10.1016/j.est.2018.03.012. [53] E.E. Miller, Y. Hua, F.H. Tezel, Materials for energy storage: Review of electrode materials and methods of increasing capacitance for supercapacitors, J. Energy Storage 20 (2018) 30–40 https://doi.org/10.1016/j.est.2018.08.009. [54] C.V.V. Muralee Gopi, R. Vinodh, S. Sambasivam, I.M. Obaidat, H.J. Kim, Recent progress of advanced energy storage materials for flexible and wearable supercapacitor: From design and development to applications, J. Energy Storage 27 (2020) 101035https://doi.org/10.1016/j.est.2019.101035. [55] A. Afif, S.M. Rahman, A. Tasfiah Azad, J. Zaini, M.A. Islan, A.K. Azad, Advanced materials and technologies for hybrid supercapacitors for energy storage – A review, J. Energy Storage 25 (2019) 100852https://doi.org/10.1016/j.est.2019. 100852. [56] Y. Zhang, H. Feng, X. Wu, L. Wang, A. Zhang, T. Xia, H. Dong, X. Li, L. Zhang, Progress of electrochemical capacitor electrode materials: A review, Int. J. Hydrogen Energy 34 (2009) 4889–4899 https://doi.org/10.1016/j.ijhydene.2009. 04.005. [57] M.A. Scibioh, B. Viswanathan, Fundamentals and energy storage mechanismoverview, Mater. Supercapacitor Appl. (2020) 15–33 https://doi.org/10.1016/ B978-0-12-819858-2.00002-0. [58] K.K. Kar, Handbook of Nanocomposite Supercapacitor Materials I, Springer Series Mater. Sci. (2020), https://doi.org/10.1007/978-3-030-43009-2. [59] C. Lu, D. Wang, J. Zhao, S. Han, W. Chen, A Continuous Carbon Nitride Polyhedron Assembly for High-Performance Flexible Supercapacitors, Adv. Funct. Mater. 27 (2017) 1606219https://doi.org/10.1002/adfm.201606219. [60] R. Lin, Z. Li, D.I. Abou El Amaiem, B. Zhang, D.J.L. Brett, G. He, I.P. Parkin, A general method for boosting the supercapacitor performance of graphitic carbon nitride/graphene hybrids, J. Mater. Chem. A. 5 (2017) 25545–25554 https://doi. org/10.1039/c7ta09492b. [61] J. Zhu, L. Kong, X. Shen, H. Zhou, G. Zhu, Z. Ji, K. Xu, S.A. Shah, Nitrogen-enriched carbon spheres coupled with graphitic carbon nitride nanosheets for high performance supercapacitors, Dalt. Trans. 47 (2018) 9724–9732 https://doi.org/ 10.1039/c8dt01549j. [62] Y.X. Gan, A.H. Jayatissa, Z. Yu, X. Chen, M. Li, Hydrothermal Synthesis of Nanomaterials, J. Nanomater. (2020) (2020) 8917013https://doi.org/10.1155/ 2020/8917013. [63] A.A. Ensafi, M.M. Abarghoui, B. Rezaei, Graphitic carbon nitride nanosheets coated with Ni2CoS4 nanoparticles as a high-rate electrode material for supercapacitor application, Ceram. Int. 45 (2019) 8518–8524 https://doi.org/10.1016/ j.ceramint.2019.01.165. [64] Y. Xu, L. Wang, Y. Zhou, J. Guo, S. Zhang, Y. Lu, Synthesis of heterostructure SnO2/graphitic carbon nitride composite for high-performance electrochemical supercapacitor, J. Electroanal. Chem. 852 (2019) 113507https://doi.org/10. 1016/j.jelechem.2019.113507. [65] S.A. Ansari, M.H. Cho, Growth of three-dimensional flower-like SnS2 on g-C3N4 sheets as an efficient visible-light photocatalyst, photoelectrode, and electrochemical supercapacitance material, Sustain. Energy Fuels 1 (2017) 510–519 https://doi.org/10.1039/c6se00049e. [66] A.V. Rane, K. Kanny, V.K. Abitha, S. Thomas, Methods for Synthesis of Nanoparticles and Fabrication of Nanocomposites, Synthesis of Inorganic, Nanomaterials (2018) 121–139 https://doi.org/10.1016/b978-0-08-101975-7. 