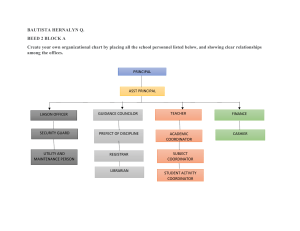

“Annexure- Document of Risk Assessment” M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT 7 ADDITIONAL STUDIES 7.1 RISK ASSESSMENT 7.1.1 Introduction CH-7: ADDITIONAL STUDIES ZACL propose to implement a modernization project for revamping of liquid ammonia storage by replacement of the existing Horton spheres by a double wall type atmospheric pressure storage tank with superior safety features. 7.1.2 Scope & Methodology Scope of this Quantitative Risk Assessment (QRA) study of 1X5000 MT capacity is to assess the risk due to the proposed double wall type atmospheric pressure ammonia tank in place of existing Horton spheres have capacity of 2X 3000 MT and suggest measures to reduce the risk to levels as low as reasonably practicable. This QRA study is carried out using the renowned DNV Phast Risk (also known as Safeti) software package. Risk due to a hazard is measured by considering severity level of the consequence as well as likelihood of its occurrence. The general criteria for risk acceptance are as follows: Individual risk exceeding 1 x 10(-)4 per year is not tolerable; Individual risk below 1 x 10(-)6 per year is broadly acceptable; Individual risk between the above two levels is tolerable if it is demonstrated to be as low as reasonably practicable (ALARP). 7.1.3 Facility Description The details of liquid ammonia storage are summarized in Table 7-1. Table 7-1: Details of Existing and Proposed Liquid Ammonia Tanks Description No. of Tanks & Capacity of Each (MT) Total Capacity (MT) Temperature (C) Pressure (kg/cm2g) 2 x 3,000 6,000 5 4 1 x 5,000 5,000 (-)33 450- 900 mm WCg Existing Horton Spheres Proposed Wall Type Double Atmospheric Pressure Tank 7.1.4 Details of Proposed Atmospheric Pressure Liquid Ammonia Storage Liquid Ammonia received from road tankers & from Ammonia Plant will be stored in an Atmospheric Ammonia Storage Tank having a net effective capacity to store 5,000 MT of liquid Ammonia excluding vapor space. The outer tank is designed for full containment of vapors and liquid in the event of failure of inner tank. The tank is equipped with two pressure relief valves to safeguard against overpressure. (Isolation valves will be provided with suitable mechanical interlock). The tank shall rest on elevated foundation. Tank pressure is maintained between 450-900 mm WCg and adequate alarms and interlocks are provided to safeguard the tank against pressure excursions on either side of the operating range. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 194 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. CH-7: ADDITIONAL STUDIES Refrigeration System Liquid Ammonia, at a maximum rate of 90 MT/hr, is received from the tanker unloading line through a 8” line and at a rate of 45 MT/hr through 6” line from existing Ammonia plant line with suitable tapping taken at Battery limit (B/L) near the tank. Vapors from flashing and boil off are withdrawn by two Ammonia Refrigeration Screw Compressors. The gas is compressed and condensed in water cooled condensers and sent to the Ammonia Receiver. Liquid is withdrawn from the Receiver under level control. A part of this liquid is flashed in the Economizer, which operates at a pressure of approximately 1.5 Kg/cm2g. Flashed Ammonia vapors at about -15°C are admitted into the Economizer port of the Screw Compressors. The balance liquid Ammonia from the Receiver gets cooled to about – 10°C in the Economizer by the resultant chill from the above described flashing and is returned back to the storage tank. Transfer of Liquid Ammonia Liquid ammonia from tank will be transferred at the rate of 46 m3/h to NPK A/B plants by using the ammonia transfer pumps and existing ammonia preheater. Flare System A Hot Flare system shall be provided for the Ammonia tank (for emergency purposes). Thermal relief valves are provided in sections of pipelines where liquid Ammonia can get blocked in. Site map showing location of the existing Horton spheres and proposed atmospheric pressure tank is presented in Figure 7-1. Figure 7-1: Site Map Showing Existing and Proposed Liquid Ammonia Tanks Proposed Atmospheric Pressure Ammonia Tank Existing Horton Spheres 7.1.5 Input Data for QRA Weather data Weather data for site used in risk analysis is listed in Table 7-2. Table 7-2: Weather Data for Goa Month January Temperature (C) 31.2 21.5 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 Relative Humidity (%) 69 61 195 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. Month CH-7: ADDITIONAL STUDIES Relative Humidity (%) Temperature (C) February 30.7 22.2 72 65 March 31.5 24.3 75 69 April 32.4 26.3 74 70 May 32.6 26.9 75 72 June 30.2 24.9 86 83 July 28.9 24.2 86 86 August 28.6 24.1 89 86 September 29.5 24.1 87 83 October 31.4 24.5 80 76 November 32.7 23.5 66 65 December 32.4 22.5 63 61 Wind rose diagram showing annual distribution of wind direction and wind velocity is shown in Figure 3-2, Chapter 3. Generic Failure Rate Data This QRA study is based on generic failure rate data as available in the following publications. OGP Risk Assessment Data Directory Report No. 434-3: Storage Incident Frequencies published by International Association of Oil & Gas Producers. Guidelines for Quantitative Risk Assessment “Purple Book” – Doc. No. CPR 18E. The input data for QRA including the estimated failure rates is shown in Table 7-3. Table 7-3: Failure case data for QRA S. No. Description A Leak Size Material & Phase Temperature Pressure (C) (kg/cm2g) Leak Frequency (per year) Existing Horton Spheres for Ammonia Storage (2 Nos.) 1 Ammonia Tank failure Catastrophic Failure Liquid Ammonia 5 4 1.0E-06 (each tank) 2 Liquid outlet pipe failure Line Rupture Liquid Ammonia 5 4 (+ Liquid head in tank) 1.0E-05 (each tank) B Proposed Atmospheric Ammonia Storage Tank (1 No.) 1 Ammonia Tank failure Catastrophic Failure Liquid Ammonia (-)33 450-900 mm WCg 2.5E-08 2 Liquid outlet pipe failure Line Rupture Liquid Ammonia (-)33 400 mm WG (+ Liquid head in tank) 1.0E-05 Note: 1.0E-06 per year denotes 1.0 x 10(-)6 per year 7.1.6 Study Results Consequence Analysis Results Results of consequence analysis by Phast software for leak from 100 mm diameter hole are summarized in Table 7-4. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 196 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Table 7-4: Consequence Analysis Results Down Wind Distance (Meters) Description Weather 2 m/s; E 3 m/s; D 5 m/s; D Parameter Horton Sphere: Liquid ammonia leak – 100 mm size IDLH: 300 ppm ammonia 4439 3101 2709 ERPG-3: 750 ppm ammonia 1959 1629 1424 Atmospheric Pressure Tank: Liquid ammonia leak – 100 mm size IDLH: 300 ppm ammonia 1705 890 753 ERPG-3: 750 ppm ammonia 860 422 380 It is seen that the downwind distances for toxic dispersion of ammonia in case of leak are much less in case of atmospheric ammonia tank compared to Horton sphere. Horton sphere is semi-refrigerated type storage in which liquid ammonia is stored at about 4 kg/cm2g pressure and 5C temperature. Release of liquid ammonia under pressure by leak from Horton sphere will cause much flashing of vapor due to depressurization and formation of liquid droplets which will be carried over in the air. This will result in ammonia vapor dispersion over long distance. In contrast atmospheric tank is fully refrigerated type storage in which liquid ammonia is stored close to atmospheric pressure at (-)33C temperature. In case of release of liquid ammonia by leak from atmospheric tank there will be very little flashing of vapor. The dispersion will be mainly due to vaporization of liquid ammonia falling on the ground close to the tank. QRA Results Results of QRA are presented in the form of iso-risk contours for individual risk. The iso-risk contours for location-specific individual risk due to the two horton spheres in the existing facility are shown in Figure 7-2. Figure 7-2: Is-Risk Contours – Existing Horton Spheres (2 Nos.) 1E-06/year KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 197 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES The location-specific individual risk at eastern boundary of the plant near the Horton Sphere area is found to be 3E-06 per year. The iso-risk contours for location-specific individual risk due to the proposed atmospheric ammonia tank are shown in Figure 7-3. Figure 7-3: Is-Risk Contours – Proposed Atmospheric Ammonia Tank (1 No.) 1E-06/year 1E-07/year The location-specific individual risk at the plant boundary near the proposed atmospheric ammonia tank area is found to be within 1E-07 per year. Conclusions The conclusions of QRA study for ammonia storage at ZACL, Goa comparing the existing Horton spheres and proposed double wall double integrity type atmospheric tank are as follows. In the double wall double integrity tank, the inner tank and outer tank each can contain the liquid ammonia inventory safely. Therefore In comparison to Horton sphere, the likelihood of failure of double wall double integrity tank is negligible. According to the best industry practice, double wall double integrity tank has proven to be the safest mode of storage of liquid ammonia. Results of QRA clearly indicate that the individual risk at plant boundary is very much reduced by replacing the Horton spheres by atmospheric ammonia storage tanks. Individual risk at plant boundary in case of Horton spheres: 3E-06 per year Individual risk at plant boundary due to atmospheric tank: 1E-07 per year Based on the above factors, it is concluded that replacement of the two Horton spheres each 3000 MT capacity with one double wall double integrity type atmospheric tank of 5000 MT capacity will result in considerable reduction of risk and enhancement of safety. This also conforms to the best industry practice for liquid ammonia storage. Recommendations While implementing the installation of double wall double integrity type atmospheric ammonia tank the following points need attention. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 198 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. 1. 2. 3. 4. CH-7: ADDITIONAL STUDIES Liquid ammonia product stored in the atmospheric ammonia tank should contain not less than 0.2% water to prevent stress corrosion cracking in low temperature carbon steel (LTCS) plates of the tank. Proper quality assurance/ quality control programme including positive material identification (PMI) should be followed to ensure that only the material (plates, pipes, fittings, welding etc.) conforming to the specifications are installed. Safety instrumented system with adequate reliability/ redundancy should be provided for tank overfill and overpressure protection based on safety integrity level (SIL) analysis. While commissioning the tank due care should be taken for removal of air from the system by purging with adequate quantity of nitrogen to prevent stress corrosion cracking due to presence of oxygen. 7.2 ONSITE EMERGENCY MANAGEMENT PLAN Name and Address of the Person Furnishing the Information Telephone nos. Particulars Office Residence 0832 2592418 0832 2592501 0832-2592549 0832-2592537 0832-2592602 0832-2592517 Factory Manager Mr. Ranjit Singh Chugh Chief Manufacturing Officer Zurinagar, Goa- 403726 In charge Fire & Safety Mr. G. S. Lotlikar Chief Manager-Fire & Safety Zuarinagar, Goa- 403726 In charge of Occupational Health Dr. A.G. Vaidya Deputy General Manager-Medical Zuarinagar, Goa- 403726 Contact nos. In case of any emergency FIRE STATION: 3992101, 3992622 SECURITY : 3992100, 3992603 OCCUPATIONAL HEALTH CENTRE : 3992102 EMERGENCY CONTROL CENTRE : 3992111, 8805060002 7.2.1 Introduction Disaster is a major emergency which has the potential to cause serious injury or loss of life and / or which tends to cause disruption inside or outside the works and requires the use of outside resources. The emergency is termed "on-site" when it confines itself within the factory even though it may require external help and "off-site" when the emergency extends outside the factory premises. It is to be understood that if emergency occurs inside the plant and could not be controlled, it may lead to an "off-site emergency". It is imperative that plant emergencies like fire, explosions are by nature fast acting and the control system would normally be of prevention from spreading, rescue and relief work. The planning for emergency will thus incorporate resources and action for concentrating on evacuation, containment and relief work. On the other hand in case of disaster due to toxic gases, the measures will be on long-term basis and will depend upon the distance and weather condition. We have adopted an "ON-SITE EMERGENCY MANAGEMENT PLAN" to instill confidence in employees and public to tackle any situation that may arise. