I

,.

@oo ®rP

manual

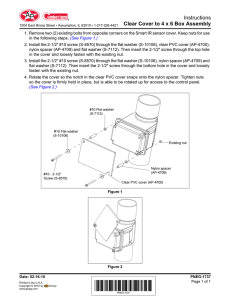

D

~- ,"· ·· · ski-da

_'II®

~

I

.

)

'

,

I

I

·"

·- .

-

.

•'

;

"

-

.

·

.:

,

. .

.

~

-.

.

- u~

Quality

Service

Legal deposit :

National Library of Quebec

4th trimester 1988

National Library of Canada

All rights reserved. No parts of this manual may be reproduced in any form without the prior written permission of Bombardier Inc.

©Bombardier Inc. 1988

Printed in Canada

®*Registered trademarks of Bombardier Inc.

Loctite® is a trademark of Loctite Corporation

Metton TM is a trademark of Hercules Inc.

Molykote® is a trademark of Dow Corning Corporation

Posidriv® ia a trademark of Phillips Screw Company

Silastic® ia a trademark of Dow Corning Corporation

Snap-on® ia a trademark of Snap-on Tools Corporation

Versilube® ia a trademark of General Electric Company

TABLE OF CONTENTS

SECTION

SUB-SECTION

PAGE

01

TOOLS

.01 - Basic tools

02 - Service tools

03 - Service products

01-01-1

01-02-1

01-03-1

02

ENGINE

01

02

03

04

05

06

07

08

09

10

11

247 Engine type

253 Engine type

377 Engine type

467 Engine type

503 Engine type

536 Engine type

583 Engine type

Rewind starter

Engine dimensions measurement

Carburetor and fuel pump

Air intake silencer and fuel tank

02-01-1

02-02-1

02-03-1

02-04-1

02-05-1

02-06-1

02-07-1

02-08-1

02-09-1

02-1 0-1

02-11-1

03

TRANSMISSION

01 ·_

02 03 04 05 06 07 0809 -

Pulley guard

Drive belt

Drive pulley

Driven pulley

Pulley alignment

Brake

Chaincase

Gearbox

Drive chain

03-01-1

03-02-1

03-03-1

03-04-1

03-05-1

03-06-1

03-07-1

03-08-1

03-09-1

04

ELECTRICAL

01

02

03

04

05

06

-

Wiring diagrams

Ignition timing

Spark plugs

Battery

Electric starter

Testing procedure

04-01 - 1

04-02-1

04-03-1

04-04-1

04-05-1

04-06-1

05

SUSPENSION

01

02

03

04

05

06

07

08

09

10

- Bogie wheel

- Slide suspension

- TRS 6 suspension

- SP suspension

- PRS suspension

-· Monoshock PRS suspension

- Hinged suspension

- Rear axle

- Drive axle

- Track

06

STEERING /SKIS

01 - Steering system

02 - Ski system

06-01 -1 .

06-02-1

07

BODY /FRAME

01 - Body

02 - Frame

07-01 -1

07-02- i

08

TECHNICAL DATA

,.-

-

05-01 - 1

05-02- 1

05-03-1

05-04-1

05-05- 1

05-06- 1

05-07- 1

05-08-1

05-09- 1

05- 10-1

08-00-1

r

c

SAFETY NOTICE

This manual has been prepared as a guide to correctly service and repair 1989 Ski-Doo

snowmobiles.

This edition was primarily published to be used by snowmobile mechanics who are already

familiar with all service procedures relating to Bombardier made snowmobiles.

Please note that the instructions will apply only if proper hand tools and special service tools

are used.

This shop manual uses technical terms which may be slightly different from the ones used

in parts catalog.

The content depicts parts and I or procedures applicable to the particular product at its

time of manufacture. It does not include dealer modifications, whether authorized or not

by Bombardier, after manufacturing the product.

In addition, the sole purpose of the illustrations/photographs throughout the manual, is to assist

identification of the general configuration of the parts. They are not to be interpreted as technical drawings or exact replicas of the parts.

The use of Bombardier parts is most strongly recommended when considering replacement

of _a ny component. Dealer and I or distributor assistance should be sought in case of doubt.

Torque wrench tightening specifications must be strictly adhered to. Locking devices (ex. : lock

tab, elastic stop nut) must be installed or replaced with new ones, where specified. If the

efficiency of a locking device is impaired, it must be renewed.

This manual emphasizes particular information denoted by the wording and symbols;

•

WARNING: Identifies an instruction which, if not followed, could cause serious personal

injury including possibility of death.

·

TCAUTION : Denotes an instruction which, if not followed, could severely damage vehicle

components.

Q NOTE: Indicates supplementary information needed to fully complete an instruction.

Although the mere reading of such information does not eliminate the hazard, your understanding of the information will promote its correct use.

This information relates to the preparation and use of Bombardier snowmobiles and has been

utilized safely and effectively by Bombardier Inc.. However, Bombardier Inc. disclaims liability

for all damages and I or injuries resulting from the improper use of the contents. We strongly

recommend that any services be carried out and I or verified by a highly skilled professional

m echanic. It is understood that certain modifications may render use of the vehicle illegal under

existing federal, provincial and state regulations.

c

Ill

J

1989 BOMBARDIER SNOWMOBILES

SHOP MANUAL

INTRODUCTION

(TYPICAL)

This Shop Manual covers the following Bombardier made

1989 snowmobiles.

MODELS

MODEL NUMBER

ELAN®

3046

ALPINE® II 503

3348

SAFARI CITATION®

3233

SAFARI CITATION® E

3234

TUNDRA*

3235

TUNDRA* LT

3236

SAFARI SCOUT *

3638

SAFARI SCOUT* E

3639

SAFARI SAGA*

3632

SAFARI CHEYENNE*

3234

SAFARI VOYAGEUR*

3637

SAFARI ESCAPADE*

3635

FORMULA* MX

3735

FORMULA* MX LT

3736

FORMULA* PLUS

3737

FORMULA* PLUS LT

3738

FORMULA* MACH I

3739

Veh icle serial number

A015 007 023

The engine also has a serial number.

Liquid-cooled engines

®*Trademarks of Bombardier inc.

Furthermore, each vehicle has its particular vehicle serial

number.

Serial number meaning :

AOOO 002 062

Fan-cooled engines

0000 00000

Model-----rno

AOOO 000 013

IV

·'

Vehicle

no

1989 BOMBARDIER SNOWMOBILES

SHOP MANUAL

DEFINITION OF NUMBERING SYSTEMS

The use of "Right" and "Left" indications in the text,

always refers to driving position (when sitting on vehicle)

Sections and sub-sections system

The manual makes uses of a 2-part digital numbering

system (i.e. 01-01), in which the first digit represents the

section, the second digit the sub-section.

01 - -01-

- -

/~

Section

Sub-section

LEFT . . .

. . . RIGHT

Pages system

The numerotation at the bottom of each page assists the

user in page location .

c

01-01-01

/!~

Section

Sub-section

Page

ARRANGEMENT OF THE MANUAL

The manual is divided into 8 major sections :

01 Tools

02 Engine

03 Transmission

04 Electrical

05 Suspension

06 Steering and skis

07 Body / frame

08 Technical data

Each section is divided in various sub-sections, and again,

each sub-section has one or more division.

AOOO 000 002

GENERAL

The information and component/ system descriptions contained in this manual are correct at time of publication.

Bombardier Inc. however, maintains a policy of continuous

improvement of its products without imposing upon itself

any obligation to install them on products previously manufactured.

Bombardier Inc. reserves the right at any time to discontinue or change specifications, designs, features, models or equipment without incurring obligation.

ILLUSTRATIONS & PROCEDURES

An exploded view is conven iently located at the beginning of each section and is meant to assist the user in

identifying parts and components.

This Shop Manual uses technical terms which may be

sligthly different from the ones of the parts catalog.

EX.: 02 ENGINE

04 Engine type 467

-

Cooling system

-

Magneto

-

Etc.

v

1989 BOMBARDIER SNOWMOBILES

SHOP MANUAL

When ordering parts always refer to the parts catalog.

The illustrations show the typical construction of the different assemblies and, in all cases, may not reproduce

the full detail or exact shape of the parts shown, however, they represent parts which have the same or a similar

function.

When something special applies (such as adjustment,

inspection, etc.), boldface numbers in exploded views

are used for specific parts and referred to in the text.

.,.,. CAUTION : Pay attention to torque specifications.

T Some of these are in lbf•in instead of lbf•ft. Use

appropriate torque wrench .

