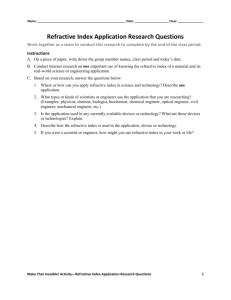

Rafet Kayıs Engineering Faculty Mechanical Engineering Reflectometer Experiment Student Name: Süleyman Anis Student ID: 180209072 1 Table of Contents 1. The Aim of Experiment .............................................................................................................. 3 2. Introduction ................................................................................................................................. 3 3. Theory of Refractive Index ......................................................................................................... 3 4. Traditional Reflectometer ........................................................................................................... 4 5. Equipment needed in the experiment:......................................................................................... 5 6. Procedure of the experiment: ...................................................................................................... 5 7. Results and Discussion: .............................................................................................................. 5 8. Conclusion .................................................................................................................................. 6 9. References ................................................................................................................................... 6 List of Figures Figure 1: Refraction of a light ray .................................................................................................................4 Figure 2 Changes in light used to determine soluble solids content and °Brix in a sample..........................4 Figure 3 scale.................................................................................................................................................4 List of Table Table 1 Coolant name and concentration.......................................................................................................6 ` 2 1. The Aim of Experiment The traditional reflectometer is used to measure the degree Brix (symbol °Bx), its unit is typically g/dl (g/100ml), which helps to determine concentration. In the industrial sector, the reflectometer is periodically used to check the state of the coolant machine oil concentration, and appropriate decisions are made based on the results obtained after comparing them with standard machine’s oil values. Therefore, during this experiment, it is important to learn how to measure the Brix degree and calibrate the oil concentration used in coolant process. 2. Introduction In our study, Utilizing the refractometer tool as it works towards assessing %Brix values and deriving conclusions about concentration levels. Operating on principles grounded in 'refractive index', variation detection becomes possible by analyzing fluctuations resulting from shifting solute amounts within samples. When traveling from one medium to another with different refractive indices, light bends due to changes in its speed. The ratio between velocities of light in vacuum and material is called the refractive index. Refractometers rely on this phenomenon for measuring the concentration of substances entrained within liquid solutions. This is achieved by shining a beam of light through a prism onto said solution and measuring how it bends upon entry based on that liquid’s respective refractive index [2]. To conduct such measurements experimentally, it would require traditional handheld devices like those mentioned before along with solutions containing dissolved substances. Additional materials include pipettes or measuring cylinders for preparation purposes and calibration standards that possess known concentrations. The next step demands visibly distinct concentrated levels so multiple trials can be run with different variances present across each mixture. %Brix Levels are then obtained via use of your device as described earlier. Finally, establishing calibrated curves begins once all data has been collected accurately. % Brix values data obtained are then plotted against those of calibration standards to fabricate said calibrated curve. Once completed, this calibration curve can be used to accurately determine the actual concentration of any test sample based on its purely measured % Brix values. 3. Theory of Refractive Index The refractive index plays an important role in understanding materials properties. Essentially, it is nothing but an indicator that tells us about how much a material would alter incident light passing through it compared to light travelling through space freely - whether it bends more or less than space itself. What determines this level depends upon multiple factors: what that material is made up of, how tightly packed its molecules are and what wavelength band that incoming wave travels at [2]. Now coming onto measuring these levels: Refractometers catch up on this principle by passing incident light through samples under varied conditions (usually when poured over prisms). The device uses scales to quantify changes in wave direction after interaction with these samples - based on which we may arrive at several conclusions regarding their physics. The angle of refraction is then used to calculate the refractive index of the material using Snell's law, which relates the angle of incidence, the angle of refraction, and the refractive indices of the two materials involved. The relative refractive index of an optical medium 2 with respect to another reference medium 1 (n21) is given by the ratio of speed of light in medium 1 to that in medium 2. 