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 199 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES The plan complies with the legal responsibility of the Occupier of the Factory as per Section-41B (4), 1948 and Rule 13 of the Goa Control of Industrial Major Accident Rules, 1991 and also under Manufacture, Storage and Import of Hazardous Chemicals Rules, 1989 (MSIHC). It also complies with the elements of the On-site Emergency Plan suggested in the Guidelines on the Chemical (industrial) Disasters issued in May 2007 by National Disaster Management Authority, set up under the Disaster Management Act, 2005. The recommendations made by National Disaster Management Authority during mock drill conducted on November 13, 2009 have also been implemented in this revision. 7.2.2 Key Personnel and their responsibilities The Emergency Management Plan spells the transition from normal operation to emergency operations and effective delegation of the authority from operations personnel to emergency response personnel. An emergency response organization has been identified with appropriate lines of authority and how the response management will take over. Each responder’s position in the emergency organization, line of reporting, responsibilities and duties have been identified and clearly defined. 7.2.3 Concept of Emergency Response Operation During any emergency in the factory, the effectiveness of the plan depends upon how fast and effective is the communication system among the responders and the other agencies involved in handling emergency. We have developed a communication system for 24-hour notification of the first responders and other coordinators who will provide necessary direction and control. An “alternate” person is also identified for each key position of the designated authority. The plan also includes a list of alternate personnel for each emergency response and their contact number. A procedure of a call to one person/agency who in turn calls one or more key individuals during emergency is used so that all the levels in the organization are communicated. 7.2.4 Emergency organization Command and control of an emergency condition encompasses the key management functions necessary to ensure the health and safety of workers, as well as community living in the vicinity,. In addition, the implementation of an Emergency Response Plan relies on a number of response functions, which deals with different aspects of the emergency, with the most important ones being: Communication and coordination between coordinators; Emergency Control system at Incident site & Emergency Control Centre; Firefighting and Rescue; Medical Services; Security & traffic control; Liaison with Govt. as well as external support agencies; Administration (Transport, welfare). KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 200 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Figure 7-4: Emergency Management Organization 7.2.5 List of Key Persons S. No. Role Location 1. Overall in charge: (Chief Manufacturing Officer ) Alternate –CGM-CS /CGM-O ECC 2 Chief Coordinator :Chief GM-Operations/GM-Manufacturing Alternate –DGM-Concerned Plant Site 3. Maintenance Coordinator: DGM-Maintenance & Civil Alternate – SM-Mechanical (Nitrogen) Site 4. Environment & Technical Coordinator: Head-Projects & TS Alternate –CM-TS/ Dy.GM.-Prod (unaffected) Site 5. Medical Coordinator: SM-Medical Alternate – Nurse on duty 6. Site Coordinator: DGM- concerned Plant Alternate – CM-concerned Plant 7. Fire & Safety Coordinator: CM-Fire & Safety Alternate – M-FS Health Centre Site Site/ECC One of the Officer from F&S will report to ECC depending upon availability. 8. Security Coordinator: CM-HR&S Alternate – Manager-Security (NISA) KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 Site 201 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES 9. Welfare Coordinator : Manager-HR Alternate : SM-CSR&PR ECC 10. Communication Coordinator: Sr. Manager-PH Alternate: Manager-Stores ECC 11. Incident Controller*: CM/SM/Mgr (concerned Plant) Alternate – In charge (Concerned Plant) Site Other Key personnel’s 12. DGM’s from Unaffected Plants & CM’S from Unaffected Plants DGM’s - ECC; CM’s - as per the instructions from Chief Coordinator * In charge of the concerned plant, shall rush to the site along with his team and take charge till arrival of Site Coordinator. (Concerned Plant DGM). 7.2.6 Duties and responsibilities of key personnel Overall In-charge The Overall-in-charge has an overall responsibility for directing operations and calling outside help. Chief Manufacturing Officer (CMO) will take charge as Overall in-Charge. During his absence, Chief General Manager-CS (CGM-CS) /Chief General Manager-Operations (CGM-O)or will act as Overall In-Charge. He will decide upon the activation of Emergency Control Centre (ECC) depending upon the prevailing wind direction. If required, he can activate the Mobile Emergency Control Centre. The ECC is allocated next to Fire Station while alternate ECC is located at DAP gate. Overall inCharge will rush to ECC and perform roles/responsibilities as under. 1. 2. 3. Continually review and assess existing & possible developments to determine the most probable course of events and effective methods to deal with them; Ensure that casualties are receiving adequate attention; Decide in consultation with Chief Coordinator & key persons whether an off-site emergency exists or is likely to take place. If an off-site emergency exists; o o o o o 4. 5. 6. 7. To alert evacuate the public living in the vicinity of the plant; Call the outside emergency services; Inform district emergency authorities; Coordinate with district emergency authorities to mitigate the consequences outside the factory; Coordinate with District Emergency Authorities for evacuation, shelter, rescue & rehabilitation of general public in the vicinity of affected area. Issue authorized statements to the press or the media; Inform MD regarding the status and action taken; Rehabilitate the affected area after the emergency is over; In case of strike by the plant personnel, identify critical areas of the plant in advance. If emergency occurs during the strike, following arrangements required to be made in advance; o o o Keep the list of technical records needed to run the factory in an emergency and train the team. Keep the records of Personnel (Non-executive) likely to be available during the strike and keep the same in safe custody. Identify the alternate arrangements for meeting any emergency, ie by mutual aid with other factories, etc. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 202 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Chief Coordinator Chief General Manager-Operations (CGM-O)/General Manager- Manufacturing (GM-M) will act as Chief Coordinator. Deputy General Manager (DGM)-of the Concerned Plant will act as alternate in case of absence of CGM-O/GM-M. The senior most available i.e. Plant in charge (Chief Manager/Sr. Manager) or Shift In-charge for that shift will work as Site Coordinator till the arrival of seniors in case the emergency occurs after Office hours or on holidays,. After getting information about the emergency from the shift-in-charge/CM-concerned or on hearing emergency, he will inform Chief General Manager-Operations who in turn will inform Chief Manufacturing Officer (CMO). Chief Coordinator will report to the incident site and will operate from the location nearest to the site. The responsibilities are as follows: 1. To assess the magnitude of the situation and decide whether a major emergency exists or it is likely to convert into a major emergency, requiring external assistance. He will instruct to sound the coded emergency siren; 2. To exercise direct operational control over the areas other than those affected; 3. To communicate to Asst. Manager–Environment to monitor the environment for toxic gases and effluent; 4. After assessing the magnitude of the situation, he will decide whether the persons inside the factory are to be evacuated to pre-identified safe places; 5. To have a constant liaison with the authorized coordinators for ensuring that the casualties are receiving adequate attention and traffic control movements within the works is well regulated; 6. To communicate about the emergency to higher ups; 7. To arrange to inform Chief Inspector of Factories, District Collector, Police, Village Sarpanch, Goa State Pollution Control Board, Fire Brigade, (Vasco-da-Gama) if required through Communication Coordinator; 8. To arrange for collecting and preservations of evidences to facilitate any enquiry into the causes and circumstances which cause or escalated the emergency. He shall arrange for the photographs, video filming, logbooks, operating charts etc.; 9. To make assessment of total no. of casualties, damage incurred to plant, Property and machinery and damage to environment during emergency; 10. After establishing normalcy from Emergency, Health Centre and other plants, he will authorise to sound ALL-CLEAR SIREN. Site Coordinator Deputy General Manager of the concerned Plant would be Site Coordinator. In his absence Chief Manager/Sr. Manager of the concerned plant will take charge as Site Coordinator. 1. After getting information about the emergency from the shift-in-charge/CM-concerned or on hearing emergency he will inform: o o o 2. GM-M; DGM’s unaffected plant; CM’s of other plants reporting to him. He will report to the incident site and take over charge from the shift-in-charge and work under Chief Coordinator; KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 203 M/S. ZUARI AGRO CHEMICALS LTD. 3. 4. 5. 6. 7. 8. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES He will assess the extent of emergency and decide if a major emergency exists or is likely to develop and also to decide to summon help if so required in consultation with Chief Coordinator; To take the command of the emergency at site, and co-ordinate all activities to bring situation under control within shortest possible time. He will coordinate with the concerned Chief Manager’s regarding shutting down of the plant, if required; To coordinate with Maintenance Coordinator, Fire & Safety Coordinator for the help; To ensure that the emergency is curtailed to cause minimum loss to the persons, machine and environment; To decide evacuation of plant personnel of the areas likely to be affected; Make sure that all hot jobs have been stopped and assist Manager/Shift-in-charges in normalizing the emergency. Maintenance Coordinator Dy. General Manager-Maintenance & Civil will act as Maintenance Coordinator. In his absence, Sr. Manager-Mechanical (Nitrogen) will act as Maintenance Coordinator. 1. After getting information from the concerned ECC or Chief Manager/Sr. Manager or on hearing siren he will inform: o o o o 2. 3. 4. 5. 6. 7. Sr. Manager’s-Mechanical; Sr. Manager-Central Maintenance (Mech); Manager-Civil; Centralised Shift Office. To rush to the site, assess the situation and facilitate maintenance support to Chief coordinator, needed to tackle the emergency; To mobilise and coordinate the teams from Maintenance Department for isolation, disconnection of equipment making bunds, repair activities, to control / mitigate effects of the emergency; To arrange for isolation of electrical lines (if required), facilitate lighting arrangements at affected locations, assembly points. Chief Manager-Electrical and his team will assist Maintenance Coordinator; To arrange earth moving equipments like Cranes etc. (if required) for handling the emergency; To arrange workshop facilities with adequate manpower (if required); To arrange for emergency procurement of material from local dealers or from other industries, additional manpower (contract) through Purchase. Environment and Technical Coordinator Head- Projects & Technical Services (H-P&TS) will act as Environmental and Technical Coordinator. His Alternate will be Chief Manager -Technical Services (CM-TS). After General Shift hours and/or Holidays, one of the Dy. GM- Plant of unaffected plant will take the charge of Environment and Technical Coordinator in absence of H-P&TS/CM-TS. After getting information from Emergency Control Centre or on hearing Emergency Siren, he will inform; o o o o CM-TS CM-Projects CM-Inspection Stores in charge KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 204 M/S. ZUARI AGRO CHEMICALS LTD. 1. 2. 3. 4. 5. 6. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Rush to the incident site and identify the hazards. Facilitate monitoring/analysis of the area inside and outside the factory premises (if required) through laboratory in charge and keep Chief Coordinator informed about the results; Remain in touch with the site coordinator and shift-in-charge for taking samples and rendering help for plant personnel; Inform the concentration of toxic gases to Overall in Charge and Chief coordinator and Medical Coordinator; Arrange for analysis of liquid effluent discharge from the factory if any; Maintain record of base data and the conditions prevailing during emergency. Fire & Safety Coordinator Chief Manager-Fire & Safety (CM-F&S) will act as Fire & Safety Coordinator. In his absence, Manager-Fire & Safety (M-FS) will act as Safety Coordinator. After getting information from ECC or on hearing Emergency Siren, he will inform Manager-Fire & Safety He will report to the scene of emergency and perform the duties and responsibilities as follows: 1. 