.,.,. CAUTION : Most components of those vehicles

T are built with parts dimensioned in the metric

system. Most fasteners are metric and must not be

replaced by customary fasteners or vice versa. Mismatched or incorrect fasteners could cause damage

to the vehicle or possible personal injury.

As many of the procedures in this manual are interrelated, we suggest, that before undertaking any task, you

read and thoroughly understand the entire section or

sub-section in which the procedure is contained .

A number of procedures throughout the book require the

use of special tools. Where a special tool is indicated,

refer to section 01. Before commencing any procedure,

be sure that you have on hand all the tools required, or

approved equ ivalents.

Technical Publications

Bombardier Inc.

Valcourt (Quebec) Canada

VI

J

Section 01 TOOLS

Sub-section 01 (BASIC TOOLS)

BASIC TOOLS

A. Screwdriver

B.

C.

D.

E.

Socket 70/13 mm

Starter rope

Socket wrench handle

Open end wrench 70 /13 mm

F. Emergency starting clip

G. Socket 2 7I 26 mm

H. Suspension adjustment wrench (cam)

I. Suspension adjustment wrench (shock absorber)

J Spring collar adjustment wrench

(PRS suspension)

K. Carry boose adapter

L. Tool bag

M. Spring collar adjustment wrench

(monoshock suspension)

6~

A

B

0

c

E

D

G

H

M

A001 001 083

c

1989 MODELS

APPLICABLE TOOLS

Elan

A, B, C, D, E, F, G, L.

Safari Citation IE

A, B, C, D, E, F, G, L.

Tundra, Tundra LT

A, B, C, D, E, F, G, H, L.

Safari Scout/ E

A, B, C, D, E, F, G, H, L.

Safari Saga

A, B, C, D, E, F, G, H, I, L.

Safari Ch eyenne

A, B, C, D, E, F, G, H, K, L.

Stratos Voyageur I Escapade

A, B, C, D, E, F, G, H, I, L.

Formula MXIMX LTIPiusiPius LT

A, B, C, D, E, F, G, J, L.

Formula Mach I

A, B, C, D, E, F, G, J, L, M.

Alpine II 503

A, B, C, D, E, F, G, L.

01 -01 - 1

)

)

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

1989 SERVICE TOOLS

TUNE UP

SERVICE TOOL

PURPOSE

APPLICATION

Dial indicator (TDC gauge)

414 1047 00

Engine timing, to determine TDC

All engine types

AOOO 001 086

Degree wheel

414 3529 00

AOOO 002 066

To mark timing position of

rotary valve

467, 536 & 583

engines

Engine timing

24 7 engine type

Continuity tests

All engine types

Engine electrical com ponents tests

All engine types

Engine ignition system

components tests

- All Nippondenso

electronic ignition

systems (All engine

types except 247)

AOOO 001 111

Circuit tester (continuity light)

414 0122 00

v~

AOOO 002 073

Bombardier ignition tester

419 0033 00

AOOO 002 056

c

Nippondenso electronic ignition

tester

419 0084 00

AOOO 004 020

01-02-1

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

TUNE UP

SERVICE TOOL

PURPOSE

APPLICATION

Carburetor tool kit

404 1120 00

To ease disassembly and assembly

of carburetor

All models

AOOO 001 087

01 -02-2

Section 01 TOOLS

Sub-section 02 (SERV ICE TOOLS)

TRANSMISSION

SERV ICE TOOL

PURPOSE

APPLICATION

Belt tension tester

To adjust belt deflection and tension

All models

414 3482 00

I It 23'11

AOOO 002 007

Drive pulley retainer

AOOO 003 008

For retaining of governor cup

529 0017 00

AOOO 002 074

Drive axle holder

529 0072 00

A001 001 050

Round shaft drive

pulley

AOOO 002 057

To hold drive axle during installation

or removal of chaincase and I or end

bearing housing

All models

A001 001 051

01 -0 2-3

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

TRANSMISSION

SERVICE TOOL

PURPOSE

APPLICATION

Crankshaft locking tool

To lock crankshaft when removing

and installing drive pulley or flywheel

All engine types

420 8766 40

AOOO 002 039

Clutch holder

529 0064 00

A001 001 041

01 -02-4

A013 002 007

To hold drive pulley when removing

and install ing drive pulley retaining

screw

Square shaft & TRA

pulleys

_)

Section 01 TOOLS

Sub-section 02 (SERVIC E TOOLS)

TRANSMISSION

SERV ICE TOOL

PURPOSE

APPLICATION

Drive pulley puller

To remove drive pul ley from

crankshaft

Engines with tapered

crankshaft end

Standard threads

529 0021 00

--~·~~------~--~

AOOO 002 008

529 0030 00

529 0048 00

Metric threads

529 0028 00

AOOO 002 009

TRA clutch

Metric threads

529 0079 00

::

A016 001 007

Spacer

529 0054 00

AOOO 002 114

Use with drive pulley pul ler

(P/N 529 0079 00) to remove

spring cover

TRA clutch

A016 001 004

Cover

529 0056 00

c

A016 001 005

A016 001 003

01-02-5

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

-

TRANSMISSION

SERVICE TOOL

PURPOSE

APPLICATION

Fork

To maintain slider shoes during

removal and assembly

TRA clutch

529 0055 00

A016 001 001

Outer flare tool

A016 001 002

To flare kahrlon bushing in inner half

529 0060 00

A016 001 008

A016 001 011

Inner flare tool

529 0061 00

•

A016 001 009

01 -0 2-6

A016 001 0 10

TRA clutch

c

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

TRANSM ISSION

SERVICE TOOL

PURPOSE

APPLICATION

Engine support positioner

To ease pulley alignm ent

Safari Citation I E

Tundra / LT

529 0081 00

A003 001 001

Elan

Safari Citation I E

Tundra I LT

Pulley al ignment gauge

529 0080 00

A003 001 003

A) Alignmen t gauge

A003 001 002

To ease pulley alignment

529 0084 00

A) All Safari Voyageur,

Safari Escapade,

Safari Cheyenne

A003 001 003

B) 529 0083 00

A003 001 003

B) Safari Scout/ E

Safari Saga

A019 001 006

01 -02-7

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

TRANSMISSION

SERVICE TOOL

PURPOSE

APPLICATION

Alignment bar

Used as go I no go gauges to check

pulley alignment

TRA clutch

529 0071 00

Formula

Formula

Formu la

Formu la

Formu la

Alpine II

A001 001 049

Spring scale hook

529 0065 00

A001 001 043

01 -02-8

MX

MX LT

PLUS

PLUS LT

MACH I

A001 001 048

To hook the spring scale to driven

pulley wh en checking pre-load

A001 001 044

All models except Elan

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

TRANSMISSION

SERV ICE TOOL

PURPOSE

APPLICATION

Drive belt tension adjuster

529 0087 00

to adjust drive belt tension

Formula MX/ MX LT

Formula PLUS I PLUS LT

Formula MAC H I

Alpine II

0

A015 001 004

Alignment tool

420 4760 10

AOOO 002 049

NOTE : Can be used with the socket

handle provided in the tool box.

A015 001 005

Drive shaft and layshaft sprocket

al ignment

Alpine 3-speed

transmission

A01 7 003 009

01 -0 2-9

Section 01

TOOLS

Sub-section 02

(SERVICE TOOLS)

TRANSMISSION

SERV ICE TOOL

PURPOSE

APPLICATION

3-speed transmission

bearing extractor

To remove the bearings from the

drive shaft and the lay shaft

Alpine II

1- screw M8 x 25 (2)

420 2402 75

I

r· -

I

0 0

0

l

I

2- plate

420 9777 00

3- half ring (2)

420 8763 30

«::;> 0 0

12

0

4- ring

420 9774 80

e:g~3

4

AOOO 002 047

Transmission ball mounting pin

420 4760 20

AOOO 002 048

01 -0 2-10

A017 003 006

Transmission cover index rod ball

installation

A017 003 011

Alpine II

c

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

Magneto housing holder

420 9765 50

c

253 & 377

engines

AOOO 002 026

247 engine type

AOOO 002 068

AOOO 002 067

Fan holder

503 engine

APPLICATION

Axial fan cooled

engines

420 8763 55

420 8763 57

A009 002 013

01 -0 2-11

-

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

APPLICATION

Magneto puller ring

420 8766 55

Used with crankshaft locking tool

(PI N 420 8766 40) & magneto puller

to remove flywheel

All engine types

except 247

Pu ller

A013 002 008

AOOO 002 044

Used with magneto puller to remove

flywheel

Magneto puller ring

420 8760 80

AOOO 002 063

Al l eng ine types

Magneto puller

247 engine

420 9762 35

253,377,

46 7,503,537

engines

420 8760 65

Puller

ring

AOOO 002 046

01-02-12

AOOO 002 045

Puller

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

ApPLICATION

Magneto coil centering tool

420 8769 22

To adjust the gap between coi ls and

f lywhee l

All Nippondenso CDI

_,-

A001 001 067

A001 004 003

Mounting support

420 8768 30

Screw M10 x 16 mm

420 8416 60

To hold engine

253 engine type

0

0

0

0

A002 001 002

A003 002 001

01 -0 2-13

Section 01

TOOLS

Sub-section 02

-

(SERVICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

APPLICATION

24 7 engine type

Connecting rod holder

420 9779 00

Connecting rod

Holder

AOOO 002 023

Piston pin puller

529 0068 00

AOOO 002 024

To remove piston pin

1. Spring pin

372 1010 00

2. Stop notch

529 0068 01

AOOl 001 04 5

01 -02-14

A001 001 046

All engine types

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

APPLICATION

Piston circlip installer

To install circlips on piston

Al l engine types

529 0086 00

Place

circlip in

Restrain

Oil

....,-CAUTION: Ensure that the circlip

T is well seated and correctly positioned in the piston groove.

