The Journal of Supercritical Fluids, 1995,8, 295-301

295

Supercritical Carbon Dioxide Extraction of Black

Pepper

Helena Sovov&,* Jaromir

Jez, Milena B6rtlov6, and Jitka St’astov6

Institute of Chemical Process Fundamentals, Academy of Sciences of the

Czech Republic, Rozvojova’ 135, Prague 16502, Czech Republic

Received January 17, 1995; accepted in revised form July 5, 1995

Oleoresin was extracted from ground black pepper with carbon dioxide at 28 MPa and 24 to 60 “C.

The yield and contents of piperine in the extract were determined as a function of extraction time and the

solvent amount. The concentration profile of piperine inside the fixed bed of pepper was also measured.

The total extract contained piperine and essential oil in the proper ratio to be used directly in food industry.

The experimental results showed a strong variation of extract composition during the extraction.

They were simulated using the extended Lack’s model with mass transfer coefficients in the solvent and

solid phase and with grinding efficiency as parameters. The parameters were determined individually for

each of the three extract components, representing essential oil, piper-me,and other nonpolar substances.

Keywords:

supercritical-fluid

extraction, black pepper, oleoresin, mass transfer, fractionation

INTRODUCTION

Food flavors and aroma are traditionally obtained

from spices in a rather complicated way. It involves separation of volatile essential oil with steam distillation

which is followed by extraction of oleoresin with liquid

solvent, separation of the solvent from the oleoresin using distillation, and mixing the oleoresin and essential oil

in the ratio occurring in the original spice. Extraction

with supercritical carbon dioxide enables us to obtain

complete and unchanged flavor and aroma in one step and

without any residues of organic solvents. As the extraction is carried out at a relatively low temperature and under inert atmosphere, the labile extract components are

preserved. The advantage of this procedure is demonstrated here on the extract from black pepper (Piper nigrum).

The dense carbon dioxide extraction from black pepper has been described in the literature several times.ib5 A

semicontinuous arrangement with the solvent flowing

through a fixed bed of ground pepper with constant rate

was used in all cases. Hubert and Vitzhum’** extracted

pepper at 350 atm and 60 “C with dry carbon dioxide for

three hours and then with wet CO2 at the same conditions

for another two hours. They obtained a yellowish semisolid mass with a crystalline fraction. The yield was 7 wt

%. There was 98% of piperine (the hot principle) transferred into the extract. Kasyanov et a1.3 extracted black

pepper, disintegrated into flakes of 0.14-0.18-mm thickness and a bulk density of 300 kg me3, with liquid carbon

0896-8446/95/0804-0295$7.50/O

dioxide below critical pressure. After three hours, they

obtained an oily liquid of yellow-brown color containing

yellow crystals. The yield was between 6.5 and 7.5 wt

%. Kurzhals at a1.4 extracted pepper at 52 “C and 78 bar

with a mixture of carbon dioxide and propane in molar ratio 58.8:41.2. After two hours there was 98% of piperine

transferred into the extract, and total yield was 18.7 wt %.

Beutler at a1.5 reported rate of pepper extraction to be dependent on the direction of solvent flow. Downflow of

carbon dioxide through the bed of extracted material was

more effective than the upflow; the initial loading increased from 2 mg g-l CO2 with the upflow to 3.4 mg g-*

CO2 with the downflow.

In this work, the change of mass transfer rate and

extract composition during the extraction are studied. The

process is described with a simplified mathematical model

of supercritical-fluid extraction from ground plant materials.6

MODEL

Mass Balance.

On the assumptions that a plug

flow of the solvent exists in the fixed bed of solid particles and that axial dispersion is negligible, the material

balances for an element of bed are given by

0 1995 PRA Press

296

SOVOV~et al.

The Journal of Supercritical Fluids, Vol. 8, No. 4, 1995

p,&+p

at s(l-E)-=,

Nab

’

If it is assumed that the solvent is solute-free at the entrance of the extractor and that all particles have the same

initial solute content x0, then the boundary conditions are

x(t=O,

h)=x,;

y(t=O,

h)=y,(h);

x=x,(1-rexp[-Z(h-hk)]}

(2)

for

rlZIY<Y’,,

y(t, h=O)=OP)

h>h,

x=1+exp[Y(41

-1exp(-Yh)

1

1

and the mass of solute extracted out of the fixed bed equals

l-r

E = Qjr(t,

h = 1)dt.

(4)

0

for

Rate of Interphase

Transfer.

As the plant

tissue is torn during the grinding, part of the solute is released. Concentration of this easily accessible solute in

the solid phase is rxc at the beginning of extraction. It is

extracted in the first period of extraction with a rate controlled by its diffusion in the solvent

J = k,ap, (yr - y) for x > (1 - r-)x,.