2. 3. 4. 5. To take charge of fire fighting responsibility under the guidance of Chief Coordinator; To arrange for additional firefighting equipment/material like hoses, branch pipes, fire extinguishers, foam compound, fire suits, breathing apparatus etc; To advise Chief Coordinator regarding external help and direct outside fire fighting services whenever called for; To assist the employees in the rescue operation & use of safety appliances; To brief Chief Coordinator about overall emergency and safety procedures followed during the emergency. Security Coordinator Chief Manager-HR & S (CM-HR&S) will act as Security Coordinator. In his absence, ManagerSecurity (NISA) will act as Security Coordinator. After getting information from Main Gate House or on hearing Emergency Siren, he will inform; o o 1. 2. 3. 4. 5. 6. 7. 8. 9. CGM-CS M-HR Rush to the Incident Site and report to Chief Coordinator; Control the traffic movement in and out of the factory. This involves both movements of vehicles and the persons; Maintain Law and Order and to avoid gathering of personnel at the scene of emergency. Cordon off the affected area; Provide assistance to Fire & Safety Coordinator for firefighting or for removing the casualties or supply of safety appliances etc.; Keep liaison with Police; Direct external help from local authorities to respective coordinators; He will be responsible for public announcement of the hazards and action to be taken on Public Address System; Arrange for vehicles from outside local transport agencies in case of need; Assist Site Coordinator, Medical Coordinator, Fire & Safety Coordinator for the transportation of victims from the affected area to safe places. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 205 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Medical Coordinator Sr. Manager-Medical (SM-M) will act as Medical Coordinator. In his absence, the Male Nurse on duty at the Health Centre will act as Medical Coordinator. On getting information from Health Centre, he will rush to the Health Centre and perform the duties and responsibilities as follows: 1. 2. 3. 4. 5. 6. Call the trained First Aiders from the unaffected plants/township; Arrange for additional doctor (if required) and ambulances; Have liaison with local medical authorities and hospitals in case the casualties are more and situation demands treatment from additional Medical Centres; Ensure the up-keep of medical supplies, antidotes for treating victims for burns and hazardous chemicals; Remain in touch with Overall-In charge and Chief Coordinator for any help required; Liaison with Security Coordinator for the transportation of the injured to the Hospitals. Communication Coordinator Sr. Manager-Product Handling (SM-PH) will act as Communication Coordinator. In his absence Manager-Stores (M-S) will work as Communication Coordinator. After getting information from ECC or on hearing Emergency Siren, he will rush to Emergency Control Centre and report to Overall In-charge; 1. 2. 3. 4. Take charge of communication through telephones, messengers, Walkie-talkie sets etc.; Arrange for announcements on public address system and maintain contacts with Canteen, Main Gate, Control Room, Fire Station etc; Maintain a log of major emergency with timings about the various communications received / passed from the Emergency Control Centre; Seek help/assistance from the other coordinators reporting to ECC in case of need. Welfare Coordinator Manager-HR will act as Welfare Coordinator. In his absence Sr. Manager-CSR & PR will act as Welfare Coordinator. After getting information from Security Coordinator or on hearing Emergency Siren, he will inform; o o CGM-HR SM- CSR & PR He will rush to Emergency Control Centre and report to Overall In-charge; 1. 2. 3. 4. 5. 6. Arrange for supply of food and beverages to emergency fighting crew both from inside and outside agencies as and when required; Arrange for supply of food and other necessary items to injured and affected persons; Intimate about the casualties to the relatives of the injured persons; Keeps record of attendance of emergency fighting crews and exact number of people inside the factory; Assess the situation in the surrounding areas; Evacuate colony and affected areas and make arrangement for shifting them to alternate safe places, if required. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 206 M/S. ZUARI AGRO CHEMICALS LTD. 7.2.7 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Responsibilities of the key persons during emergency Shift-in-charge (Concerned Plant) 1. Proceed to the emergency site, assess the situation and inform; o o 2. 3. 4. 5. Fire Station /Emergency Control Centre (101, 2622, 111) giving the details, type of emergency; Inform Chief Manager/GM-M. Till the arrival of the designated Chief Coordinator act as Chief Coordinator; Initiate the control operations for controlling the hazards; Do not allow any person to enter the area without required PPE’s; Direct rescue operations with the help of fire, Safety & Security staff; Civil Coordinator: (Sr. Manager-Civil/Manager -Civil) 1. 2. 3. Rush to the scene of the emergency after getting information from Maintenance Coordinator or on hearing emergency siren; Mobilize contractors, contract workers and heavy earth moving equipment to carry out civil jobs like making bunds, closing drains, filling sand bags, excavation as per the requirements during the emergency; Be available at the incident site and constant in touch with Maintenance Coordinator and Site Coordinator. Public Relations Coordinator: (Sr. Manager-CSR & PR) 1. 2. 3. On getting information from Welfare Coordinator or on hearing emergency siren, he will report to Emergency Control Centre. He will work directly under Overall In-Charge; He will also carry out the role of Welfare Coordinator in absence of M-HR; He will release the authorized information, statements from CMO to the media & Press. Essential Staff Plant Technicians and plant staff shall remain in the plant and take the corrective action, safe shutdown action depending upon the instructions/directions from the concerned sectional heads and superiors. The maintenance staff of respective plants will be available at the plant and will work under instructions from shift-in-charge/plant in charge/maintenance in charge; Trained First Aiders of the respective plant/sections shall reach the incident Site and render First Aid till assistance from Health Centre arrives and thereafter assist the Medical Team. The trained first Aiders from non plant areas should report on hearing emergency siren or on call from Medical coordinator and follow instructions from him; Trained Fire Fighters of the effected site (including those of service Dept) shall reach the incident site to help the Fire Fighting and mitigating the emergency. They shall remain at site to assist the fire fighting and follow the instructions/directions from Fire & Safety Coordinator. The trained fire fighters from other unaffected plants/sections should get in touch with ECC; The Security Guards in their respective posts within the factory and at other posts shall not allow any unauthorized entry or person. They shall properly guide Goa Fire & Emergency Services, Mutual Aid Group and other external authorities whenever called for to the incident site. They will keep inform about any abnormal movements/activity to the Security Coordinator/Main Gate. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 207 M/S. ZUARI AGRO CHEMICALS LTD. 7.2.8 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Actions by the other persons present On hearing emergency siren, all the persons who are not a part of response teams would immediately evacuate their place of work and proceed to the nearest Assembly Point. The concerned officers will be responsible to evacuate the visitor to the Assembly Point. Locations of the Assembly Points along with in-charges are as under: Assembly Point Location Person Assembling In charge AP-1 Ammonia/Urea Ammonia/Urea Operation Staff Ammonia Shift Manager AP-2 Power Station Power Station Operation Staff Shift Manager AP-3 Water Treatment Water Treatment Operation Staff Shift Manager AP-4 NPK-A Operation staff & Contract Staff Shift Manager AP-5 NPK-B Operation staff & Contract Staff Shift Manager AP-6 NPK-A & B maintenance office Field maintenance staff of NPK-A & B & contract staff ManagerMechanical AP-7 PH Office Operation Staff & Field maintenance PH/RMH Shift Manager AP-8 Passage in front of instrument dept. Laboratory, Instrument workshop, electrical workshop & mechanical workshop , Stores, maintenance office staff ManagerInstruments AP-9 Near Fire Station Works Office Staff , Tanker crew of furnace oil & Ammonia, Visitors and Works Canteen Staff ECC coordinator AP-10 Behind DAP/Bagging Phosphoric acid, Sulphuric acid tanker crew, Stacking & unshackling gangs of monsoon shade, Contract bagging staff & Labour canteen NEHA foreman AP-11 In front of Jai Kisaan Bhawan For Administration Staff, SBI staff , drivers and Adm. Visitors M-HR/SM-P&IR It is the responsibility of all job in charges to train the personnel including the contract staff working under him as to how to assemble safely to the designated Assembly Point and to listen and follow the instructions issued by the in-charges of the Assembly Point; It is the responsibility of the Sr. Officials to direct the Visitors, service providers to assemble to the nearest Assembly Point and follow the instructions; It will be the responsibility of the concerned Assembly Point In-charge to shift the personnel under his charge to the other Safest Assembly point depending upon the wind direction; In case any person is suspected to be missing, the Assembly Point in Charge should inform the Overall In-Charge and Chief Coordinator; After “ALL CLEAR” siren, all Assembly point in-charges will report to ECC with the list of Roll Call. 7.2.9 Outside organizations if involved in assisting during On-site Emergency In case any emergency going out of control and requires any external help, the same will be decided by the Overall In-Charge in consultation with the Chief Coordinator. The communication to these external agencies will be made by Communication Coordinator from ECC. Either Chief Manager-Fire & Safety/Manager-Fire & Safety/Fire & Safety Officer will assist the Communication Coordinator in this communication. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 208 M/S. ZUARI AGRO CHEMICALS LTD. 7.2.10 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Statutory bodies and their addresses S. No. Statutory bodies 1 Telephone Fax Inspectorate of factories & boilers a. b. c. Chief Inspector of Factories & Boilers Institute of Occupational Safety, Health & Environment, Altinho, Panaji-Goa 2227670, 2226181 2226510 Inspector of Factories Institute of Occupational Safety, Health & Environment, Altinho, Panaji-Goa 2226181 2226510 Inspector of Boilers Institute of Occupational Safety, Health & Environment, Altinho, Panaji-Goa 2226181 2226510 Goa State Pollution Control Board 2 a. Chairman Goa State Pollution Control Board Patto Plaza Panjim-Goa 2438563 2438528 b. Member Secretary Goa State Pollution Control Board Patto Plaza Panjim-Goa 2438563 2438528 3 Dept. of Explosives a. Chief Controller of Explosives Dept. of Explosives, C.G.O. Complex 5th Floor, Seminary Hills, Nagpur-440 006, MAHARASHTRA (0712) 2510248, 2510579 b. Joint Chief Controller of Explosives A-1 & A-2 Wing, 5th Floor, C.G.O Complex CBD, Belapur Navi Mumbai (MAHARASHTRA) 400 614 (022) 27564941 List of Govt. Officials and their contact details Contact Number Designation of Person Office Mobile Residence STATE GOVT. OFFICIALS Chief Secretary 2419402 - - Collector-North Goa 2223612 9822123071 2420710 Collector-South Goa 2705333 9423884900 - Dy. Collector, Mormugao 2512688 9822588399 - Supdt. of Police-North 2416100 - Supdt. of Police-South 2732218 - - Dy. Supdt. of Police-Mormugao 2500222 - - PI, Verna police Station 2782325 - - PI, Vasco Police Station 2512304, 2513273 - - PI, Harbour Police Station 2520740 - - Director, Goa Fire& Emergency Services 2225500, 2227616 9763717044 2225033 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 209 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. CH-7: ADDITIONAL STUDIES Contact Number Designation of Person Office Mobile Residence Station Fire Officer, Vasco 2513840 9763717056 - Station Fire Officer, Verna 2887122 9763717060 - Asst. Divisional Officer, Margao 2714600, 2715825 9763717052 - Chief Inspector of Factories & Boilers 2227670, 2226181 9411440008 - 2404876 - Inspector of Factories MAJOR HOSPITALS 7.2.11 Goa Medical College 2458700, 2458702 - - SMRC 2540218, 6691919 - - MPT Hospital 2512768 - - Hospicio Hospital 2705754, 2704363 - - Details of Liaison Arrangement between the Organisations Mutual aid and response group Details of liaison arrangement between the mutual aid partners are worked out. Then an agreement is signed between all the mutual aid partners. The agreement contains all the procedures like communication, place of reporting, responsibilities and duties during the emergency. The outside agencies from whom the assistance will be sought are Mormugao Port Trust, Indian Navy, Goa Shipyard Ltd., Indian Coast Guard. The mutual aid partners will be made aware of various types of hazards in each plant and the existing fire fighting system. Mock drills with mutual aid partners will also be carried out at regular intervals. Telephone nos. S. No. Name of contact person 1. 