AIIE Transactions

ISSN: 0569-5554 (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/uiie19

Artificial Intelligence in Manufacturing Planning

and Control

William I. Bullers , Shimon Y. Nof & Andrew B. Whinston

To cite this article: William I. Bullers , Shimon Y. Nof & Andrew B. Whinston (1980) Artificial

Intelligence in Manufacturing Planning and Control, AIIE Transactions, 12:4, 351-363, DOI:

10.1080/05695558008974527

To link to this article: https://doi.org/10.1080/05695558008974527

Published online: 06 Jul 2007.

Submit your article to this journal

Article views: 404

View related articles

Citing articles: 2 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=uiie21

Artificial Intelligence in Manufacturing

Planning and Control

WILLIAM I. BULLERS

Anderson School of Management

University of New Mexico

Albuquerque, N.M. 871 31

SHIMON Y. NOF

SENIORMEMBER, AIIE

School of Industrial Engineering

ANDREW 1;. WHINSTON

Krannert School of Management and

Computer Science Department

Purdue University

West Lafayette, Indiana 47907

Abst,-act: This paper explores some of the typical problems in manufacturing systems planning and

control, particularly those pertinent t o the automatic operation, and describes how artificial intelligence

methods can be applied. We demonstrate how predicate logic and theorem proving techniques using

resolution can be used in a manufacturing environment. Assertions of fact and axioms representing the

knowledge required are given in an underlying data base. Illustrative problems demonstrate how user

problems, such as assignment of jobs t o machines when conflicts occur, can be handled by a decision

support system in the fratnework of resolution in a problem reduction approach.

Manufacturing planning and control involves managerial

decision making in three main levels of activities: the

strategic level of production and inventory planning and

control; the tactical level of manufacturing operations planning and control; and the operational level of process and

material flow planning and control. The dynamic nature of

the manufacturing environment stems from the highlyvariable nature of factors such as customer orders influencing

the strategic level; material and capacity constraints in the

tactical level, and machine or work-station availability in the

operational level. In order to'aid manufacturing managers in

achieving productivity goals, various concepts of information

systems and computer control have been developed as

described, for example, in [26, 28, 311.

In more automatic systems, where facilities operate

directly under computer control, managerial supervision

becomes even more critical and complicated. Information

and control aspects of computerized manufacturing were

described in [27]. The high degree of interdependency

among machines, material handling devices, and other

process resources requires a large number of timely decisions

at the various levels of operation to be made. Typically,

these decisions are based on large amounts of information

Received April 1979; revised March 1980. Paper was handled by

Simulation, Gaming and Information Systems Department.

December 1980, AIIE TRANSACTIONS

and under time pressure. Due t o the dynamic nature of the

manufacturing environment, decision problems are often

unstructured, and have to be continuously reviewed in view

of the changing status of the system.

Traditionally, the manufacturing environment has been

controlled by process controllers, shop-floor computer controllers, and other computer aids for production planning.

But process controllers are typically dedicated to well

defined processes which vary within predetermined ranges.

When multi-level, highly variable operations reqvire more

timely, complex controls hierarchical systems of monitoring

and management have to be applied. A major drawback of

such procedures is their limited ability t o cope with unstructured problems, and to be responsive to dynamic variations;

particularly, this stems from time delays in comprehension

of the new circumstances and new problems by human

operators.

While computer technology can rapidly process large

amounts of data by sophisticated logic, many of the

necessary decisions must wait until human operators can

sift through the data, become familiar with the system

status, and select proper actions. This is where artificial

intelligence techniques can provide better planning and

control towards a higher productivity of automatic manufacturing. In simple terms, some of the human intelligence

which is needed t o make decisions will be transferred t o the

computer machinery; many decisions will then either be

0569-5554/80/1200-0351/$2.00/0

1980 AIIE

35 1

made automatically, or information will be prepared for

human operators to minimize delays in their decisions.

Artificial intelligence techniques can be used to develop

decision aids that are capable of handling large streams of

data as well as performing logic manipulation for conflict

resolution, sequencing and resource allocation, etc.

In previous work [I 9, 21) this problem was discussed

and the concept of the Manufacturing Operating System

(MOS) was suggested as a framework for handling the

necessary decision support. Artificial intelligence methods

were indicated as a useful approach to systematically

represent planning and control knowledge in the control

system.

The purpose of this paper is first to explore some of the

typical manufacturing planning and control problems, particularly those pertinent to the automatic environment, and

second, to describe how artificial intelligence methods can

be applied to them.

variable x, y, z or expression f(al=tl, . . . , aj=tj) where f isa

j-ary function symbol, ai is a function attribute identifier,

and ti is a term. Predicate symbols, function symbols, and

variables are any three sets of mutually disjoint symbols. A

constant is any 0-ary function symbol such as a, b, c. To

help minimize the number of symbols used, we permit the

number of attributes to vary for a given predicate or function

symbol. This contrasts with the usual syntax in which predicates and functions are fixed in size. The complement of a

predicate P is denoted -P. Methods for transforming an

arbitrary first-order predicate calculus sentence into clausal

form are shown in Nilsson [ l 7 ] , or Chang and Lee [5] .

The semantics of sentences in clausal form are also simple

[30]. Interpret the sentence{C1, Cz, . . . , C, ) as a conjunction:

C1 and C2 and . . . and C ,

Interpret the clause B1,. . . , B, +A

. . , xk as:

. . ,A, with variables

XI..

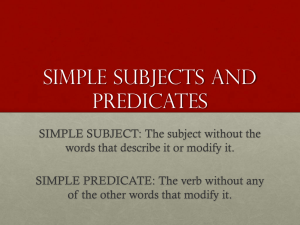

Predicate Logic in Artificial Intelligence

Predicate Logic as a Programming Language

A number of question-answering and problem-solving systems

have been developed using first-order predicate logic as a

language for representing knowledge and resolution-type

theorem provers for a deductive mechanism. Predicate logic

is a natural language for describing states or stating problems.

Moreover, predicate logic can be used to express algorithms

in addition t o merely facts. Kowalski 1131 and van Emden

[29] have both given supportive arguments for the use of

predicate logic as a high level programming language. Predicate logic addresses the descriptive aspect of a program by

permitting a specification of what is to be done, not how to

do it. Yet with respect to a given deductive mechanism, a

predicate logic specification has implications for the imperative aspect.

The deductive mechanism most commonly used to make

inferences uses resolution, a theorem-proving technique

developed by Robinson [24]. Theorem-proving procedures

using some adaptation of Kowalski and Kuchner's SLresolution (linear resolution with selection function) [14]

are well suited to heuristic search for efficiency in proving

theorems. In particular, Kowalski's LUSH (Linear resolution

with Unrestricted Selection for Horn clauses) system [13] ,

provides a proof procedure that can solve problems a t least

as complex as those that can be programmed in a high-level

programming language [29].

For automatic deduction, the "clausal form" of firstorder predicate logic has evolved. Its syntax is quite simple.

A sentence in clausal form is a set of clauses. A clause is a

pair of sets of atomic formulas B1, . . . , B,+-A,, . . . , A,.

An atomic formula has the form P(al=tl, . . . , ak=tk)where

P is a k-ary predicate symbol, ai is a predicate attribute

identifier, and ti is a term. An attribute identifier, not

normally a part of the clausal form syntax, is used here as a

notational aid in interpreting predicate terms. A term is a

B1 or

. . . or B, is implied by A l and . . . and A , .