A001 001 061

Piston pin I connecting rod bearing

centering tool

529 0091 00

A001 001 062

To center the piston pin with the

connecting rod bearing during

installation

All engine types

0

NOTE: The circlip on the opposite

side can be in stalled before pin

installation, the tool wi ll easily go out

A001 001 063

AOOl 001 064

01 -0 2-15

Section 01 TOOLS

Sub-section 02 (SERVIC E TOOLS)

ENGINE

SERV ICE TOOL

PURPOSE

Ring compressor

To compress piston rings when

inserting piston in cylinder

APPLICATION

A) 420 8760 90

A) 377 engine type

B) 420 8769 74

B) 467 engine type

C) 420 8769 70

C) 253, 503, 536

engine types

A001 001 065

01 -02-16

A001 001 066

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENGINE

SERV ICE TOOL

PURPOSE

APPLICATION

Puller assembly

To rem ove crankshaft bearings

All eng ine types

420 8762 96

With 145 mm screw

Accessories

AOOO 002 018

AOOO 002 017

PULLER ASSEMBLY

COMPONENT

APPLICABLE TO ENGINE TYPES

P/N

420 9407 55

Distance ring

Distance ring

Puller ring

Puller ring

'y

4 20 2760 20

Half ring ass'y

420 9774 70

01 -0 2-17

-

Section 01 TOOLS

Sub-section 02 (SERVICE TOOL)

ENGINE

SERVICE TOOL

PURPOSE

APPLICATION

Crankshaft feeler gauge

420 8766 20

On PTO side

PTO : 377 & 503

engines

AOOO 002 037

Bearing simulator

420 8761 55

AOOO 002 053

AOOO 002 038

To adjust crankshaft end-play

A001 002 036

All oil injection engines

Injection pump gear holder

253 & 377 engines

420 8766 95

AOOO 001 109

467, 536 & 583 engines

420 2779 00

AOOO 002 042

01 -02-18

253 engine type

AOOO 002 043

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

Rotary valve shaft pusher

420 8766 12 (for 10 mm shaft)

AOOO 002 01 5

Polyamid ring pusher

420 2769 30

AOOO 002 035

467' 536 & 583

engine types

AOOO 002 016

To install polyamid ring in crankcase

24 7 engine type

AOOO 002 036

247 engine type

Engine seal pusher

420 9779 20

AOOO 002 031

APPLICATION

AOOO 002 032

01 -02-19

Section 01 TOOLS

Sub-section 02 (SERV ICE TOOLS)

ENGINE

SERVICE TOOL

PURPOSE

APPLICATION

Sea l protector sleeve

To avoid seal damage during

crankshaft installation

24 7 engine type

PTO 420 9779 10

MAG 420 2769 00

Sea I protector sleeve

(on crankshaft)

AOOO 002 013

Sea l protector sleeve

AOOO 002 014

To avoid sea l damage during rotary

va lve shaft insta llation

467, 536 & 583

engine types

420 8769 80 (for 10 mm shaft)

••

AOOO 002 013

Rotary va lve sea l pusher

420 8766 05

A013 002 012

AOOO 002 01 3

To install seal and rotary

va lve shaft

··~-- ~

AOOO 002 034

01 -02-20

A013 002 020

467, 536 & 583

engine types

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

ENG INE

SERVICE TOOL

PURPOSE

APPLICATION

Seal pusher

420 8765 12 (for 10 mm shaft)

To install water pump seals

467, 536 & 583

engine types

AOOO 002 033

Bearing pusher

420 8765 00

AOOO 001 091

A015 002 014

To install water pump bearing

467, 536 & 583

engine types

A015 002 028

01 -02-21

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

-

ENGINE

SERVICE TOOL

PURPOSE

APPLICATION

Cylinder aligning tools

To align cylinders

Twin cylinder engines

377, 503 engines

lo

Alig ning

too l

420 8761 71

o el

AOOO 001 106

Screw M8 x 25 mm

377, 503 engines

420 2402 75

A017 002 001

Align ing tools

no 420 8765 70

AOOO 002 020

467 engine

536 & 583 engines

420 8765 75

420 8765 70

AOOO 001 007

A015 002 052

Exhaust flange align ing too l

467,536 engines

420 8769 00

Exhaust flange

aligning tool

P/N 420 8769 00

AOOO 001 008

01 -0 2-22

A01 5 002 052

AOOO 001 008

c

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

SUSPENSION

SERVICE TOOL

PURPOSE

APPLICATION

Steering arm installer

To install steering arm

Alpine II

529 0088 00

,.,. CAUTION : Key and keyway must

T align perfectly before tightening

nut.

A017 001 003

Spring insta ller

A017 001 004

To install suspension springs

529 0050 00

AOOO 002 054

Tundra I LT,

Safari Scout/ E,

Safari Saga

A009 005 007

01 -0 2-23

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

SUSPENSION

SERVICE TOOL

PURPOSE

APPLICATION

Suspension spring installer

To install suspension springs

Safari Voyageur,

Safari Escapade,

Safari Cheyenne

529 0066 00

A019 001 003

Spring remover

414 5796 00

A015 001 001

Spring sdaptor

529 0057 00

A019 005 008

Pry spring

into its seat

To remove spring from shock

absorber

SP & PRS suspension

types

A014 005 025

Used with spring remover to remove

spring from shock absorber

SP suspension type

A014 001 003

01 -02-24

A014 005 024

Section 01 TOOLS

Sub-section 02 (SERVICE TOOLS)

-

SUSPENSION

SERVICE TOOL

PURPOSE

APPLICATION

Track cleat remover

To rem ove track cleats

All track cleats

529 0082 00

A001 001 055

Position 1-3 : large cleats

Position 1-2 : sma ll cleats

Strongly

push

Spare pins

Rotate

529 0082 04

0

NOTE : Pins can be rotated of 180°

depending on whether the tool is

used by a left-hander or right-hander.

A001 001 057

Al Track c leat installer

A001 001 056

To insta ll track cleats

A) Large track cleats

529 0077 00

Bl Small track c leats

Bl 529 0085 00

A001 001 059

Second step

(to push tabs

into rubber

A001 001 058

A001 001 060

01-02-25

-

-.

I

~

-

,1

1

1

-

_)j

.l

Sub-section 03

Section 01 TOOLS

(SERVICE PRODUCTS)

SERVICE PRODUCTS

SERVICE PRODUCT

PURPOSE

APPLICATION

Silastic 732 RTV

747 0020 00

To seal joints.

Flat washers on cylinders

of 536 engine type .

To seal pipe fittings. Prevents

leakage and vibrational loosening .

Engine pipe plugs .

A bonding compound for use on

unthreaded metal cylindrical parts

to prevent vibrational loosening

and wear.

Drive and driven pulley

bushings.

Makes, dresses and repairs gaskets

of sizes and shapes.

Crankcase halves .

Transmission and gearbox

mating surfaces.

Bonds nonporous materials in

seconds. For use on metal, vinyl,

plastic, rubber and ceramic .

'' L' '-plates in posi-steer

suspension .

A medium-strength adhesive for

threadlocking and threadsealing .

Vibration-proof nuts, bolts and

screws.

General purpose, nuts,

bolts screws.

Magneto ring nut,

crankcase studs, etc.

Hi-strength threadlocking

threadseal ing adhesive for

large parts.

Fasteners and studs

under 1" dia.

