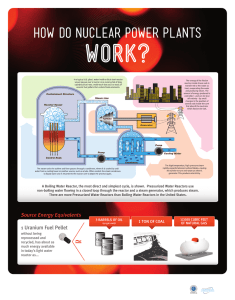

Jens Martensson University Teaching Department, Rajasthan Technical University, Kota Practical Training Report: Rajasthan Atomic Power Plant, Rawatbhata 1 SUBMITTED BY - MALAY JADIA B. TECH IV YEAR ELECTRONICS & COMMUNICATION ENGINEERING UTD, RTU, KOTA TRAINING PERIOD : JUNE 13, 2022 TO JULY 11, 2022 SUBMITTED TO : Dr. MITHILESH KUMAR Dr. M. L. MEENA 2 Jens Martensson 3 PREFACE • As we know that an engineer has to serve an industry, for that one must be aware of industrial environment, their management, problems and the way of working out their solutions at the industry. • After the completion of the course an engineer must have knowledge of interrelation between the theory and the practical. For this, one must be familiar with practical knowledge with theory aspects. • I have been lucky enough to get a chance for undergoing this training at RAJASTHAN ATOMIC POWER STATION (RAWATBHATA). It is a constituent of board of Nuclear Power Corporation of India, Limited. This report has been prepared on the basis of knowledge acquired by me during my training period at the plant. 4 ACKNOWLEDGEMENTS It awards me abundant pleasure and aspiration in presenting my training report consisting of various pages along with suitable drawings and references. As this is my first effort to prepare a training report, I have tried my best to compile all necessary data yet there may be possibility of error and omission. I want to express my heartiest gratitude to Mr. N. K. Pushpkar, Site Director, RR Site ; Mr. A. P. JAIN, Training Superintendent and my training coordinator Scientific Officer SO/F at NTC RR SITE for providing me an opportunity to get a rigorous training at Rajasthan Atomic Power Station, Rawatbhata. I would like to convey my special thanks to my project-guide Mr. A. P. Jain, SO/F NTC RR SITE for his guidance and supervision during my training period. I would like to extend my thanks to all other field engineers, supervisors and technicians of RAPS, those who directly and indirectly helped me during this training period with there valuable guidance and help provided in understanding the task of this training. 5 My training at RAPS covered gathering information about the general working of the plant, safety features and various technical aspects of the design. This gave way to general classification of various systems of the plant, then covering the information about the theory and working of Control Systems of the plant. Further it included knowing about the maintenance work carried in the NTC Control & Instrumentation Shop. 6 •THREE STAGES OF INDIAN NUCLEAR POWER PROGRAMME •Introduction India figured on the nuclear power map of the world in 1969, when two Boiling Water Reactors (BWRs) were commissioned at Tarapur (TAPS-1&2). M/s. General Electric Company (GEC) of USA built these reactors on turnkey basis. The main objective of setting up these units was, largely to prove the techno-economic viability of nuclear power and to obtain experience in operation & maintenance of nuclear power plants and to demonstrate technical viability of operating the nuclear power stations with Indian regional grid system. For Tarapur plant all the components and nuclear fuel were imported and the roles of Indian Industries were limited to construction, erection and service contract. However, as a long term strategy, the Nuclear Power Programme formulated embarked on the three stage nuclear power programme, linking the fuel cycle of Pressurized Heavy Water Reactor (PHWR) and Fast Breeder Reactor (FBR) for judicious utilization of our reserves of Uranium and Thorium. The emphasis of the programme is self-reliance and thorium utilization as a long-term objective. The three stages of our Nuclear Power Programme are: •Stage-I envisages, construction of Natural Uranium, Heavy water moderated and Cooled Pressurized Heavy Water Reactors (PHWR). Spent fuel from these reactors is reprocessed to obtain Plutonium. •Stage-II envisages, construction of Fast Breeder Reactors (FBR) fueled by Plutonium and depleted U produced in Stage-I. These reactors would also breed U233 from Thorium. •Stage-III would comprise power reactors using U233 -Thorium as fuel, which is used as a blanket in these types of reactors. 7 The PHWR was chosen due to the following: 1) It uses natural uranium as fuel. Use of natural uranium available in India, helps cut heavy investment on enrichment, as uranium enrichment is capital intensive. 2) Uranium requirement is the lowest and plutonium production is highest. 3) The infrastructure available in country is suitable for undertaking manufacture of equipment. Now, let’s see some basic and important components in a Nuclear Power Plant. 