2. Office Residence Central Fire Station-MPT 2521300, 2594812 2522690 Indian Coast Guard 2520584, 2521051 - 3. Goa Shipyard Ltd. 2512152- 2512156 2540912 4. Duty Staff Officer-Indian Navy 2582200 - 5. Terminal Manager -IOC 2513067, 2512617 2521856 7.2.12 Preliminary Hazard Analysis Type of Accident, system elements & Hazards Type of Accident System Elements or Event that can lead to the Main Hazard Hazard Ammonia leakage Ammonia Hortonshere Process area Transfer line Ammonia Unloading Station Toxic release Fire Hazard Spillage of Corrosive chemicals Acid storage: H2SO4, H3PO4 Alkali (NaOH) storage Process lines Acid, caustic unloading area Acid and alkali burns Acid spills in small, medium and large quantities Spillage and Fire HSD storage Oil console in process area/compressor KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 Pool Fire Fire Hazard 210 M/S. ZUARI AGRO CHEMICALS LTD. Type of Accident EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES System Elements or Event that can lead to the Main Hazard Hazard Empty bag storage area in PH Chlorine leaks Chlorine tonners Chlorine pipelines/manifolds Toxic release Fire & Explosion Process area GAIL metering station/terminal Gas line from GAIL to process plants Fire/pool fire Flash fire explosion VCE Boiling Liquid Expanding Vapour Explosion (BLEVE) Boilers BLEVE High Pressure Component Rupture System Elements/Events that can lead to major accidents, hazard and safety related components Ammonia storage handling facility Existing Horton sphere storage will be converted to Atmospheric Ammonia Storage Tank (Double wall, Double Integrity tank) which is more safest technology to store Ammonia. Chlorine storage and handling area At ZACL, Chlorine is used in following three locations: Water Treatment Plant Cooling Tower-I Cooling Tower-II The following are the safety features incorporated: Chlorine detector is provided to detect ant leak of Chlorine. These detectors generate an alarm in the Water Treatment Control Room; Chlorine emergency kit is provided at the Chlorine handling location; Chlorine Absorption system is also provided which automatically will start on leakage of Chlorine and will neutralize with NaOH solution; Self Contained Breathing Apparatus and specialize suits for handling Chlorine are provided at Chlorine Handling area; Eye was and Safety Showers are provided; PPPE’s like Protective clothing, gloves, face shield, goggles, canister gas masks are provided for the persons handling Chlorine; The trained technicians/employees are employed. Boilers The Boilers are designed and fabricated as per the relevant codes and standards and installed after due approval from Chief Inspector of factories & Boilers, Goa. All the boilers are offered to the Annual survey to the Inspector of Boilers; Boilers have inbuilt Boiler Management System logic for safe and smooth normal operation, start-up/shutdown; Logic like conditions of purge ready to start, burner ready to start, tripping on Natural Gas, tripping on furnace pressure, furnace pressure high, drum level low etc are incorporated in the BMS logic; KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 211 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Safety valves are provided at each Boiler drum and Super heater steam line; Reliable instrumentation, including level gauges & transmitters are provided on each boiler. HSD storage, Furnace oil Storage (both at power station), transformer areas and Oil console Adequate nos. of extinguishers are provided, tested and maintained; Fire hydrant system is provided near and around the area; Dykes are provided for HSD and Furnace Oil storage areas; Manual Call Points are provided; Sufficient nos. of sand buckets is provided; The areas are maintained free from combustible materials; Steam hoses are also provided near oil consoles. Storage of corrosive liquids like sulphuric & phosphoric acid, caustic lye Bunds walls/dyke are provided; Level gauges with indication and alarm is provided; Eye wash and safety showers are provided near to the storage and handling area; Manual call points are available; The floor area is made acid proof; Caution boards and what to do in case of spill are displayed; Full protective suits, gumboots, goggles, gloves, face shield are provided to the person handling corrosive liquids. Details about the Site Location of dangerous substances Ammonia Ammonia is an intermediate product which is in liquid state and vapor state. Ammonia is used in the manufacture of Urea and complex fertilizers. Ammonia is fed to the plants through pipelines and stored in hortonsphere. The ammonia is used/processed and handled in Ammonia plant, Urea Plant, NPK-A, NPK-B and RMH plants. Storage: Ammonia is stored in Hortonsphere which is located near Ammonia Plant. One hortonsphre is always kept stand by Chlorine Chlorine is used in the treatment of water at water treatment plant. It is available in the connected piping and manifold in Water Treatment plant. Storage: Chlorine tonners are kept in Water Treatment plant under covered storage. Hydrogen Hydrogen exists in gaseous intermediate for manufacturing Ammonia. It exists in the process gas and is not stored. Carbon Monoxide Carbon monoxide exists as gaseous intermediate which then gets converted into carbon monoxide with steam in shift converters and exists in Ammonia Plant. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 212 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Phosphoric acid Phosphoric acid is used as a raw material in NPK-A & NPK-B Plant. It exists in pipelines and process equipment. Storage: It is stored in tanks and day tanks in RMH, NPK-A & NPK-B plants. High Speed Diesel (HSD) HSD is used as a fuel for initial start up of Boilers, diesel generator is a fuel used for emergency generator. Storage: It is stored in tanks located at Power station Sulphuric acid Sulphuric acid is used as raw material for production of complex fertilizers and also for water treatment. It is available in pipelines connected from storage tanks to the process equipment in NPK-A, NPK-B, Water treatment and Utilities Plants. Storage: It is stored in tanks located in NPK-A, NPK-B, RMH, Water Treatment and Utilities Plant. Furnace oil Furnace oil is used as a fuel in DG, NPK-A and NPK-B plants. It exists in pipelines connected from day tanks to the boilers and furnaces. Storage: Furnace oil is stored in storage tanks and day tanks located at Power Station, NPK-A and NPK-B plants. Caustic Lye (Sodium hydroxide) Caustic lye is used for water treatment. It exists in pipelines. Storage: It is stored in tanks at Water Treatment Plant. Natural Gas Natural gas is used as feed material for Ammonia Production and also as fuel in Boilers, and NPK Plant. It is supplied through a gas pipeline from GAIL Terminal. 7.2.13 Seat of Key Personnel The location and seat of the Key personnel during normal operations and during emergency is as follow: S. No. During normal operation During emergency Designation Location Coordinator Location 1 Chief Manufacturing Officer Admn. Block/B-Colony Overall In-charge Alternate –CGM-CS/ CGM-O ECC 2 CGM-O/GM-M Admn. Block/ Work Office/B-Colony Chief Coordinator Alternate –DGM-Concerned Site 3 DGM-Maintenance & Civil Maint. Office/ C-Colony Maintenance Coordinator Alternate –SM-Mech. Site 4 Head-Projects & TS Works Office / B-Colony Environment & Technical Coordinator Alternate –CM-TS/Dy.GM.-Prod (unaffected) Site 5 SM-Medical Health Centre /C-Colony Medical Coordinator Alternate – Nurse on duty: Health Centre KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 213 M/S. ZUARI AGRO CHEMICALS LTD. S. No. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT During normal operation CH-7: ADDITIONAL STUDIES During emergency Designation Location Coordinator Location 6 DGMconcerned Plant Works Office/ C-Colony Site Coordinator Alternate – CM-concerned Plant Site 7 CM-Fire & Safety Work Office/C-Colony Fire & Safety Coordinator Alternate – M-FS Site/ECC 8 CM-HR&S Admn. Block/ C-Colony Security Coordinator Alternate – Manager-Security (NISA) Site 9 M-HR Admn. Block/ D-Colony Welfare Coordinator Alternate : SM-CSR & PR ECC 10 SM-PH (ISM) PH/ C-Colony Communication Coordinator Alternate: Manager-Stores ECC 11 CM/SM/Mgr (concerned Plant) Plant Incident Controller Alternate – In charge (Concerned Plant) Site 12 DGM’s from Unaffected Plants Plant/ C-Colony - ECC 13 CM’S from Unaffected Plants Plant/ C-Colony - ECC 7.2.14 Emergency Control Centre Two emergency Control Centres are set up: Emergency Control Centre. (Alternate control centre at DAP gate). In case both the ECC are not suitable, a mobile ECC in Emergency Rescue vehicle can also be set up; Incident control room. Location of ECC Fire station is identified as Emergency Control Centre. The Control Centre will be the focal point in case of emergency from where the overall operation to handle the emergency is directed and coordinated. In case of adverse wind direction affecting the Emergency Control Centre, Emergency Rescue Vehicle will be converted into Mobile Emergency Control Centre for this purpose. At all Emergency Control Centers i.e. Fire Station, DAP gate and Mobile Centre the following information is available. Facilities available at ECC Lay out plan of the complex, indicating all the plants, emergency control centre, roads, escape routes, health centre, fire station, location of fire water pumps and highlighting hazardous areas, location of wind socks, ammonia leak detectors; List of fire fighting and safety equipment; Population distribution map of surrounding area up to 10 km radius; Copy of on-site emergency management plan; List of telephone numbers of key personnel; List of important telephone numbers like members of mutual aid scheme, fire brigade, police station, District Collector's office, Chief Inspector's office, etc.; Self Contained breathing sets (2 nos.), Explosive meter (1 no.), safety torches (2 nos.), chemical suit (1 no.); Walkie-talkie sets and Base station (set.); Office facilities including internal telephones /external (3 nos.), Mobile phone (1 no) chairs, table, stationary, etc. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 214 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Manning of ECC during Emergency During any emergency, ECC will be manned by the following personnel: Overall In-Charge and his alternate; Communication Coordinator and his Alternate; Welfare Coordinators and his Alternate; Other Key Personnel like Dy. GM’s of unaffected plant, Public Relation Coordinator. 