AOOO 001 117

PST Pipe Sealant with Teflon (50 ml)

413 7023 00

AOOO 001 104

Retaining Compound RC / 609 (10 ml)

413 7031 00

AOOO 001 100

Gasket Eliminator 515 (50 ml)

413 7027 00

AOOO 001 101

Super Bonder Adhesive 495 (3 ml)

413 7032 00

AOOO 001 103

Lock'n seal (242) blue

medium strength (10 ml)

413 7030 00

A000001110

Lock 'n sea l (2 71) red

high strength (10 ml)

413 7029 00

I

I

..

-

AOOO 001 102

01 -03-1

Section 01 TOOLS

Sub-section 03 (SERVICE PRODUCTS)

SERV ICE PRODUCT

PURPOSE

APPLICATION

Molykote G-n paste

(2.8 oz)

413 7037 00

A balanced blend of molybdenum

disulfide and other lubricating

solids to handle extreme pressure.

Reduces frictional force and

surface damage. Provides excellent

protection aga inst fretting wear

temperature range from

-100°Fto 750° F (-73°C to 399°C).

For rewind starter

locking spring. (Not

to be used on rewind

springs as is does not

stay on when dried) .

Th is General Electric silicone lubricant

is highly resistant to oxidation, shear

and heat decomposition - and will

provide excellent lubrication over

long intervals of no maintenance

under temperatu res from -73 ° C to

240°C such cond itions. Lubricates

under (-100°F to 400°F)

Used to lubricate

manua l starter rewing

spring. (not to be used

on rewind starter locking

makes it run out) .

Very fast cure primer. Primer NF

provides fixturing in only 15-30

seconds with full cure in 4 hours

or less. On pa rt life is 30 minutes

and parts should be assembled as

soon as possible after adhesive is

applied.

Mainly used when

assembling engine

era n kcases.

For cleaning mating surfaces

before assembly

Used to clean mating

surfaces.

Protects moving and stationary

parts against high temperature

seizi ng. Prevents rust and corrosion

on parts exposed to high heat.

Unpainted su rfaces of

drive pulley countershaft.

Special dielectric grease that

prevents moisture and corrosion

build-up in electric connections.

On all electric connections.

High tension coi l.

Spark plug connections.

Connector housings, etc.

ll@IL111:!1ii1\rl

~~=:r-:~AOOO 001 064

G.E. Versilube G341 M

8 oz

413 7040 00

AOOO 001 065

Primer crankcase sealant

spray (6 oz)

413 7024 00

AOOO 001 066

STRIPPER NO 157

413 7021 00

AOOO 001 092

Antiseize lubricant

(12 oz)

413 7010 00

AOOO 001 068

Silicone dielectric grease (3 oz)

413 7017 00

AOOO 001 069

01 -03-2

Sub-section 03

-

Section 01 TOOLS

(SERVICE PRODUCTS)

SERVICE PRODUCT

PURPOSE

APPLICATION

Grease tube LMZ no

(400 g)

413 7064 00

Multi purpose Lithium based

grease containing zinc monoxide

which makes it a good conductor

for heat & electricity.

Mainly used between

regulators or rectifiers

and upper column to

transfer the heat build-up

and to assure a good

ground.

Special low temperatu re metallic

lubricant for clutch shafts only.

For roller round

shaft drive pulleys.

Specially formulated oil for chain

and roller lubrication. Assures

proper lu brication at low

temperatures.

Chaincase lubricant on

all models.

Specially formulated oil that meets

lubrication requirements of the

Bombardier-Rotax engine.

All models.

Th is oil will flow at -40°C (-40°F).

Compounded of base oils and

add itives, specially selected to

provide outstanding lubrication,

engine cleanliness and minimum

spark plug fouling.

All engine types.

AOOO 001 070

Clutch lube

(4 oz)

413 800 7 00

.:...~.----=-=,.---

AOOO 001 071

Chaincase oi l

(250 ml)

413 8019 00

AOOO 001 099

Blizza rd oil

496 0135 00 (500 ml)

AOOO 001 074

Injection oil

496 0133 00 (1 litre)

496 0140 00 (4 litres )

Fully efficient for:

INJ ECTION, PRE-MIX,

ROTARY VALV E.

AOOO 001 075

Bea ring grease

(400g)

413 7061 00

Multi-purpose lithium based grease.

It is an antifriction, anticorresion

and water resistant bearing grease

for use through temperatures

between -40 ° to 95°C

(-40° to 200°F).

For idler bearings, ski legs,

leaf spring cush ion pads,

seal interior lips, rear hub

bearings, bogie wheels,

countershaft bearings,

etc...

AOOO 001 093

01 -03-3

Section 01 TOOLS

Sub-section 03 (SERVICE PRODUCTS)

SERVICE PRODUCT

PURPOSE

APPLICATION

Primer for gasket eliminator

413 7053 00

General purpose primer.

Primer N assures fixturing of parts

in 15-30 minutes and full cure in

12 hours or less. On part life is 30

days, but it is recommended that

parts be joined within 10 minutes

after adhesive is applied over

primer.

Mainly used when

assembling engine

crankcases and

transmission cases.

For frame touch-up.

Elan, Alpine II

Ice orange

(Spray can)

For hood touch-up.

Alpine II

Storage oil

(350 g spray can)

To protect engine from rust during

storage period.

All models.

AOOO 001 077

Paint

413 4010 00

413 4031 00

Black semi-gloss

(Spray can)

AOOO 001 094

496 0141 00

AOOO 001 116

01 -03-4

c

Section 02 ENGINE

Sub-section 01 (247 ENG INE TYPE)

247 ENGINE TYPE

ENGINE REMOVAL AND INSTALLATION

Engine support and muffler

22 N•m

(16 lbf· ft)

Q)!a@--0-I L,J

5

6

37

16 N• m

(142 lbf•in )

32

17

I

o~--21-e

22 -~

i

31 N• m

~ - 23 ~-- (23

l

-

lbf• ft)

20

I

I

I

@ -

25

® - 26

' yg__

I

,

39

c

41

£-31

A002 002 069

0 2-01 -1

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

7.

2.

3.

4.

5.

6.

7.

8.

9.

70.

7 7.

72.

73.

74.

75.

76.

77.

78.

79.

20.

2 7.

Metal screw 8 x 518 (2)

Washer (2)

Rubber spacer !2)

Air duct

Hexagonal screw 714 x 20

Washer

Stud M8 X 79 (2)

Muffler gasket

Lock washer 8 mm (2)

Hexagonal nut 8 mm (2)

Muffler

Bushing

Washer

Rubber washer

Hexagonal screw M8 x 25

Exhaust grommet

Starter grip

Rubber buffer

Distance sleeve 22 mm (4)

Stud M70 X 42 (4)

Elastic stop nut 3/8-24 (4)

22.

23.

24.

25.

26.

27.

28.

29.

30.

37.

32.

33.

34.

35.

36.

37.

38.

39.

40.

4 7.

Washer (4)

Elastic stop nut 5176-24 (4)

Engine support

Lock washer 70 mm (4)

Hexagonal nut 70 mm (4)

Cross support (2)

Vibration damper (4)

Threaded spacer !4)

Carriage bolt 318-24 (4)

Knurled screw 5176-24 (4)

Rotax engine 247

Exhaust socket

Spring (4)

Connecting tube

Muffler female ball joint

0 -ring

Heat shield

Elastic stop nut 7/4-20 !2J

Washer !3)

Hex. cap screw 714-20 x 3/4 in !2J

REMOVAL FROM VEHICLE

INSTALLATION ON VEHICLE

Remove or disconnect the following then lift engine from

vehicle:

To install engine on vehicle, reverse removal procedure.

However, pay attention to the following :

- console

-Check t ightness of engine mount nuts, and drive pulley screw.

- pulley guards

- drive belt

- muffler

- primer hose

- decompressor cable

- throttle cable

- fuel lines

- impulse line

- electrica l connectors

- separate steering column support at upper column

-engine mount nuts

ENGINE SUPPORT AND MUFFLER

DISASSEMBLY & ASSEMBLY

10,23,26, Manifold nut, engine support

nut & engine mount nut

Torque the manifold nuts to 22 N•m (16 lbf•ft).

Torque the engine support nuts to 31 N•m (23 lbf•ft).

Torque the engine mount nuts to 38 N•m (28 lbf•ft).

02-01 -2

- After throttle cable installation, check maximum throttle

slide opening.

- Check pulley alignment and drive belt tension.

- Should a light exhaust leak is experienced at muffler

ball joint, Dow Corning sealer #763 RTV can be used.

