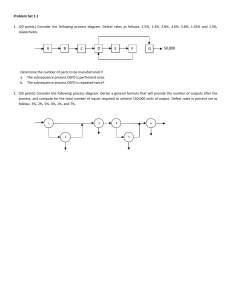

Enhancing the SRAM Failure Analysis Process Raymond G. Mendaros Global Failure Analysis (GFA) Analog Devices General Trias (ADGT) Gateway Business Park, Brgy. Javalera, Gen. Trias, Cavite, Philippines 4107 Phone: +63 2 867703, Email: raymond.mendaros@analog.com Abstract- The advent of the 65nm silicon fabrication technology node and smaller geometries; particularly for static random-access memory (SRAM) array, posed several Failure Analysis (FA) challenges such as the fault isolation capability limitations, physical FA (PFA) approach identification intricacy, defect node localization complexity and defect to fail mode correlation difficulty. To address these challenges, device defect modeling (DDM) process through software simulations and building of defect databases were introduced. Through the aid of the DDM process, defect sites were reduced to a single transistor or node from the SRAM array. Defect models were derived from the simulation process that guided analysts in identifying the suitable PFA approach. DDM process was effective in the failure mechanism to failure mode simulations. The DDM process was likewise instrumental in building defect databases for SRAM layout designs. These databases contained relevant information such as circuit simulation results, fabrication material stacking, suggested fault isolation techniques and potential defect locations that served as references for analysts. geometries such as the 65nm technology node. The limitation encountered on the PEM system is a common shortcoming for the OBIRCH and thermal systems. Keywords –Defect Modeling, Static Random Access Memory, fault isolation, 65nm technology node, SRAM defect database The PFA technique or approach to be used may vary depending on the defect type. For instance, an electrostatic discharge (ESD) damage such as “pinholes”, due to its miniscule physical attribute, is preferred to be chemically deprocessed. Deprocessing will enable the inspection of the whole layer (top down inspection), thus, has higher chances of locating submicron defects as compared to the progressive cross section approach. A via or plug formation defect, on the other hand, is preferred to be cross-sectioned using a Focus ion beam (FIB) equipment to have a good view of the defect site (cross sectional view). I. INTRODUCTION Driven by the industry’s requirement of reducing chip size, semiconductor companies implemented in their products the 65nm silicon die fabrication process and smaller geometries [1]. This die fabrication process node, due to the reduced component size, posed several FA challenges. In this technical literature, the focus of the study is on the failure analysis process improvement for 65nm embedded 6T SRAM devices wherein the learning can be fanned out to smaller fabrication technology geometries. The FA challenges for leading technologies are as follows: 1. FA tools and techniques’ fault isolation limitations Advanced photon emission microscopy (PEM), optical beam induced resistance change (OBIRCH) and thermal camera’s failure analysis fault isolation tools do not anymore have enough resolutions to pinpoint the exact anomalous SRAM memory transistor for 65nm and smaller technologies. As an example, the PEM photo in Figure 1 was captured on a huge 0.18um technology node. There were two metal–oxide–semiconductor field-effect (MOSFET) transistors in the emitting site but because of the tool’s limited optical and camera magnification capability, even at this huge technology node, the exact emitting transistor could not be identified. This capability limitation is magnified when dealing with smaller Figure 1. PEM detected photon emissions from two NMOS transistors however, the machine resolution could not resolve which transistor was emitting. This is a 0.18um technology process. 2. Identification of the suitable physical failure analysis (PFA) technique or methodology 3. Defect node localization is another FA challenge SRAM cell has six transistors in its circuit. Since DDM process simulates a possible defect site through replicating the failing electrical output response, the suspected defect site can be narrowed down to a node or transistor. 