7.2.15 Description of Hazardous Chemicals at Plant Site Chemicals (Quantities, Purity and Toxicological data) Details of Chemicals in process Hydrogen Hydrogen is in gaseous intermediate for manufacture of Ammonia. This is produced and is not stored. It is one of the constituent for manufacturer of Ammonia. Carbon monoxide Carbon Monoxide is a gaseous intermediate. This gets converted into CO2 with steam. Details of Chemicals in storage S. No. Name of chemical Toxicity Total Licensed/ Storage capacity No of tanks/ storages Purity of chemical Whether transformation could occur 1 Ammonia Toxic 5600 MT 2 99.6-99.8 No 2 Chlorine Toxic 6 Tonners 6 99.9 No 3 Phosphoric acid Corrosive 13264 MT 5 52-54% No 4 Caustic Lye Corrosive 56 MT 2 46% No 5 Sulphuric acid Corrosive 3107 MT 6 98-99% No 6 High speed diesel Flammable 24.8 KL 2 - No 7 Furnace oil Flammable 314 KL 7 100% liquid No 8 Process gases Flammable - - Varies No Likely Dangers to the Plant Risk assessment study has been carried out in April 2009 through NEERI, Nagpur with the aim to estimate the distances likely to be affected in case of Ammonia release and impacts of fire. The scenarios considered are summarized below with the following assumptions: Stability Class F with wind speed 2 m/s and for class D with 3 m/s; IDLH for Ammonia: 300 ppm. Toxic/pool fire/jet fire/flash fire TOXIC 1. Ammonia storage tank Leak size 25 mm diameter Source strength 0.38 Kg/sec Toxic cloud At stability class 2F: distance 261 m At stability Class 3D: distance=235 m 2. Ammonia storage tank Leak size 50 mm diameter Source strength 1.52 Kg/sec Toxic cloud At stability class 2 F: distance 394 m At stability Class 3 D:distance=470 m KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 215 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Pool fire/Jet fire vapour cloud explosion/flash fire 3. Natural gas pipeline Pressure: 40 Kg/cm2g Flow rate: 1.65 MSCMD Leak size 25 mm, Source strength 2.96 kg/sec Flash fire At stability class 2F LFL distance-15.83 m At stability Class 3D LFL distance-14.90 m 4. Natural gas pipeline Pressure: 40 Kg/cm2g Flow rate: 1.65 MSCMD Leak size 50 mm, Source strength 11.8 kg/sec Flash fire At stability class 2F LFL distance-41.18 m At stability Class 3D LFL distance-38.42 m 5. Natural gas pipeline Pressure: 40 Kg/cm2g Flow rate: 1.65 MSCMD Catastrophic rupture, Source strength 86.35 kg/sec Flash fire At stability class 2F LFL distance-133.27 m At stability Class 3D LFL distance-123.34 m 6. Ammonia storage tank Temp: 4 deg, C Pressure: 4 kg/cm2g Capacity 3000 MT VCE At stability class 2F bar, damage distance 901.65 m At stability class 3D, 0.1 bar, distance-893 m 7. Natural gas pipeline Pressure: 40 kg/cm2g Flow rate: 1.65 MSCMD Leak size: 25 mm Source strength 2.96 Kg/sec VCE At stability class 2F bar, damage distance 49.43 m At stability class 3D, 0.1 bar, distance-38.79 m 8. Natural gas pipeline Pressure: 40 kg/cm2g Flow rate: 1.65 MSCMD Leak size: 50 mm Source strength: 11.8 Kg/sec VCE At stability class 2F bar, damage distance 113.6 m At stability class 3D, 0.1 bar, distance-101.18m 9. Natural gas pipeline Pressure: 40 kg/cm2g Flow rate: 1.65 MSCMD Catastrophic rupture VCE At stability class 2F bar, damage distance 293.51 m At stability class 3D, 0.1 bar, distance-282.01 m 7.2.16 Natural and Manmade Calamities which can Lead to Emergency Scenerio Goa exhibits low seismic activity (zone III) and has favourable location on the West Coast where storms/cyclones are rare and mild. It is pertinent to note that even in Gujarat and Orissa 9 Paradeep), in spite of occurrence of major earthquakes as well as super-cyclones, Ammonia storage tanks were unaffected and intact. Incidents having off-site implications can be caused by: manmade causes like air raids or crashing of aircraft sabotage A major emergency can originate from one or a combination of the following events: Slow isolated fires Fast spreading fires Explosions Bursting of pipelines/high pressure vessels KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 216 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Other Incidents Other incidents, which can also result in a off-site emergency are: Agitation/forced entry by external group of people/vandalism Bomb explosion Effects of Stress & Strain cause during Normal Operation In any industry during the plant operations, deviation from the normal condition is likely to occur sometimes. These deviations may result in to certain stress and strain either in the equipment or to controls. The stress and the strain generated so are nothing but the accumulation of the chemicals/mechanical or electrical energy or a combination of these. This energy if not handled properly may result in to the occurrence of hazard. The stress and strain can be caused by corrosion & erosion, vibration and hammering. Corrosion & Erosion Ammonia, carbon dioxide, urea carbamate, acids etc. are corrosive in nature and can cause corrosion to the equipment, vessels, piping’s etc.. Engineering controls have been taken in design and operation to minimize or nullify the corrosion. For external protection, special paints are used. Along with the engineering control regular monitoring are done to ascertain the health. The techniques used are: External checks if vessels, equipment, piping’s; Regular monitoring by operations & service dept.; Non destructive testing methods by our Inspection dept.; Corrosion coupons are also used in cooling water lines to know the healthiness of heat exchangers and pipelines; Residual life assessment. Vibration Vibration is another phenomenon which can cause stress and strain during the normal operations and may cause damage. Some of the reasons can be imbalance of rotating components, defective support system etc. For critical machinery online vibration monitoring system with alarm and trip systems have been installed from design stage. The indications are available in control room for operator guidance. In addition inspection dept conduct regular monitoring and keep history; all these data are utilized for analysis to know health and take appropriate actions in time to avoid damages. Hammering Hammering is another phenomenon which can cause stress and strain on the structure and pipeline. This can dislocate the pipes from it’s place and lines get damaged from different locations. Hammering can be caused due to accumulation of condensate in lines. Adequate precautions are like steam traps, condensate removal system, vent and drains are provided to minimize this effect. Fire and explosion inside the plant and effect if any of fire and explosion outside Fire and explosions inside the plant can be caused in the systems associated with Natural gas, process gases in vessels. There may not be any direct effect of fire and explosion outside. We have adequate in built safety features, monitoring and fire fighting facilities. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 217 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. 7.2.17 CH-7: ADDITIONAL STUDIES Details regarding Warning, Alarm, Safety & Security Systems Warning, Alarm, Safety & Security System An audible emergency siren system is provided which can be operated from two locations viz. from Ammonia Plant and from Fire Station/Emergency Control Centre. There are 4 sirens located in the entire factory so that the siren is audible as follows: Above Ammonia Control room Roof of DG building Above WTP control room Above NPK truck loading in Bagging plant In addition to above “Off-site Siren” is also provided on the DG building which can be sounded from Emergency Control Centre. In addition buzzers have been provided in NPK-A, NPK-B and Bagging Control rooms. The sirens will operate as below: Onsite Emergency Siren : Wailing sound for two minutes (4 seconds “on” & 2.5 seconds “off”) Off-site siren : Wailing sound for 2.45 minutes (2.5 seconds “on” and 1 second “off”) All Clear Siren Testing : A continuous sound for a period of two minutes : All sirens /buzzers are tested on 1st Monday of every month at 10:30 a.m. from Ammonia Plant as well as from Emergency Control Centre Safety System ZACL has a good safety management system and a Fire & Safety Dept with qualified and dedicated Safety Professionals. Necessary studies like HAZOP, QRA, EIA have been carried out through reputed organizations like NEERI, EIL. The safety has been taken right from the design stage. Any changes in the process/modifications are done under Plant Modification procedure which involves HAZOP, Safety Assessment from Technical and Fire & Safety Dept. All the plants have well established documented emergency shutdown procedures, safety relief system, early warning and alarm system, round the clock monitoring of operations, uninterrupted power supply etc. All the jobs within and ZACL campus are carried out under a well documented Work Permit and lock out tag out system. All the personnel including the contract workers have been provided with PPE’s and action taken against the defaulters. 3 Tier Safety Committees are constituted involving shop floor employees and meeting are conducted regularly. Safe Operations Committee headed by MD are held once in 3 months. For the involvement of contractor’s workers and also safe transportation of raw materials, separate committees are constituted and action plan is drawn for implementation. We have a system of reporting Make to Good condition/Near miss/incident/accident. The accidents are investigated, analyzed and recommendations are implemented. All the accidents are reviewed by Sr. Management. The employees as well as the contract staff undergo fire & Safety training programs through internal as well as through external faculties. Safety promotional activities are conducted to motivate the staff. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 218 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Specialized community awareness programmes are conducted on regular basis in association with District Administration and Inspectorate of Factories & Boilers, Govt. of Goa. Leaflets on Dos’ and Don’ts of Ammonia and what to do in case of emergency distributed among the community. Periodic internal as well as external audits are conducted and review of the same is done for implementation. Security System ZACL factory & other ZACL estate area in Goa, including the ZACL colonies in segregated pockets are spread safeguarded by of 80 security personnel. Security is provided at all vulnerable points throughout the complex all round the clock. The main body of security personnel are in 3 categories i.e. guards, head guards & security inspectors. The entry and exit at all gates are verified by the security and then only allowed. Cameras are provided at the main gate and railway siding which are monitored by Security Head. Metal detectors are provided at the main gate and the DAP gate. All the contract staff are physically checked at the entry and exit. The entry of the employees and regular contract workers is recorded at the entry and exit points. The security has one four wheeler and two wheelers for carrying out the security job. Alarm and hazard control plan in line with Disaster Control and hazard control planning, ensuring the necessary technical and organizational precaution. Technical Support Services S. No. Services 1 Toyo Engineering Corporation. Japan 2 Toyo Engineering (India) Ltd., Mumbai 3 Projects Development India Ltd., Sindri 4 Engineers India Ltd, New Delhi 5 National Environmental Engineering Research Institute, Nagpur 6 KLG-TNO, New Delhi 7 Confederation of Indian Industry 8 Tata Consultant Engineers, Mumbai 9 KBR, U.S.A. 10 Thermax 11 UHDE India Ltd. 12 BHPV, Vishakapatnam 13 LIQUE, France 14 Hindustan Dorr Oliver 15 INCRO, Spain 16 BHEL, Tiruchapally 17 TROJKA, Poland Measuring instruments and control units and servicing of such equipment Leak detectors have been installed in different plants depending upon the storage and handling of the hazardous chemical. The types of detectors and their location depends upon probability of the leak and it’s effect. Most of the detectors are connected to the plant control rooms. Manual Call point alarms are available at Fire Station. All the detectors are calibrated periodically and checked for working regularly. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 219 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES The list of detectors with their type, location and nos. is as below: S. No. Type Location Qty. Ammonia Plant 1 NG leak detector -%LEL Reformer, combustion chamber 25 2 Ammonia leak detectors -PPM Storage and pump area 15 3 Ammonia leak detectors -PPM Ammonia Unloading 3 4 Smoke detectors compressor house 4 1 Ammonia leak detectors -PPM Urea Plant - storage and pump area 4 Urea Pant Utilities 1 Ammonia leak detectors -PPM Water Treatment Plant 1 2 NG leak detector -%LEL Power Plant -burner area 5 3 Chlorine leak detector - PPM Pre- treatment in WTP 1 4 Smoke detectors DG room 2 1 Smoke detectors Product Handling Plant Bag storage area 4 Incident control room will be established as soon as emergency occurs. The control room of the affected plant will be the incident control room. Site Coordinator will send / receive communication from this control room to persons concerned. Telephone nos. of the incident control room shall be immediately conveyed to the Emergency Control Centre or Alternate Control Centre. 