The special cases with n=O and/or m=O have special interpretations:

1. If n=O, then read B1, . . . , B,+ as:

for all x l , . . . , x k : B1 or . . . or B,.

2. If m=O, then read +Al, . . . , A , as:

for no x l , . . . , x k : A1 and . . . and A,.

3. If n=O and m=O, then write the null clause

ted as denoting falsity (or contradiction).

interpre-

The basic framework for interpreting programs in predicate logic is given by Kowalski with his procedural interpretation of Horn clauses [13]. A Horn clause B+A 1,. . . ,An

is interpreted as a procedure declaration with the implication

B equivalent to a procedure name, and the set (A 1, . . . , A,}

equivalent to a procedure body consisting of a set of

procedure calls Ai. The clause, B e , is viewed as an assertion

of fact; the clause, +-A . . . ,A, as a goal statement (procedure with no name) which is the goal of successfully

executing all procedure calls Ai; and the null clause

viewed as a halt statement (satisfied goal statement).

Sentences in predicate logic are interpreted as programs,

derivations as computations, and proof procedures as feasible

executors of predicate logic programs. Computation applied

to Horn clause programs concerns the repeated use of

resolution to derive new goal statements from old ones.

Kowalski views resolution as procedural invocation, operating as follows:

Given (1) a goal statement +A I , . . . , Ai-l, Ai, Ai+l ,

. . . , A , and

AIIE TRANSACTIONS. Volume 12, No. 4

(2) procedure B+Bl, . . . , B, whose name B

"matches" the selected procedure call A i(i.e.,

a general substitution of terms for variables makes A i and B identical),

then resolution derives a new goal statement (with substitution 6 ) :

This matching, called "procedure invocation by pattern

matching" in PLANNER [12], is known as a feature of

several programming languages for A1 research [ I ] . Procedural invocation comprises the LUSH rule of inference. It is

resolution with the goal statement and a Horn clause as

parents. A proof procedure with a selection rule for choosing

A, and a search strategy as components serves to execute

the predicate logic programs.

Predicate Logic in Question-Answering and Problem Solving

Many question-answering systems, such as QA1 [ l o ] , have

used first-order predicate calculus to express the semantic

content of data in the systems. Others, including QA2 [ l o ]

and QA3 [9] have also used a resolution-type theorem

prover as the deductive mechanism as well as first-order

predicate calculus as the system language. More recently,

predicate logic has been used in several deductive query

systems that combine resolution-type theorem proving

techniques with an underlying data base system for knowledge storage and retrieval. These systems use LUSH to

partially prove theorems, then invoke a data base query

system to complete the proof. Chang's DEDUCE system [4]

and Minker's inferential relational system [I 5 , 161 are two

examples. Problem-solving systems have also made use of

predicate logic theorem proving techniques. PROLOG has

been used to perform automatic programming tasks 1297,

while STRIPS [8, 71 and ABSTRIPS [25] formulate plans

to solve robot problems. In this paper we demonstrate how

predicate logic and the LUSH rule of inference can be used

at a high level of control in a manufacturing environment to

solve operations management problems.

Manufacturing Planning and Control Requirements

In all three levels of manufacturing activities defined above,

planning and control are required mainly in order to achieve

efficient, productive utilization of resources to meet a

schedule of production demands. Because of the dynamic

nature of the manufacturing system which is due t o external

and internal forces of change, planning and control decisions

December 1980, AIIE TRANSACTIONS

are critical to the overall performance of the system. In [22]

an extensive survey includes a discussion of literature concerning such decisions. For example, in the strategic level,

planning is needed of the production schedule to satisfy

quantities which are demanded by the market. In parallel,

inventory has to be controlled such that sufficient components, materials, tools are available for the planned production schedule, and such that no excessive quantities are manufactured which necessitate lengthy, costly storage.

In the tactical level the planned production schedule and

inventory have t o be coordinated with machine capacity,

maintenance plans, and with labor availability for the given

period. Physical storage capacities should also be considered

at this level.

Managerial processes in the above two levels have been

traditionally performed quite successfully with the aid of

information systems. At the operational level, an interface

between human managers and machines is lacking, particularly in the automated manufacturing systems. Two recent

works [18, 201 describe several repetitive, typical control

issues in computerized manufacturing, in which parts in

process travel automatically between work stations (usually

numerically controlled machines). Three such issues are the

Part Mix, the Part Entry and Assignment, and the Process

Selection which are representative of many other manufacturing planning and control issues.

The Part Mix problem is to select for sub-periods particular sets of parts out of the larger set of parts scheduled for

production in the whole period. Since different parts require

different manufacturing resources, conflicts between competing parts can be minimized with the proper selection of

part mix.

The Part Entry and Assignment problem is to sequence

individual part entry into the system, including initial entry

into an empty system, general entry into a saturated system,

and assignment of parts to machines when conflicts occur.

The Process Selection problem is to decide which one of

several alternative processes, all producing the same part but

requiring different machines and different times, should be

selected for a given part.

The three problems are intertwined in that the particular

part mix selected for simultaneous production determines

the nature of the part flow, entry and assignment, based on

the balance and conflict in process, machine, and time

requirements. Analysis of these problems and others, and

evaluation of the consequences of following different policy

decisions with regard to overall performance, show that such

planning and control issues are critical. But while off-line,

time-consuming analyses such as digital simulation indicate

the importance of the problem, a different approach is

necessary when decisions have t o be made and implemented

in real-time, and mistakes can be highly costly. In the latter

case some decisions should probably be delegated to an

automatic control mechanism, which must possess knowledge of the manufacturing system as well as its momentary

status. In the following sections this approach is developed

and examples illustrate how some of the issues described

here can be handled.

Use of Predicate Logic in Operations Management

Problem Solving in a Static Time Domain

Many operations management problems deal with a static

time domain. Problems of this type can be adequately

handled by problem-solving techniques utilizing a single

state representation of the computerized manufacturing

system. Predicate logic is a natural language for stating facts

and making inferences in such an environment.Computerized

manufacturing system entities, as well as simple relationships

among these entities, can be modeled by predicates, while

complex relationships among the entities can be defined by

axioms. As we shall illustrate in the next section, a description of the manufacturing system can be given by assertions

of fact in predicate logic.

Problem solving in this domain can be performed using a

problem-reduction approach (see [17]) and a rule of

inference such as LUSH. Combining resolution with data

base retrieval to prove theorems permits us to use a slightly

less restrictive clausal form of predicate calculus than that

introduced earlier. Goal statements and procedure declarations (axioms) are given with explicit quantifiers preceding

the clause. Unlike the clausal form given in the second section (with implicit universal quantifiers for all variables), we

permit both existential (3) and universal(V) quantifiers for

variables. During resolution, however, an existentially quantified variable would be replaced by a Skolem function (see

[17] or [5] for a discussion of replacement technique).

We also eliminate the implication symbol, +, from goal

statements and assertions of fact, retaining it only for

procedure declarations.

Thus the problem reduction representation of the system

is given in predicate logic as follows:

1. A problem description representing a problem to be

solved is given by a goal statement:

consisting of procedure calls (predicates) Ai with

quantifiers Q , , . . . , Q, and variables x l , . . . , x,.