However after some hours of use, carbon deposits accumulation should seal joint.

r

Section 02 ENGINE

Sub-section 01 (247 ENGINE TY PE)

TOP END

\

11 - - @

12 - -@

\

2 1 N• m

I 15 lbf• ftl

)

I

~

01

18

1

15-- -- -- -----

o-22

1---- --

10

- -- 23

- - - -- - 8

~f-------

9

A002 002 070

1. Decompressor cable

2. Decompressor lever

3. Switch rod

4 . Dowel tube

5. Cap nut M18 x 1. 5

6. Switch housing

7. Spring

8 . Circlip (2)

9. Needle bearing

10. Gudgeon pin

11. Nut 8 mm (4)

12. Washer 8,4 mm (4)

13.

14.

15.

16.

17.

18.

19.

Cylinder head

Head gasket

Stud M 8 x 19,5 (2)

Tab lock (2)

Nut 8 mm (2 )

Decompressor

Locking sleeve

20. Cylinder

21. Flange gasket

22. Rectangular ring (2)

23. Piston

02-01 -3

Section 02 ENGINE

Sub-section 01 (24 7 ENGINE TYPE)

0

NOTE : The following procedures can be done

without removing the engine from chassis.

REMOVAL

CLEANING

Discard all gaskets.

Clean all metal components in a non-ferrous metal cleaner.

(Without removing engine from chassis)

Scrape off carbon formation from cylinder exhaust port,

cylinder head and piston dome using a wooden spatula.

Remove the following then lift cylinder and cylinder head :

0

NOTE : The letters "AUS" (over an arrow on the

piston dome) must be visible after cleaning .

-

console

-

pulley guards

-

spark plug

Clean the piston ring grooves with a groove cleaner tool,

or with a piece of broken ring.

-

air duct

DISASSEMBLY

-

muffler, connecting tube and exhaust socket

-

spark plug cable clamp from fan cowl

-

primer hose from carburetor

-

untighten rubber fla nge collar then move carburetor

-

steering column U bolt at upper column and spiro!

pin, washer and short tie rod from bottom end

- air deflector and decompressor cable at cylinder head

-four nuts retaining fan cowl and move it sideway until

it is against the voltage regulator

- move steering column toward left to clear engine top

end

8,1 0,23, Circlip, gudgeon pin & piston

Place a clean cloth over crankcase, then with a pointed

tool inserted in piston notch, remove circlip from piston.

To remove piston pin, use piston pin puller (P/N 529 0068

00) as follows :

l

- Fully screw puller hand le.

- Place stop notch of puller in line w ith the puller axis.

- Insert puller end into piston pin.

- Rotate stop notch of puller so that corners protude

the puller end.

-

Fan cowl

moved against

voltage regulator

1

t

1

I

j

AOOl 001 054

t

- Hold puller firm ly and rotate puller handle counterclockwise to pull piston pin.

A002 002 068

02-01-4

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

EXHAUST

A001 002 001

To center the piston pin with the connecting rod bearing,

use centering tool (P IN 529 0091 00).

A001 001 046

0

NOTE: 0.5 mm oversize piston and rings are available if necessary.

Centering tool

INSPECTION

(PIN 529 0091 00)

The inspection of the engine top end must include the

following measurements:

TOLERANCES

MEASUREMENTS

FITTING NEW PARTS

(MIN.)

(MAX.)

WEAR LIMIT

Cylinder taper

N.A.

N.A.

0.08 mm

(0031")

Cylinder out of

round

N.A.

N.A.

0.05 mm

(0020")

Cylinder/piston

clearance

0.08 mm

(0031 ")

0.10 mm

(0039")

0.20 mm

(008")

Ring/piston groove

clearance

0.04 mm

(002")

0.11 mm

(004")

0.20 mm

(008")

Ring end gap

0.20 mm

(008")

0.35 mm

(014'')

1.0 mm

(039")

0

NOTE: For the measurement procedures, refer to

"Engine dimensions measurement", section 02-09.

A001 001 064

0

NOTE : The circlip on the opposite side can be installed before pin installation, the fool will easily

go out

To min imize the effect of acceleration forces on circlip,

install each circlip so the circlip break is at 6 o'clock as

illustrated. Use piston circlip installer (P IN 529 0086 00).

Piston c irclip installer

(PIN 529 0086 00)

ASSEMBLY

8,10,23, Circlip, piston pin & piston

At assembly, place the piston over the connecting rod

with the letters "AUS" (over an arrow on the piston dome)

facing in direction of the exhaust port

Oil

A001 001 062

02-01-5

Section 02

ENGINE

Sub-section 01

(247 ENGINE TYPE)

16, Tab lock

Tab lock should be replaced if bent more than three times.

If in doubt replace.

1,2, Decompressor cable & lever

To adjust: From "Off" position, pull lever to feel a light

resistance. A gap of 1.5 mm (1/16 in) is required .

~~

~~ ~

f\.=

'----

Circlip break

A001 002 002

A002 002 011

1.5 mm

(1/16 in)

J~

"Off"

position

,..-CAUTION : Circlips must not move freely in the

T groove after installation. If so, replace them .

7, Spring

20, Cylinder

Remove spring then turn adjustment sleeve clockwise to

increase free-play or counterclockwise to reduce. Reinstal l

spring.

Before inserting piston in the cylinder, lubricate the cylinder

with new injection oil or equivalent.

Spare parts pistons and cylinders are identified with a

green or red dot, it is important to match piston and cylinder

with the same color.

-

1,13, Nut & cylinder head

Position cylinder head on cylinder with fin s in line with

crankshaft center line. Cross torque retaining nuts to 21

N•m (1 5 lbf•ft).

;

~

i

l

I

02-01 -6

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

BOTTOM END

3

10

I

2

7

@----2 1

@ - 22

18

tJ

I

21 N•m

(15 lbf• ft)

23

38 N•m

(28 lbf• ft)

17

13

I

21 N•m

( 15 lbf•ft)

A002 002 071

7. Crankcase half fPTO side)

2. Polyamid ring (2)

3. Stud M8 x 56 (crankcase with studs) (2)

Hexagonal cap scre w M8 x 64 (crankcase with screws) {2)

4. Shim 7.0 mm

5. Woodruff key 5 x 6, 5

6. Shim 0, 7, 0,2, 0,3, 0,5, 7,0 mm

7. Ball bearing 6305 {2)

8. Crankcase gasket

9. Dowel tube 70 mm x 75 (2)

70. Stud M8 X 777 (4)

7 7. Crankcase half (mag side)

72. Lockwasher 8 mm (5)

Hexagonal nut 8 mm (crankcase with studs) (5)

73.

74.

75.

76.

77.

78.

79.

20.

27.

22.

23.

Labyrinth ring

Slotted head screw M6 x 70 (4)

Seal (2)

Stud M8 x 46 (crankcase with studs) (3)

Hexagonal cap screw M8 x 55 (crankcase with screws) (3)

Loctite 242

Crankshaft

Distance sleeve 22 mm (4 )

Stud M70 x 42 (4)

Lock washer 70 mm (4J

Hexagonal nut 70 mm (4)

Anti-seize lubricant

02-01 -7

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

0

NOTE : Engine must be removed from chassis to perfom the following procedures.

CLEANING

INSPECTION

The inspection of the engine bottom end must include

the following measurements :

Discard all oil seals and gaskets.

TOLERANCES

Clean all metal components in a non-ferrours metal cleaner.

MEASUREMENTS

DISASSEMBLY

FITTING NEW PARTS

(MIN.)

(MAX.)

WEAR LIMIT

Crankshaft

deflection

N.A.

N.A.

0.10 mm

(.0039" )

To remove drive pulley, refer to "Drive Pulley", section

03-03.

Connecting rod big

end axial play

0.20 mm

(.008")

0.53 mm

(.021")

1.0 mm

( 039")

To remove magneto, refer to "Magneto" in this section .

Crankshaft end play

0.10 mm

( 004")

0.30 mm

(.012")

N.A.

General

1,1,1, Crankcase half

0

NOTE : For the measurement procedures, refer to

When disassembling crankcase halves, do not heat the

crankcase. If heat is necessary, temperature must not

exceed 55° C (130° F).

ASSEMBLY

2, Polyamid ring

7, Bearing

Do not remove polyamid rings unless necessary.

Smear anti-seize lubricant (PIN 413 7010 00) on part

of crankshaft where bearing fits.

To remove, heat slightly with a butane torch then pry out

using a screwdriver.

15, Seal

To remove seals, push from outside the crankcase towards

the inside.

7, Ball bearing

To remove bearing from crankshaft use a protective cap

and special puller as illustrated. (See Tools Section)

"Engine dimensions measurement", section 02-09.

Prior to installation, place bearings into an oil container

and heat the oil to 75°C (167°F) for 5 to 10 min. This

wi ll expand bearings and ease insta llation.