7.2.18 Precautions in designing of the foundations and load bearing parts of the building Safety in design of foundations Foundation of a structure is like the roots of a tree without which the tree cannot stand. Thus, the Design of Foundation of and Civil Engineering Structure, may it be a simple Residence Building or a Sky Scraper, is of paramount importance. Foundations can be broadly classified as Shallow Foundations and Deep Foundations, depending upon the difference of level between the ground surface and the base of the foundation. A specific type of Foundation is adopted after undertaking extensive Geo Technical studies to determine the type of soil and to ascertain the depth at which the hard strata is available. While designing Foundations the following point should be borne in mind: It is necessary that a Foundation is so designed that if at all a settlement should occur, then it will be uniform ie the settlement for all the footings will be more or less the same. All structures in Zuari Agro Chemicals Ltd. have been designed considering a Safe Bearing Capacity of Soil as 20 tonnes per sq.mts. The foundations of structures in Zuari are resting on hard lateritic strata. Safety in design of load bearing parts Load Bearing structures play a vital role in effective transfer of load to the foundations. As such, it is of vital importance that they have to be designed properly after working out the loads that will be transmitted to the various load bearing components of a structure. Correct Engineering KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 220 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Practices as laid down in the National Building Codes have to be followed at the time of casting / erection of the load bearing structures. Some of the most common Load Bearing Structures of any Engineering structures are Beams, Columns, Slabs, Shear Walls etc. For enhancing the stability of load bearing Masonry walls, RCC bands are provided at the Plinth level and below the roof slab level. It is of paramount importance that a stability check of such load bearing structures is undertaken, at least once in 5 years, to ascertain the health of the same. In Zuari Agro Chemicals Ltd., the load bearing components of an RCC or Steel structure are tested once in every 5 years by appointing an approved residual life assessment agency who carries out the inspection work by using Non Destructive techniques like Rebound Hammer Testing, Visual Inspection etc. Continuous surveillance of operations Continuous surveillance of Operation of the process is done through the following online systems: Continuous monitoring of the necessary process parameters from the centrally located control room; Continuous automatic process control from automatic Coordinators; Continuous monitoring of the process analysis through process analyzers; Emergency shutdown systems; Quality control Laboratory. This system enables the operators who work on shifts to be in complete command of the process status. Continuous Monitoring This is being done by sensing the process parameters through dedicated transmitters, which in turn send signals to the monitors in the control room. These monitors consist of analog and digital indicators, recorders, and graphic displays in some plants on DCS (Distributed Control System) or Data acquisition system, which in essence are Programmable Computers. The signals also are provided for annunciators, which alarm the operator to the alert and danger levels of the respective process parameters so that suitable action may be taken to restore back the normal conditions. The motors and other drives have continuous indications on the panel showing their status of operation. In some areas/plants there are data acquisition systems, which use computer displays, showing the active process graphics, trending, and alarm summary displays, all on real time basis. Also it gives historical trending and archives, which give the data storage for days together. These computers are capable of giving the shift report and daily reports as desired by the operational requirement. A large array of data helps in obtaining plant efficiencies, loading capabilities, desired capacity levels, optimization and other flexibility as required for higher order data management. Continuous Automatic Process Control Process Coordinators with artificial intelligence of pneumatic and electronic origin are used to automatically control the process parameters under closed loop basis. Accordingly the operator sets desired set point where the process parameters should be resident. The Coordinator automatically controls the process parameters to keep the measurements coinciding with the set point set by the operator. Momentary deviations between set point and measurement valves are immediately controlled from the control algorithms processed automatically by Coordinators. The Coordinator commands the actuating element mostly control valve which actuate the process to KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 221 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES maintain it at desired set point. The option of automatic and manual switch is provided in the control station located in the control room. This control station serves as the man-machine interface to the operator to decide if the particular parameter needs to be controlled either in manual or in auto. While in auto the Coordinator takes charge of the parameter to control it automatically and the manual mode serves the operator to control himself manually should he desire to do so. Process Analysis The online process analysis is done through these analyzers who determine the chemical compositions of the process. This helps in the basic processing of the intermediary and end product and indirectly the efficiencies. The sensors for these analysers are strategically located at different sections of the plant to enable the operator to analyse the process conditions. Alarms in the monitoring of these analysers alert the operator of its threshold and danger levels so that any limitations can be maneuvered to correct the process quality. Emergency Shutdown Systems To automatically determine the safety of the process equipment and manpower, the automatic emergency shutdown system has been provided for each plant. The shutdown and safety devices which consist of trip relays, solenoid valves, relief valves, safety valves, control valves, programmable logic Coordinator will set and integrate to trip the plant/shutdown automatically or manually on request, should there be any override of the process parameters, reaching to danger levels. Every time before starting the plant, this shutdown trip system is tested by simulation to check the health of the trip device, its response time, set values and its authenticity. The emergency shutdown system has alarming functions to diagnose the cause of the trip and whether a safe shutdown has taken place. The components of this system is most of the time duplicated to provide redundancy and enhanced reliability so that it serves as a watchdog to guard the plant from abnormal process parameter levels. Quality Control Laboratory The Laboratory is well equipped to provide detailed analysis of all the compositions as required by the process. Its manpower works in rotational shifts round the clock and has a schedule of various analysis which are to be carried out, offline on periodic time basis. In some plants, there are facilities of automatic analyzer to analyse the composition of end product of some of the products manufactured by the Company. Most of the instruments are of the latest microprocessor based origin having very high fidelity and accuracy. Some of the instruments are gas chromatographs, spectrophotometers, digital titrators, electronic balances, pH and conductivity monitors etc. Other forms of analysis through reagents, titrations and dedicated reactions are carried out to determine and counter-check various compositions. The complete data is logged through computers and store in its database. The Laboratory operating personnel have fixed scheduled to give the process data analysis of the respective plants at predetermined times to the plant operators. Maintenance & Repair Work Procedures according to the Generally Recognised Rules of Good Engineering Practices The maintenance work in the continuous chemical process plants at ZACL may be classified under disciplines namely Civil, Mechanical, Electrical and Instrumentation. The maintenance work may be categorised in all the above disciplines as follows: Day to day minor repair work in the running plants; Preventive maintenance during the running of the plants; KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 222 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Preventive Maintenance during plant shutdown; Plant shutdown repairs; Replacements of the equipment/machinery due to ageing and obsolescence; Technical inspection of pipelines, vessels, rotating machines, based on the guidelines of the standard practice; Predictive condition based maintenance of various machinery’s; Redesign and modifications for optimizations and prevention of recurring failures and downtime; Procurement of spares and update parts / machinery /equipment / instruments. Monitoring of all these above activities is being followed through registrations in the computerized maintenance management system (IMPACT). Also history of all maintenance work carried out, which was previously maintained in history cards has been updated into IMPACT. The latest methodology of computerized maintenance work is being used. This computerization helps to update the data management of all the maintenance work and provides a ready reference guide to plan the work in advance in an enhanced structured manner. Monitoring of individual equipment as regards its maintenance is now being trended/recorded to facilitate the logistics towards determining the health of the equipment. Maintenance work followed under good engineering practices. Day to Day Minor Repair Work in the Running Plants This work is initiated by the operations on daily basis through the formats of work request and safety permits. Proper isolations of the work area is being done in the presence of operation and maintenance staff and once the isolations are confirmed by checking through various instruments such as explosive meters, oxygen meters, CO/CO2/H2 meters etc. Work is being carried out under the direct supervision of maintenance engineers. Once the work is completed and the units are tested and found satisfactory to be taken in line/commission, through the same work permit, maintenance engineers hand over the jobs done to the operation supervisors, who in turn put back the units in operation. Preventive Maintenance during the Running of the Plants Preventive maintenance schedules in the standby equipment and in the equipment/ units/ instruments wherever possible is being carried out on time basis. This also includes LLF methods (Look-Listen-Feel method) wherein operation staff / maintenance engineers/technicians make regular rounds to check the leakage, the abnormality of sounds, the heat dissipations, optimum lubrication oil levels and its make up, external vibrations. They thus obtain the first hand knowledge of the performance of the plant equipment/instruments/machinery. Preventive Maintenance during Plant Shutdown During the shutdown of the plants or annual turnaround, checking the alignment of machinery, testing and simulation of instrumentation, electrical equipment, periodic replacements of units such as bearings, bushes etc., internal cleaning and servicing of equipment/machinery, replacements of worn-out parts well in advance before a breakdown occurs, testing of foundations of equipment and machines, calibration of instruments, emergency trip devices, checking of the safety devices such as safety valves, relief valves etc. are the areas which are planned as a shutdown activity during the plant shutdown. All the moving and rotating parts are being lubricated, fresh lot of lubrication oils are replenished in order to render a trouble free service till the next annual turnaround. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 223 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Plant Shutdown Repairs The repair work based on the breakdowns or inspections done during the running condition of the plants are being carried out during the shutdown in all the disciplines including Civil. Replacement and repair of refractory of furnaces, repairs of vessels and pipelines, repairs of control valves, instruments, repair of rotating machines, safety equipment, etc. are few examples where the work is taken up during shutdowns. The isolation procedure of shutdown jobs during shutdown is the same as that of the isolation procedure during running of the plant. Job permits are being renewed in every shift and maintenance as well as operating personnel does monitoring. Replacements of the equipment/machinery due to ageing and obsolescence To enable the long term planning so as to keep the plant running for a long time, safeguards against ageing and obsolescence is of utmost important and this is mostly being planned for execution during plant shutdowns/ turnarounds. At times, detail engineering to redesign these modifications is required to incorporate suitable alternatives due to the non-availability of spares, so as the equipment/machinery is serviceable without sacrificing safety and good engineering practices. Technical inspection of pipelines, vessels, rotating machines, based on the guidelines of standard practice A separate section is in charge to check/inspect the quality of welding, the vessel internal leakage’s, equipment internal deterioration, and to monitor the long-term health prospects of the equipment. All the fresh weld joints are tested/ X-rayed as per the standard procedures. Recommendations for the type of materials and a constant pursuit to incorporate better materials are supervised by this section. This work is being carried during the breakdowns or annual turnaround, or during the running of the plants. Internal testing of the