2. Problem reduction operators used to transform a

problem description into a subproblem description are

given by procedure declarations (axioms):

3. Primitive Problem descriptions (the objective of problem reduction) are given by procedures for retrieving

(or otherwise confirming) assertions of fact:

problem reduction operators, is applied to reduce the

initial goal statement to a set of primitive problem

descriptions.

The primitive problems derived are solved by methods

other than resolution. Two methods, both utilizing "built-in

predicates" are used t o evaluate these primitive problems.

We classify the primitive problems by the type of procedure

used t o evaluate the predicate:

1. Primitive data base management system (DBMS) procedures describe primitive problems that are evaluated

using data base retrieval methods. For a primitive

problem such as:

with variablesxl, . . . ,x,, a primitive DBMS procedure

"B" is invoked to retrieve all data explicitly represented

in the data base that satisfies the predicate. The n

assertions of fact retrieved from the data base have the

form:

where the constants (cil, ci2, . . . , cir) represent the

ith data base record satisfying the predicate "B". The

underlying DBMS can be either a relational system [6]

such as in Chang's DEDUCE [4] , Minker's inferential

relational system [16], or a CODASYL network data

base system such as GPLAN [ I l l where predicates

are represented as described in [2] .

2. Primitive subroutine procedures are used to evaluate

predicates such as LESS-THAN (x, y) and return a

"true" value if x < y . This type of procedure is used

in the comparison of characters and numbers, as well

as for other functions.

These methods for evaluating predicates permit us t o vary

the number of attributes for a given predicate symbol. We

define a predicate such as P(al=xl, a2=x2) with two attributes, yet use the predicate symbol "P" to denote a class of

predicates which use various combinations of the two attributes. Thus P(al =xl ), P(a2=x2), and P(al =xl, a2=x2) use

the predicate symbol "P," but each represents a distinct

predicate as qualified by its attribute list. This convention

tends to minimize the number of different predicate symbols

used in the problem representation, and hence minimize the

number of evaluation procedures required.

The problem reduction representation, along with the

LUSH rule of inference and proof procedure, form the basis

for problem solving in the static time domain of operations

management.

B(al = x l , . . . , a, = x,)

where the ai's are attributes and the xi's are variables.

The top-down proof procedure of LUSH, deriving new

goal statements from old ones by application of the

354

Problem Solving in a Dynamic Time Domain

In a computerized manufacturing system, as in many

AIIE TRANSACTIONS.Volume 12, No. 4

environments, the state of the system is not static, however

A multitude of changes continually occur over time: part

orders are entered into the system, machines are scheduled

to produce the parts, a series of operations are performed

on the parts, and completed parts depart from the system.

Even an entity such as a machine, whose existence is static

in the system (i.e., it is always present for the life of an

inference session), undergoes state changes as it goes from

an idle state to an allocated state while machining a part,

then back to idle again. To model the status of an entity

with respect to an attribute that changes we use a predicate

to represent the attribute. Take for example a predicate

such as:

MCH-IDLE(mch=x) .

ment that changes over time, such a representation is not

sufficient. We often wish to know the time of occurrence of

an event (e.g., when the machine last became idle), or the

multiple times of occurrences of events (e.g., what times the

machine became idle during the previous 8 hours). The concept of time in a dynamic environment has been discussed

in the context of planning for robot problem solving as in

STRIPS [7] , as well as with respect to temporal references

in natural language as in a question answering system [3].

To reflect the changing states in manufacturing, we introduce time into all predicates for which assertions of fact are

dynamic. The predicate MCH-IDLE now becomes:

For a machine "Ml" we specify an assertion of fact:

where attribute "t" represents the time this assertion of fact

was stated. Now, however, we can no longer merely use the

absence of the assertion to indicate allocation. To do so

would mean the loss of information as to time of allocation.

Thus, for each predicate involving time we also introduce a

complementary predicate denoting the negation of the original predicate. Such a predicate will always be prefixed by an

"N" to indicate negation as in:

to indicate that "Ml" is idle. (All constant terms will be

preceded by the symbol "#" for ease of identification). The

absence of such an assertion of fact can be interpreted

in one of two ways: either we are uncertain as to whether

"Ml" is idle, or we assume the machine is not idle (i.e., it is

allocated). Reiter [23] has categorized the assumptions

underlying these two interpretations as "open world" and

"closed world" respectively. In deductive question and

answering with an open world assumption, the only facts

which are known for certain to be true are those which can

be explicitly derived from the knowledge base. One recognizes that there might be "gaps" in histher knowledge.

Conversely, under a closed world assumption, a negative fact

is implicitly known if its positive counterpart cannot be

explicitly derived. Thus, if we cannot derive the fact that

"MI is idle," we haveimplicitly shown that "M1 is not idle."

This implicit representation of negative facts presumes total

knowledge about thed domain being modeled.

The closed world assumption is involved in our information system. In doing so, we recognize the concommitant

requirements for a detailed analysis and design of the information system tojustify this presumption of total knowledge

about the environment of a computerized manufacturing

system. Yet this requirement is typical in the design of

any information system or simulation model. The system

designer is responsible for specifying the knowledge base

and logic of system operation in adequate detail to assure

validity of the model and correctness of the information

output. We also note that while the closed world assumption

can lead to inconsistencies in the data base, Reiter has

shown [23] that no such inconsistencies can arise if facts

stored in the data base are restricted to Horn clauses.

Thus, in a static case, we can evaluate the two mutually

exclusive assertions of fact:

MCH-IDLE(mch=#Ml)

-MCH-IDLE(mch=#Ml)

(machine "M 1" is idle)

(machine "MI" is not idle)

to determine if "MI" is idle or allocated. Yet in an environ-

-

--

--

-

December 1980, AIIE TRANSACTIONS

MCH-IDLE(mch=x, t=y) (mch x became idle at time =y)

N-MCH-IDLE(mch=x, t=y)

(mchx became allocated at time

time = y ) .

Using such predicate/complement pairs we can model changing states over time.

The introduction of time in such a manner necessitates

one further construct to permit inferences to be made in a

reasonable manner. Consider alternating MCH-IDLE and

N-MCH-IDLE assertions of fact during the time period "t "

through "t9":

From these assertions we see the machine was idle from t l

until t3, t4 until t7, then from t9 on. To determine if a machine is presently idle (say, at time t 12), or if a machine was

idle at some time in the past (say, at time t8), it is no longer

sufficient to examine solely MCH-IDLE predicates. Retrieval

of one or all MCH-IDLE assertions of fact must be coupled

with retrieval of N-MCH-IDLE assertions. Given a reference

time, we need to determine which assertion, MCH-IDLE or

N-MCH-IDLE, is the most recent with respect to the

reference time.