Install bearings with groove outward.

0

NOTE : Crankshaft end-play requires adjustment only

when crankshaft and I or crankcase is replaced. Prior

to magneto side bearing installation, determine crankshaft end-play and install required shim(s) on crankshaft

extension. For the crankshaft end-play adjustment procedure, refer to "Engine dimensions measurement", section

02-09 .

2, Polyamid ring

To install polyamid ring, apply oil on outside diameter then

use polyamid ring pusher (P I N 420 2769 30).

AOOO 001 080

02-01 -8

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

Also, prior to crankcase adjoining, install a protector sleeve

on each crankshaft extension to prevent oil seal damage

(See Tool Section). Apply a light coat of lithium grease

on seal lip. Spray some new injection oil on all moving

parts of the crankshaft.

'1lr CAUTION : To ensure appropriate crankshaft

T bearing lubrication, seal outer surface must be

pressed on seal crankcase shoulder.

3,12,16, Stud or bolt & nut

Torque the nuts or bolts to 21 N•m (15 lbf • ft) following

illustrated sequence.

Polyamid ring

pusher

(P i N 420 2769 30)

Crankcase half

AOOO 001 081

Install as illustrated.

\

Chamfered side

towards the

crankshaft bearing

Inside lip

facing towards

the crankcase

\.~

A002 002 003

22, Engine mount nut

Torque the engine mount nuts to 38 N•m (28 lbf • ft).

15, Seal

13, Labyrinth ring

To install new seal into crankcase use oil sea l pusher

(P/N 420 9779 20) .

Position labyrinth ring w ith bevelled side on top.

To install magneto, refer to "M agneto" in this section.

I

Oil seal pu sher

(PIN 420 9779 20)

AOOO 001 079

0 2-01 -9

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

-

MAGNETO AND COOLING SYSTEM

2

3

~~

19

A002 002 072

02-01-10

Section 02

Sub-section 01

1.

2.

3.

4.

5.

6.

Magneto parts set

Contact breaker set

Lubricating wick

Grommet

Condenser assembly

Generating coil with cable

Distance sleeve 11 mm (2)

Brake lighting coil with cable

Phillips head screw M5 x 32 (2)

Breaker cam

Magneto ring

Magneto housing

Loctite 242

Hexagonal nut 18 mm x 1. 5

Fan

Pulley spacer

Lock washer 6 mm (3)

Hexagonal nut M6

Air deflector

Spring washer B5 (2)

Slotted head screw M5 x 8 (2)

Cable clamp

Slotted head screw M3 x 16

Armature plate

Washer 5. 5 mm (3)

Lock washer 5 mm (3)

Hexagonal cap screw M5 x 18 (3)

Female connector 6.3 (5)

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

0

NOTE : The following procedures can be done

w ithout removing t he engine from chassis.

CLEANING

Clean all metal components in a non-ferrous metal cleaner.

-,... CAU T ION : Clean armature using only a clean

T cloth .

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

4 7.

48.

49.

50.

51.

52.

53.

54.

ENGINE

(247 ENGINE TYPE)

Lighting coil with 2 cables

Phillips head screw M5 x 28 (2)

Cam spring washer

Breaker cam spring

Hexagonal cap screw M6 x 22 (4)

Lockwasher 6 mm (8)

Bearing screw M6

Centrifugal lever

Centrifugal lever spring

Hexagonal nut M6 (4)

Hexagonal screw M6 x 20 (2)

Starting pulley

Hexagonal self-tapping screw (3)

Hexagonal nut 8 mm (4)

Lock washer 8 mm (4)

Stud MB x 23 (3)

Stud MB X 34

Fan cowl

Spark plug

Spark plug protector

Protection cap (2)

Ignition cable 360 mm

Slotted head screw M5 x 22 (3)

Junction box bracket

Ignition coil

Mass cable

Protector cap

14, M agneto retaining nut

To remove magneto retaining nut :

- Lock crankshaft with magneto housing holder (PIN

420 9765 50) as illustrated.

- Remove magneto reta ining nut.

DISASSEMBLY

To gain access to magneto assembly, remove :

muffler

upper column

air duct

air deflector

spark plug cable c lamp

fan cowl

starting pulley

pulley spacer

0

NOTE : Before disassembling magneto, indexing

marks shou ld be located to facilitate reassembly

AOOO 002 068

0

NOTE: It should be noted that to correctly remove

a Loctite locked fastener it is first necessary to tap

on the fastener to break Loctite bond. This w ill elim inate

t he poss ibility of thread breakage.

02-01-11

Section 02 ENGINE

Sub-section 01 (24 7 ENGINE TYPE)

0

NOTE : Crankshaft can be locked with crankshaft

locking tool (PIN 420 8766 40) inserted in pulsation line fitting.

To check air gap, insert a feeler gauge of 0.25-0.38 mm

(.01 0 in .,015 in) between magnet and coil ends. If necessary

to adjust, slacken retaining screws and relocate coil.

12, Magneto housing

To remove magneto housing (flywheel) : use flywheel puller

(PIN 420 9762 35) and magneto housing holder (P IN

420 9765 50) as illustrated (or crankshaft locking tool

(PIN 420 8766 40) .

~ ~

Flywheel puller

!PIN 420 9762 35

Feeler gauge

Checking air gap

A002 002 001

ASSEMBLY

Clean cran kshaft extension (taper).

Apply Loctite 242 (blue, medium strength) .

Position magneto on crankshaft with the keyway and the

cam notch indexed as illustrated :

AOOO 001 078

Magneto housing

holder

!PIN 420 9765 50)

Keyway

Rotate cam

Tighten puller nut and, at same time, tap on bolt head

using a hammer to release magneto from its taper.

REPAIR

5, Condenser

To replace a condenser :

- Unscrew condenser nut and remove both black leads.

- Drive the condenser out of the armature plate using

a suitable pusher.

A002 002 002

Cam notch

- To reinstall, reverse procedure.

10,36, Breaker cam & centrifugal lever

2,3, Contact breaker & lubricating wick

Rotate breaker cam to check centrifuga l lever operation.

When replacing contact breaker:

- Apply a light coat of grease on lu bricating wick .

- Clean breaker points with acetone, alcohol or ether.

6,8,29, Generating coil, brake lighting coil &

lighting coil

Whenever a co il is replaced, the air gap (distance between magnet and coil end) must be adju sted.

02-01-12

Section 02 ENGINE

Sub-section 01 (247 ENGINE TYPE)

37, Centrifugal lever spring

At assembly, apply a sma ll amount of low temperature

grease (PIN 413 7061 00) into spring seating.

13,21,33,50, Loctite 242, air deflector screw,

magneto ring screw & junction box screw.

At assembly of air deflector, magneto and junction box,

apply Loctite 242 on screw threads.

13,14, Loctite 242 & magneto housing nut

At assembly, thoroughly clean threads and apply Loctite

242, th en torque retaining nut to 85 N•m (63 lbf•ft).

48, 53, Protection cap & mass cable

At reassembly coat all electric connections w ith silicone

dielectric grease to prevent corrosion or moisture from

penetrating. (P / N 413 7017 00) .

....,. CAUTION : Do not use silicone "sealant", this

T product will corrode contacts.

For ignition timing refer to section 04-02.

c

0 2-01 -13

-

-

_,..,

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

253 ENGINE TYPE

ENGINE REMOVAL & INSTALLATION

Safari Citation/E, Tundra/LT

a

I

39

29

I

40

· -37

~- 38

28

• For electric starti ng only.

AOOS 002 001

02-02-1

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

1.

2.

3.

4.

5.

•

*6.

*7.

8.

9.

10.

11 .

12.

13.

14.

15.

16.

17.

18.

19.

20.

Rotax engine 253

Engine bracket

Lock washer 10 mm (3)

Hexagonal head cap screw M 10 x

Hexagonal head cap screw M10 x

Hexagonal head cap screw M10 x

Electric starter support

Spacer

Hexagonal elastic stop nut 10 mm

Cup (2!

Loctite 242 (blue)

Mounting rubber (3)

Front support (2)

Washer (3) • (4)

Lock washer 10 mm (2)

Hexagonal head cap screw M10 x

Hexagonal head cap screw M10 x

Washer (2!

Internal tooth lock washer (2)

Hexagonal elastic stop nut 10 mm

Rear support

20 (3)

35 (2)

45 (2)

(2)

40 (3)

25 (2!

