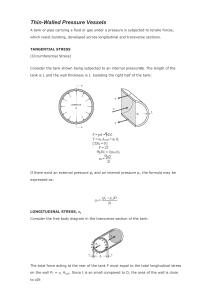

THIN-WALLED PRESSURE VESSELS Cylindrical or spherical vessels are commonly used in industry to serve as boilers or tanks. When under pressure, the material of which they are made is subjected to a loading from all directions. “Thin wall” refers to a vessel having an inner-radius to- wall-thickness ratio of 10 or more r ≥ 10 t the pressure in the vessel is understood to be the gauge pressure (measures the pressure above atmospheric pressure) A. CYLINDRICAL VESSELS In cylindrical vessel with an inner radius “r”, wall thickness “t” and containing fluid pressure there will be stress in parallel and perpendicular axis of the cylinder which callled s1 and s2 respectively. They are called principal axes. s1 is called the hoop stress or tangential stress s2 is called longitudinal stress I. Tangential Stress Consider the free-body diagram PROBLEMS Taking the summation of force at z-axis SFz = 0: 2T - F =0 2 σ 2 dA− pdA=0 s1(2t)(Dx) – (p)(2r)(Dx) = 0 s1 = ( p)(2 r)( Δ x) (2 t)( Δ x) s1 = ( p)(r ) pD = 2t (t ) where; s1 = tangential stress p = gauge pressure (internal pressure) r = radius of vessel D = diameter of vessel t = thickness II. Longitudinal Stress To determine the longitudinal stress s2 , consider the free body consisting of the portion of the vessel and its contents located to the left of the section Noting that the area of the fluid section is pr2 and that the area of the wall section can be obtained by multiplying the circumference 2pr of the cylinder by its wall thickness t, the equilibrium equation is: ΣFx = 0 T–F=0 σ 2 dA− pdA=0 σ2(2prt) – p(pr2) = 0 σ2 = p (π r 2 ) 2 πrt σ 2= pr pD = 2t 4t σ 2 = longitudinal stress p = gauge pressure (internal pressure) r = radius of vessel D = diameter of vessel t = thickness Notice that tangential stress is twice as much as longitudinal stress σ 1 =2 σ 2 B. SPHERICAL PRESSURE VESSEL consider a spherical vessel of inner radius r and wall thickness t, containing a fluid under a gage pressure p For reasons of symmetry, the stresses exerted on the four faces of a small element of wall must be equal σ 1 =σ 2 consider the free body consisting of the portion of the vessel and its contents located to the left of the section ΣFx = 0 T–F=0 σ 2 dA− pdA=0 σ2(2prt) – p(pr2) = 0 σ2 = p (π r 2 ) 2 πrt σ 1 ¿ σ 2= pr pD = 2t 4t This is the same result as that obtained for the longitudinal stress in the cylindrical pressure vessel PROBLEMS (LEDESMA) 1. The cylindrical tank with a spherical end-cap has an outer radius of 2 m and a wall thickness of 25 mm. If the tank is pressurized to 1.5 MPa, determine the longitudinal and circumferential stresses in the cylinder, and the stress in the end-cap. SOLUTION SOLUTION Given: Radius = 2 m Thickness = 25mm = 0.025m P = 1.5 MPa Since the given radius is not the inner radius, subtract the wall thickness of the tank to the radius of tge tank. r inner =2 m−0.025 m=1.975 m Check if it is qualified for Thin wall analysis: r 1.975 m = =79 t 0.025m Since 79 ≥ 10, hence the problem can be solve through thin-wall analysis Longitudinal stress: pr ( 1.5 MPa ) (1.975 m) = =59.25 MPa 2t 2( 0.025 m) Circumferrencial / Tangential Stress σ 2= pr ( 1.5 MPa )( 1.975m) = =118.5 MPa t (0.025 m) Spherical Cap o Determine the radius of spherical cap. From the figure, σ1= sin ( 45 )= r sphere 2r cylinder r sphere=2 ( sin 45 )( 1.975 m )=√ 2 (1.975 ) ≈ 2.793 m σ sphere = 2. pr ( 1.5 MPa )(1.975m)( √ 2) = =83.79215357 MPa ≈ 83.79MPa 2t 2(0.025 m) A spherical weather balloon is made of 0.2-mm-thick fabric that has a tensile strength of 10 MPa. The balloon is designed to reach an altitude where the interior pressure is 1500 Pa above the atmospheric pressure. Find the largest allowable diameter of the balloon, using 1.2 as the factor of safety. SOLUTION Given t = 0.2 mm = 0.2 x 10-3 m p = 1500 Pa σ ult =10 MPa (Ultimate Stress) N = 1.2 D= ? Determine the setting or working stress in the balloon using σ 10 MPa σ = ult = =8.3333 MPa N 1.2 Determine the diameter using stress for spherical pressure vessel pD σ Sphere = 4t 6 8.3333 ×10 Pa= D= (1500 Pa) D 4 (0.2 ×10−3 m) ( 8.3333 ×10 6 Pa ) ( 4 ) ( 0.2× 10−3 m ) 1500 Pa =4.444427 m≈ 4.44 m 3. A spherical shell with 70-in. outer diameter and 67-in. inner diameter contains helium at a pressure of 1200 psi. Compute the stress in the shell. SOLUTION Given: Outer Diameter = 70 in Inner diameter = 67 in ¿ Thickness =70∈– 67∈ 2 ¿ = 1.5in P = 1200 psi Check if it is qualified for Thin wall analysis: r 67 /2 = =22.333 t 1.5 Since 22.333 ≥ 10, hence the problem can be solve through thin-wall analysis Spherical stress: σ sphere = pD ( 1200 psi ) (67) = =13 400 psi=¿13.4 ksi 4t 2(1.5) 4. A