For any given predicate, B(al = x l ,. . . ,ar =x,, t=x,.+ ),

we introduce a generic predicate:

MRA-B(al =xl,. . ., a, = ~ , t = x , + ref-time

~,

=x,+~)

to denote the "Most Recent Assertion of B." Note that

the attributes of "MRA-B are identical to those of " B

except for the addition of a reference time attribute. For

given variables x l , . . . , x,, assertion time x,+ 1 , and a reference time xr+, , the predicate "MRA-5" is true if (1) the

most recent assertion of "B" with respect to time x,,, was

made at time & + I , and (2) no "N-B" assertion was made

between time x , + ~and time x , + ~(i.e., no assertion was

made for the negation of B between

and x , + ~ ) . In

axiom format the MRA predicate for MCH-IDLE can be

given as follows:

MRA-MCH-IDLE (mch=x, t=y,, ref-time = y,) +

(mch x was most recently idle at time

y, with respect to time y,) if

MCH-IDLE (mch=x, t=yi), (x was idle at times

LEO-Ii, yn),

,...,y i ))

(where y i <y,)

MCH-IDLE(mch=x, t=y,) (x was idle at time y,)

LEbm, yn),

where y, G y,)

GEGm, yi),

b,

is the most recent y i )

N-MCH-IDLE(mch=x, t=zj), ( x was not idle at {z l , . .. , zj ))

LE(zj>~ n , )

(where zj <y,)

N-MCH-IDLE(mch=x, t=z ), (X was not idle at time z )

<y,)

LE(zl, yn)

(where z

GE(z1, zj)

(zl is the most recent zj)

GTbJrn,z l )

('ym>zl, i.e., the last "idle assertion" is more recent that the last

"not idle assertion") .

Using the preceding MCH-IDLE and N-MCH-IDLE assertions

for time period "tl" through "t9," we observe that the following MRA-MCH-IDLE and N-MRA-MCH-IDLEassertions

are all "true" based upon axiom (Al):

MRA-MCH-IDLE(mch= #M2, t = #t 1, ref-time = #t 1)

MRA-MCH-IDLE(mch= #M2, t = #t I , ref-time = #t2)

N-MRA-MCH-IDLE(mch= #M2, t = #t3, ref-time = #t3)

MRA-MCH-IDLE(mch= #M2, t = #t4, ref-time = #4)

etc.

Note that another way of stating the N-MRA-MCH-IDLE assertion above is:

356

That is, for all times y, it is not true that machine "M2"

was idle as of time "t3."

The "most recent assertion predicate" enables dynamic

inference with predicates that have a corresponding complementary predicate. Yet the axiom given above is too unwieldy to be utilized for frequent evaluation ofmost recent

assertion predicates. Fortunately, however. such a generic

predicate, applicable to each predicate utilizing time, can be

efficiently evaluated at the primitive problem level. Data

base retrieval procedures can readily determine the most

recent assertion of a data base fact and compare the time of

that assertion to that of the most recent assertion of that

predicate's complement.

Utilizing (1) a problem reduction representation to model

a system, (2)a time attribute in all dynamic predicates, (3) a

corresponding coinplementary predicate for all dynamic

predicates, and (4) most recent assertion predicates, we can

represent the dynamic state of a computerized manufacturing system (CMS). Given a representation of the system in

predicate logic, we can then utilize the LUSH rule of

inference and proof procedure to solve operations management problems in such an environment.

Operation and Simulation Mode in a Dynamic Time Domain

The preceding approach to representation of a CMS enables

us to model the system and also its operations. This will be

shown in the illustrative operations management problem in

the next section. However, we should note here how the

modes of updating the system state will enable problem

solving associated with past, present, and future states.

Generation of past and present states of the CMS will be

done concurrently with actual operation of the manufacturing system. Assertions of facts in the data base can be accommodated as information pertaining t o system entities

and relationships is processed. We denote this phase of the

decision support system operation as the "operation mode."

Since each dynamic assertion of fact is flagged with a time

attribute, the data base reflects both current and past states

of the system. This data base forms the "operational data

base" of the system. Problem solving using the LUSH rule

of inference and proof procedure can then be used on this

operational data base to solve many operations management

problems.

Problem solving for future states is another matter,

however. To forecast future states of the CMS, we utilize a

"simulation mode" of the decision support system. The

simulation mode updates the system state to some future

time. Axiomatic operators are used with the set of states as

the domain and the range. The operators are applied according to various parameters specifying how the simulated system is to be operated. Each parameter set simulated leads to

a different future state. The assertions of fact generated,

comprising the "simulation data base," can then be used by

the same theorem proving techniques used on the operational data base. Comparison of criterion across the different

simulated states can be used to determine what operational

AIIE TRANSACTIONS. Volume 12, No. 4

parameters should be used in actual operation over the

forecast horizon.

Illustrative Operations Management Problems

Consider a CMS as shown in Fig. 1. A direct numerical

control line (DNC-line) such as this embodies automation of

workpiece flow through a series of machine tools. Assume

this line includes two automatic tool-changer machines

(M2 and M3) and a load/unload station (MI) for palletizing

parts. A bi-directional cart capable of carrying two palletized

parts travels along a track linking the machines. Parts

fuctured in the load/unload station are mounted on pallets,

then shuttled by the cart t o the various machines on the

line. A part routing, detailing the individual operations to be

performed on each part type, governs scheduling of a part

to a machine. Some operations can be performed on either

machine but processing times vary depending upon the

machine assigned. Thus scheduling of parts t o a machine

can be nondeterministic. The optimal schedule to maximize

some performance criterion (e.g., maximize part production,

minimize lateness of parts having due-dates, etc.) is dependent upon the dynamic state changes occurring in the

system. If an operation for a part is scheduled at a machine,

the part is delivered by the cart and shuttled to that

machine's work center if the machine is idle.

Tools

IIm

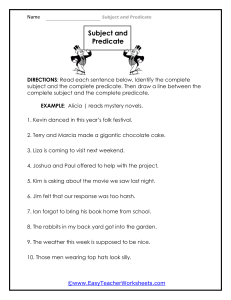

Table 1 : Predicates.

CMS

Predicate

I

A. Entity Assertions

1. Static Assertions

MCH(mch,mch-type)

CART(cart,cart-speed,part-position)

TOOL(tool,tool-type,tool-use-count)

TRACK(track-loc,next-loc,distance)

PALLET(pallet,pallet-type)

OPERATION(op)

INPUT-BINtbin)

OUTPUT-BIN(bin)

PART (part,part-type,part-due-date,t)

B. Elementary Relationship Assertions

1. Static Assertions

MCH-TOOLING(mch,tool,tool-type)

MCH-OP(mch,op,op-time)

OP-TOOLING(op,tool-type)

PART-ROUTING(part-type,op,next-op)

PART-PALLET(part-type.pallet-type)

LOAD-OP(op)

MCH-TRACK(mch,track-loc,shuttletime)

2. Dynamic Assertions

MCH-PART(mch,part,t)

CART-PART(cart,part-position,part,t)

MCH-PALLETS(mch,pallet,t)

MCH-UP(mch,t)

CART-LOCATION(cart,track-loc,t)

PALLETIZED-PART(part,pallet,t)

INPUT-PART(mch,input-bin,part,t)

OUTPUT-PART(mch,output-bin,part,t)

COMPLETE-PART-OP(part,op,t)

Um

I

Unload

Machine T a b l e

cart

part-position

Fig. 1. A computerized manufacturing system.

A number of predicate logic assertions of fact are needed

to represent the machines, parts, pallets, operations, etc.,

and their relationships in this CMS. Table I shows a list of

such predicates. These assertions of fact, both static and

dynamic, form the underlying data base of the decision

support-system. More complex relationships, represented

by axioms, will be shown in the problems to follow.