(5)

and for

r <Y<Y’,,

z-

for x5(1-r-)x,

E = Nx, w[ 1- exp( -Z)]

-!$p[Z(h

-1,]}

for

r/ZIY<Y’,

E=Nx,

1-ln

X

’

for Y < r / Z

(6)

with one solid-phase mass transfer coefficient k,.

Solution.

Equations 1 to 6 can be integrated

numerically to obtain the concentration profiles and the

mass of extract in dependence on time. However, an approximate analytical solution exists6 which can be applied

on conditions that (i) the accumulation term pf.c(&ldt) in

eq 2 can be neglected due to the low solubility yr, so that

the equation becomes

p.(l-E)-=J

5

Ndh

(7)

and with the mass of extract

The second period of extraction starts when the easily accessible solute has been removed. The rate of extraction

depends now on the diffusion of solute from the interior

of the plant tissue to the surface. Instead of taking into

account the complex nature of the vegetable matrix, we

apply a simplified formula

J=k,ap,(x-x+)

h 5 h,

(

l+[exp(Y)-l]exp

[ Y (;-

y)]o-‘)}I

y)

1

for

Y2Yy,.

63)

In these equations h, Y are dimensionless variables, hk is

the coordinate of the level inside the bed where the free solute has just been exhausted,

(24

h, =$ln(l+{exp[Y(Y-i)]-l}/r)

(ii) k, G kf, so that it holds in the second period y c<yr, x

- x+ 5 x, and eq 6 can be rearranged as follows:

J = k,ap,x( 1 - y / y,) for x 2 (1 - r)x,

(64

The set of eqs 1, 2a, 3-5, and 6a represents the extended

Lack’s model6 with the solid-phase concentration profile

x=x,[l-ZYexp(-Zh)]

for Y<rlZ

for

rlZSY<Y’k.

(9)

Yk is the dimensionless time when the free solute has

just been exhausted from the whole bed,

The Journal of Supercritical Fluids, Vol. 8, No. 4, 1995

(10)

Y’, =~++ln[l-r[l-exp(Y)]}

and Z, Y are quantities proportional

coefficients,

Extraction of Black Pepper 297

to the mass transfer

i

(__ -.--...._._._._.._._.__

- _____

z =

NkfaPf

Q(l - E)P, ’ ’ =

~fwo

Q(l - E)Y,

The solvent-phase mass transfer coefficient kf is assumed

to increase with interstitial solvent velocity according to

the relation7

k

f-

- ,,0.54

I

(11)

= Q0.54

which was proved in the range of v from 0.04 to 2.8 mm

I

j

!

@I

5

678

7_i

L

..--_._._--

__,.._.__i

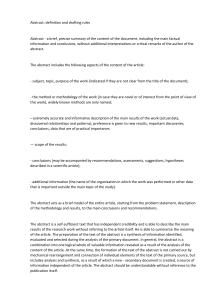

Figure 1. Experimental apparatus for supercritical-fluid

extraction. 1, CO2 cylinder; 2, compressor; 3, pressure regulator; 4, surge tank; 5, extractor; 6, micrometer valve; 7,

separator; 8, wet flow meter.

s-1.

This model was used with good results to determine

the overall mass transfer coefficients kfa, k,a, and the

grinding efficiency r by matching the calculated and experimental extraction curves of grape oil.*

Multicomponent

Extraction.

If several solutes are extracted simultaneously, the overall mass of extract obtained during the time interval 9 - 9-1 equals

(13)

E(tj)-E(tj-l)=CIEi(tj)-Ei(tj-l)]

i

and the concentration of i-th component in j-th sample of

extract is

Wi,j

=[Ei(tj)-Ei(tjw~)]l[E(tj)sE(tj-,)]’

Cl41

If there are no interactions between the solutes, the model

of one-component extraction can be used to calculate the

amounts of extract E for each solute independently and to

substitute them for Ei in eqs 13 and 14.

EXPERIMENTAL

Materials.

Ground black pepper with mean particle size 0.05 mm was supplied by EKO Tanvald. It

contained 4.5 wt % piperine, 2.1 wt % essential oil and

11.5 wt % water. Average density of pepper determined

with pycnometer was 1339 kg m3, its bulk density after a

slight pressing was 636 kg rnM3. Density of pepper essential oil was 877 kg me3 at 20 “C.

The carbon dioxide was 99.5 to 99.7 wt % pure and

was supplied by Chemical Works Litvinov.