00005-1. [67] V. Ragupathi, P. Panigrahi, N. Ganapathi Subramaniam, g-C3N4 doped MnS as high performance electrode material for supercapacitor application, Mater. Lett. 246 (2019) 88–91 https://doi.org/10.1016/j.matlet.2019.03.054. [68] W.K. Chee, H.N. Lim, Z. Zainal, N.M. Huang, I. Harrison, Y. Andou, Flexible Graphene-Based Supercapacitors: A Review, J. Phys. Chem. C. 120 (2016) 4153–4172 https://doi.org/10.1021/acs.jpcc.5b10187. [69] M. Tahir, C. Cao, N. Mahmood, F.K. Butt, A. Mahmood, F. Idrees, S. Hussain, M. Tanveer, I. Aslam, Multifunctional g-C3N4 Nanofibers A Template-Free Fabrication and Enhanced Optical, Electrochemical, and Photocatalyst Properties, ACS Appl. Mater. Interfaces 6 (2014) 1258–1265 https://doi.org/10.1021/ am405076b. [70] M. Tahir, C. Cao, F.K. Butt, F. Idrees, N. Mahmood, Z. Ali, I. Aslam, M. Tanvir, M. Rizwan, T. Mahmood, Tubular graphitic-CN, A Prospective material for energy storage and green photocatalyst, J. Mater. Chem. A. 1 (2013) 13949–13955 https://doi.org/10.1039/C3TA13291A. [71] X. Zhang, H. Liao, X. Liu, R. Shang, Y. Zhou, Y. Zhou, Graphitic carbon nitride nanosheets made by different methods as electrode material for supercapacitors, Ionics 26 (2020) 3599–3607 https://doi.org/10.1007/s11581-020-03458-z. [72] C. Shen, R. Li, L. Yan, Y. Shi, H. Guo, J. Zhang, Y. Lin, Z. Zhang, Y. Gong, L. Niu, Rational design of activated carbon nitride materials for symmetric supercapacitor applications, Appl. Surf. Sci. 455 (2018) 841–848 https://doi.org/10.1016/j. apsusc.2018.06.065. [73] R. Gonçalves, T.M. Lima, M.W. Paixão, E.C. Pereira, Pristine carbon nitride as active material for high-performance metal-free supercapacitors: Simple, easy and cheap, RSC Adv. 8 (2018) 35327–35336 https://doi.org/10.1039/c8ra06656f. [74] M.B. Idris, D. Sappani, Unveiling Mesoporous Graphitic Carbon Nitride as a High Performance Electrode Material for Supercapacitors, ChemistrySelect 3 (2018) 11258–11269 https://doi.org/10.1002/slct.201801752. [75] Q. Chen, Y. Zhao, X. Huang, N. Chen, L. Qu, Three-Dimensional Graphitic Carbon Nitride Functionalized GrapheneBased High-Performance Supercapacitors, J. Mater. Chem. A. 3 (2015) 6761–6766 https://doi.org/10.1039/C5TA00734H. [76] P. Wen, P. Gong, J. Sun, J. Wang, S. Yang, Design and synthesis of Ni-MOF/CNT composites and rGO/carbon nitride composites for an asymmetric supercapacitor with high energy and power density, J. Mater. Chem. A. 3 (2015) 13874–13883 https://doi.org/10.1039/c5ta02461g. [77] Y. Ding, Y. Tang, L. Yang, Y. Zeng, J. Yuan, T. Liu, S. Zhang, C. Liu, S. Luo, Porous nitrogen-rich carbon materials from carbon self-repairing g-C3N4 assembled with graphene for high-performance supercapacitor, J. Mater. Chem. A. 4 (2016) 14307–14315 https://doi.org/10.1039/c6ta05267c. [78] T. Oh, M. Kim, J. Choi, J. Kim, Design of graphitic carbon nitride nanowires with captured mesoporous carbon spheres for EDLC electrode materials, Ionics 24 (2018) 3957–3965 https://doi.org/10.1007/s11581-018-2544-0. [79] J. Zhu, L. Kong, X. Shen, G. Zhu, Z. Ji, K. Xu, H. Zhou, X. Yue, B. Li, Carbon cloth supported graphitic carbon nitride nanosheets as advanced binder-free electrodes for supercapacitors, J. Electroanal. Chem. 873 (2020) 114390https://doi.org/10. 