exchangers or peel-off of vessel linings, or internal material erosions are another areas where this section plans and advises to other sections for the repair activities if necessary. Predictive maintenance of various machinery All rotating machines of different types are undergoing online and off-line predictive monitoring to determine its performance on continuous basis. This monitoring includes vibration, axial thrust, eccentricity analysis, check of bearings through shock pulse methods, orbit analysis to determine the alignment of shafts are some of the areas where the dedicated team under equipment section is continuously monitoring on off-line basis. All the daily readings are tabulated and computerised and various trends are drawn to manage the data and provide signals, which can alert the maintenance and the operation. The on-line predictive monitoring consists of sensors which continuously monitor the parameters such as vibration, axial thrust displacements etc. and provide a direct on-line recording. This helps in triggering signals to alert the plant operators and trip the plants in case of emergencies. Redesign and Modification for Optimization and Prevention of Recurring Failures and Downtime These are the backup services for maintenance which give a continuous feed backs of the latest developments so that it can be incorporated in the existing system to keep the equipment/ machinery updated with the latest technology. It also helps to eliminate the long-term shortcomings in the older designs and look for upgrading the plant efficiencies and energy savings. Its work is of project nature, mostly to be done or hooked up during shutdowns. The job KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 224 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. CH-7: ADDITIONAL STUDIES involves design, detail engineering, procurement, erection/installation and commissioning and is undertaken by Maintenance Department. Procurement of spares and updated parts /machinery /equipment /instruments Planning for the complete maintenance work, its spares, replacements, and redesigns wherever necessary is a continuous activity, which is being planned in anticipation to the actual maintenance needs for the plant use. 7.2.19 Emergency Control Procedures Evacuation Procedure In case of any emergency, evacuation of the personnel is very essential. We have identified 12 Assembly Points where the personnel have to assemble. All these Assembly Points are in charge of persons who will be responsible for doing Head count and shifting them to a safer place. The Welfare Coordinator along with Security coordinator shall be the Key Persons who are in charge of evacuation. If required, they may take assistance from the other persons reporting to ECC. For evacuation of the plant personnel, two routes are identified which shall be used depending upon the wind direction. Main Gate House DAP gate (Materials Gate) List of vehicles which will be made available for transporting people in case evacuation is required is as follows: Type of vehicle No. of vehicles Contact No Buses 5 9850035599, 9765376438 Light motor vehicle 8 9921853500, 9762476107, 9823157833 The company owned cars and personal cars of the employees if required can also be used for evacuation. Medical Emergency Procedure The affected persons will be provided first aid and then transported with available means of transport to the Health Centre. Once the casualties arrive at Health Centre, Medical Coordinator will examine and decide upon sending them to the pre-identified hospitals. It is the responsibility of the Medical Coordinator to inform the Over-all in Charge about the condition of the injured. Restoration of Normalcy After confirmation from all the coordinator that the emergency is controlled and in consultation with the Over-all in Charge, the Chief Coordinator will authorize to sound “ALL CLEAR”. Once the “ALL CLEAR” is sounded, it is indication that the emergency is over; All external agencies like District Collector, Inspectorate of Factories & Boilers, and Police will be informed by the Overall in Charge regarding cessation of the emergency; Overall in-charge informs to higher up about the end of emergency; Each plant shall resume to the normal operation after assessing the situation and following the laid down procedure of plant start-up. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 225 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Training and Emergency Drills Training All the key persons, the coordinator of the response team and other required persons in the plant are trained on their role during emergency. The following are the some of the areas where the persons will be made aware of. Safe handling of hazardous chemicals; Procedure to be followed in reporting emergency; Siren and manual call points; Usage of fire extinguishers; Use of different types of PPE’s; First aid; Evacuation procedure; Emergency drills. The following types of exercises and drills will be conducted. Wet drills : Once in a month Full-scale drill : January and December Plan Review and Updating The plan will be reviewed and updated. The shortcoming observed during conduct of table top exercises/ mock drills. Any change of process, handling of new hazardous chemicals. Change in coordinator, their contact numbers. The updating of the plan would be the responsibility of In-charge of Fire & Safety Dept. The updated Plan would circulated to the concerned after the same is approved by Chief General Manager-Operations/Chief Manufacturing Officer. Controlled copies Each controlled copy of the plan will be serially numbered and then issued to the concerned person. The details of the same will be documented by in-charge of Fire & Safety. It will be the responsibility of the concerned person to send back the old copy/pages to Fire & Safety Dept. 7.2.20 Details of Communication Facilities Available during Emergency Method of Reporting and Declaration of Emergency Any person noticing a fire, explosion or release of hazardous material should shout 'FIRE’ or ‘HELP’ and attempt to control the incident. He/she should dial 101/111 (Fire Station/ECC) or break the nearest Manual Call Point, which automatically alerts the fire station, and its nearest location. The telephone number 101/111 at the Fire Station/ECC is manned round the clock. He should inform the shift-in-charge of the affected plant, giving the location of incident, brief description of the emergency. The shift-in-charge should confirm by repeating the message back to caller to proper communication; Fires station will then press the bell to call Panel Operator from Weigh Bridge and Fire & Security Inspector from main gate; KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 226 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Panel Operator will immediately contact the coordinators and the information will flow as per the attached communication chart. The Message must be Clear, Short and should Contain: Identification of the speaker; Brief Description of the incident; Location incident; Status and seriousness of the situation; Actions taken; Immediate assistance required. Declaration of Emergency Localized emergency The emergency situation arising in any section of one particular area which is minor in nature can be controlled within the affected section itself with the help of in-house resources available at site and the fire department. such emergencies should be informed to the chief coordinator. Such an emergency does not have the potential to cause serious injury or damage to property/environment and the domino effect to the sections of the affected plant or near by plants/areas. Major emergency The emergency which cannot be controlled locally and has the potential to develop into a major emergency with a potential to cause serious injuries or damage to properly/environment within the affected area or to the nearby areas should be considered as a major emergency needing immediate action and this plan would need to be activated. Such emergency situations always warrant mobilizing the necessary internal and external resources to handle the emergency and mitigate it’s consequences. Immediate Actions for Major Emergency The senior most officer available at the site must immediately inform Chief Coordinator and ECC about the escalation of emergency; After receipt of the call, Chief Coordinator will rush to the incident site; Chief Coordinator after assessing the situation, take appropriate action to control the situation and if it is beyond his control, informs the Overall In-charge. Chief Coordinator will direct the Fire & Safety Coordinator to initiate sounding of emergency siren who in turn will ensure prompt/immediate action for sounding of siren; Overall In-charge would get in touch with ECC; The panel operator at ECC would inform GM-M, Health Centre, Main Gate House, CM-F&S, DGM-M&S, CM-I&E; Overall In-charge would then rush to ECC; After assuming the position of Overall In-charge in ECC, he shall contact with other senior members in the plant. Procedure for Sounding the Emergency Siren An emergency alarm switch is installed in the Emergency Control Centre (Fire Station) and also in Ammonia Plant. The siren can be sounded with the actuation of an “Emergency Alarm Switch”. Chief Coordinator will direct Fire & Safety Coordinator to initiate sounding of the emergency siren KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 227 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES from the ECC. The siren can also be sounded by the shift-in-charge only in case of an extreme emergency. The siren will be operated in the following modes. Onsite Emergency Siren A wailing sound for two minutes (4 seconds “on” & 2.5 seconds “off”) Off-site siren A wailing sound for 2.45 minutes (2.5 seconds “on” and 1 second “off”) All Clear Siren A continuous sound for a period of two minutes Action by emergency staff Fire pump operation We have a good net work of fire hydrant system all throughout the plant. The water pressure is continuously maintained at 7.5 kg/cm2. Any drop in water pressure, the fire pumps will start automatically. Security On hearing emergency siren or on information, the fire fighting team will report to the incident site; Control and monitor the traffic movement; All hot jobs inside the plant to be stopped. Trained Fire fighting staff All the trained fire fighting staff from the non plant areas will report to the Emergency Control Centre and assist the emergency team, if required. First Aiders The certified first aiders belonging to non-plant areas have to proceed to the Health Centre and assist the medical team, if required. Other personnel All the personnel not directly involved in emergency operations should proceed to the designated Assembly Points, if the same is ordered by the Overall in-charge. Sequence of Actions after Declaration of Emergency After declaration of emergency, overall in-charge instructs communication Coordinator to inform nearby hospitals, Police Station and Mutual Aid Members. Chief Manager-Fire & Safety/Manager will assist in these operations; Maintenance team reports to the incident site, if needed; Overall In-charge will keep contact with Chief Coordinator; The other plan in-charges occupy their respective plant and follow the instructions from Chief Coordinator/Overall in Charge; Overall In-charge in consultation with the Chief Coordinator and other key personnel decides whether to shutdown the plant. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 228 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Other Guidelines Fire personnel The fire personnel represent in ECC/Fire Station or other designated person will act as ECC operator. ECC operator To receive all incoming calls; To inform Health Centre, Chief Manager-Fire & Safety, Main gate house; To keep record of all incoming calls; To assist the Communication Coordinator/Overall In-charge in communications. Communication of Emergency The emergency will be communicated to all by sounding of Emergency Siren. The Chief coordinator briefs the Overall In-charge about the status, likelihood to affect other plants. The mode of communication will be public address system, walkie talkie sets, internal /external telephones or messengers. The various channels of communication are as below: External communication 1. If, required key personnel can be contacted by external telephones. 2. Communication to nearby communities Overall In-charge through GM-HR establishes telephonic contact with the identified key persons in the neighbouring communities. 3. Communication to local authorities Overall In-charge will contact local authorities like District Collector, Dy. Collector, Police, Fire Station, Chief Inspector of Factories & Boilers. through the Communication coordinator. 