Scripta Materialia 215 (2022) 114706

Contents lists available at ScienceDirect

Scripta Materialia

journal homepage: www.journals.elsevier.com/scripta-materialia

In-situ observations of static recrystallization and texture formation in a

cold-rolled CoCrFeMnNi high entropy alloy

Baoqi Guo a, *, Ranjit K. Ray a, b, Shuhei Yoshida a, Yu Bai a, c, Nobuhiro Tsuji a, d

a

Department of Materials Science and Engineering, Kyoto University, Yoshida-Honmachi, Sakyo-ku, Kyoto 606-8501, Japan

Indian Institute of Engineering Science and Technology, Shibpur, 711103, India

c

School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China

d

Elements Strategy Initiative for Structural Materials (ESISM), Kyoto University, Yoshida-Honmachi, Sakyo-ku, Kyoto 606-8501, Japan

b

A R T I C L E I N F O

A B S T R A C T

Keywords:

Texture

Recrystallization

High entropy alloy

In situ TEM

Static recrystallization and texture development in a CoCrFeMnNi high entropy alloy cold-rolled to various

strains and annealed were studied. Microstructural and crystallographic evolution was recorded by identical area

observations using quasi in-situ electron backscatter diffraction (EBSD). The deformation texture was preserved

after recrystallization, but the texture was weakened at this stage. Shear bands served as the preferential

nucleation sites for recrystallization. Thin foils of the deformed alloy were in-situ observed during heating in a

transmission electron microscope (TEM). It was observed that subgrains formed from deformed microstructures

by dislocation rearrangement and annihilation. The subgrains coarsened by boundary migration and coalescence.

These enlarged subgrains were the viable nuclei for the recrystallized grains.

High entropy alloys (HEAs) are composed of five or more principal

elements in equimolar ratios. The HEAs have attracted wide attentions

due to their excellent mechanical properties, such as high strength and

wear resistance as well as outstanding fracture toughness at cryogenic

temperatures [1–5]. Properties of metals and alloys are primarily

affected by microstructures and grain orientations [6,7]. Since industrial

manufacturing of HEAs will entail, almost invariably, thermomechan­

ical processing, it is of great significance to investigate the evolution of

microstructure and texture in HEAs during deformation and

recrystallization.

Evolution of texture during static recrystallization of a cold-rolled

CoCrFeMnNi high-entropy alloy has been described by Bhattacharjee

et al. [8]. It was demonstrated that brass-type texture formed after heavy

cold rolling by 90%, and annealing twins developed during annealing.

Other factors such as grain size and heating rate have been considered in

the study of annealing textures in a CoCrFeMnNi alloy [9]. It was shown

that heating rate could determine the grain size as well as its distribution

during annealing while they rarely affected the texture evolution during

annealing [10]. Recently, the work by Haase and Barrales-Mora [11]

showed that the microstructure and texture evolution during recrystal­

lization in a CoCrFeMnNi alloy were controlled by nucleation at grain

boundaries and annealing twin formation. Recrystallized grains were

found to show rolling texture components and annealing twins gave rise

to an overall texture randomization, although the mechanisms of texture

formation and recrystallization were still unknown at the time.

The previous works have focused on textural changes during

annealing, but the relationship between recrystallization texture and

deformation microstructures, such as the role of shear bands in recrys­

tallization texture formation, has been missed. Moreover, the afore­

mentioned studies with regard to recrystallization and textures were

carried out by means of ex-situ methods (i.e. observation of quenched

microstructure). Due to the limitation of ex-situ techniques, the precise

mechanisms of the recrystallization process in HEAs are still unclear.

The objective of the present work is to bridge the gaps by elaborating on

the nucleation and growth of recrystallized grains in the CoCrFeMnNi

alloy, and the concomitant texture evolution, using in-situ and identicalarea experimental techniques.

An as-cast equi-atomic CoCrFeMnNi HEA was forged at 1150◦ C and

homogenized at 1100◦ C for 24 h. The materials were subsequently coldrolled to 50% reduction in thickness followed by annealing in vacuum at

1100◦ C for 5 min. The annealed samples were further cold-rolled to

50%, 70% and 90% reductions. Subsequent annealing of the cold-rolled

sheets was carried out at 750◦ C for various periods of time, followed by

water quenching.