8 The pressurized water reactor (PWR) is a type of nuclear reactor used to the generate electricity and propel nuclear submarines and naval vessels. They make use of light water or heavy water as their coolant and neutron moderator. As the name implies, the water in the reactor is pressurized. This is due to the fact that as the pressure gets higher, the boiling point of water increases with it. This means that at high pressures the water can operate at extremely high temperatures without boiling to steam. This is important for the reactor as higher pressures allow for greater power output and higher thermal efficiency. The pressure is maintained by the pressurizer, which acts to stabilize pressure changes caused by changes in electrical load. Water enters the reactor at 290°C, and by the time it exits it is at around 325°C. In order for it to remain a liquid at these temperatures, the pressure must be 15 MPa, or about 150 times atmospheric pressure. By keeping the water in liquid form, the control rod system is simplified as they are able to be placed in from the top. Therefore, if the power is lost in the plant, the electromagnetic system holding the rods will give out, and gravity will cause the rods to fall into the core, stopping the reaction. The hot water flowing from the reactor flows through inverted U-tubes which acts as a heat exchanger, heating up a secondary loop of water in what is called a "steam generator". This secondary loop is at a lower pressure so it is able to boil to steam, which then passes through turbines in order to generate electricity. Large reactors have up to 4 steam generators, 9 each of which may be larger than the reactor itself. A nuclear reactor is a system used to initiate and contain a nuclear chain reaction, and they have many useful applications. These nuclear reactions produce thermal energy through either nuclear fission (in practice) or nuclear fusion (in development). Nuclear reactors are primarily used for the generation of electricity, however they can be used for propulsion in vehicles such as submarines or naval vessels, for production of useful isotopes or neutrons, and for research and training. How do they work? The basic operating principles of a nuclear reactor for the production of power are as follows: Nuclear chain reactions within the reactor produce heat, which is transferred to a coolant, the coolant either boils to steam directly or heats another loop of water into steam, it then passes through a turbine which spins a generator, and produces electricity. Although the basic principles appear simple, the process is fairly complex. Economics The building of nuclear reactors is economically intensive. The initial capital costs are high compared to fossil fuel plants with similar output. Nuclear power requires a high amount of additional safety, and is completely responsible for all possible nuclear waste. What makes nuclear power economically feasible is the large amount of energy that comes from a small volume of fuel. This relationship is known as energy density, and provides a cost advantage to using nuclear fuels. The cost of fuel is relatively lower for a nuclear power plant compared to fossil fuels. This is what makes nuclear reactors competitive despite high initial capital costs. 10 Moderators are used to slow down the neutrons produced from fission. This is necessary because many nuclear fuels (uranium-235, for instance) require neutrons to be slow-moving in order to absorb them. Nuclei with low mass numbers are most effective at doing so, therefore materials like water or graphite are often used. Most reactors use light water as a moderator, such as pressurized water reactors and boiling water reactors. Carbon works similarly and is used in reactors such as the RBMK. A third type of moderator used in CANDU reactors is heavy water, which is water composed of heavy hydrogen, called deuterium, rather than normal hydrogen. The graphic here should help in visualizing how a moderator does its job: neutrons that are going too fast are absorbed by uranium-238 and do not yield fission (green) and the moderated neutrons are absorbed by uranium-235 which splits into smaller atoms and produces excess neutrons to continue the reaction (red). 11 THE FUEL Nuclear reactors require the use of nuclear fuels, elements that can be readily altered and will release thermal energy. Uranium is the most common element used as a nuclear fuel, although thorium is also possible. The naturally occurring isotopes are found in countries such as Kazakhstan, Canada and Australia. The uranium fuel is manufactured into small fuel pellets and are packed into fuel rods and surrounded by cladding to avoid leaking into the coolant. These fuel rods are assembled into a fuel bundle, as seen below. There can be hundreds of fuel bundles in a nuclear reactor, meaning there can be tens of thousands of fuel rods. 12 Coolant The coolant, as its name implies, is used to remove heat from the core and move it to somewhere that it is useful. This keeps the fuel from overheating and melting down, at the same time as transferring the heat to water to make steam. Light water, heavy water, and various gases are the most common coolants for nuclear reactors. Coolants may also serve as the moderator, as is the case in many water-moderated reactors. CONTROL RODS Control rods can be inserted into the reactor core to reduce the amount of fuel which undergoes fission reactions. The rods contain neutron absorbing atoms such as cadmium. By absorbing neutrons within the core, it prevents those neutrons from reacting with the fuel. Control rod movement can be used to adjust the number of reactions occurring at the core, or fully inserted to shut down the reactor completely. Safety systems Safety systems are those in place to shut down the reactor and prevent radioactive material from being released. Some systems are passive, such as the dropping the control rods into the reactor core in CANDU reactors. The control rods are suspended above the core and held there by an electromagnet. In the event that a loss of power occurs, the control rods work to stop the reactions in the core. Strong containment buildings must also surround the reactor to prevent any