4. Physical defect to failure mode correlation Not all visual anomalies seen during physical failure analysis (PFA) will necessary result to a failure. A suspected physical defect observed in the chip can be electrically simulated using the DDM process to determine its consistency with the device’s failure mode. To address these FA challenges, DDM process and defect database generations were implemented in FA process. Authorized licensed use limited to: Fondren Library Rice University. Downloaded on July 18,2020 at 13:02:11 UTC from IEEE Xplore. Restrictions apply. II. EXPERIMENTS The study was focused on one embedded 6T SRAM layout design. The memory failures were confined to “stuck to low” and “stuck to high” memory failures. Timing and voltage sensitive failures were not included due to the absence of the exact transistor models for the LTSpice simulation software. The memory failure types that were covered were single bit, dual (twin) bit, full row and full column failures. DDM simulated defect models were documented in the database. An LTSpice student version (version 1.0.0.1) was used in all the circuit simulations. The exact transistor models of the 65nm memory device were not available due to proprietary reasons. The inputs of the process are the gathered electrical failure characteristic or behavior of the sample being analyzed. These are the memory type (e.g. “single bit”) and output response (e.g. “stuck to low”). The outputs are the simulated failure memory type and output response that corresponds to the introduced defect model (e.g. “added resistance”) in the simulation circuit. The introduced defect model, location of the defect in the circuit and the plots of the simulated electrical failure characteristic or behavior are documented in the database. The process flow is shown in Figure 2. Figure 2. Conceptual framework process flow. This section was divided into 5 subsections. The first section was the creation of an SRAM Device Defect Modeling (DDM) simulation circuits using LTSpice (version 1.0.0.1) software. Figure 3 is a representative single SRAM 6T cell created in the LTSpice schematics software. For the actual DDM simulation circuit, several SRAM cells were created in the software. The memory failures that were considered were confined to “stuck to low” and “stuck to high” memory failures. The memory failure types that were covered were: single bit, dual (twin) bit, full row and full column failures. Figure 3. LTSpice representative circuit of a single SRAM cell The second section was the creation of a process flow for the defect simulations using the DDM circuit. The inputs of the process were the fail memory types (e.g. single bit, dual bit, etc.) and output response (e.g. “stuck to low”). The output of the process were the simulated electrical failure responses. The modeled defects were recorded in a database. The third section was the building of defect databases for specific SRAM layout designs. The contents of the databases are as follows: The memory failure type column contained the four common memory array failures types: Single bit, Dual bit, Row and Column failures. The Input signal column contained the input pattern going to the memory array. The failure output response column listed the SRAM failing response. These were either “stuck low” or “stuck high” output failure condition. Commonly for embedded SRAMs, SPI communication protocol is used. Thus, the output response was either logic “low” or “high” only. The simulated defect column represented the modeled defect that replicated the electrical failure mode or characteristic. The lay-out location of the simulated defect column, on the other hand, indicated the location of the modeled defect in the layout. The next column, cross sectional illustration of the fab process stacking of the simulated defect, illustrated the Fab process material stacking of the defect site. The FA techniques to be considered column listed the fault isolation and PFA techniques to be utilized based on the modeled defect and location. Finally, the Images/ Output plots column documents the simulated electrical output response. The last two sections (4th and 5th) revealed the areas in FA process where the DDM process were utilized and demonstrated. DDM’s usefulness in addressing the different failure analysis challenges. At least two case studies each were discussed to validate these two sections of the methodology. Evidences of the simplified process were discussed. Authorized licensed use limited to: Fondren Library Rice University. Downloaded on July 18,2020 at 13:02:11 UTC from IEEE Xplore. Restrictions apply. III. RESULTS AND DISCUSSION Figure 6a. Simulator circuit for the dual bit cell 6T SRAM DDM Simulation Circuit Creation Creating simulation circuits required knowledge on both the simulation software and electronic circuit’s functionality. In this study, there were three simulation circuits that were created. The first circuit is a single cell to simulate single bit failures. There were two variations of the circuit; with and without output inverter. See figures 5a and 5b for the LTSpice circuit and input/output responses. Figure 6b. Input and output plots of the dual bit cell