To examine how the CMS is represented in predicate

logic and how theorem proving is used in the operations

management environment,, we first consider a static time

domain. Table 2 details two parts and corresponding operations using the predicates defined in Table 1. Part member

"pl" is of type "A" and is due on Julian date 79180. Part

number "p2" is of type " B and is due' 79185. Four

December 1980, AIIE TRANSACTIONS

(machine)

(cart)

(tool)

(cart track location

points)

(pallet)

(operation)

(part input bin)

(part output bin)

2. Dynamic Assertions

Tools

Load/

Interpretation

C. Subroutine Assertions

ADD(addend 1, addend 2, sum)

LE(operand 1,operand 2)

etc.

(part)

(machine tooling)

(machine operations)

(operation tooling)

(part routing)

(part pallet)

(load operation)

(track location of

machine)

(machine has part)

(cart has part)

(machine has pallets)

(machine i s up)

(cart i s at track location)

(part is mounted on pallet)

(part is i n input bin)

(part is in output bin)

(part operation is complete)

(part operation i s

currently in progress

(machine i s idle)

(addendl +addend2=sum)

(operandl < operand2)

operations are defined: "opl", "op2", "opcF", and "op6".

The part routing for a part of type "A" specifies that

operations "opl", "op4", and "op2" are t o be performed

in that sequence. Parts of type "B" require "opl", ''op6':

and "op2". Finally, part "pl" has already had operation

"op 1" performed.

The operations management problems that can be addressed range from elementary ones that can be solved

directly by primitive problem procedures to complex problems requiring complex derivations. We illustrate problems

of both types in order of increasing complexity by showing:

(a) an example problem, (b) the corresponding goal statement expressed in predicate logic, (c) procedure declarations

(i.e., axioms) if theorem proving is required to solve the

problem (d) computation used to derive the solution,

(e) the derived assertions of fact, and (f) the problem

Table 2: Assertlons of fact needed for lllustratlve problem.

1 . Part Assertlons

PART(part=#pl ,part-type=#A,part-due-date=79180,t=to.o)

PART(part=#p2,part-type=#B,part-due-date=79l85,t=to

2. Operation Assertlons

OPERATION(op=#opl)

OPERATION(op=#op2)

OPERATlON(op=#op4)

OPERATION(op=#op6)

3. Part Rout~ngs

PART-ROUTING(part-type=#A,op=@,next-op=#opl )

PART-ROUTING (part-type=#A,op=#opl ,next-op=#op4)

PART-ROUTING(part-type=#A,op=#op4,next-op=#op2)

PART-ROUT1 NG (part-type=#A,op=#op2,next-op=@)

PART-ROUTING(part-type=#B,op=@,next-op=#pl )

PART-ROUTlNGIpart-type=#B, oP=#opl ,next-op=#op6)

PART-ROUT1 NG(part-type=#B,op=#op6,next-op=#op2)

PART-ROUTING(part-type=#B,op=#op2,next-op=@)

I

4. Machine Operat~ons

MCH-OP(mch=#Ml ,op=#opl .op-t1me=2.0)

MCH-OP(mch=#Ml ,op=#op2,op-tlme=2.0)

MCH-OP(mch=#M2,op=#op4,op-time=15.0)

MCH-OPlmch=#M2,op=#op6,op-t1me=40.0)

MCH-OP(mch=#M3,0p=#opG,op-t1me=48.0)

5. Completed Part Operatlons

COMPLETE-PART-OP(part=#pI ,op=#opl , t = t 2 : ~ )

6. incomplete Part Operatlons

N-COMPLETE-PART-OP (part=#pl ,op=#op4, t't0.0)

N-COMPLETE-PART-OP (part=#pl ,op=#op2, t = t ~ . ~ )

N-COMPLETE-PART- OP (part=#p2,op=#opl, t=ts.o)

N-COMPLETE-PART-OP( (part=#p2,op=#op6, t'ts.0)

N-COMPLETE-PART-OP (part=#p2,op=#op2, t't5.0)

procedure PART. For each part returned, invoke

primitive subroutine procedure LESS-THAN until a

part with a due-date less than 79200 is found.

e. Derived assertions of fact satisfying the,goal statement

(i.e., multiple solution):

PART(part=#pl ,part-due-date=#79 180),

LESS-THAN(#79 180,#79200)

PART(part=#p2, part-due-date=#79 185,

LESS-THAN(#79 185, #79200)

f. Problem answer: part=#pl or part=#p2.

The multiple solutions satisfying a goal statement such

as in problem 2 can be easily handled by DBMS procedures and subroutine procedures. Thus the following

query and goal statement can be handled just 7 s

easily as a goal statement using only existentia

quantifiers for the variables.

3. a. Problem: What parts are due before 79200?

b. Goal statement: V x 3 y PART(part=x, part-due-date=

y), LESS-THANe,#79200)

c. Procedure declaration: None

d. Computation: Invoke the primitive DBMS procedure

PART. For each part returned satisfying the PART

predicate, invoke procedure LESS-THAN t o check if

the due-date is less than 79200.

e. Derived assertion of fact: same as (2e).

f. Problem answer: Parts=(#pl , #p2).

Procedure lnvocation o f a U n i q u e A x i o m a t i c Procedure

Problem that requires the invocation of a unique procedure

to reduce the goal statement to a set of primitive problems.

answer. An answer predicate such as that used by Green [9]

can be used to keep track of variable instantiations during

resolution.

Illustrative Problem Solving in a Static CMS Domain

(Present Time)

Primitive Problem procedure lnvocation

Solve a problem by a procedure call to the data base

management system (DBMS) for primitive data base problems, and/or by the invocation of primitive subroutines.

1. a.

b.

c.

d.

Problem: Are there any parts of type B in the system?

Goal statement: 3 x PART(part=x, part-type =#B)

Procedure declarations: None

Computation: Invoke a call to the primitive DBMS

procedure PART.

e. Derived assertion of fact: PART(part=#p2,part-type=

#B)

f. Problem answer: Part=#p2.

2. a. Problem: Are any parts due before 79200?

b. Goal statement: 3x 3 y PART(part=x, part-due-date=y),

LESS-THAN@,#79200)

c. Procedure declarations: None

d. Computation: Invoke a call to the primitive DBMS

358

4. a. Problem: What is the first operation for part p l ?

b. Goal statement: -j y FIRST-PART-OP(part=#pl, op=y)

c. Procedure declaration (Axiom):

(Al) V x V y V z

~ ~ ~ s T - P A R T - o p ( p a r t op=y)

=x, +

PART(part=x, part-type=z),

OPERATION(op=y),

PART-ROUTING (part-type = z, op=A

next -op= y )

The interpretation of this axiom is: (op y is first

for part x) if (part x is of type z), @ is an operation),

( jis~

on type 2's routing with no operation preceding op Y ) .

d. Computation: call procedure FIRST-PART-OP by

invoking axiom (Al). Then solve the conjunction of

primitive problems PART, OPERATION, and PARTROUTING, with "pl" substituted for "x."

e. Derived assertion o i tact: FIRST-PART-OP(part=#pl ,

op=#opl).

f. Problem answer: Part p l ' s first operation is o p l .