radioactive leaks or external damage to the reactor. Other safety systems require activation. An example of such a system is the release of large 13 quantities of water to surround the reactor core. This provides cooling for the core to disperse the thermal energy and avoid a melt down. •INTRODUCTION TO POWER PLANTS •Power plays a very important role in the development of the country. • The industrial and economic growth of a developing country largely depends upon quality and quantity of power production. • In a developing country like India generation of power should be sufficient to satisfy industrial, agricultural, household and other needs. • An important factor related to the generation of power is the cost of production, i.e., the cost of production should be minimized. • Among the various ways of power production (power generation by coal, hydroelectric power, nuclear power, power generation by natural gas, etc.) nuclear power is most economical and provides minimum cost of production. •In India, generation of power is by three ways: •Thermal power plants •Hydro power plants •Nuclear power plants 14 In thermal power plants, the heat energy generated by burning of coal is utilized to generate steam at high pressure, which is impinged on the blades of a rotor (steam turbine) this steam turbine is coupled to a generator, which produces power. Thus heat energy produced by burning of coal is used to generate electricity. 15 In hydro power plants, the pressure head of a jet of water impinges on the blades of a hydraulic turbine that is coupled to a generator. Hence the potential energy of water is used to generate electricity. 16 In nuclear power plants, the heat produced during the nuclear fission of a heavy radioactive nucleus is efficiently utilized to produce steam at high pressure. This steam is made to impinge on the blades of a steam turbine that is coupled to a generator. Among the above mentioned ways of generating power, India meets its most of the power demands by thermal and hydro power plants, and nearly 3% of total power generation is by nuclear power plants and that’s why power generation from nuclear means needs more attention. 17 18 Rawatbhata Rajasthan Site Rawatbhata Rajasthan site is situated at Rawatbhata, District Chittrogarh, via Kota, Rajasthan. Rawatbhata Site consists of 6 units of PHWR under operation and two unit of PHWR under construction. •Rajasthan Atomic Power Station (RAPS 1) (100 MWe) PHWR completely defueled and maintained under dry preservation •Rajasthan Atomic Power Station (RAPS 2) (200 MWe) under operation •Rajasthan Atomic Power Station (RAPS 3 & 4) (2 x 220 MWe PHWR) •Rajasthan Atomic Power Station (RAPS 5 & 6) (2 x 220 MWe PHWR) •Rajasthan Atomic Power Project (RAPP 7 & 8) (2 x 700 MWe PHWR) 19 Introduction to Nuclear Energy: Nuclear Fission A neutron splits into two big parts hits when a heavy nucleus likes that of uranium – 235 & in addition 2 or 3 neutrons are released. However, the mass of the parts is slightly less than the mass of the uranium nucleus. The mass that is destroyed is converted into energy (200Mev/ fission). This process is called nuclear fission reaction. It is much more likely if neutrons are slow, in a reactor, some of the neutrons produced are absorbed so that for every neutron causing fission, only one is left. This neutron in turn collides with another U235 nucleus & causes fission. A chain reaction is thus set up. Also, the neutrons have to be slowed down. The fuel in a nuclear reactor consists of Uranium that may be natural or enriched in which proportion of U235 is increased. Either light water (for enriched uranium) or heavy water (for natural uranium) may be used as a moderator, for slowing down the neutrons. The water (either light or heavy) absorbs the energy released. This coolant in turn transfers its energy to the light water. Ultimately water is turned into steam at high pressure that is used to derive turbines as in any conventional power plant. Some Important Nuclear Reactions: 1) 92U238+0n1→92U239→93Np239→94PU239 Typical fission reaction: 2)92U235+0n1→38Sr90+54Xe144+20n1+ γ +200MeV Reactor poisoning reaction: 3)52Te 135→53I135→54Xe135→55Cs135→56Ba135 (Stable) 20 21 22 23 24 •PLANT LAYOUT In RAPS 3&4 plant layout has been developed on the basis of two unit modules of 220MWe and takes care of current international safety standards. The two unit modules have the following principle features: •The layout is basically dependent on a unitized concept except that in some of the no safety related areas, sharing of common facilities has been allowed on module basis. • In some cases such as control building where safety/safety support systems of both reactors of a module are located, the principle on physical separation between the two is adhered to. •The turbine building is located radial to the reactor building. The safety related structure such as Reactor Building, Reactor Auxiliary Building, Control Building, Diesel Generator Building etc., are also located as to provide safety against the low trajectory turbine disintegration missile. •The seismic class of structure is commensurate with the seismic class of equipment to be housed in them. • From this consideration a separate building called Control Building designed for SSE intensities has been provided which will house various safety and safety support systems. •Three diesel generators provided for class III emergency power requirements of each unit are distributed and housed in two