4. Designated person for interaction with media Sr. Manager-CSR & PR would be the Company’s authorized spokesperson for interacting with media (TV channels, newspaper, etc) 5. Procedure for notifying families of the injured person The responsibility of communicating to the families would be of GM-HR. 6. Centralised reporting office ECC would be the Centralised Reporting office during the emergency. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 229 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Details of Fire Fighting & Other Facilities The fire protection system at ZACL consists of the following: Fire water hydrants, water foam monitors with fire pump system; Long range trolley mounted water foam monitor; Portable fire extinguishers; Fire vehicles (2 nos.) – Foam Tender & Water Mist Tender; Emergency Response Vehicle; Hydrocarbon/smoke detectors with alarm; Manual call point system (break glass type). List of firefighting Equipment & Others S. No. Equipment Quantity 1 2 Fire hydrant Single hydrant 45 nos. Double hydrants 72 nos. Fire escape risers 54 nos. Water/foam capacity for fire fighting 9687 M3 Raw Water Pond Water monitors tank farm area 6 nos. Foam compound in foam tank 2800 lts. Fire pumps 3 Diesel engine driven pump : 2 no’s, 410 m3/hr, head 88m Electrically driven pump : 1 no., 410 m3/hr, head 88m Jockey Electrically driven pump : 2 no’s, 50 m3/hr, head 88m Smoke /Heat detectors 4 5 Ammonia Compressor house 8 no’s DG Room 2 no’s Product handling plant 8 no’s Library 04 no’s Safety Training Centre 04 no’s Stores 11 no’s Works Office 25 no’s Health Centre 11 no’s Manual Call points 17 no’s 6 Hoses 7.5 m length 2 15 m length 7 103 Fire extinguishers Dry Chemical powder 5 Kg 20 Dry Chemical powder 10 Kg 264 Dry Chemical powder 25 Kg 9 Dry Chemical powder 50 Kg 5 Foam type 9 liters 55 Carbon dioxide 2 Kg capacity 5 Carbon dioxide 4.5 Kg capacity 61 Carbon dioxide 9 Kg 23 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 230 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. Equipment S. No. 8 Quantity Foam tender Water tender 1 no Water tank capacity 4000 lts. Foam capacity 1000 lts. Pump capacity 3000 lpm @ 7 kg/cm2 DCP 75 Kg (2 no’s) Water Mist Tender 1 no. Water tank capacity 2000 liters. DCP vessel capacity 500 Kg. Pump capacity 150 lpm @ 100 kg/cm2 Emergency Rescue vehicle 1 no. 9 10 CH-7: ADDITIONAL STUDIES Equipped with various types of items 11 Trailer mounted foam monitor 1 no. Capacity 4500 lpm Self Contained Breathing Apparatus 44 nos. 13 Chemical suits 14 nos. 14 Dewatering pump 1 no. Capacity 700 lpm 15 Fire proximity suits 2 nos. 16 Compressor for filling breathing air 1 no. 12 List of other Safety Equipment S. No. Equipment Quantity 1 Trolley mounted long range breathing apparatus 3 nos. 2 Self contained breathing apparatus nos. 45 minutes duration 24 - 30 minutes duration 20 17 3 4 Spare cylinder Sets Air line respirator 8 nos. Canister gas masks Ammonia 13 no’s Urea 9 no’s Utilities 10 no’s NPK-A 8 no’s NPK-B 7 no’s RMH 4 no’s DAP Gate house 5 no’s Laboratory 2 no’s Detecting Instruments Plant Measuring Components Ammonia LEL, O2, CO Urea NH3 Urea O2 NPK-A NH3 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 231 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT M/S. ZUARI AGRO CHEMICALS LTD. CH-7: ADDITIONAL STUDIES Plant Measuring Components NPK-B LEL, O2 Power Plant LEL, O2 Laboratory LEL, O2, CO Fire Station LEL, O2 Wind direction indicators Wind directors have been provided at various locations which are as under: Old Horton sphere : 1 no. New Horton sphere : 1 no. Chlorine handling area : 1 no. In front of Health Centre : 1 no. CO2 absorber : 1 no. RMH office : 1 no. Details of First AID & Hospital Services Available & It’s Adequacy Medical Arrangements On receipt of emergency call ambulance will be immediately sent to the emergency site. First aiders of the affected plant shall assist the emergency team at the site immediately and subsequently the medical team at health centre. First aiders of non affected plant may be called to assist the medical team depending on the number of the casualties. List of trained first aiders is appended. Medical officer (in his absence male nurse on duty) will act as medical coordinator. He will guide the first aiders and the medical team. The Doctor will coordinate with chief coordinator. After giving the first aid the casualty would be referred to higher medical care centre or detained at health centre depending on the nature and severity of the trauma. Health Centre Occupational health centre situated inside the factory premises operates round the clock with following facilities: S. No. Manpower Number 1 Resident Doctor 1 2 Visiting Doctor 1 (Retainer) 3 Nursing Staff 4 4 First Aiders 50 S. No. Equipment Number 1 Ambulance 01 2 Beds 04 3 Oxygen Cylinders 02+02 4 Oxygenators 02 5 Stretchers 04 6 ECG 01 7 Glucometer 01 8 Nebulizer 01 9 Casualty Tables KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 02 232 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Ambulance There is an ambulance stationed at health centre round the clock. Whenever there is an emergency ambulance is sent to the site and with the help of first aiders/rescuers the casualty is brought to the health centre. If the person is serious he is referred to hospitals after giving first aid for further management. List of Emergency Medicines at Health Centre S. No. Emergency medicine S. No. Emergency medicine S. No. Emergency medicine 1 Inj Atropine. 18 I V Fluids. 35 Tab Vertin. 2 Inj Adrenaline. 19 Inj Tramadol. 36 Tab Valium 2. 3 Inj Rabipur. 20 Inj Calmpose. 37 Tab Trika 0.25. 4 Inj Tetanus Toxoid. 21 Inj Eptoin. 38 Tab Digine. 5 Inj Avil. 22 Inj Dolokind Aqua. 39 Tab Calpol/Crocin. 6 Inj Dexona. 23 Tab Sorbitrate. 40 Tab Lostat. 7 Inj Voveran. 24 Tab Avil. 41 Tab Stamlo. 8 Inj Reglan. 25 Tab Combiflam. 42 Tab Meftal Spas. 9 Inj Phenargan. 26 Tab Diclogesic. 43 Tab Mobizox. 10 Inj Gentamycin. 27 Tab Lasix. 44 Tab Bidanzen Forte. 11 Inj Stemitil. 28 Tab Atenolol 45 Tab Flexon Mr. 12 Inj Lasix. 29 Tab Enam. 46 Eye Wash Cups. 13 Inj Deriphyline. 30 Tab Telmisat. 47 Silverex Cream 14 Inj Betropose. 31 Tab Ecosprin. 48 Ryele’s Tube. 15 Inj Ranitidine. 32 Tab Clopitab. 49 Foley’s Catheter. 16 Inj Cyclopam. 33 Tab Depin. 50 Eye/Ear Drops 17 Inj 25% Dextrose 34 Tab Cardace Facilities Available Consultation; Emergency handling; Suturing facility; Medical examination; Transportation to referral centers. Multiple Casualties Handling In the event of a disaster involving multiple casualties, help of nearby hospitals/ doctors and their paramedical staff would be available. The Company doctor shall arrange such help from the outside whenever required. The list of such hospitals is given below: List of Hospitals –Govt & Private S. No. Name & location Type Beds Phone no. 1 Primary Health Centre, Cansaulim Govt. 12 2754036 2 Primary Health Centre, Cortalim Govt. - 2550274 3 Cottage Hospital, Chicalim Govt. 60 2540864 4 SMRC, Chicalim Private 100 6691919 5 MPT Hospital, Semi Govt. 100 2594931 6 INHS, Jeevanti, Vasco Govt. 79 2501233, 2501022 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 233 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Name & location Type Beds Phone no. 7 Talaulikar Hospital, Vasco Private 22 2513456 8 Dr. Kamat Nursing Home, Vasco Private 12 2512354 9 Dr. Pai Hospital, Vasco Private 25 2513641, 2511899 10 Sanjeevani Hospital, Baina Private 39 2510024 11 Raj Tara Hospital, Vasco Private 8 2514883 12 Dr. Mesquita Maternity & Eye Hospital, Vasco Private 14 2513696 11 Vasco Clinic, Vasco Private 11 2513164 S. No. 12 Goa Medical College Govt. 955 2458700 13 Dr. Parulekar Nursing Home, Baina Private 25 2513672 List of Employees Trained in First AID S. No. EPR Section Section Tel. no. 1 2339 Sarvesh Karapurkar Utilities Plant 2690 2 2420 Gauresh Arondekar Laboratory 2653 3 2421 Rupesh Kotharkar Laboratory 2653 4 2423 Seby Barreto Utilities 2690 5 2426 Nitesh Nadkarni NPK-B maintenance 2332 6 2447 Hanumant Bykod Ammonia Plant 2670 7 2448 Suraj Chodankar Ammonia Plant 2670 8 2449 Savel Selveira Urea Plant 2661 9 2442 Manesh Naik NPK-B Plant 2660 10 2454 Gladwin Gonsalves Ammonia Plant 2670 11 2456 Samarth Tendulkar NPK-A Plant 2685 12 2434 Amresh Sawal Fire & Safety 2622 13 2467 Preetesh Prabhu Urea Plant 2661 14 2463 Rahul Gurav NPK-B plant 2660 15 2464 Arjun Kattimani Utilities Plant 2690 16 2466 Clive Lobo Laboratory 2653 17 2465 Aditya Kalangutkar Utilities 2690 18 2457 Satish Vaghmare NPK-A Plant 2685 19 80001 Armildo Dias Utilities Plant 2690 20 80003 Utkarsh U Laad Ammonia Plant 2670 21 80004 Roland F.Pereira Ammonia Plant 2670 22 80005 Dattaram M Sawant Ammonia Plant 2670 23 80006 Bhaskar M Naik Ammonia Plant 2670 24 80007 Akshay Naik Urea Plant 2661 25 80008 Manu Krishnan Ammonia Plant 2670 26 80009 Jayant G Kopardekar Utilities Plant 2690 27 80002 Minanath Mandrekar Laboratory 2653 28 80012 Audhut Parker NPK-A 2686 29 2495 Sarvesh G. Naik Instruments 2547 30 2504 Siddhesh Mhalsekar Civil 2618 31 2515 Avinash Bhargav Technical Services 2591 32 2514 Kishor J. Urea Plant 2661 33 2516 Santhosha Ammonia Plant 2670 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 234 M/S. ZUARI AGRO CHEMICALS LTD. S. No. EPR 34 35 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Section Section Tel. no. 2517 Nishanth Gowda R.S. Ammonia Plant 2670 2510 Reuben Anthony Torcato Inspection 2638 36 2508 L. Ramesh Babu Ammonia Plant 2670 37 2513 Kanakava Roy Instruments 2547 List of Employees Trained in Fire Fighting S. No. EPR Name Plant /Section Tel. No. 1 2036 Prashant Salvi Utilities 2690 2 2351 Sankalp Kulkarni Technical Services 2591 3 2448 Suraj Chodankar Ammonia 2670 4 2508 Ramesh Babu Ammonia 2570 5 80008 Manu Krishnan Ammonia 2670 6 2083 Akash Valke Urea 2661 7 80007 Akshay Lobhanand Naik Urea 2661 8 2457 Satish Vaghmare NPK-A 2685 9 2422 Manesh Govind Naik Utilities 2660 10 2086 Vivek Mayenkar Product Handling 2586 11 2068 C.L.A. Fernandes Mechanical 2332 12 2510 Reuben Anthony Torcato Inspection 2638 13 2378 Ramesh Meti Mechanical 2452 14 2345 Saurabh Bandodker Electrical 2584 15 1566 Savio Barreto Electrical 2451 16 2340 Jayant Nirmalker Instruments 2547 17 2280 Chandresh Chari Mechanical 2480 18 2386 Aditya Kuttikar Laboratory 2653 19 2277 Anup Madkaikar Inspection 2638 7.3 OCCUPATIONAL HEALTH Details of workers health of ZACL is given as below: KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 235 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Health Status of Workers, ZACL KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 236 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES ECG Report KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 237 M/S. ZUARI AGRO CHEMICALS LTD. KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES 238 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Audiometry Report KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 239 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES Health Check-up Report KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 240 M/S. ZUARI AGRO CHEMICALS LTD. EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES List of W/C & Urinals in Factory Premises S. No LOCATION GENTS W/C LADIES W/C URINALS 1 FIRE STATION 1 0 1 2 DOCUMENTATION/KNOWLEDGE CENTRE 1 1 0 3 WORKS OFFICE 3 1 2 4 WORKS CANTEEN 1 1 2 5 MAIN GATE 1 0 1 6 HEALTH CENTRE 1 0 0 7 STORES 2 0 2 8 MAINTENANCE WORKSHOP 2 0 2 KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 241 M/S. ZUARI AGRO CHEMICALS LTD. S. No EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES LOCATION GENTS W/C LADIES W/C URINALS 9 MAINTENANCE OFFICE 1 1 2 10 INSTRUMENT WORKSHOP 2 0 2 11 ELECTRICAL WORKSHOP 1 0 0 12 LABORATORY 2 1 0 13 WATER TREATMENT PLANT 2 0 0 14 LABOUR TOILET NEAR WTP 1 0 0 15 AMMONIA/UTY/UREA MAINT OFFICE 3 0 4 16 POWER PLANT CONTROL ROOM 2 0 1 17 DG CONTROL ROOM 1 0 1 18 DAP GATE SECURITY OFFICE 1 0 0 19 CONTRACTOR`S LABOUR TOILETS 2 2 1 20 AUTO WORKSHOP 1 0 3 21 NPK LABOUR TOILET 1 0 2 22 NPK -A CHANGE ROOM 2 0 1 23 NPK-B CHANGE ROOM 2 0 1 24 NPK-B LABOUR TOILET 2 0 2 25 UREA MAINT OFFICE 0 0 1 26 AMMONIA/UREA CONTROL ROOM 3 0 3 27 DAP-PH LABOUR TOILET 2 0 4 28 PH LABOUR TOILET 4 0 5 29 PH MAINT OFFICE 1 0 2 30 UREA PACKER SCALE LABOUR TOILET 1 0 0 31 NPK PACKER SCALE LABOUR TOILET 1 0 0 32 LABOUR CANTEEN 1 1 2 33 NPK-DAP MAINT OFFICE 2 0 2 34 AUTO LABORATORY 1 0 0 35 RAILWAY SIDING (UREA/DAP SIDE) 2 0 2 36 RAILWAY SIDING MARKETING OFFICE 3 0 1 37 RAILWAY SIDING LABOUR TOILET below Mkt office 1 0 1 38 EFFLUENT RECYCLE PLANT 1 0 0 39 SULPHURIC ACID U/L STATION 1 0 0 40 EXCISE OFFICE & CHANGE ROOM 2 0 0 41 LABOUR TIOILET NEAR NEW KCL SILO 4 0 2 42 CONTRACTORS FABRICATION YARD 0 0 3 43 CSO 1 0 0 44 PH-NEHA OFFICE 1 0 1 45 DAP GATE MARKETING/ LOGISTIC OFFICE 1 0 1 46 PH- CONTROL ROOM 1 0 2 71 8 62 TOTAL KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 242 M/S. ZUARI AGRO CHEMICALS LTD. 7.4 EIA & EMP FOR CUSTOMIZED NPK FERTILIZERS UNIT, GT, HRSG, AAST & UREA GRANULATION UNIT CH-7: ADDITIONAL STUDIES EHS POLICY OF ZUARI AGRO CHEMICALS LIMITED KADAM ENVIRONMENTAL CONSULTANTS | SEPTEMBER 2016 243