Procedure lnvocation of a N o n - u n i q u e A x i o m a t i c Procedure

Problems that require selection of one of many procedures

AIIE TRANSACTIONS. Volume 12, No. 4

with the same name to reduce the goal statement to a set of

primitive problems.

5. a. Problem: What operation is to be done next on part p l ?

b. Goal statement: 3y NEXT-PART-OP(part=$pl ,op=y)

c. Procedure declarations:

(A2) Invoke to determine if the first operation for a

part is next.

Vx V y Qz

NEXT-PART-OP(part=x, op=y)+

PART(part=x, part-type=z),

OPERATION (op=y),

PART-ROUTING(part-type=z, op=@,next-op=y),

N-COMPLETE-PART-OP(part=x,

op=y)

Interpretation: (op y is next for part x) if (part x is

of type z), O, is an operation), (Y is on type z's

routing with no operation preceding op y) and (op y is

incomplete).

(A3) Invoke to determine if a subsequent operation

is next.

Vx Vy Vz 3 w

NEXT-PART-OP(part=x, op=y) +PART(part=x, part-type=~),

OPERATION(op=y),

PART-ROUTING(part-type=z, op=y),

PART-ROUTING(part-type=z, op=w, next-op=y),

COMPLETE-PART-OP(part=x,

op=w) ,

N-COMPLETE-PART-OP(part=x,

op=y) .

Interpretation: (op y is next for part x) if (part x is of

type z), (y is an operation), (y is on type z's routing),

(y succeeds some op w), (op w is complete), and (op

y is incomplete).

d. Computation: Call procedure NEXT-PART-OP by invoking either axiom (A2) or (A3). Suppose axiom (A2)

is invoked. Solving the four primitive problems in the

antecedent (i.e., procedure body) of axiom (A2) we

obtain the following assertions of fact:

PART(part=#p 1, part-type=#A),

OPERATION(op=#op I),

PART-ROUTING(part-type=#A, up=@,next-op=y),

IN-COMPLETE-PART-OP(part=#p

1,op=#op 1).

The first three assertions of fact are compatible with

the assertions of fact in the data base given in Table 1.

However, the last assertion of fact above, N-COMPLETE-PART-OP(part=#pl , op=#opl ), is not true.

This can be determined by attempted data base retrieval, or more likely by a primitive subroutine

procedure operating under the closed world assumption. Such a procedure would confirm that N-COMPLETE-PART-OP(part=#pl , op=#opl) is false since

it is in conflict with COMPLETE-PART-OP(part=#pl,

op=#opl) which is explicitly stored in the data

base. This conflict implies no solution t o the given

goal statement when axiom (A2) is invoked. If, however, axiom (A3) is invoked, the resulting primitive

December 1980. AIIE TRANSACTIONS

problems can be solved. The following assertion of

fact thus satisfies the goal statement.

e. Derived assertion of fact: (from axiom (A3) invocation): NEXT-PART-OP(part=#p 1, opz#op4),

f. Problem answer: Operation op4 is to be done next on

part p l .

6. a. Problem: What operation is to be done next on part

p2? This problem is identical to that preceding except

we are now using part p2 as the argument. However,

this problem leads to a different computation.

b. Goal statement: 3 y NEXT-PART-OP(part=#p2,op=y)

c. Procedure declarations: (A2) and (A3) above

d. Computations: Unlike problem 5, invocation of axiom

(A2) leads to a solution for problem 6 while axiom

(A3) leads t o a contradiction.

e. Derived assertion of fact: (from axiom (A2) invocation): NEXT-PART-OP(part=#p2, op=#opl).

f. Problem answers: Operation opl is to be done next on

part P2.

Procedure Invocation of Multiple, Possibly Non-unique

Axiomatic Procedures

In the most complex problems, solution requires multiple

invocations of axiomatic procedures.

7. a. Problem: On what machine should part p2 be scheduled for its next operation if the part is to be assigned

to the machine which will require the shortest processing time (SPT) to perform that operation.

b. Goal statement: 3 y 3 2 SCHEDULE-MCH-OP(part=

#p2, mch=y, op=z)

c. Procedure declarations: in addition t o axioms (A2)

and (A3) we need:

(A4) Vx Q y Vz

POSSIBLE-SCHEDULE(part=x,mch=y, op=z)+

NEXT-PART-OP(part=x, op=z),

MCH-OP(mch=y, op=z) .

Interpretation: (possible schedule for part x ) if (op z

is the next op for part x), and (mch y can perform op

z).

Interpretation: (schedule part x on rnch y for op z )

if (mch w is any possible rnch), (u is time for rnch w

to perform op z), (mch y is one possible rnch), (v is

time for rnch y to perform op z),(time for rnch y is <

time for rnch w), (part x is of type s), and (SPT

scheduling is in effect for type s). Axiom (AS) determines from all possible machines that can be scheduled

for the next operation the one machine with an operation time v for that operation where v is less than or

equal to all operation times for other machines.

d. Computation: Invoke axiom (AS) for procedure

SCHEDULE-MCH-OP, then invoke axiom (A4) for

each of the two procedure calls of POSSIBLESCHEDULE resulting from the invocation of (AS).

Axioms (A2) and (A3) are then invoked to satisfy

procedure calls to NEXT-PART-OPERATION. The

resulting primitive problems are solved procedurally.

e. Derived assertion of fact: SCHEDULE-MCH-OP(part=

#p2, mch=#M2, op=#op6)

f. Problem answer: Schedule part p2 on machine M2 for

the next operation (which is op6).

Note that axiom (AS) will lead to a successful theorem proof

only if predicate SPT(part-type=s) evaluates to true for the

part type in question. Thus procedure (As) will only be

successfully invoked when shortest processing time scheduling is in effect for the given part type. Alternative

SCHEDULE-MCH-OP procedures could be invoked for

shortest processing time by idle machine, arbitrary scheduling, or any other applicable scheduling algorithm. For a

shortest processing time by idle machine procedure, replace

the SPT(part-type=s) predicate in (AS) by the following

three predicates:

MCH-IDLE(mch=y),

MCH-IDLE(mch=w),

SPT-BY-IDLE-MCH(part-type=s).

Predicates SIT and SPT-BY-IDLE-MCH comprise a set of

mutually exclusive operating parameters, only one of which

should evaluate to true at a given time.

Illustrative Problem Solving in a Dynamic CMS Domain

(Past States)

To illustrate the use of past tense in operations management

problem solving, including invocation of the most recent

assertion predicate, we repeat problem 2 with a reference

to a past state of the system.

8. a. Problem: Were any parts in the system at time t4 due

before 79200?

b. God statement: 3 x 3 w MRA-PART(part=x, part-duedate=w, ref-time=#t4), LESS-THAN(w,#79200)

c. Procedure declaration: None

d. Computation: Invoking the most recent assertion procedure MRA-PART, we obtain through resolution a

new goal statement with the following primitive

problems:

(a) PART(part=x,part-due-date=w,t=yi),

(b) LEOi, #t4),

(c) PART(part=x,part-due-date=w,t=y,),

(4 LEO,, #t4),

Only one PART predicate instantiation from Table 2,

name! y :

solves this conjunction of primitive problems. This of

course assumes that N-PART(part=#pl ,part-due-date=

$79 180,t=#t,)

is true for some time r- preceding

the assertion of any PART facts. This can easily be

handled if the MRA predicate is invoked procedurally

rather than by actual application of a MRA axiom

through resolution. The other PART assertion of fact:

PART(part=#p2,part-due-date=#79185, ~ # t s . o ) ,

fails to satisfy the assertion (b) above, LE(#t5.",#t4).

e. Derived assertion of fact:

MRA-PART(part=#pl ,part-due-date-#79180,

ref-time=#t4), LESS-THAN(#79 180,#79200),

f. Problem answer: part=pl.