3 This can be expressed as follows: When considering a pair of media, it can be observed that the correlation. between the sine ratios of incident angle (Q1) and refracted angle (Q2) is equivalent to the refractive index of the second medium with respect to the first (n21). This relationship is identical to the proportion of refractive indices. (n2/n1) in the two media or the ratio of phase velocities (v1/v2) within the pair Figure 2: Refraction of a light ray of media [2]. sin 𝑄1 𝑛2 𝜈1 = 𝑛21 = = sin 𝑄2 𝑛1 𝜈2 (1) Where 𝑛 is the medium of substance, 𝑄 is the angle and 𝜈 is the speed. 4. Traditional Reflectometer A conventional handheld reflectometer is an optical apparatus that employs the principle of total internal reflection to determine the refractive index of a liquid. In the realm of optics, the refractive index of a liquid is utilized as a quantifiable property for the degree to which a beam of light undergoes deviation from its original trajectory upon traversing the said liquid medium. The concentration of coolant oil has a significant impact on its refractive index. A conventional manual reflectometer is suitable for ascertaining the refractive index of coolant oil and determining the oil concentration. As can see from figure 2, the processes of measuring the concentration of sample by reflectometer based on reflective index theory. While in figure 3 the results of measurement appear in unit Brix %. Figure 2 Changes in light used to determine soluble solids content and °Brix in a sample. 4 Figure 3 scale 5. Equipment needed in the experiment: 1-Traditional handheld refractometer. 2-Substances (samples). 3- Data sheet of used substance to compare the results. 4-Thermometer (to measure the temperature of the coolant oil). 6. Procedure of the experiment: 1- Measure the temperature of the substances which should be between (25-20) degrees. 2-Open the cover, following which the refractometer should be directed towards a plentiful source of light or an illuminating object, with the prism in focus. If deemed requisite, one should rotate the focus ring until the gauge renders a clear image. 3-Open the cover and wipe the prism with a soft cloth. 4-Apply a few drops of fluid to measure the prism. Close the cover and press lightly so that the liquid spreads over the prism without forming bubbles. 5-Hold the gadget evenly and hold up 30 seconds for temperature stipend to work. Read the value on the dividing line between white and blue. 6-Clean and dry the prism. 7. Results and Discussion: In this section will mention why it is important to calibrate coolant oil and the effect of disorder in concentration, also discuss how to calibrate some values that were gotten from measuring the concentration of coolant oil used to cold the cutting part of milling machine based on stander value of dissolving. Why is calibration of coolant oil periodically important [3]? Prevents cutting tool overheating. Prevents corrosion. Improves engine performance. Extends cutting tool life. The most common coolant oil used in the manufacturing department, as can be seen in table 1 need to calibrate the concentration of oil in solution that is water [4]. 5 Table 2 Coolant name and concentration. Coolant Oil Type Percentage of oil in the water 1 petroleum-derived hydrocarbon oil 5-10 % 2 Chemically synthesized hydrocarbon oil (a lot of heat) 10-15% 8. Conclusion in conclusion, the experiment was a success. It can be able to measure the degree Brix (symbol °Bx) and calibrate the oil concentration used in the coolant process. This information can be used to ensure that the coolant oil is at the correct concentration and that the cutting tool and machine are properly cooled. This will minimize the risk of machine and product damage. Overall, the experiment was a success and it provided valuable information about the use of the traditional reflectometer to measure the concentration of coolant oil. The information that was gathered can be used to improve the performance of cutting tools and prevent tool damage. 9. References [1] Qiao, C., Li, C., Wang, J., & Xiao, H. (2015). Application of on-line measuring concentration of emulsion explosive based on fiber optic sensor. Optics & Laser Technology, 69, 48-53. [2] Young, H. D., Freedman, R. A., & Ford, A. L. (2012). Sears and Zemansky's university physics: With modern physics (13th ed.). Pearson. [3] J. W. Sutherland, A. Gandhi, V. N. Kulur, W. K. Chan, Y. K. Siow, “Cutting Fluids in Machining: Heat Transfer and Mist Formation Issues”. Department of Mechanical Engineering - Engineering Mechanics, Michigan Technological University, Houghton, MI 49931-1295. [4] Mayer, M., & Behrens, B. A. (2018). Optimal Management and Monitoring of Metalworking Fluids. Society of Manufacturing Engineers. 6