View metadata, citation and similar papers at core.ac.uk

brought to you by

CORE

provided by Lehigh University: Lehigh Preserve

Lehigh University

Lehigh Preserve

Fritz Laboratory Reports

Civil and Environmental Engineering

1964

High strength bolting in the U.S.A., August 1964,

Reprint 275

J.W. Fisher

L. S. Beedle

Follow this and additional works at: http://preserve.lehigh.edu/engr-civil-environmental-fritz-labreports

Recommended Citation

Fisher, J.W. and Beedle, L. S., "High strength bolting in the U.S.A., August 1964, Reprint 275" (1964). Fritz Laboratory Reports. Paper

163.

http://preserve.lehigh.edu/engr-civil-environmental-fritz-lab-reports/163

This Technical Report is brought to you for free and open access by the Civil and Environmental Engineering at Lehigh Preserve. It has been accepted

for inclusion in Fritz Laboratory Reports by an authorized administrator of Lehigh Preserve. For more information, please contact

preserve@lehigh.edu.

Large Bolted Connections

by

"John W. Fisher

Lynn S. Beedle

CONTRIBUTION TO THEME lIb:

HIGH STRENGTH BOLTING IN THEUoSoA o

by

John Wo Fisher, Research Assistant Professor

of Civil Engineering,Lehigh' University

Bethlehem, Pennsylvania, and

Lynn S.Beedle, Research Professor of Civil Engineering,

Lehigh University, Bethlehem, Pennsylvania

DESIGN CONCEPTS IN THE U9 SQA Q

The original application of

~.SoAo

~igh-strength

was based upon friction-type joints only.

A325 bolts in the

The first specifica-

tion in 1951 merely permitted the substitution of a like number of

bolts for hot-driven rivets(l)o

It is well known that friction-type joints are dependent on

proper bolt tension and an adequate coefficient of frictlono

In the

UoSoA o the faying surfaces are usually only clean mill scale, and

numerous tests of A7 stee 1 Joints have indicated that a slip coeffi.cient

of 0035 is representative of values encountered in actual construction.

Because of higher labor costs in the UoS.Ao it 18 considered uneconomical to increase tpa slip coefficient by treating the faytngsurfacese

Generally it is less expensive to use a larger joint with more bolts.

the recent introduction of the higher strength AA90 bolt(2) will allow

the use of smaller joints because of higher clamping force per bolt;

thus it can be expected that there will be even less of a tendency to make

use of special faying surface treatments.

288.22

-2-

The concept of a bearina-type conneetionw81flrstlntroduced

when the specification was revised in 19.54.

At that time,the omission

of palntwas required ·to apply only to Ja,tnts subJected· to stress rever . .

•

.:."

>

sal or vlbration,or where joint . sllppalewou,1c1 beuncleslrable

0

Tests

conducted at the University of Washingtonh.d sbQwn, thatpaintlna the

faylngsurfaees8ubstanti.ally, reclucedt,he slipcoefflctent

o

••••

".

•

•

•

•••••

'

•••••••

'• • • • •"

•••••••

'

• •

,"

••••

'• • • • • • • • • • • • • • • • • • • • • • • •

(3)

.' . I t "8S

recognlz.d tbat many jolnts were'e r ecce:<I,ln bea'tioa 'ndthat slipP',ge

was not a'problettto

into beart'hg

Movement althe conn.ecteclpart,. brlnI1ns··the bolts

a8~in8ttheslcle8ofthebol.8~a.

t'othestren:gth or sbape of tne8truetUr'e6

'1naowaydetrtmental

Allo,thecc>,.t ofle.vins

I,ft the 1960 revision of the a,eclflb.fiIt 1011 of the Research

Counci.l onliveted and Bolte'd Structural Joiri.ts selear 4tstinetiotl

this time the greater sbear. streoICh·..,of· .the blllliliJl,tlie,qtb ·b,(),lt··.w8s

not recognized.

planes.