The second circuit is a two adjacent cell to simulate dual (double) bit failures. See Figure 6a and 6b. Two separate adjacent circuits were created, one lateral and one vertical dual bit circuits. Figure 6a and 6b represent a lateral dual bit simulator. The third circuit is composed of nine transistors, 3-rows by 3-columns memory array, to simulate row and column failures. See Figure 7a. The circuits were validated by observing their output responses. See Figure 7b and 7c. An SRAM cell without an inverter circuit at its output manifested an opposite of its input signal. Figure 7a. A 3-rows by 3 columns array simulation circuit for row and column failures Figure 5a. Single cell simulator without inverter circuit at the output Figure 7b. Input to the 3-rows by 3 columns array Figure 5b. Single cell simulator with inverter circuit at the output Figure 7c. Outputs of the 3-rows by 3 columns array Authorized licensed use limited to: Fondren Library Rice University. Downloaded on July 18,2020 at 13:02:11 UTC from IEEE Xplore. Restrictions apply. Defect simulation process using the DDM circuit The defect simulation process flow is shown in Figure 2. The inputs of the process are the fail memory type (e.g. single bit) and output response (e.g. “stuck to low”). The outputs of the process are the simulated failure responses and updated database. Defect Database Databases were created with the consideration to the embedded SRAM lay-out design being utilized by ADI. The defect database serves as reference and guide for analysts. The benefits and advantages of the databases are as follows: a. Defect sites’ locations are identified in the layout This avoided the tedious circuit analysis, commonly manual approach, before the DDM process was implemented as potential defect sites were already identified. Through the database, once memory fail type and failure output response are known, analysts already have an idea where to focus the physical failure analysis and inspection. DDM failure mechanism-to-fail mode simulations Two representative failure mechanisms were simulated. a. Simulation #1 – A Particle Defect A known programming pattern was loaded into the device, particularly to the embedded SRAM, but the read codes (checksum values) do not match the written pattern. Bitmapping analysis was performed to test the memory array and found a single bit failure with “stuck to high” output condition. The bitmapping tool was able to identify the cell’s physical location in the memory array. Physical FA (PFA) done by ADI’s subcontractor uncovered a random fabrication defect. A fall-on nitride (N) particle between the gate and drain terminals of a transistor in the failing site was identified. See Figure 8. The electrical failing signature of the memory cell was confirmed when a short on the gate and drain and an open contact on the drain defect models were introduced into the simulation circuit. The anomalous contact is the common drain of the NMOS in one of the inverters and pass transistor drain of the worldline. See Figure 9 for the DDM simulation results. b. The die fabrication material stackings are illustrated The information about material stacking were further verified through Focus Ion Beam (FIB) cross-sections of actual memory cells. With this information being available, analysts can effectively plan their physical failure analysis approach. On the other hand, without this information, the analyst recourses to layout review and consultations which can cause significant delays. c. Transistor and SRAM cell’s nodes such as, source, drain, gate, Vdd, ground, etc., are identified and labelled. The delays incurred due to the repeated access and viewing of lay-outs to identify nodes are avoided. Furthermore, this complements the material stacking information. The defect locations are mapped in the FA reports from a top down (layout) and cross-sectional (material stacking) perspective. Table 1 showed a portion of the database. Table 1. Representative defect database from one of the SRAM designs Figure 8. TEM post FIB cross section (left) and EDX (right) results of the suspect site Figure 9. Stuck high output failure was confirmed Authorized licensed use limited to: Fondren Library Rice University. Downloaded on July 18,2020 at 13:02:11 UTC from IEEE Xplore. Restrictions apply. b. Simulation #2 –Resistive W-Plug Contact Defect ADI ATE testing showed that the programmed value of “0” was showing an erroneous read value of “1”. Bitmapping analysis showed two adjacent cells were failing. All the fault isolation analysis techniques that were performed (PVC, C-AFM and nano-probing) on the failing cells yielded no anomalies. Physical analysis was still pursued and found silicide and