separate safety related diesel generator buildings located one on the north side and the other on the south side of the control building. •Reactor auxiliary building which houses mainly the heavy water systems and other safety related systems are located adjacent to the reactor building. This location is mainly selected from the consideration of reducing the locked up heavy water inventory in the pipe lines running between the two buildings and to shorten the length of the piping carrying active fluids. •A common spent fuel building is provided centrally between the two reactors building on the west side. •The orientation and location of the building is so decided as to reduce the total number of bends traversed by the shuttle carrying spent fuel from each reactor building to the respective inspection bay. • This building is safety related and designed as class III. The common exhaust ventilation system for Reactor Building, Reactor Auxiliary Building, Spent Fuel Building, Service building etc. is located on the first floor of SFB at 106 m elevation. 25 26 Main function and objectives To transport 756 MW of thermal power from reactor core to steam generators (four in number) during normal operation. To maintain acceptable integrity of reactor coolant pressure boundary. To maintain acceptable integrity of the cladding of the fuel in the reactor core. To remove heat from the core, after a failure of the reactor coolant pressure boundary, in order to limit fuel damage within acceptable limits. To prevent the failure or to limit the consequence of failure of a component or a structure whose failure would cause the impairment of a safety function. To maintain cool able geometry of the core during all operational states and postulated accident conditions. It also acts as a barrier against the release of radioactivity from the core. To ensure that the fuel is cooled in the core by appropriate amount and proper quality of coolant during all operation states and following accident conditions. A feed and bleed system is provided to maintain PHT system pressure and also to provide flow to purification system. A relief system is provided to limit the PHT system pressure. 27 Reactor Safety System Other advanced design features include safety against low trajectory internal missiles. The philosophy behind the design of safety systems is “fail safe design philosophy”. Components are so engineered that their functional failure does not affect the safety of the reactor and other engineered safety systems. Shutdown System The design objective for shutdown system of a reactor is to make and hold the reactor sub-critical for all anticipated operational occurrences and postulated accident conditions even for the most reactive core. This objective is achieved with the help of following systems: Primary Shutdown System – also referred to as Mechanical Shut off system. Secondary Shutdown System – also referred to as Liquid Shut off system. Liquid Poison Injection System (LPIS). The first two systems are capable of making the reactor sub-critical, under all anticipated operational occurrences and postulated accidental conditions. Liquid Poison Injection System helps to hold the reactor sub-critical for prolonged period of shutdown, including under station black out conditions. 28 Containment Double containment philosophy has been followed. The containment system consists of an inner (primary) containment enveloped by an outer (secondary) containment. The annulus between the inner and outer containments is kept at a slightly negative pressure with respect to the atmosphere so as to minimize ground level activity release to the environment during an accident condition. Emergency Core Cooling System (ECCS) ECCS is provided to cool the core and thereby limit the core damage in the event of postulated loss of coolant accidents. The design requirement of the emergency core cooling system is to provide sufficient cooling of the core following a LOCA, so as to limit the release of fission products from the fuel and to ensure integrity of fuel channels. The emergency core cooling system incorporates the following: High-pressure heavy water injection. Intermediate pressure light water injection. Low-pressure long-term recirculation. 29 Reactor In concept, the Indian pressurized heavy water reactor is a pressure tube type reactor using heavy water moderator, heavy water coolant & natural uranium dioxide fuel. The reactor consists primarily of calandria a horizontal cylindrical vessel. It is penetrated by a large number of Zircaloy pressure tubes (306 for 235MWe reactor), arranged in a square lattice. These pressure tubes also refer as coolant channels; contain the fuel & hot high – pressure heavy water coolant. The pressure tubes are attached to the alloy steel and fitting assemblies at either end by special role expended joints. End – shields are the integral parts of the calandria and are provided at each end of the calandria to attenuate the radiation emerging from the reactor, permitting access to the fueling machine vaults when the reactor is shutdown. The end fittings are supported in the end shield lattice tubes through bearing, which permit their sliding. The calandria is housed in a concrete vault, which is lined with zinc metallized carbon steel & filled with chemically treated demineralized light water for shielding purposes. The end shields are supported in openings vault wall, and form part of the vault enclosure at these openings. Removable shield plugs fitted in the end fittings provide axial shielding to individual coolant channels. 