1016/j.jelechem.2020.114390. [80] C. Lu, Y. Yang, X. Chen, Ultra-Thin Conductive Graphitic Carbon Nitride Assembly through van der Waals Epitaxy toward High-Energy-Density Flexible Supercapacitors, Nano Lett. 19 (2019) 4103–4111 https://doi.org/10.1021/acs. nanolett.9b01511. [81] Y. Wang, J. Guo, T. Wang, J. Shao, D. Wang, Y.W. Yang, Mesoporous transition metal oxides for supercapacitors, Nanomaterials 5 (2015) 1667–1689 https://doi. org/10.3390/nano5041667. 24 Journal of Energy Storage 32 (2020) 101840 M.G. Ashritha and K. Hareesh [82] W. Xu, T.T. Li, Y.Q. Zheng, Porous Co3O4 nanoparticles derived from a Co(II)cyclohexanehexacarboxylate metal-organic framework and used in a supercapacitor with good cycling stability, RSC Adv. 6 (2016) 86447–86454 https:// doi.org/10.1039/c6ra17471j. [83] M.A. Scibioh, B. Viswanathan, Electrode materials for supercapacitors, Mater. Supercapacitor Appl. (2020) 35–204 https://doi.org/10.1016/B978-0-12-8198582.00003-2. [84] F. Shi, L. Li, X.L. Wang, C.D. Gu, J.P. Tu, Metal oxide/hydroxide-based materials for supercapacitors, RSC Adv. 4 (2014) 41910–41921 https://doi.org/10.1039/ c4ra06136e. [85] L. Shi, J. Zhang, H. Liu, M. Que, X. Cai, S. Tan, L. Huang, Flower-like Ni(OH)2 hybridized g-C3N4 for high-performance supercapacitor electrode material, Mater. Lett. 145 (2015) 150–153 https://doi.org/10.1016/j.matlet.2015.01.083. [86] L. Zhang, M. Ou, H. Yao, Z. Li, D. Qu, F. Liu, J. Wang, J. Wang, Z. Li, Enhanced supercapacitive performance of graphite-like C3N4 assembled with NiAl-layered double hydroxide, Electrochim. Acta. 186 (2015) 292–301 https://doi.org/10. 1016/j.electacta.2015.10.192. [87] L. Li, J. Qin, H. Bi, S. Gai, F. He, P. Gao, Y. Dai, X. Zhang, D. Yang, P. Yang, Ni (OH)2 nanosheets grown on porous hybrid g-C3N4/RGO network as high performance supercapacitor electrode, Sci. Rep. 7 (2017) 43413 https://doi.org/10. 1038/srep43413. [88] Q.Y. Shan, B. Guan, S.J. Zhu, H.J. Zhang, Y.X. Zhang, Facile synthesis of carbondoped graphitic C3N4@MnO2 with enhanced electrochemical performance, RSC Adv. 6 (2016) 83209–83216 https://doi.org/10.1039/C6RA18265H. [89] Q.Y. Shan, X.L. Guo, F. Dong, Y.X. Zhang, Single atom (K/Na) doped graphitic carbon Nitride@MnO2 as an efficient electrode Material for supercapacitor, Mater. Lett. 202 (2017) 103–106 https://doi.org/10.1016/j.matlet.2017.05.061. [90] X. Chang, X. Zhai, S. Sun, D. Gu, L. Dong, Y. Yin, Y. Zhu, MnO2/g-C3N4 nanocomposite with highly enhanced supercapacitor performance, Nanotechnology 28 (2017) 135705https://doi.org/10.1088/1361-6528/aa6107. [91] B. Guan, Q.Y. Shan, H. Chen, D. Xue, K. Chen, Y.X. Zhang, Morphology Dependent Supercapacitance of Nanostructured NiCo2O4 on Graphitic Carbon Nitride, Electrochim. Acta. 200 (2016) 239–246 https://doi.org/10.1016/j.electacta.2016. 03.175. [92] B. Dong, M. Li, S. Chen, D. Ding, W. Wei, G. Gao, S. Ding, Formation of g-C3N4 @ Ni(OH)2 Honeycomb Nanostructure and Asymmetric Supercapacitor with High Energy and Power Density, ACS Appl. Mater. Interfaces 9 (2017) 17890–17896 https://doi.org/10.1021/acsami.7b02693.s001. [93] L. Liu, J. Wang, C. Wang, G. Wang, Facile synthesis of graphitic carbon nitride/ nanostructured α-Fe2O3 composites and their excellent electrochemical performance for supercapacitor and enzyme-free glucose detection applications, Appl. Surf. Sci. 390 (2016) 303–310 https://doi.org/10.1016/j.apsusc.2016.08.093. [94] S.V.P. Vattikuti, B.P. Reddy, C. Byon, J. Shim, Carbon/CuO nanosphere-anchored g-C3N4 nanosheets as ternary electrode material for