Microstructures on sections perpendicular to the transverse direction

(TD) of the cold-rolled sheets were observed by electron backscatter

* Corresponding author.

E-mail address: guo.baoqi.7z@kyoto-u.ac.jp (B. Guo).

https://doi.org/10.1016/j.scriptamat.2022.114706

Received 20 February 2022; Received in revised form 18 March 2022; Accepted 22 March 2022

Available online 29 March 2022

1359-6462/© 2022 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

B. Guo et al.

Scripta Materialia 215 (2022) 114706

measuring area fractions of texture components using orientation im­

aging microscopy (OIM) software by TSL co. Identical areas in the

specimens cold-rolled and annealed for different periods were observed

by EBSD, which is called quasi in-situ EBSD observations hereafter. In the

quasi in-situ EBSD observations of identical areas, fiducial marks were

firstly made on the surfaces of the cold-rolled samples. The samples were

diffraction (EBSD) in a field-emission scanning electron microscope (FESEM) and transmission electron microscopy (TEM). The EBSD specimens

were electropolished using electrolyte containing 90 vol.% ethanol and

10 vol.% perchloric acid at room temperature with a voltage of 30 V for

15 s. Texture components were identified using Euler angles determined

by the Bunge method. The texture intensities were obtained by

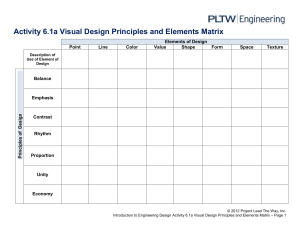

Fig. 1. EBSD micrographs containing (a) an inverse pole

figure (IPF) map, (b) image quality (IQ) map, and (c) Kernel

average misorientation (KAM) map showing deformation

microstructures in the 50% cold-rolled CoCrFeMnNi alloy. IPF

maps of an identical area in the 50% cold-rolled specimen

obtained by the quasi in-situ EBSD observations during

annealing at 750 ◦ C for (d) 0 min (as cold-rolled), (e) 8 min,

(f) 12 min, (g) 17 min, (h) 27 min, (i) 40 min, respectively.

Note that Fig. (d) is the same as Fig (a). Colors in the IPF map

indicate crystallographic orientation parallel to transverse

direction (TD) according to the key stereographic triangle

inserted. ND and RD indicate the normal direction and rolling

direction, respectively, in the cold-rolled specimens.

2

B. Guo et al.

Scripta Materialia 215 (2022) 114706

wrapped by titanium foils to minimize oxidation and repeated annealing

at the same annealing temperature was conducted in a vacuum furnace.

Water quenching was employed after each annealing operation.

Thin foils for TEM were prepared by twin-jet electro-polishing at a

voltage of 15 V and -30◦ C using electrolyte with a composition of 70 vol.

% methanol, 20 vol.% glycerin, and 10 vol.% perchloric acid. A TEM

(JEM-3200FSK) and a specimen holder equipped with a heating stage

were used in the in-situ TEM observations. The experiment was carried

out at an accelerating voltage of 200 kV. A low heating rate of 0.5◦ C s− 1

was used during annealing to reduce the drift of specimen caused by

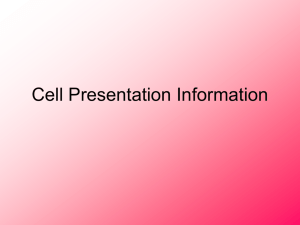

Fig. 2. Texture components of the identical area (the same area as shown in Fig. 1) in the 50% cold-rolled and 750◦ C annealed specimen. The colors of texture

components are consistent with those in the table. The white color denotes random texture. The black color regions from (b) to (f) refer to unrecrystallized parts. The

specimen was annealed at 750◦ C for (a) 0 min (as cold-rolled), (b) 8 min, (c) 12 min, (d) 17 min, (e) 27 min and (f) 40 min.

3

B. Guo et al.

Scripta Materialia 215 (2022) 114706

heating. The samples were heated from room temperature (20◦ C)–750◦ C

and then isothermally held for 30 min.