In 1960, the stresses u.e4: to proportlonbeari.ng-type-

Thus) the allowable stresses

u",d

in ,ft.lctton-typeJof.nts

reflect the abl1ityof' the jolnttore'18tllil.pwhet."lJtbilvalues

for the bearing-type joint reflecttb.,.h••riqltrllft8':tb of the bolt.

type joints correspo<nd to a factor. of safety alainst Ilip of, 104·0

under grayity and live 108480

It is recQgnlzed that the bolts are

not actually stressed in shear nor 18 bear,inS a eQn8ideratlonin frlc-

tion-type connection8 o

However, "It is conventeotto specify an allow-

able "shear'stres. 1n ordertbatproportionlns of friction-type co;nnectiona may be carried, out usinlth.s&mewell-eeta..,lllbed methods

as

areuBed In the del:lsn of rlvetedjolnt8q

A'llo".b1e stresse. for tiearlftl-type con••etloR8 are b•••clon

the ultimate.h••r ",Ct:enltb of thef•• tlllClr.Jla.eo.:lvetelt.ofllJ:lt

A7 and .l\440.lt881 JalAli have .hown that'tbe faetor,of •• fety ".ri••

from about 303 for'hort connection. eleva to 202 for Joints up to

.50 inches long (4)(.5

>.

In bearins-typedointe ,even thougb the bolt.

are tightened so'thatfrlctlonmay ,earl", tbe WOrking load. frict10nal

resistance 1s not requlredandthe deslgnls 'properly based on th.

shearing strenathofthe bolts.

1 'P'lltlIYe. T.'~.'.()f. JO~Qt, 'Co~n.<;~.4bYA3~5Io1t

•..·wltbOQt.W... btra

0

Durinl the'pastfew year•• number of fatlgue·te8ts on bolted

lap spU.ees we.re. conducted at tbe. Unive.rl1ty of tlHnots (6).

Theee

tests tl'lcludedspecirnensde818ned for extreme conditions:

overliled

holes"no washers. and inmostc8ses, minimum clampini

employed.

When the

turn~of-nutmetbodwa8 used

w~s

to preload the bolt' none bf,the

specimens faUe.duntil at least 2.4 x 1Q6 ..._ •• we..e applied at a

0-30 kai stress cycle o

This was true even tboulh .nuDtber 0·£ the

specimens slipped into bearing during the flr8t cycle of loading.

-4-

One specimen with no washers and oversized holes (1/8-ino

instead of 1/16-in.)s11pped into bearlol during the first cycle of

loading and ran 3 x 10

6

cycles at 0 to 30 kll without failure.

Rel.xation teats tooetarmine 101. of clamping force tilth

time were also conducted by the University of:nll11noll on blab-tler.oatb

bolts (6)

There wa. no differen.e·e 1n bolt load for boltIiJ with 1/16-1n.

0

overslzeholes. whether ·or not a wa.herwa. URoer' tb.e·bolt he.do

when no washers were u8ed.

during the first d·.yo

Tbe

Molt olthi'• •utlll loslaenerally occurred.

:Measurement on boltl Cllntened by the turn-of..

nut method in test joints agreed with the.e special relaxation tesu(5).

Even after 10 months, elongation measurements indicated no signif:Lcant

addit"ional relaxatton other than whatoe,eurred l1X1tled.1ately .ftertbe

initial tightening o

As a· result of thesestudies,washerB are no lonler required

under the turned element when A325 bolt•••re installed by the turn-of-

nut method.

They are used

under ·the turned a lame n.t to minimize iriteau-

larities in the torque-tension relationship When bolts are tightened by

the calibrated wrench method o

The use of washers' in the U.S.Aopra.ct:Lce 1s specified in

order to provide a non-galling surface under thepat:tturned in

ti.abteft~

ing as tests have shown they only play a minor role in distributing

pressure due to bolt tensiono

,-5-

288.22

3. Static Testa of A7 .oct ~44Q$tt'.1 JQlrtt'

Numerous tests of connections of structural carbon steel

connected by high-strength bolts have indicated that for clean mill

scale a slip coefficient of 0.35 is repre.-entative (3) (4) (5) (7) •

Neither length norwldth was found to appreciably affect the slip

resiStance (5).

