dokumen.tips fanuc-r-j3ib-maintenance-manual-for-europe-b-81465en-1-02

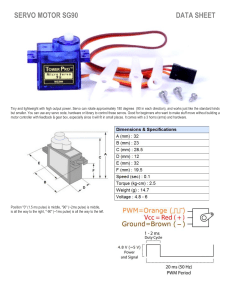

advertisement