Microstructures of the CoCrFeMnNi HEA after 50% cold-rolling are

shown in Fig. 1(a)–(c). In-grain shear bands frequently formed in the

cold-rolled specimens, as revealed in IPF map (a) and IQ map (b). The

Kernel average misorientation (KAM) map (c) indicated large local

misorientations and strains on the shear bands and heterogeneously

deformed local areas with large local misorientations. The shear bands

were more copious and well-delineated at the higher rolling reduction of

90%, as shown in the TEM image provided in the supplementary file

(Fig. S1). Here, it was confirmed that the shear bands penetrated twin­

ned areas (or twin-matrix lamellae) composed of very fine deformation

twins and matrices aligned parallel to the rolling direction (RD).

Fig. 1(d–i) shows EBSD micrographs of an identical area in the 50%

cold-rolled specimen (the same as Fig. 1(a–c)) taken in the quasi in-situ

observations during recrystallization annealing at 750◦ C for different

times. Sites “A”, “B” and “C” in the as-rolled (0 min. annealed) micro­

structure represent three shear bands and the region “D” surrounded by

broken lines indicates a heterogeneously deformed local area with large

local misorientations. After annealing for 3 min, there was no apparent

change in the microstructure. Then, recrystallization occurred on the

shear bands and in the heterogeneously deformed local areas, when the

sample was annealed for 8 min. The recrystallization nuclei became

more copious after annealing for 12 min. Further nucleation and growth

Fig. 3. EBSD maps obtained by the quasi in-situ observations of the specimens 70% cold-rolled and annealed at 750◦ C. IPF maps (a, d, f), texture component maps (b,

e, g) and KAM map (c) of the as-70%-rolled state (a-c) and those annealed at 750◦ C for 3 min (d, e) and 6 min (f, g). The colors in the texture components maps (b, e,

g) correspond to different texture components summarized in the table. The white color in texture component images denotes random texture.

4

B. Guo et al.

Scripta Materialia 215 (2022) 114706

of recrystallized grains occurred with increasing the annealing time.

The texture components in the 50% cold-rolled and 750◦ C annealed

specimen shown in Fig. 1 are displayed in Fig. 2. The areas of which

orientations were close to typical texture components in cold-rolled and

annealed alloys (e.g., Brass {110}<112> and Goss {110}<001> ori­

entations) were exhibited in different colors, as indicated in the table

inserted. Here texture characterization allows for a misorientation of

15 ◦ from the ideal orientation of the typical texture component. It

should be noted that the Goss/Brass in olive color refers to {110}<115>

orientation that is in the middle between the Brass and Goss

orientations. When the orientation of the area did not belong to any of

these typical texture components, it was categorized as “Random”

orientation and colored in white. It was found that the initial recrys­

tallization nuclei possessed orientation components which were present

in the cold-rolled microstructure. The shear bands “A” and “B” in the as

cold-rolled state were characterized by Goss (orange) and S (light blue)

orientation components. A magnified image of Fig 2(a) that shows

detailed texture components is provided in the supplementary file

(Fig. S2). As recrystallization progresses, some recrystallized grains

appeared on the shear bands “A” and “B” with Goss and S orientations,

Fig. 4. Images of an identical area obtained from the in-situ TEM observation of nucleation during annealing. Bulging of the dislocation boundary was detected at

450◦ C in Fig. (d).

5

B. Guo et al.

Scripta Materialia 215 (2022) 114706

In order to clarify the nucleation sites for recrystallization at early

stages, the quasi in-situ EBSD observations of the 70% cold-rolled ma­

terial were carried out during annealing at 750◦ C for various times. The

EBSD maps of an identical area obtained are shown in Fig. 3. The IPF

map Fig. 3(a) of the cold-rolled specimen showed a banded structure

composed of initial grains elongated to the rolling direction (RD) and

deformation bands. Specifically, the region “X” was an elongated initial

suggesting that local textures formed by cold rolling were preserved and

developed during recrystallization. It should be noted, however, that

many recrystallized grains had Copper (blue) and Random (white) ori­

entations. The heterogeneously deformed area “D” contained Brass (red)

and Goss as well as S orientations in the cold-rolled state. Apart from

these cold rolled textures, other orientations such as Copper were found

in some recrystallized grains formed during annealing.