supercapacitors, J. Solid State Chem. 262 (2018) 106–111 https://doi.org/10.1016/j.jssc.2018.03.019. [95] H.L. Zhu, Y.Q. Zheng, Mesoporous Co3O4 anchored on the graphitic carbon nitride for enhanced performance supercapacitor, Electrochim. Acta. 265 (2018) 372–378 https://doi.org/10.1016/j.electacta.2018.01.162. [96] J. Zhang, J. Ding, C. Li, B. Li, D. Li, Z. Liu, Q. Cai, J. Zhang, Y. Liu, Fabrication of Novel Ternary Three-Dimensional RuO2/Graphitic-C3N4@reduced Graphene Oxide Aerogel Composites for Supercapacitors, ACS Sustain. Chem. Eng. 5 (2017) 4982–4991 https://doi.org/10.1021/acssuschemeng.7b00358. [97] Y. Zhao, L. Xu, S. Huang, J. Bao, J. Qiu, J. Lian, L. Xu, Y. Huang, Y. Xu, H. Li, Facile preparation of TiO2/C3N4 hybrid materials with enhanced capacitive properties for high performance supercapacitors, J. Alloys Compd. 702 (2017) 178–185 https://doi.org/10.1016/j.jallcom.2017.01.125. [98] J. Kavil, P.M. Anjana, P. Periyat, R.B. Rakhi, Titania nanotubes dispersed graphitic carbon nitride nanosheets as efficient electrode materials for supercapacitors, J. Mater. Sci. Mater. Electron. 29 (2018) 16598–16608 https://doi.org/10.1007/ s10854-018-9753-1. [99] J. Kavil, P.M. Anjana, P. Periyat, R.B. Rakhi, One-pot synthesis of g-C3N4/MnO2 and g-C3N4/SnO2 hybrid nanocomposites for supercapacitor applications, Sustain. Energy Fuels 2 (2018) 2244–2251 https://doi.org/10.1039/C8SE00279G. [100] X. Zhang, H. Liao, X. Liu, R. Shang, Y. Zhou, Y. Zhou, Facile synthesis of Fe2O3 nanospheres anchored on oxidized graphitic carbon nitride as a high-performance electrode material for supercapacitors, Int. J. Electrochem. Sci. 15 (2020) 2133–2144 https://doi.org/10.20964/2020.03.54. [101] J. Shen, P. Wang, H. Jiang, H. Wang, B.G. Pollet, R. Wang, S. Ji, MOF derived graphitic carbon nitride/oxygen vacancies-rich zinc oxide nanocomposites with enhanced supercapacitive performance, Ionics (2020) 1–11 https://doi.org/10. 1007/s11581-020-03597-3. [102] L. Hou, W. Yang, X. Xu, B. Deng, J. Tian, S. Wang, F. Yang, Y. Li, In-situ formation of oxygen-vacancy-rich NiCo2O4/nitrogen-deficient graphitic carbon nitride hybrids for high-performance supercapacitors, Electrochim. Acta. 340 (2020) 135996https://doi.org/10.1016/j.electacta.2020.135996. [103] X. Rui, H. Tan, Q. Yan, Nanostructured metal sulfides for energy storage, Nanoscale 6 (2014) 9889–9924 https://doi.org/10.1039/c4nr03057e. [104] X. Xu, W. Liu, Y. Kim, J. Cho, Nanostructured transition metal sulfides for lithium ion batteries: Progress and challenges, Nano Today 9 (2014) 604–630 https://doi. org/10.1016/j.nantod.2014.09.005. [105] P. Geng, S. Zheng, H. Tang, R. Zhu, L. Zhang, S. Cao, Transition Metal Sulfides Based on Graphene for Electrochemical Energy Storage, Adv. Energy Mater. 8 (2018) 1703259https://doi.org/10.1002/aenm.201703259. [106] X.Y. Yu, X.W. (David) Lou, Mixed Metal Sulfides for Electrochemical Energy Storage and Conversion, Adv. Energy Mater. 8 (2018) 1701592https://doi.org/10. 1002/aenm.201701592. [107] N. Parveen, S.A. Ansari, S.G. Ansari, H. Fouad, N.M. Abd El-Salam, M.H. Cho, Solid-state symmetrical supercapacitor based on hierarchical flower-like nickel sulfide with shape-controlled morphological evolution, Electrochim. Acta. 268 (2018) 82–93 https://doi.org/10.1016/j.electacta.2018.01.100. [108] W. Guo, J. Wang, C. Fan, Z. Chen, P. Liu, D. Zhu, Z. Xu, L. Pang, T. Li, Synthesis of Carbon Self-Repairing Porous g-C3N4 Nanosheets/NiCo2S4 Nanoparticles Hybrid Composite as High-Performance Electrode Materials for Supercapacitors, Electrochim. Acta. 253 (2017) 68–77 https://doi.org/10.1016/j.electacta.2017. 