(3)

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

Hexagonal head cap screw M8 x 20 (3)

Lock washer 8 mm (3)

Flat washer 8.4 mm (3)

Spring

Front shell

Female ball joint

Male ball joint

Spring (2)

Muffler

Female ball joint

Muffler support

Hexagonal head cap screw M6 x 45

Spring

Hexagonal flanged elastic stop nut 6 mm

Spring

Spring

Spring

Exhaust grommet

Rubber stopper

Starter grip

*For electric starting only

REMOVAL FROM VEHICLE

INSTALLATION ON VEHICLE

Remove or disconnect the following then lift engine from

vehicle:

To install engine on vehicle, inverse removal procedure.

However, pay attention to the following :

- battery ground cable, (if applicable)

- Check tightness of engine mounting supports screws.

- pulley guard, chaincase support, drive belt and drive

pulley (refer to section 03-03)

4,8,15,19, Engine ·mount screw & nut

- impulse line

-starter cable (if applicable)

WARNING: Before disconnecting any electrical

wire in starter system always first disconnect the

•

negative black battery cable.

- muffler

- hood retaining cable

-oil injection pump cable

-

- Torque both screws #15 of front engine bracket and

nut #19 of rear support to 55 N•m (41 lbf•ft)

- Torque screws #4 and nuts #8 to 48 N•m (35 lbf•ft) .

- Check pulley alignment and drive belt tension.

- Check throttle cable condition .

- Should a light exhaust leak is experienced at muffer

ball joint, Dow Corning sealer #763 RTV can be used.

However after some hours of use, carbon deposits accumulation shou ld seal joint.

- electrical connectors

- clamp retaining carburetor on engine

-rewind starter cable

- engine mount screws (3)

02-02-2

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

TOP END

7--

a2 1 N•m

( 15 lbf· ft )

9

@

_@

10-a

13

~~-10

AOOS 002 002

·-15

02-02-3

-

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

1. lmegral cylinder head

2. Spring bracket

3. Lock washer 6 mm

4. Screw M6 x 12

5. Injection fitting

6. Head cylinder gasket

7. Stud M8 X 158.5 (4)

8. Lock washer 8 .4 mm (4)

0

NOTE: Engine must be removed from chassis to

perform the following procedures.

Use engine mounting support (PIN 420 8768 30) to hold

engine while working on it.

(TYPICAL)

9. Nut M8 (4)

10. Circlip (2)

11.

12.

13.

14.

15.

Semi-trapez ring

Rectangular ring

Piston

Gudgeon pin

Needle bearing

DISASSEMBLY

10,13,14, Circlip, piston & gudgeon pin

Place a clean cloth over crankcase to prevent eire/ips

from falling into crankcase. With a pointed tool inserted

in piston notch, remove eire/ips from piston.

To remove piston pin, use piston pin puller (PIN 529 0068

00) as follows :

- Fully screw puller handle.

- Place stop notch of puller in line with the puller axis.

- Insert puller end into piston pin.

- Rotate stop notch of puller so that corners protude

the puller end.

A003 002 001

0

NOTE : This engine is designed with an integral

cylinder head unit and its mounting nuts are underneath era n kcase.

CLEANING

A001 001 054

- Hold puller firmly and rotate puller handle counterclockwise to pull piston pin.

Discard all gaskets.

Clean all metal components in a non-ferrous metal cleaner.

Scrape off carbon formation from cylinder exhaust port,

cyl inder head and piston dome using a wooden spatula.

0

NOTE : The letters "AUS" (over an arrow on the

piston dome) must be visible after cleaning.

Clean the piston ring grooves with a groove cleaner tool,

or with a piece of broken ring.

A001 001 046

02-02-4

-

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

0

NOTE: 0.25 and 0.5 mm oversize pistons and rings

are available if necessary.

INSPECTION

Centering tool

(PIN 529 0091 00)

The inspection of the engine top end must include the

following measurements :

TOLERANCES

MEASU REMENTS

Cylinder taper

FITTING NEW PARTS

(MAX .)

(MIN .)

0.03 mm

I 0012"!

WEAR LIMIT

0.07 mm

(0028")

NA

A001 001 064

Cylinder out of

round

N.A.

NA

0.10 mm

I 0039")

Cylinder I piston

clearance

0.08 mm

(0031 ")

0.10 mm

(0039")

0.20 mm

(008")

Ring I piston groove

clearance

0.04 mm

(002")

0.11 mm

I 004")

0 .20 mm

(008")

Ring end gap

0 .20 mm

(008")

0.35 mm

I 014")

1.0 mm

I 039")

0

NOTE : For the measurement procedures, refer to

"Engine dimensions measurement", section 02-09.

0

NOTE: The circl ip on the opposite side can be

installed before pin installation, the tool will easily

go out.

To minimize the effect of acceleration forces on circlip,

install each circlip so the circlip break is at 6 o'clock as

illustrated. Use piston circl ip installer (P/N 529 0086 00).

Piston circl ip installer

IP IN 529 0086 00)

ASSEMBLY

10,13,14, Circlip, piston pin & piston

At assembly, place the piston over the connecting rod

with the letters "AUS" (over an arrow on the piston dome)

facing in direction of the exhaust port.

A001 001 062

A001 002 001

Spare pa rts pistons and cylinders are identified with a

green or red dot, it is important to match the piston with

the cylinder of the same color.

To center the piston pin with the connecting rob bearing,

use centering too l (P/N 529 0091 00).

A001 002 002

02-02-5

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

.,..-CAUTION : Circlips must not move freely in the

T groove after installation. If so, replace them.

1, Integral cylinder head

Before inserting piston in cylinder, lubricate it with new

injection oil or equivalent.

Install ring compressor (PIN 420 8769 70) on piston

assembly.

0

NOTE: The ring compressor will not fit on overSIZe p1ston.

Remove spa rk plug .

Install integral cyl inder head, then rotate crankshaft to

position.

7, Stud

The longer threaded end must be screwed into the integral cylinder head.

9, Nut

Cross torque integral cylinder head nuts to 21 N•m

(15 lbf•ft).

Retorque both crankcase screws to 9 N•m (80 lbf•in).

Torque to

9 N•m (80 lbf•in)

Torque to

21 N•m (15 lbf•ftl

BOTTOM VIEW

A003 002 002

02-02-6

ENGINE

Section ON2GINE TYPE)

.

Sub-section

0 2 (253 E

BOTTOM END

I

19

g N• m

!SO Jbf•in)

AOOS 002 003

t>

Section 02

ENGINE

Sub-section 02

-

(253 ENGINE TYPE)

I. Upper crankcase

2. Rubber plug (2)

3. Oil seal PTO side

4 . Sh1m

5. Ball bearing 6206 (2)

6. Distance nng (2)

7. Crankshaft

8. Woodruff key

9. Sh1m (as required)

I 0 . Beanng reta1ner

I I.

I 2.

I 3.

14.

I 5.

0

3,11, Oil seal

NOTE : Engine must be removed from chassis to

perform the following procedures.

16.

I 7.

18.

I 9.

Oil seal mag. side

Loctite 5 I 5

Lower crankcase

Lock washer M6 (2)

Screw M6 x 30 (2)

Loctite 242 (blue, medium strength)

Lock washer 22 mm

Nut M22

Anti-seize lubricant

CLEANING

At seal assembly, apply a light coat of lithium grease on

seal lips.

Discard all seals, gaskets and 0 -rings.

For bearing lubrication purpose, a gap of 1.0 mm (040 in)

must be maintained between seals and bearings.

Clean all metal components in a non-ferrous metal cleaner.

Remove old sealant from crankcase mating surfaces with

Bombardier sealant stripper (P/N 413 7021 00).

When installing plain seals (seal without locating ring or

without spacing legs), ensure to maintain the specified

gap between shim I bearing retainer and the seal.

~

CAUTION : Never use a sharp object to scrape

away old sealant as score marks incurred are detrimental to crankcase sealing.

T

Shim

1.0 mm (040 in)

DISASSEMBLY

General

To remove magneto, refer to "M agneto" in this section.

5, PTO side bearing & MAG side bearing

To remove bearings from crankshaft use a protective cap

and special puller, as illustrated. (See Tools section) .

PTO side

Oil seal

A003 002 003

2, Rubber plug

Prior to installing the crankshaft, make sure both rubber

plugs are into upper holes.

1,12,13, Upper crankcase, Loctite 515 &

lower crankcase

Crankcase halves are factory matched and therefore, are

not interchangeable as single halves.

AOOO 002 017

02-02-8

-

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

Prior to joining of crankcase halves, spray new injection

oil on all the moving parts of the crankshaft.

ASSEMBLY

Apply Loctite 515 (P/N 413 7027 00) on mating surfaces.