Fig. 5. Images of an identical area obtained from the in-situ TEM observation during annealing. Three pre-existing cells with irregular shapes formed by cold rolling

are indicated by red arrows in (a). With increasing the temperature, the three sites grew from (a) to (e).

6

B. Guo et al.

Scripta Materialia 215 (2022) 114706

grain with small misorientations inside Fig. 3(c), having Brass orienta­

tion (Fig. 3(b)). The regions “Y” and “Z” represented heterogeneously

deformed local areas with large local misorientations (Fig. 3(c)), which

showed Brass, S, Goss and rotated Goss, along with partly Cu and BrassGoss orientation components (Fig. 3(b)). During annealing, very small

recrystallized grains were found to nucleate in the heterogeneously

deformed local areas (regions Y and Z). Some of new recrystallized

grains nucleated at boundaries of elongated initial grains. The recrys­

tallization nuclei within the heterogeneously deformed local areas

formed from or near the regions with similar orientations in the asdeformed state, comparing Fig. 3(b) and (e). As indicated by the black

arrows, two small areas “A” and “B” (blue in IPF image, Fig. 3(a)) had

Brass orientation (Fig. 3 (b)) in the as-deformed state. These two areas

acted as nucleation sites to form new recrystallized grains in annealing

for 3 min (d), and most grains nucleated and grown had Brass orienta­

tion (Fig. 3(e)). In a similar manner, heterogeneously deformed areas

with Goss and Copper orientation in the “Z” region were formed by 70%

cold rolling and these areas developed into recrystallized grains having

their original texture components. The major texture components found

in the 6 min annealed specimen were similar to those of the cold rolled

material.

In order to get a deeper insight into the early stages of nucleation of

recrystallized grains, in-situ heating experiments were conducted in the

heating stage of a TEM. A 90% cold-rolled specimen was heated from

room temperature to 750◦ C at a heating rate of 0.5◦ C/s. Fig. 4 (a)–(i)

showed a series of micrographs of an identical area, taken at different

stages of heating. The cold rolled thin foil showed a typical elongated

cell structure. The present observation focused on the area indicated by

the dashed red circle. Dislocation movement and interaction started

when the temperature reached 192◦ C. Annihilation of dislocations

continued during further annealing till 271◦ C. The bulging of the

dislocation boundary was activated from 450◦ C to 609◦ C. Finally, after

holding for 300s at 750◦ C, annihilation and rearrangement of disloca­

tions almost completed, forming a small recrystallization nucleus. Some

distinct movement of cell boundaries could also be observed.

Fig. 5(a)–(f) represent initial stages of the formation of recrystalli­

zation nucleus, adjacent to a heavily twinned area in the 90% cold rolled

alloy, obtained from the in-situ TEM observations. Fig. 5(a) shows three

small areas with nearly free of dislocation contrasts (which could be

described as pre-existing cells) close to the twin edges, marked as ‘X’, ‘Y’

and ‘Z’. When the temperature increased to 298◦ C, the boundaries of the

three sites became sharper and clearer due to dislocation rearrangement

and annihilation. At this temperature, the small subgrain at ‘X’ joined up

with another one below it, possibly by subgrain coalescence. With an

increase of temperature to 710◦ C, some growth of these subgrains could

be clearly seen, and they invaded adjacent twin-matrix bundles. The

subgrains at ‘X’, ‘Y’ and ‘Z’ showed some growth at this stage, and new

subgrains formed, typically in the area marked K, where a rather large

subgrain formed by dislocation annihilation and grain boundary

migration. The misorientation as well as dislocation density tended to

become high in the interface between twin bundle and deformed matrix,

which could facilitate the occurrence of nucleation of recrystallization.

What we have been describing as subgrains could be recrystallized

nuclei. When a subgrain enlarged, it built up sufficient misorientation

with surrounding areas, becoming a recrystallized grain.