The amount of essential oil in pepper was determined using steam distillation. Concentration of piperine

in pepper was determined, after its quantitative extraction

with benzene, by UV spectrophotometry using a Unicam

SP1750. The maximum absorption peak of piperine in

benzene was at 342 nm. Piperine, limonene, a-pinene,

and Ppinene supplied by Fluka and declared as “purum”

were used as standards.

SCF extracts were analyzed by HPLC using a

Hewlett Packard 1090M chromatograph equipped with

diode array UV-VIS detector. The conditions were as follows: column 250-mm x 4-mm i.d.; Nucleosil C 18 5pm; mobile phase methanol; flow rate 0.6 mL mini.

Piperine content was determined at 340 nm, the other

components at 220 nm.

Equipment

and Procedure.

The supercritical-extraction apparatus is schematically represented in

Figure 1. It was operated in a single-pass mode of CO2

down through the bed of ground pepper, with extract recovery by depressurization to atmospheric pressure in micrometer valve. The bed of pepper was situated in the extractor between two layers of glass beads. The extractor

was a cylindrical stainless steel vessel immersed in thermostatic water bath. Two vessels were used alternatively:

150-mL extractor with 33-mm i.d., or 12-mL extractor

with 8-mm i.d. Extraction pressure was maintained

within 28 + 0.1 MPa. The capillary from the extractor to

the micrometer valve and the valve itself were wrapped

with heating tape and maintained at a temperature higher

than that in the extractor to prevent clogging. Extraction

yields were measured gravimetrically by collecting the

products precipitated at room temperature in glass U-tubes

used as the separator. The mass of carbon dioxide was determined by wet flow meter and by the pressure and temperature conditions measured at the end of assembly.

Extract samples were stored in the dark in a refrigerator to

prevent chemical reactions such as isomerization.

Conditions.

Solvent flow rates ranged from 0.8

to 1.9 g min-l, interstitial solvent velocity was in the

range from 0.06 to 1.5 mm 5-l. Pepper feed was between

6 and 61 g and the amount of CO;! consumed in one experiment was in the range from 180 to 540 g. Extraction

pressure was 28 MPa in all experiments, extraction temperatures were 24, 40, and 60 “C, total number of extraction experiments was 22.

298

Sovovi et al.

The Journal of Supercritical Fluids, Vol. 8, No. 4, 1995

110

100

6

90

00

70

2

E

60:

501

40:

30:

20:

10

8

Figure 2. Chromatozram of extract samnle obtained at 40 “C, detected at 220 nm. Conditions: pepper feed 31 g, solvent flow

fate 1.8 g mint, extract collected for 17 min from t = 10 min. Components: l-3, essential oil, 6, piperine, 4, 5, 7, and 8, unidentified substances.

One experiment at each temperature was stopped

when 30 to 60% of piperine had been extracted.

Depressurized bed of pepper was transferred gradually,

starting from the top, into six sampling vessels. Piperine

profile in the bed was estimated from the average piperine

concentrations in the individual samples.

RESULTS

Extracts

and

Rate

of

Extraction.

Appearance of extract samples taken during the extraction

was changing from a yellow liquid containing white crystals, over a pasty substance changing from yellow to orange and red and fading again, up to a light yellow powder. This suggests that the extraction of liquid essential

oil and carotenoids was practically complete.

A typical chromatogram of a pasty extract sample is

shown in Figure 2. The substances with longest retention times were identified by comparison with a chromatogram of pepper distillate (see Figure 3) as the main

components of essential oil. The oil is known to consist

mainly of monoterpenes as a-pinene, sabinene, ppinene,

and limonene,9 oxygenated monoterpenes as p-menthen-l01, 2,8-p-menthadien-l-01

and trans-pinocarveol,10 and

sesquiterpenes, as caryophyllene.3 Using limonene, CG

pinene, P-pinene, and piperine as standards, peak 2 was

identified as a mixture of monoterpenes, and peak 6 as

piperine. Substances corresponding to peaks 4, 5, 7, and

8 are non-volatile because they were not detected in the

essential oil. They are probably not polar since they

show high solubility in carbon dioxide. Most probably

these peaks represent lipids.

Starting here, only three (pseudo)components will

be distinguished in the extract: essential oil comprising

peaks l-3, piperine with peak 6, and lipids denoting the

other compounds. Figure 4 shows the changes of their

Figure 3. HPLC analysis of essential oil obtained from

black pepper by steam distillation.

0

0.2

1.3

2.1

3.7

8.3

Q/N

Figure 4. Changes of peak areas in HPLC chromatograms

of extract samples at the temperature 40 “C.