Problem 3 , dealing with all parts in the system due before

79200, can be solved for a past state using an "all recent

assertion" predicate very similar to the "most recent assertion" predicate, but retrieving all facts of a particular type

asserted before the reference time.

Illustrative Problem Solving in a Dynamic CMS Domain

(Future States)

Problem solving with respect to future time promises to

provide the most valuable benefits from applying theorem

proving techniques to operations management. Given an

operational data base, we utilize the simulation mode of

the decision supgort system to update the knowledge base

to some future time. A set of operators in axiomatic form

serve to describe the operation of the manufacturing system.

For example to describe the performance of a machine

operation on a part, we define the following four predicates

as procedure declarations:

We had defined SCHEDULE-MCH-OPearlier as axiom (AS).

The remaining procedure declarations follow as axioms(A6)

- (A8):

-

--

AIIE TRANSACTIONS. Volume 12, No. 4

state. Axioms (A5) and (A6) are both complete in this

sense; no assertions are implied other than the assertion

explicitly given. Yet axioms (A7) and (A8) imply new

assertions relevant to the knowledge base that are not

explicitly specified. For example, the application of axiom

(A7) to machine M2 for operation op4 for part p l at time

t,,, implies a new assertion other than just the INIT-MCHOP assertion given. The start of this operation also implies

the assertion that operation op4 is now currently in progress

for part p l , i.e., we need to add assertion:

Interpretation: mchx is ready to operate on part y

for op z as of time t1 if rnch x has part y as of time

t 2 , part y is scheduled on rnch x for operation z as of

time t3 ,op z requires tooling w , rnch x has tooling w,

and t l is the latest time in the set {t2, t3 ).

Interpretation: initiate rnch x operation z for party as

of time tl if rnch x is ready to operate on party for

op z as of t 2 , mch x is up as of t3, and J . ~is the later

time of {t2, t3 ).

Similarly, the application of (A8) to machine M2 for operation op4 for part pl at time tZ5., (assuming an operation

time of 15.0 for op4 on machine M2) also implies additional

assertions:

where N-CURRENT-PART-OP is the negation of the

CURRENT-PART-OP assertion implied by axiom (A7).

These additional implications in the simulation mode operation of the decision support system are handled by an ADD

list similar to that used in STRIPS [8]. Thus axiom (A7)

would have the associated ADD list:

(A7) ADD list: CURRENT-PART-OP(part=y,op=z, t=t 1 )

and axiom (A8) would have:

Interpretation: end rnch x operation z for party as of

time t l if rnch x started op z on party as of time t 2 ,

rnch x op z has an op-time of t g time units, and t l =t2

f3

.

+

Note the relationship between a predicate assertion in one

axiom and a reference to the most recent assertion of that

predicate in a subsequent axiom. For example, consider the

predicate INIT-MCH-OP. Axiom (A7) specifies under what

conditions (preconditions in STRIPS terminology [83 ) we

can enter a new INIT-MCH-OP assertion into the knowledge

base. In axiom (A8), however, we are concerned with

retrieving the most recent such assertion of INIT-MCH-OP

(i.e., MRA-INIT-MCH-OP)to be able to assert END-MCH-OP,

denoting the end of the machine operation. Also observe

the specification of time passage in axiom (A8). The end of

a machine operation follows the start of that operation by a

time span equal to the operation performance time. Axioms

(A5) - (A7) on the other hand do not necessarily imply the

passage of time.

One further distinction among these four axioms involves

the completeness of the axiom in explicitly asserting all

facts that are implied by that axiom's application to an input

December 1980, AIIE TRANSACTIONS

(A8) ADD list: COMPLETE-PART-Op(part=y,op=z,t=tl),

N-CURRENT-PART-OP(part=y

,op=z,t=tl ) .

We do not, however, utilize the DELETE list of STRIPS.

The complementary predicates introduced earlier (those prefixed by the character "N") serve the same purpose as

deleting an assertion but without the cost of lost information pertaining to the time of occurrence.

9. a. Problem: Given the current time tS and an SPT scheduling algorithm, when will part p2 complete its last

operation?

b. Goal statement: 3 y 32

COMPLETE-PART-OP(part=#p2, op=y ,t=z),

LAST-PART-OP(part=#p2,op=y) .

c. Procedure declaration:

(A9) Vx Vy 3 w

LAST-PART-OP(part=x,op=y)+PART(part=x,part-type=w),

OPERATION(op=y),

PART-ROUTING(part-type=w, op=y,next-op=@).

d. Computation: Before attempting to solve the goal

statement, the simulation mode of the decision support system must be invoked. Commands specifying

the time limits for the simulation, as well as the

operating parameters in effect might have the format:

In simulation mode the operational axioms are applied

to the operational data base to update the state of the

system. Axiom (A9) is then invoked and primitive

problems solved using the simulation data base for

data retrieval.

e. Derived assertions of fact: Using the data from Table

2 (which ignores inter-machine shuttle times and

machine to cart shuttle times) we obtain:

COMPLETE-PART-OP(part=#p2,0p=#op2,t=#t59),

LAST-PART-OP(part=#p2,0p=#op2).

References

[I]

(21

[3]

[4]

f. Problem answer: Completion at time t,, .

[5 ]

Simulating the completion time for a number of alternative

scheduling algorithms enables us t o then select that algorithm

for operation that provides the best value of a criterion

measure of performance over the simulation time horizon.

[6]

[7]

Conclusions

[8]

In this paper we have explored the application of predicate

logic and mechanical theorem proving to the management

of a computerized manufacturing system. Predicate logic

permits a descriptive and nonprocedural representation of

knowledge related to the operation of the facility. The

predicate calculus language allows both static and dynamically changing knowledge t o be modeled, while theorem proving permits "new" knowledge to be deduced from the

current knowledge base.

From a decision support viewpoint, the resolution procedure allows the knowledge base to be applied to specific

operations management problems stated by the user. In

more general terms, theorem proving as described by

Kowalski [13] can be interpreted as synthesizing a particular program t o solve a user specified problem. The paper

presents axioms representing knowledge typical in a manufacturing environment and demonstrates how user problems

can be handled in the framework of resolution in a problem

reduction approach.

Further work is needed to implement such a system.

Questions on how axioms should be stored and how

resolution can be effectively carried out must be investigated. From the user point of view, a more natural

English-like problem statement language is needed. Techniques must be found to translate sentences in this natural

language into an equivalent predicate calculus form. In

addition, relationships between the problem solving techniques described here and more classical techniques of

integer programming models of scheduling would be of

interest.

191

Acknowledgment

Mr. W. I. Bullers gratefully acknowledges the fellowship

support made possible by a grant from IBM.

362

[lo]

[ll]

[12]

(131

[14]

(151

[ I 61

[ 17 ]

[18]

[19]

[20]

1211

[22]

Bobrow, D. G. and Raphael, B., "New Programming Languages

for A1 Research," Computing Surveys, 6, 3, 15 3-174 (September 1974).