General

NOTE: Prior to applying Loctite 515 it is possible

to use primer N (P/N 413 7053 00) or primer NF

(P/N 413 7024 00). It increases cure speed and gap

fill ing capability. Refer to supplier instructions.

0

.,.,. CAUTION : Before engine reassembly, make sure

T there is no axial pressure on crankshaft and that

the crankshaft end-play is properly adjusted .

Position the crankcase halves together, rotate crankshaft

2 or 3 turns, then evenly tighten crankcase screws. Torque

them to 9 N•m (80 lbf•in).

Crankshaft end-play adjustment

Refer to "Engine Dimensions and Measurement" section 02-09 for the procedures.

6, Distance ring

At installation, always locate its inner radius against counterweight radius. Make sure it does not slip between the

counterweight and the bearing.

5, Crankshaft ball bearing

Torque to

9 N•m !80 lbf•inl

Smear anti-seize compound (P/N 413 7010 00) on part

of crankshaft where bearing fits.

Prior to installation, place bearings into an oil conta iner

fill with oil heated to 75°C (167°F) . This will expand

bearings and ease installation. Install outer race groove

outward.

BOTTOM VIEW

A003 002 002

Refer to "Top end " section to complete the assembly.

INSPECTION

The inspection of the engine bottom end must include

the following measurements :

TOLERANCES

M EASUREMENTS

Crankshaft

deflection

Connecting rod big

end axial play

Crankshaft end play

0

FITT ING NEW PARTS

(MAX.)

(MIN.)

WEAR LIMIT

N.A.

N.A.

0.08 mm

(003" )

0.20 mm

(008")

0.53 mm

(.021")

1.0 mm

(039")

0.1 - 0.3 mm

(004" - 012")

NOTE : For the measurement procedures, refer to

"Engine dimensions measurement", section 02-09.

c

02-02-9

Section _0 2 ENGINE

( 3 ENGINE TYPE)

Sub-section 02 25

MAGNETO

eb

t-2

23

02-02-10

32

31

~

~/u

c

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

1. Spark plug protector

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

0

Spark plug

Ignition coil

Ground wire (2)

Taptite screw M5 x 20 (2)

Amplifier box

Washer 6 mm (2)

Lock washer 6 mm (2)

Screw M6 x 20 (2)

Wiring grommet

Wire ass'y

Splice connector (6)

Protector tube (6)

Washer 5.5 mm (2)

Lock washer 5 mm (2)

Loctite 242 (blue, medium strength!

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Screw M5 x 18 (2)

Generating coil

Lock washer 5 mm (2)

Screw M5 x 35 (2)

Lighting coil

Screw M6 x 25 (2)

Magneto flywheel

V-belt pulley

Starting pulley

Lock washer 8 mm (3)

Screw M8 x 12 (3)

Lock washer 22 mm

Nut M22

Armature plate

Screw M5 x 8 mm

Clamp

NOTE : The following procedures can be done

without removing the engine from chassis.

CLEANING

Clean all metal components in a non-ferrous metal cleaner.

.,.,. CAUTION : Clean armature and magneto using

T only a clean cloth.

DISASSEMBLY

24,25,29, V-belt pulley, starting pulley & nut

Crankshaft

locking tool

(420 8766 40)

To gain access to magneto assembly, remove :

- injection oil line

- rewind starter

Impulse

fitting

-starting and v-belt pulleys

0

NOTE : Before disassembling magneto plate, indexing

marks should be scribed to faci litate reassembly.

To remove magneto flywheel retaining nut :

- Lock crankshaft with crankshaft locking tool (PIN 420

8766 40).

AOOJ 002 005

0

NOTE: It should be noted that to correctly remove

a Loctite locked fastener it is first necessary to tap

on the fastener to break Loctite bond. This will eliminate

the possibility of thread breakage.

02-02-11

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

I.

23, Magneto flywheel

To remove :

.

''t

- Unscrew magneto retai~ nut and install the suitable

,

.

·

puller as shown.

1

- -- - - - -- - -,

I

I

I

I

PiN 420 8760 65 1

Protect harness

from flame

I

Heat

A001 002 003

PiN 420 8766 55 I

~------ - --__!

Magneto housing

. puller and ring

A003 002 006

T

CAUTION : Protect ha-~ness from flame.

- Remove screws (use Phillips no. 2 or suitable flat screw

driver).

· - Cut the four wires as close as possible to the coil body.

0

NOTE : For the above procedure, the locking type

puller can be used without crankshaft locking tool.

- To pass new co.il wires in harness, tape the old wires

to the end of new wires and pull them through the

harness protector tube.

- Insert the new wires into the old connector housing

and install connectors.

Insert

new wires

PiN 420 8760 65

PiN 420 8760 80

AOOO 001 083

.:_ Tighten puller bolt and at same time, tap on bolt head

using a hammer to release magneto from its taper.

REPAIR

AOOl 002 004

18, Generating coil

.... CAUTION : Replace the old wires in t~e connector

. T with the same color coded new w1res.

To replace generating coil :

- Install a new receptacle connector to the black/yel·low striped wire.

- Heat the armature plate to 93°C (200°F) around the

screw holes to break the Loctite bond.

- To install the ground connector of the armature plate, .

tape th.e new black lead to the old one and pull it under

the lighting coil with the old wire.

- Solder an eye connector to the lead and fasten it under ·

the wire retaining clip.

02-02-12

r

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

Wire retaini ng clip ·

Heat

·~-~~---/.

I

I

I

I

~

.

Yfi!!J<\'!1 :.

.

I

·~

·~r

------

I

, , :----

.

I

1

I

.

.

·

--~Eye connector

A001 . 002 003

II

I

T

CAUTION : Protect harness from flame.

-Remove screws (use Phillips no. 3 screwdriver),

A001 002 005

- Remove the wire retaining clip from armature plate.

- To install the new coil on the armature plate, remove

theshipping nuts from the coil and apply Loctite 242

(blue, medium strength) to screws before assembly.

- Pull out protector tubes and unsolder the splice connectors.

- Solder the yellow wire in the harness to the white tube

·

protected wire of the coil.

- Use magneto coil centering tool (PIN 420 8769 22)

·

before tightening screws.

,...:... Solderthe yellow I black striped wire in the harness to

the black tube protected wire of the coi l.

r

A001 004 003 .

Black -protector wiih

yellow I black wire of harness

.M agneto coil centering tool

(PIN 420 8769 22)

AOOl 002 006 .

...,-- Position protector tubes over connections .

.... CAUTION : Before reinstalling the magneto, remove

T the loose epoxy from harness.

.

12,13,21,22, Splice connectors, protector

tubes, lighting coil & screw

. White protector with

yeUow wire of harness

.

~ Prior to assembiy, apply Loctite 242 (blue, medium

strength) on the lighting coil screws. Use magneto coil

centering tool (PIN 420 8769 22) before tightening

screws.

To replace lighting coil :

- Heat the armature plate to 93°C (200°F) around the

. screw holes to break the Loctite bond.

02-02-13

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

Magneto coil centering tool

(PIN 420 8769 22!

A001 004 003

- Fasten retaining clip onto protector tubes.

'W' CAUTION : Before reinstalling magneto, remove

T the loose epoxy from harness.

ASSEMBLY

23,28,29,30, Magneto flywheel, lock washer,

armature plate & nut

Position the armature plate on the crankcase aligning the

marks on both parts.

Clean crankshaft extension taper.

Apply Loctite 242 (blue, medium strength) on taper.

Position key, magneto flywheel and lock washer on

crankshaft.

Clean nut threads and apply Loctite 242 (blue, medium

strength) before tightening nut to 85 N•m (63 lbf•ft) .

At reassembly coat all electric connections with silicone

dielectric grease (P/N 413 7017 00) to prevent corrosion or moisture penetration.

'W' CAUTION: Do not use silicone "sealant", this pro-

T

0

duct will corrode contacts.

NOTE: For ignition timing procedure refer to "Ignition timing" section 04-02.

02-02-14

--.

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

-

COOLING SYSTEM

22

~

/21- - 0 -

lf- 23

0

/ / 2o- @ ) -@)

@-©

~011ii1/ 19 @f~/

~~

'

~

16

17

c

18

10

I

55 N•m

(41 lbfoft)

15

13

AOOS 002 005

02-02-15

Section 02 ENGINE

Sub-section 02 (253 ENGINE TYPE)

1.

2.

3.

4.

5.

6.

7.

B.

9.

10.

11.

12.

Fan housing

Snap ring

Shim (2)

Bearing 6203 (2)

Fan shaft

Woodruff key

Spacer

Pulley half

Shim 0. 5 mm

Fan

Lock washer 76 mm

Nut M76

0

73.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

V-belt