The Journal of Supercritical Fluids, Vol. 8, No. 4, 1995

Parameters

Component

of Extraction

T(“C)

Model

Extraction of Black Pepper 299

TABLE I

for 1, Essential

A,

r

Yr

Oil;

2, Piperine;

kfa* (mini)

3, Lipids

k,a (mini)

1

24

40

60

0.021

0.8

0.02

0.04

0.03

0.6

0.6

0.4

0.007

0.010

0.020

2

24

40

60

0.045

0.82

0.0013

0.0019

0.0033

0.9

0.8

0.6

0.003

0.004

0.008

3

24

40

60

0.013

0.017

0.019

0.5

0.003

0.005

0.004

0.2

0.2

0.16

0.004

0.006

0.012

* Parameter kp is related to the fixed interstitial solvent velocity v = 1 mm s-i

mutual relation in extract samples taken during the extraction. Peak areas detected by HPLC at 220 nm are plotted

against the mean extraction times multiplied by specific

solvent flow rate Q/N. Initial samples contain mainly the

essential oil, which is extracted fast. Percentage of piperine in the extract increases and piperine becomes the main

component in the extract sample at a distinct extraction

time. The higher the extraction temperature, the shorter

is this time.

Rate of extraction was increasing with the temperature. For example, in experiments carried out in the

smaller extractor, the specific amount of carbon dioxide

QtlN necessary to extract 5 wt % of organic compounds

from black pepper was 18 at 23 “C, 11 at 40 “C, and only

6 at 60 ‘C. The experiments were stopped after extraction

had slowed down below 0.5 mg g-i CO;?. As a result, the

yield obtained was 6.7 to 7.6 wt %, and the total extract

contained 28 to 31 wt % essential oil, 50 to 54 wt %

piperine, and 15 to 22 wt % other substances. For comparison, the standardized black pepper oleoresin contains

50 wt % piperine and 15 mL essential oil/100 g.

Comparison

with the Model.

There is an

interaction between the essential oil and lipids during the

extraction with carbon dioxide.” Besides, the solubility

of essential oil in carbon dioxide under extraction conditions is too high to permit neglecting the accumulation

term in eq 2. However, as most of the essential oil was

extracted in a short initial period and the further course of

extraction was not affected by its presence, we did not take

into account these complications and tried to fit the extended Lack’s mode1 on the experimental data, substituting

Ei, i = 1, 2, and 3 calculated from eq 8 into eqs 13 and 14.

Carbon dioxide density at 28 MPa was determined

with Altunin and Gadetskii’s equation:i2 pr = 968 kg mm3

at 24 “C, pf = 899 kg me3 at 40 “C, pf = 8 15 kg rnM3at 60

‘C. Density and void fraction of the solid phase, ps =

1340 kg m-3, E = 0.53, and the initial content of piperine

-0

0.2

0.4

0.6

0.8

i

h

Figure 5. Measured and calculated solid phase concentration profiles. Conditions: pepper feed 61 g, solvent flow

rate 1.8 g min.‘, extraction temperature 40 “C. Extraction

was stopped after 300 min. a) measured mean concentrations,

b) calculated profile.

and essential oil, x0’ = 0.021, xo2 = 0.045, were measured

independently.

The other model parameters listed in Table I were

determined by matching eq 13 to the experimental extraction curves, eq 14 to piperine concentration in extract

samples, and eq 7 to the experimental piperine concentration profiles in the bed. As these experimental data contain more information on piperine than on the pseudocomponents, parameters of piperine could be fitted better

than the others. The regression was performed at each extraction temperature separately, with sum of squares of

deviations of calculated points from experimental data as

the criterion. Solid-phase mass transfer coefficients k,a

and piperine solubility yr2 were found to be more temperature dependent than other parameters.

Accuracy of the piperine parameters was estimated

at 5% for r, 10% for yr and kfa, and 20% for k,a.

300

Sovovi et al.

ov

0

7

The Journal of Supercritical Fluids, Vol. 8, No. 4, 1995

30

10

CX,N20

Figure 6. Measured and calculated extraction curves.

Conditions: pepper feed 7 g, solvent flow rate 1.1 g min.‘,

extraction temperature 40 “C. (B) experimental data; (-)

model: a) piperine; b) piperine + essential oil; c) total extract.

80 ,

I

of the first section of the curve, r to the height of the edge

between the slow and fast extraction region, the solubility

yr to the horizontal shift of the steep section from the

origin, and kfa to the slope of this section. Slope of the

calculated extraction curve c in Figure 6 decreases step by

step, as the extraction curves of individual components

switch to the slow extraction period. Slight discrepancy

between the calculated extraction curve and experimental

points may be caused by hold-up of a small portion of extract inside the micrometer valve and by its irregular release in the course of extraction. In Figure 7, the calculated time dependence of piperine concentration in extract

samples shows unusual sharp-edge points corresponding

to the transitions between the fast and slow periods of extraction and suggests thus limits of application of the

simplified model.