The texture development in the current high entropy alloy during

annealing of the 70% cold-rolled alloy annealed at 750◦ C for different

periods of time is shown in supplementary material (Fig. S3(a)). Even

after 5 min of annealing, the texture intensity decreased drastically, and

this trend continued till recrystallization took place after annealing for

30 min. It should be noted that the volume fractions of texture com­

ponents of recrystallized grains remained approximately unchanged

during annealing (Fig. S3(b)). In Fig. S3(c), the fractions of Brass and

Goss components in the unrecrystallized initial grains increased during

annealing, which indicated that the grains with Brass and Goss com­

ponents were hard to recrystallize. In contrast, fractions of Copper and

Random textures in the unrecrystallized initial grains decreased with

increasing the annealing periods, suggesting that these components

were preferentially recrystallized and contributed to randomization of

the texture. Such a weak recrystallization texture has also been reported

previously in CoCrFeMnNi HEA by several researchers [8,11]. Their

works demonstrated that the basic characteristics of the textures of the

recrystallized grains and the un-recrystallized grains were essentially

similar. The texture of the recrystallized grains was the weakest, and

that of the un-recrystallized grains was the strongest. The overall texture

intensity of the entire sample located between these two extremes. This

analysis demonstrated that the deformation texture was preserved after

recrystallization, but the overall texture intensity was drastically

weakened, which could be further explained by the results obtained

from the in-situ TEM observations (Figs. 4 and 5). These experiments

have shed much light on the formation and growth of the subgrains from

the cold rolled dislocation structures. The subgrains formed were the

precursors to the new strain-free recrystallization nuclei. The current

investigations showed that dislocation rearrangement and annihilation

gave rise to the formation of nearly dislocation-free subgrains, which

coarsened by the classical processes like sub-boundary movement. The

reduced texture intensity during annealing is related to the recrystalli­

zation in shear bands. As shown in Figs. 1 and 2, cold rolling produced

numerous shear bands that acted as the preferential sites for recrystal­

lization. With few Goss and S orientations, the recrystallization textures

in shear bands appeared to be weak during annealing. Annealing twins

in FCC crystals contributes to weak textures during annealing as well

[12]. According to a recent work [13], annealing twins in CoCrFeMnNi

high entropy alloy generated new orientations such as Cube orientation

that weakened the textures during recrystallization.

In addition, the similarity in the nature of the texture from the

deformed, as well as from the recrystallized materials [8,11], indicated

that the process was oriented nucleation. That is, the nuclei of recrys­

tallized grains of particular orientations form at or near the deformed

regions of same or similar orientations. The oriented nucleation was

further illustrated during the recrystallization via evolution of

pre-existing cells indicated in Figs. 3 and Fig. 5. In-situ TEM has shown

that the processes of subgrain formation and their growth are rather

slow. It has been claimed that diffusion is sluggish in high entropy alloys

[2]. For example, Tsai et al. [14] concluded that the diffusion co­

efficients of the individual elements in the CoCrFeMnNi alloy were

indeed lower than those in conventional FCC metals. Although clarifi­

cation of diffusion mechanisms in HEAs requires further study, sluggish

diffusion could be closely related to the slow growth of recrystallized

grains in these alloys. Since the grain boundary migration involves

jumps of atoms (diffusion) across grain boundaries, elements with a slow

diffusion rate can dominate the recrystallization process. In fact, Liu

et al. [15] and Tsai et al. [14] reported that the activation energy of

grain growth in the same HEA was found to be comparable to that of the

lattice diffusion of Ni with the slowest diffusion rate among all the

constituent elements. The solute drag effect due to the interaction be­

tween elements and grain boundaries can also be another important

factor. As different elements occupy various lattice sites in the HEA,

some specific elements with very low potential energy can be trapped

and dragged by grain boundaries, leading to deceleration of grain

boundary migration kinetics. In conventional alloys, this solute drag

effect is evident in low-angle boundaries, but it is possible that the effect

in HEA can inhibit boundary migration even in high-angle boundaries.

The slow growth rate of the recrystallized grains will not allow grains of

any particular orientation or grains of several orientations to grow

preferentially at the expense of grains of other orientations. This will

result in the formation of a fine grain size and random texture in the

recrystallized material, as has been found to be the case.