Reference 8 reported similar reau1ts.

Tests at Lehigh University on A440 hi-p-strength steel connec-

ted by 1\325 high-strength bolt. showed a slllht deere.le in the mean

slip coefficient (10).

More recently. tests of A440 neel connecU.ona

connected with the biaher-strength A49'O bolt have given a 811pcoefflThe te,.ta are too

cient sl18ht1y h·igher than that reported in Itef. 100

few to give conclusive results; however, the indication 1s that

th~

higher clamping force of the A490bolt .y. improve the slip coef,ficient

0

A few constructional alloy steel joints connected by A325 orA490 bolts

were also tested at Lehigh and have yielded similar resultso

Recently. theoretical solution w.Re developed for the unequal

distribution of load among the bolts in double-lap tension spl:lceswhlch

have non-linear behavior(ll).

Analytical studies supported by tests

have shown that an increase in net plate area increases the .'verale

shear strength of the fasteners in the lon,aer jo:lnts

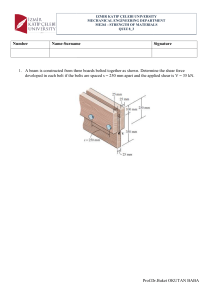

:- summarizes the analytical and experlmentalfindings

40 Joint

~ovement~:l.n

0

Figure 1

0

II Railroad Bridge

During the BUDmer of 19598n inveitigation was undertaken in

conjunction with the through-truss bridge for the Michigan Central

Railroad near Chicago, Il11nois.

A cooperative investigation by the

288.22

-6-

Association of American Railroads Research Laboratory and the University

of Ililnois was initiated at the time of fabricatlon o

Initial readings

were taken in the fabrication yard durlngfinal assembly and reaminlo

Additional readings were taken after erectioft and at periodic intervals

thereafter.

The readinll were taken at all joints of'one trus80

The

bolts were installed by the turn-af-nut method.

\

Reference 12 presents the results of the measurements which

were conducted over a J-,!-year ,eriod o

In aeneral. this study has shown

that little 1f any chanse has occurred in the structure

Duringerec-

0

tion, movements up to 1/16-1n. were noted '1n randomdirectioRs.

Joint

movements measured over 3 years ofd:ervice averased only Oo002-ino and

were so small that experimental techniques could have caused the varia...

t1on o

No significant change in camber has oecurred o

The erection

movements were random in direction and magnitude and did not always

coincide with the direction of dead load Stre.ss:lng (12)

0

5. Tests of Bolted Steel Moment Connections

Three identical beam spli.ces with lap connections .were tested

in a project at Corne 11 Uni versity (13) •

The bolts were designed on the

'basis of 22 kai shear stress as permitted In.bearing-type connections o

None of the connections slipped belOW the working loadP

w

the connections developed the full plastic

~ment

and all of

of the gross section

and showed satisfactory deformation characteristics.

A similar test

at Cambridge University with the bolts desianed for 30 ksi shear stress

also developed the full plastic moment(14).

-7-

288 22

0

INSTALLATION QF HIGH-STRENGTH BOLTS

Early Uo So specifications stated the well-known formula

relating torque to bolt tension and listed a table of torque-tension

values(l).

However, a number of later studies indicated that such re-

lationships are unreliable because of theare4t variability of thread

condition, surface conditions under tbe Rut, lubrication an" other

factors that use up tbe torque enera, without :Ln4uclnltens1.on in the

bolto

Studies at NOJ:thwesteJ:n UniveJ:sUy in 1946(1.5) and at the

.

.

..

.

(16)

.

University of M1sIourlln 1955 . . have s:hotfllth.t thest4nd.r:d devia-

tion of torque was about 15'10

Bolt tension baaed' on applied torque

could vary as much 8£1 ±30% from the averase of ,8sroup

as shown in Fig. 2 ( 16)

by Me 81 rs

0

0

of8i~lar

bolts

This i8 cofts14eJ:ably above the .s'l. mentioned

Tomonaga and Ta j ima (8).