spherical pressure vessel has a 1.5-ft inner radius and 3/16-in. wall thickness. If the working tensile stress of the material is 6000 psi, determine the maximum allowable internal pressure. Given: Inner radius = 1.5 ft = 18 in Thickness =3/16 in = 0.1875 in σ working =σ sphere=6000 psi Check if it is qualified for Thin wall analysis: r 18 = =96 t 0.1875 Since 96 ≥ 10, hence the problem can be solve through thin-wall analysis Spherical stress: σ sphere = pr =( p ) ¿ ¿ 2t p = ( 6000 psi )( 2 ) ¿ ¿ (ESTRADA) 5. The wall thickness of a 4-ft-diameter spherical tank is 5/16 in. Calculate the allowable internal pressure if the stress is limited to 8000 psi. Given: diameter = 4 ft = 48 in Thickness =5/16 in = 0.3125 in σ working =σ sphere=8000 psi Check if it is qualified for Thin wall analysis: r 48 /2 = =76.8 t 0.3125 Since 76.8 ≥ 10, hence the problem can be solve through thin-wall analysis Spherical stress: σ sphere = pD =( p ) ¿ ¿ 4t p = ( 8000 psi )( 4 ) ¿ ¿ (LAGRADA) 6. The tank of the air compressor is subjected to an internal pressure of 90 psi. If the internal diameter of the tank is 22 in., and the wall thickness is 0.25 in., determine the stress components acting at point A. Given: Radius (r) = (22in.)/2 = 11 in. Thickness (t) = 0.25 in. Internal Pressure = 90 psi. Since r 11∈. = = 44 > 10, then thin wall analysis can be used. t 0.25∈. For hoop stress, we use this equation: σ₁ = pr t Substitute the given values: σ1= 90 psi .(11∈.) 990 psi(¿ .) = =3960 psi.=3.96 ksi .( Answer) 0.25∈. 0.25∈. (PUMARAS) 7. A water tank, 22 ft in diameter, is made from steel plates that are 1/2 in. thick. Find the maximum height to which the tank may be filled if the circumferential stress is limited to 6000 psi. The specific weight of water is 62.4 lb/ft3. Solution: Diameter of the water tank = 22 ft Thickness of steel plate = 1/2 inch Maximum circumferential stress = 6000 psi Specific weight of water = 62.4 lb/ft3 Required: The maximum height to which the tank may be filled with water (VALDEZ, JEROME) 8. A pipe carrying steam at 3.5 MPa has an outside diameter of 450 mm and a wall thickness of 10 mm. A gasket is inserted between the flange at one end of the pipe and a flat plate used to cap the end. How many 40-mm-diameter bolts must be used to hold the cap on if the allowable stress in the bolts is 80 MPa, of which 55 MPa is the initial stress? What circumferential stress is developed in the pipe? Why it necessary to tighten the bolt initially, and what is will happen if the steam pressure should cause the stress in the bolts to be twice the value of the initial stress? SOLUTION: Circumferential stress (consider 1-m strip): (HERNANDEZ) 9. A cylinder pressure vessel 10 meter long has closed ends, a wall thickness of 5 mm, and a diameter at mid thickness of 3 mm. if the vessel is filled with air to a pressure of 2 MPa, how much do the length, diameter, and wall thickness change, and in each case state whether the change is an increase or a decrease. The vessel is made of a steel having elastic modulus E = 200,000 MPa and the Poisson’s ratio v = 0.3. Neglect any effects associated with the details of how the ends are attached. Solution: Attach a coordinate system to the surface of the pressure vessel as shown below, such that the zaxis is normal to the surface. The ratio of radius to thickness, r/t, is such that it is reasonable to employ the thin-walled tube assumption, and the resulting stress equations of the vessel. Denoting the pressure as p, we have σ x= pr ( 2 MPa ) (1500 mm) = =300 MPa 2t 2(5 mm) σ y= pr ( 2 MPa ) (1500 mm) = =600 MPa t 5 mm The value of σ z varies from -p on the inside wall to zero on the outside, and for a thin-walled tube is everywhere sufficiently small that σ z ≈ 0 can be used. Substitute these stresses, and the known E and v into Hooke’s Law, which gives ε x =6.00 ¿ 10−4 ε y =2.55¿ 10−3 ε z =−1.35¿ 10−3 These strains are related to the changes in length ∆ L , circumference ∆ ( πd ), diameter ∆ d, and thickness ∆ t, as follows: ε x= ∆L L εY= ∆D D ε Z= ∆t t Substituting the strains from above and the known dimensions gives ∆ L=6 mm ∆ d=7.65 mm ∆ t=−6.75¿ 10−3 Thus, there are small increases in length and diameter, and a tiny decrease in the wall thickness. (VIGILIA) 8. A cylindrical steel pressure vessel 400 mm in diameter with a wall thickness of 20 mm, is subjected to an internal pressure of 4.5 MN/m2. (a) Calculate the tangential and longitudinal stresses in the steel. (b) To what value may the internal pressure be increased if the stress in the steel is limited to 120 MN/m2? (c) If the internal pressure were increased until the vessel burst, sketch the type of fracture that would occur.