30 Radiation Monitoring The evaluation of external radiation hazard is usually done by: a) Area monitoring. b) Personnel monitoring. a) Area Monitoring Monitoring the radiation field with a suitable radiation survey meter so as to confirm that the radiation levels around the location of use of the radiation source are well in specified limit for example: not to exceed 1 mSv/wk. (100 mrem/wk.) in the area occupied by radiation workers the radiation level must not exceed 0.1msv/wk (10mrem/wk) e.g.: in the workshop, office rooms etc. b) Personal Monitoring Using film or TLD badges & pocket dosimeters (DRD) does it. Every radiation worker must wear personnel monitoring badges, while handling radiation sources. The pocket dosimeter should be used as an additional device in special cases, which may be specified by the RSO/competent authority. Operators of Tele flex cameras must wear wrist badges or TLDs in addition to the personnel monitoring badges at the chest. 31 Radiation Detection Devices DRD: A DRD is nothing but a pen – type radiation level reader. It is abbreviated as DIRECT READING DOSIMETER. It shows the amount of radiation present in the atmosphere & also the dose taken by the radiation worker while handling some radioactive job or doing any work in third or fourth zone. This dosimeter gives the reading in the form of a graph. There is a number line inside the DRD on which a hairline movable marker in mounted which moves on the number line and gives the reading according to the radiation present in the atmosphere. TLD: TLD (THERMO LUMINISCENT DOSIMETER) is consisting of a thermo luminescent material which when exposed to ionizing radiation absorbs energy, when such a material is heated it emits light. The intensity of emitted light is proportional to the dose. Advantages of using TLD Dose measurements over very wide range are possible (5mrem to 105 mrem). Long-term use is possible since they respond only to radiation. A light which is emitted out varies directly with the dose, received simplifies calibration which is a straight line so only two points are needed to draw it. TLD response to radiation is the same as human tissue. 32 ONE BIG QUESTION Can the atomic reactor explode like an atom bomb? Atomic bomb uses 100% U235 or Pu239, where as in the reactors either it is natural uranium or enriched uranium of 1.5% to 4.5% enrichment. The effort in the bomb is to generate maximum energy in the smallest possible time there by resulting in the explosion, where as in the reactor the effort is to generate rated power on a continuing basis. So, various controls are put to ensure that the power generated is within its capacity at all the times. Thus, design of Nuclear reactor does not permit such explosions. 33 Plant Safety Measures Programmable Logic Control (PLC) The logic system is an essential system for the various instrumentation and control system of the plant. Based in the importance of nuclear safety the station logic system has been sub-divided into two independent systems. The relay logic system and PLC systems. Relay logic system is used for all safety related systems including engineered safety features. Based on the field proven ness of hardwired relay logic and the experience gained from the previous projects, the relay based system for the critical application mentioned above is used. The PLC system is technological advancement over relay based systems. Programmable Digital Comparator System (PDCS) It is a micro-processor based alarm system, generating voltage free contacts for external use in trip, set back, system logic and for alarm annunciations. This is envisaged to replace all the hardwired indicating alarm meters of earlier plants and will provide higher reliability. For trip applications, PDCS is confined to primary system only to provide diversity from secondary shut down system. Channel Temperature Monitoring System (CTM) The system consists of two computer installations for set back and flux tilt control signal generation, alarm generation and data logging. No. of cabinets required for the system has to be reduced to four. It helps in making the system more compact. 34 Beetle Monitoring System Beetle is a two-electrode device used for the detection of Heavy Water Spillage in various selected areas. The change in the resistance of the Beetle, when immersed in water is the parameter, which is measured to indicate the presence of water. Sensor for Reactor Power The signal used in the control and protection system to represent the reactor power is derived primarily from the neutron flux. Cooling Water Systems The main objective is to remove heat from various equipments and heat exchangers in Reactor Building, Reactor Auxiliary Building, Spent Fuel Building, Service Building, D2O Upgrading Plant and Waste Management Plant handling radioactive fluid. VENTILATION SYSTEMS The plant ventilation system is classified into the following three categories: Contaminated air ventilation system. Clean air ventilation system. Survival ventilation system FIRE PROTECTION SYSTEM Designed Objectives To minimize potential fire loads with the view to prevent fire. To identify fire loads for various areas. To provide appropriate fire protection, fire detection and firefighting systems based on fire loads in the plants. 35 36 Thank You MALAY JADIA ECE 19/394 19EUCEC032 UTD RTU KOTA m.jadia07@gmail.com