The 1.5'1. va lue :is can.idered to be

realistic for installation conditions in. the UoSo

The torque re18>tion-

ship becomes especially erratic when bolts are tiahtened into the 10elastic range and the threads begin to

def~rmo

In addition, installa-

tion costs are hlgh for the torque wrench method of installation and

with the large diameter A325 boltsanel the new A490 bolt considerable

torque is required to pr,eload the bolt

0

Two methods of controlling bolt tension are recommended by

the Research Council - the calibrated wrench and the turn-af-nut method o

The calibrated wrench method is essentially a torque control and success

depends on using a hardened washer under the nut in order to limit the

variation of friction between the underside of the nut and the gripped

288.22

material o

-8-

The wrench 1s usually calibrated in

8

hydraulic calibrator

as shown 1n F1go 3.

A number of factors led to the turn-of-nut methodo

As noted

earlier, tests have indicated that 'bolts suffer no injury when tightened

into their inelastic region o

Secondly, bolta actually were being

tightened far above their proof load due to faulty torque wrench inspection without any noticeable ill effect.

The tUl'n-of-nut method utilizes a strain control 8<nd there-

fore 18 ideally suited to controlling tightenina in the inelastic ranl80

The procedures currently in use have shown that a uniform tension 1s

achieved because relatively large variations 1n bolt elongations cause

only minor variations in tenslon aince the load-elonaatlon curve is

reasonably flat(17).

Numerous tests Includina those summarized by Dr o Thurlimann 1n

the Final Report of 6th Congress (18) have shown that the inelastically

loaded bolts have performed wallo

In fact, har4ened washers were once

required under both the head and nut of A325 bolts ,in order to provide

a consistent torque relation, to prevent galling of the structural

material and to prevent bolt,relaxation o

Tests have now shown that the

washer is not needed for the last two reasons and since the turn-ofnut is a strain control rather than a torque control, no washers at all

are required when this method of tightening 1s used for A325 bo1ts(2)

0

-9-

SUMMARY

Current design concepts in the UoS. are discus.ed o Two types

of connections are used: friction-type and bearing-typeo

The friction-

type connection reflects the ability of the Joint to resist sllp whereas

the bearing-type connection reflects the ultimate strength of the jolnto

Experience with bolted connection 1n the laboratory and in the field is

summarized

0

Finally, the factors which have led to currently used in-

stallation procedures are discussedo

-10-

REFERENCES

1.

Research Council on Riveted and Bolted Structural Joints of the

Engineering Foundation

SPECIFICATIONS FOR THE ASSEMBLY OF STRUCTURAL JOINTS USING

HIGH-STRENGTH STEEL BOLTS, 1951

2.

Research Council on Riveted and Bolted Structural Joints of the

Engineering Foundation

SPECIFICATIONS FOR STRUCTURAL JOINTS USING ASTM A325 or

A490 BOLTS, March 1964

30

Vasarhelyi, Do Do, Beano, So Yo, Madison, R. Bo, Lu, Zo Act and

Vasishth, U. Co

EFFECTS OF FABRICATION TECHNIQUES, Transactions ASCR, Vol.

126, Part II, 1961, pp. 764-796

4e

Foreman, Ro To, and Rumpf, J Lo

STATIC TENSION TESTS OF COMPACT BOLTED JOINTS, Transactions,

ASeE, Volo 126, Part II, 1961, PPo 228-254

5.

Bendigo, Ro A., Hansen, Ro A., and Rumpf, J. Lo

LONG BOLTED JOINTS, Journal of the Structural Division, ASCE,

Volo 89, Noo 8T6, December 1963

60

Chesson, Eo, Jr. and Munse, Wo H.

STUDIES OF THE BEHAVIOR OF HIGH-STRENGTH BOLTS AND BOLTED

JOINTS, University of Illinois, Engineering Experiment

Station, Bulletin 469, 1964

70

Hechtman, Ro Ao , Young, Do Ro, Chin, Ao Go, and Savikko, Eo Ro

SLIP OF JOINTS UNDER STATIC LOADS, Transactions, ASeE,

Volo 1'20, 1955, ppo 1335-1352

8.