contact formation defects that were one cell away from the bitmapper’s identified physical failing location. See Figure 10 for the cross-sectional view of the defect and its location in the layout. The defect observed was modeled and introduced in the simulation circuit. Simulation results showed that the defect site was consistent with the electrical failing signature. See Figure 11 for the simulation results. differs in the locations where they occur. ESD defects are expected to be situated near the edges of the transistors’ gate channel where high electric fields are present while deprocessing artifacts are observed at the center of the gate channel [4]. Deprocessing artifacts are represented by mechanically induced damaged sites in the silicon substrate. These damaged sites are manifested in the form of silicon pits, voids, slits and fractures resulting from the tensional or shearing stresses in the silicon substrate when the polysilicons separate from the silicon substrate. Figures 12a and 12b are SEM photos of a valid and invalid ESD pinholes. A DDM simulation of an artifact defect in one of the SRAM transistors did not yield to the expected failure mode. DDM process in this case was the more efficient approach rather than conducting actual evaluations. Figure 12a. Valid ESD defect: SEM photo of pinholes underneath the gate oxide layer Figure 10. Focus Ion Beam X-section found silicide and contact formation defect on the common source of the failing SRAM cells Figure 12b. Deprocessing artifact: A pit or void at the center of the channel b. Failure Mechanism Undetermined Investigation An electrical failure was confirmed to be SRAM array related. Fault isolation analysis using C-AFM confirmed a contrast anomaly on the VDD contact. See figure 13. PFA on the part, inspecting all the layers of the die, did not uncover the defect. DDM process was used to explain the potential defect site. See Figure 14. From the simulation results, the defect site was in the metal layers but was missed during the PFA. Figure 11. The stuck-to-low simulation has been confirmed when source of the output pass transistor is isolated Demonstrate the Other Usefulness of DDM a. Wet Chemical Deprocessing Induced Artifacts Verifications [2,3] Wet Chemical Deprocessing is one of the techniques in exposing embedded structures in an integrated circuit (IC). Layers of the die from the passivation to silicon substrate can be selectively etched away using this technique. From series of evaluations conducted, it was discovered that there were silicon damage sites that were induced during wet chemical deprocessing. Their physical attributes were identical to the attributes of electro-static discharge (ESD) defects. It only Figure 13. C-AFM showing a VDD contact via anomaly Authorized licensed use limited to: Fondren Library Rice University. Downloaded on July 18,2020 at 13:02:11 UTC from IEEE Xplore. Restrictions apply. Figure 14. DDM simulation results. IV. CONCLUSION The DDM process was found to be effective in identifying potential defect sites in the SRAM array. This was exemplified by the successful simulation cases. The DDM process was instrumental in generating defect databases. The information in the database hastened the failure analysis process; particularly, the fault isolation steps, as analysts had a clear understanding of the layout and material stacking that eliminated the tedious and time-consuming reverse circuit engineering analysis procedure. Furthermore, the DDM process and defect database have shown that the prevailing failure analysis challenges of the 65nm technology node can be addressed by the process. ACKNOWLEDGMENT The author wishes to express his gratitude to the ADI team from Failure analysis, TPG Product Line and Design groups for their contribution on the analysis of the failures and inputs to this technical paper. REFERENCES [1] PTI. (2013, June 6). “IIT Mandi develops next generation IC chips. The Economics Times” Retrieved from https://www.iitmandi.ac.in/news/articles/files/indianexpress_economi ctimes.pdf [2] R. Mendaros, et al., “Discovery of wet chemical deprocessing induced artifacts – A common problem affecting all MOS and CMOS Technologies”, ASEMEP 2016, Manila, Philippines. [3] R. Mendaros, et al., “Identification of Wet Chemical Deprocessing Induced Artifacts – A Common Problem Affecting All MOS and CMOS Technologies”, ISTFA 2016, Texas, USA [4] Analog Devices Incorporated. (2014). “Reliability Handbook”. Retrieved from http://www.analog.com/media/en/technical-documentation/user-guide s/UG-311.pdf Authorized licensed use limited to: Fondren Library Rice University. Downloaded on July 18,2020 at 13:02:11 UTC from IEEE Xplore. Restrictions apply.