CONCLUSION

Strong time fractionation takes place during the extraction of black pepper oleoresin with carbon dioxide at

temperatures ranging from 24 to 60 “C and at a pressure

of 28 MPa. It is explained by different solubilities and

mass transfer coefficients of extracted components - essential oil, piperine, and lipids. The rate of extraction

grows with the temperature because of the increasing solubility of piperine in carbon dioxide, and, in the second

extraction period, also due to the faster diffusion of all

components through the plant tissue.

ACKNOWLEDGMENT

The authors gratefully acknowledge the support of

the Grant Agency of the Czech Republic (Grant No.

5 10/93/2283).

0

2

4

6

8

U/N

Figure 7. Measured and calculated concentrations of

piperine in extract samples. Conditions: pepper feed 61 g,

solvent flow rate 1.7 g min-r, extraction temperature 24 “C.

(W) experimental data; (-)

model.

NOTATION

a

E

h

J

k

N

Q

Accuracy of these parameters for essential oil and lipids

was twice or three-times smaller. As mentioned above,

the parameters yr, kra for essential oil lack physical meaning due to the model inadequacy. The increase of the fitted initial concentration of the lipid pseudocomponent

with temperature could indicate that some components of

this mixture were practically insoluble in carbon dioxide

at lower temperatures.

Typical experimental data and corresponding model

curves are shown in Figures 5 to 7. In Figure 5, the easily accessible piperine is already exhausted from the first

quarter of the bed, where the slope of concentration profile

is relatively small. Fast increase of the slope denotes the

region of extraction from the surface of particles. In the

second half of the bed, the solvent is almost saturated and

the curve becomes flat. Parameter k,a relates to the slope

r

t

T

V

X

Y

Yr

Y

Z

specific interfacial area

mass of extract

dimensionless axial coordinate, 0 5 h 5 1

mass-transfer rate

mass-transfer coefficient

solid feed

mass flow rate of solvent

grinding efficiency, 0 5 r 5 1

time

temperature

interstitial solvent velocity

solid-phase concentration (g g-r)

solvent-phase concentration (g g-r)

solubility (g g-l)

parameter of the second period, defined by eq 11

parameter of the first period, defined by eq 11

GREEK

LETTERS

i

void fraction

wavelength

density

G

[=(Qy,/Nx,)t],

dimensionless time

SUPERSCRIPT

+

at interfacial boundary

The Journal of Supercritical Fluids, Vol. 8, No. 4, 1995

SUBSCRIPTS

f

i

j

k

S

0

1

2

3

solvent phase

i-th component

j-th sample

boundary between the first and second period

solid phase

initial conditions

essential oil

piperine

lipids

Extraction of Black Pepper 301

(4)

(5)

(6)

(7)

(8)

Kurzhals, H.-A.; Hubert, P. German Patent 2844781,

1980.

Beutler, H.-J.; Gaehrs, H. J.; Lenhard, U; Luerken, F.

Chem. Ing. Technol. 1980,60,

773.

SovovA H. Chem. Eng. Sci. 1994,49, 409.

Lee, A. K. K.; Bulley, N. R.; Fattori, M.; Meisen, A. J.

Am. Oil Chem. Sot. 1986,63, 921.

Sovova, H.; Kucera, J.; Jez, J. Chem. Eng. Sci. 1994,

49, 415.

(9)

Wrolstad, R. E.; Jennings, W. G. J. Food Sci. 1965,

30, 274.

REFERENCES

(1)

(2)

Vitzthum, 0.; Hubert, P. German Patent 2127611,

1973.

Hubert, P.; Vitzthum, 0. G. Angew. Chem. Int. Ed.

1978,

(3)

17,

710.

Kasyanov, G. I.; Pekhov, A. V.; Taran, A. A.

Naturalnye Pishchevye Aromatizatory CO,

Ekstrakty (Natural Food Aromas - CO, Extracts);

Pishchevaya Promyshlennostj: Moskva, 1978; pp 65,

88, 99.

(10) Jennings, W. G. J. Food Sci. 1971,36, 584.

(11) Sovova, H.; Komers, R.; Kucera, J.; Jez, J. Chem. Eng.

Sci. 1994, 49, 2499.

(12) Angus, S.; Armstrong, B.; de Reuck, K M.

International Thermodynamic Tables of the Fluid State

Carbon Dioxide; Pergamon Press: Oxford, 1976; p 38.