Bonczek, R., Holsapple, C. and Whinston, A., "The Integration

of Network Data Base Management and Problem Resolution,"

Information Systems, 4 2, 143-154 (1 979).

Bruce, B. C., "A Model for Temporal References and Its

Application in a Question-Answering Program," Artificial

lntMtklligence 3 , 1-25 (1972).

Chang, C. L., "DEDUCE 2: Further Investigations of Deduction in Relational Data Bases." IBM Research Report RJ2147

(29410) (May 1978).

Chang, C., Lee, R. C., Svmbolic Logic and Mechanical Theorem

Proving, Academic Press, New York (1973).

Codd, E. F., "A Relational Model for Large Shared Data

Banks," Comm. o f the ACM, 13,6, 377-387 (June 1970).

Fikes, R. E., Hart, P. E. and Nilsson, N. J., "Some New

Directions in Robot Problem Solving," Machine Intelligence.

7, (Eds. Meltzer, B. and Michie, D.), Halstead Press, New

York, 405-430 (1972).

Fikes, R. E. and Nilsson, N. J., "STRIPS: A New Approach

to the Application of Theorem Proving t o Problem Solving,"

Artificial Intelligence, 2 , 189-208 (1971).

Green, C., "Theorem-Proving by Resolution as a Basis for

Question-Answering Systems," Machinc Intelligence, 4 (Eds.

Meltzer, B. and Michie, D.), American Elsevier, New York,

183-205 (1969).

Green, C. C., Raphael, B., "The Use of Theorem-Proving

Techniques in Question-Answering Systems," Proc. ACM

23rd National Computer Conference, 169-181 (1968).

Haseman, W. D. and Whinston, A. B., Introduction t o Data

Management, Irwin, Homewood, Illinois (1977).

Hewitt, C., "Procedural Imbedding of Knowledge in PLANNER," Proc. Int'l. Joint Conf: on Artificial Intelligence, 2,

London, 167-182 (September 1971).

Kowalski, R., "Predicate Logic as Programming Language,"

Proc. IFIP, 74, 569-574 (1974).

Kowalski, R. and Kuehner, D., "Linear Resolution with

Selection Function,"Artificial Intelligence, 2, 227-260 (1971).

Minker, J., "Set Operations and Inferences Over Relational

Data Bases," Technical Rep. TR-427, University of Maryland,

December 19751, (invited paper for the Fourth Texas Conference on Computing Systems).

Minker, J., "Search Strategy and Selection l'unction for an

Inferential Relational System," ACM Transactions on Database Systems, 3, 1, 1-31 (March 1978).

Nilsson, N. J., Problem-Solvitzg Methods in Artificial Intelligence, McCraw-Hill, New York (1971).

Nof, S. Y., Barash, N. M. and Herald, M. J., "Analysis of

Operating Rules in a Computerized Manufacturing System,"

ASME Paper 78- WAIProd-38, (December 1978).

Nof, S. Y., Whinston, A. B. and Bullers, W. I., "Operations

Management Tools for Automatic Manufacturing Systems,"

20th Annual Canadian Operational Research (COR) Conf.,

Vancouver, B.C., (May 1978).

Nof, S. Y., Barash, M. M. and Solberg, J. J., "Operational

Control of Item Flow in Versatile Manufacturing Systems,"

to appear shortly in the Int. J. of Prod. Rex

Nof, S. Y., Whinston, A. B. and Bullers, W. I., "Control and

Decision Support in Automatic Manufacturing Systems,"

AIIE Transactions, 12 2, 156-169 (June 1980).

Phillips, D. T., Heisterberg, R. J., Backstone, J. and Sathaye.

S., "System Analysis Techniques as Applied to Manufacturing Systems, An Annotated Bibliography," Report No.

GEMS-1-77, Department of Industrial Engineering, Texah

A&M University, September 15, 1977.

AIIE TRANSACTIONS. Volume 12, No. 4

[23] Reiter, R., "On Closed World Data Bases," Logic and Data

Bases, (Eds. Gallaire, H . and Minker, J.), Plenum Press, New

York, 55-76 (1978).

[24] Robinson, J. A., "A Machine-Oriented Logic Based on the

Resolution Principle," Journal of the ACM, 12, 1, 23-41

(January 1965).

[25] Sacerdoti, E. D., "Planning in a Hierarchy of Abstraction

Spaces," Artificial Intelligence, 5, 115-135 (1974).

[26] Snodgrass, B. N., Proceedings of Job-Shop Control Interest

Group Meeting, CAM-I, Arlington, Texas, June 22-23 (1978).

[27] Talavage, J. J. and Barash, M. M., "Information and Control

in Computerized Manufacturing Systems," Proc. Int'l Fed. o f

Automatic Control Conf., Tokyo, Japan (October 1977).

[28] Thierauf, R. M., Systems Analysis and Design o f Real-Time

Management Information Systems, Prentice-Hall, Englewood

Cliffs, New Jersey (1975).

[29] van Emden, M. H., "Programming With Resolution Logic,"

Machine Intelligence, 8, (Eds. Elcock, E. W. and Michie, D.),

Halstead Press, New York, 266-299 (1977).

[30] van Emden, M. H. and Kowalski, R., "The Semantics of

Predicate Logic as a Programming Language," Journal of the

ACM, 23,4,733-742 (October 1976).

[31] Verzijl, J. J., Production Planning and Information Systems,

Wiley, New York (1976).

William I. Butlers, Jr., is an Assistant Professor and the director of

the Computing Center at the Anderson School of Management, University of New Mexico in Albuquerque. He received his BS in Mathe-

December 1980, AIIE TRANSACTIONS

matics from Carnegie Mellon University, MBA from Duquesne

University, and PhD in Management Information Systems from

Krannert Graduate School of Management, Purdue University.

Industrial experience includes systems analysis at Alcoa. Bullers is

a member of ACM, and is a holder of the CDP, Certificate in Data

Processing.

Shimon Y. Nof is an Assistant Professor of Industrial Engineering a t

Purdue University. Formerly, he worked in the R&D Division of

Manufacturing Data Systems, Inc. in Ann Arbor, Michigan, and was

an Assistant Professor of Produciton Management in the University

of Michigan, Dearborn. His research interests include production

systems design, industrial information systems, and computer control of manufacturing systems. Dr. Nof holds a BSc and MSc in

Industrial and Management Engineering from the Technion, Israel

Institute of Technology, and a PhD in Industrial and Operations

Engineering from the University of Michigan, Alrn Arbor. He is a

member of ACM, AIIE, and TIMS

Andrew B. Whinston is a Professor of Management, Economics and

Computer Science at Purdue University, an Associate Editor of

Management Science, a member of the editorial board of Discrete

Mathematics, and Chairman, Technical Committee on SocioEconomic Cybernetics, IEEE Systems, Man and Cybernetics Society.

He received his BA from the University of Michigan, MS and PhD

from the Graduate School of Industrial Administration, Carnegie

Mellon University. Dr. Whinston has published extensively in jourals

of economics, operations research, and computer science. He has coauthored a number of books, among them, Introduction t o Data

Management (Irwin), and Quantitative Planning and Control (Academic Press).

363