In summary, in-situ TEM and quasi in-situ EBSD observations of

identical areas were conducted for clarifying static recrystallization and

texture formation during annealing of a CoCrFeMnNi equi-atomic high

entropy alloy subjected to various amounts of cold rolling. The general

7

B. Guo et al.

Scripta Materialia 215 (2022) 114706

characteristics of the cold rolling texture was preserved even after

recrystallization, but with a drastically decreased intensity. The initial

micro-scale mechanisms of the formation of dislocation-free subgrains

(which were the precursors of the viable recrystallization nuclei) were

rearrangement and annihilation of dislocations, sub-boundary migra­

tion and subgrain coalescence. Shear bands acted as the preferential

sites for recrystallization and randomized the recrystallization textures.

The mechanism of recrystallization in this alloy could be understood as

“oriented nucleation” followed by limited growth of recrystallized

grains, probably due to slow diffusion in the alloy.

was also financially supported by the Grant-in-Aid for Research Activity

Start-up (No. JP21K20487), and the Grant-in-Aid for JSPS Research

Fellow (No. JP18J20766). All the supports are greatly appreciated.

Supplementary materials

Supplementary material associated with this article can be found, in

the online version, at doi:10.1016/j.scriptamat.2022.114706.

References

[1]

[2]

[3]

[4]

Declaration of Competing Interest

The authors declare that they have no known competing financial

interests or personal relationships that could have appeared to influence

the work reported in this paper.

[5]

[6]

[7]

Acknowledgment

[8]

The in-situ TEM observations in this work were conducted under

Advanced Characterization Platform of the Nanotechnology Platform

Japan (JPMXP09-A-19-KU-0324). This work was financially supported

by the Elements Strategy Initiative for Structural Materials (ESISM; No.

JPMXP0112101000), the Grant-in-Aid for Scientific Research on Inno­

vative Area "High Entropy Alloys" (No. JP18H05455), the Grant-in-Aid

for Scientific Research (A) (No. JP20H00306), through the Ministry of

Education, Culture, Sports, Science and Technology (MEXT), Japan. SY

[9]

[10]

[11]

[12]

[13]

[14]

[15]

8

D.B. Miracle, O.N. Senkov, Acta Mater. 122 (2017) 448–511.

E. Pickering, N. Jones, Int. Mater. Rev. 61 (3) (2016) 183–202.

B. Cantor, I. Chang, P. Knight, A. Vincent, Mater. Sci. Eng. A 375 (2004) 213–218.

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, E.P.J.A.M. George, Acta Mater.

61 (15) (2013) 5743–5755.

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie,

A Sci. 345 (6201) (2014) 1153–1158.

G.D. Sathiaraj, A. Pukenas, W. Skrotzki, J. Alloy. Compd. 826 (2020), 154183.

B. Cai, B. Liu, S. Kabra, Y. Wang, K. Yan, P.D. Lee, Y. Liu, Acta Mater. 127 (2017)

471–480.

P. Bhattacharjee, G. Sathiaraj, M. Zaid, J. Gatti, C. Lee, C.W. Tsai, J.W. Yeh,

J. Alloy. Compd. 587 (2014) 544–552.

G. Sathiaraj, P.P. Bhattacharjee, J. Alloy. Compd. 647 (2015) 82–96.

G. Sathiaraj, C. Tsai, J. Yeh, M. Jahazi, P.P. Bhattacharjee, J. Alloy. Compd. 688

(2016) 752–761.

C. Haase, L.A. Barrales-Mora, Acta Mater. 150 (2018) 88–103.

G. Gottstein, Acta Metall. 32 (7) (1984) 1117–1138.

L. Kaushik, J. Singh, J.H. Kang, Y.S. Ko, D.I. Kim, J.Y. Suh, S.H. Choi, Scr. Mater.

205 (2021), 114221.

K.Y. Tsai, M.H. Tsai, J.W. Yeh, Acta Mater. 61 (13) (2013) 4887–4897.

W. Liu, Y. Wu, J. He, T. Nieh, Z. Lu, Scr. Mater. 68 (7) (2013) 526–529.