Tomonag8, Ka, and Tajima, Jo

THE USE OF HIGH-STRENGTH BOLTED JOINTS IN RAILWAY BRIDGES,

Preliminary Publications, 7th Congress lABSE, 1964, PPo

0

379-385

90

Carpentier, L., and Alemany, B.

EXPERIENCE FRANCAISE DES BOlLONS A HAUTE RESISTANCE,

Preliminary Publications, 7th Congress lABSE, 1964,

ppo 397-405

10.

Fisher, Jo Wo, Ramseier, P. 00' and Beedle, Lo S.

STRENGTH OF A440 STEEL JOINTS FASTENED WITH A325 BOLTS,

Publications, IABSE, Volo 23, 1963, pp. 135-158

288 22

-11-

0

lIe

Fisher, Jo We' and Rumpf, Jo Lo

THE ANALYSIS OF BOLTED BUTT JOINTS, Fritz Engineering

Laboratory Report Noo 288.17, Lehigh University,

Bethlehem, Pa., 1964

120

Chesson, Eo, Jr.

JOINT BEHAVIOR OF A BOLTED RAIUlAY BRIDGE DURING ERECTION

AND SERVICE, SRS No o 284, University of Illinois, Urbana,

I111nois, 1964

130

Douty, Ro To, and McGuire, W.

HIGH-STRENGTH BOLTED CONNECTIONS WITH APPLICATIONS TO

PLASTIC DESIGN, Preliminary Publications, 7th Congress,

IABSE, 1964, PPo 565-576

140

Johnson, Lo G., Cannon, Jo Co, and Spooner, Lo Ae

HIGH TENSILE PRELOADED JOINTS, British Welding Journal,

September 1960, po 560

15

Maney, Go Ao

0

WHAT HAPPENS WHEN A BOLT IS TWISTED OFF?, Fasteners, Vol.

3, Noo 4, 1946

160

'auw, A o

)

and Howard~ L. Lo

TENSION CONTROL FOR HIGH-STRENGTH STRUCTURAL BOLTS, Proceedings, AISC, 1955, pp. 13-21

178

Rumpf, J o Lo, and Fisher, Jo Wo

CALIBRATION OF A325 BOLTS, Journal of the Structural Division, ASeE, Vol. 89, Noo 8T6, Decembe'r 1963', pp. 215-234

180

Thurlimann, Bo

RESEARCH ON lARGE COMPACT JOINTS WITH HIGH STRENGTH STEEL

BOLTS, Final Report 6th Congress IABSE, 1960, ppo 191-201

8~_

i

Single Bolt

/

SfJngle Dolt

(II tot)

--- ..j'/....... -- -

(8U l,ot)

-. -- -- -- -

--

--

60t-

o

Plate Failure

Uoundory

H

t2

~

::D

tj

z

~

I

!td-~

~

Test Points

~

o An/As

tI)

«

~

V)

rAJ

~

~

«

~

• An/As

:::

..

0.8

1.0

t

+ An fA 8 • 1.2

2 -

I.

in. grip

20

..

I in. grip

40

60

80

JOltrr LENGTII, INCIIES

Fip;urc 1.

SUMl1ARY OF ANALYTICAL AND EXPERlMEID'AL RESUlJTS FOR A325 BOLrrS

IN A440 STEEL JOINTS

.'

.

CALIBRAl'ED IMPACT WRE1'1Cll

Tnrget Value

198 - 7/S" bolts

15

en

10

,'0

5

I

oL

35

30

I

J

40

45

CLAMPING FORCE, KIPS

Figure 2.

HISTOGRAM OF IKTERNAL BOLT TENSION

......:-:-.>--.i-.--~...... ~..____ _

___,-----'-.... _._-.. ,

---,,,-

-'j .i. ,)l);) '~~,

,{O~;;JX ,

...... _ ..... ....,.~ -

~

i

I...~--

Fig. 3

.

~

-

- ,

- --.-----.-'- --- -.

,

~

'Hydraulic Calibrator for

Torq~ed Inst~llat~on

,'_

I