09.025. [109] Z. Li, L. Wu, L. Wang, A. Gu, Q. Zhou, Nickel cobalt sulfide nanosheets uniformly anchored on porous graphitic carbon nitride for supercapacitors with high cycling performance, Electrochim. Acta. 231 (2017) 617–625 https://doi.org/10.1016/j. electacta.2017.02.087. [110] S.A. Ansari, M.H. Cho, Simple and Large Scale Construction of MoS2-g-C3N4 Heterostructures Using Mechanochemistry for High Performance Electrochemical Supercapacitor and Visible Light Photocatalytic Applications, Sci. Rep. 7 (2017) 1–11 https://doi.org/10.1038/srep43055. [111] G.A. Snook, P. Kao, A.S. Best, Conducting-polymer-based supercapacitor devices and electrodes, J. Power Sources 196 (2011) 1–12 https://doi.org/10.1016/j. jpowsour.2010.06.084. [112] Q. Meng, K. Cai, Y. Chen, L. Chen, Research progress on conducting polymer based supercapacitor electrode materials, Nano Energy 36 (2017) 268–285 https://doi. org/10.1016/j.nanoen.2017.04.040. [113] A. Malinauskas, J. Malinauskiene, A. Ramanavičius, Conducting polymer-based nanostructurized materials: Electrochemical aspects, Nanotechnology 16 (2005) R51 https://doi.org/10.1088/0957-4484/16/10/R01. [114] X. Chen, X. Zhu, Y. Xiao, X. Yang, PEDOT/g-C3N4 binary electrode material for supercapacitors, J. Electroanal. Chem. 743 (2015) 99–104 https://doi.org/10. 1016/j.jelechem.2015.02.004. [115] S.X. Zhou, X.Y. Tao, J. Ma, L.T. Guo, Y.B. Zhu, H.L. Fan, Z.S. Liu, X.Y. Wei, Synthesis of flower-like PANI/g-C3N4 nanocomposite as supercapacitor electrode, Vacuum 149 (2018) 175–179 https://doi.org/10.1016/j.vacuum.2017.12.019. [116] F. Li, Y. Dong, Q. Dai, T.T. Nguyen, M. Guo, Novel freestanding core-shell nanofibrillated cellulose/ polypyrrole/tubular graphitic carbon nitride composite film for supercapacitors electrodes, Vacuum 161 (2019) 283–290 https://doi.org/10. 1016/j.vacuum.2018.12.046. [117] A. Alshahrie, M.O. Ansari, High Performance Supercapacitor Applications and DC Electrical Conductivity Retention on Surfactant Immobilized Macroporous Ternary Polypyrrole/Graphitic-C3N4@Graphene Nanocomposite, Electron. Mater. Lett. 15 (2019) 238–246 https://doi.org/10.1007/s13391-018-00107-6. [118] S.A. Ansari, M.O. Ansari, M.H. Cho, Facile and Scale Up Synthesis of Red Phosphorus-Graphitic Carbon Nitride Heterostructures for Energy and Environment Applications, Sci. Rep. 6 (2016) 1–12 https://doi.org/10.1038/ srep27713. [119] B. M, B. S, Zinc antimonate nanorods integrated porous graphitic carbon nitride nanosheets as hybrid electrode materials for supercapacitors, Diam. Relat. Mater. 97 (2019) 107460https://doi.org/10.1016/j.diamond.2019.107460. [120] S.S. Siwal, Q. Zhang, C. Sun, V.K. Thakur, Graphitic carbon nitride doped copper–manganese alloy as high–performance electrode material in supercapacitor for energy storage, Nanomaterials 10 (2020) 2 https://doi.org/10.3390/ nano10010002. [121] M. Talukdar, S.K. Behera, P. Deb, Graphitic carbon nitride decorated with FeNi3 nanoparticles for flexible planar micro-supercapacitor with ultrahigh energy density and quantum storage capacity, Dalt. Trans. 48 (2019) 12137–12146 https://doi.org/10.1039/c9dt02423a. 25