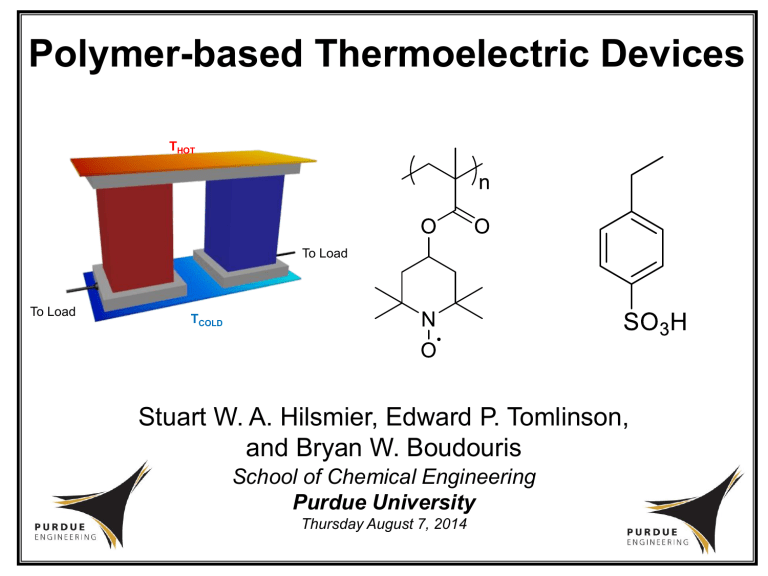

Polymer-based Thermoelectric Devices THOT To Load To Load TCOLD Stuart W. A. Hilsmier, Edward P. Tomlinson, and Bryan W. Boudouris School of Chemical Engineering Purdue University Thursday August 7, 2014 Need for Waste Energy Recovery 1. 2. 3. 4. Introduction (1 of 4) Methods (2) Results (1) Conclusion (1) Source: Lawrence Livermore National Laboratory (www.llnl.gov) Fundamentals of Thermoelectric Materials THOT To Load To Load 𝜎𝑆 2 𝑧𝑇 = 𝑇 𝜅 TCOLD Material Figure of Merit (zT) Parameters Used to compare efficiency of Electrical Conductivity (σ): Measure of the ability for electrons to move through the material materials Seebeck Coefficient (S): Measures the amount of energy an electron carries across the material 1. 2. 3. 4. Introduction (2 of 4) Methods (2) Results (1) Conclusion (1) Thermal Conductivity (κ): Measures how easily heat can move through the material Uses of Thermoelectric Devices Reliable Reduce Weight 1. 2. 3. 4. Introduction (3 of 4) Methods (2) Results (1) Conclusion (1) Improve efficiency Organic Molecules in Thermoelectric Device Poly(2,2,6,6-tetramethyl-1-piperidinyloxy-4-yl methacrylate) PTMA Testing films doped with 4-ethylbenzenesulfonic acid EBSA • PTMA previously used in solid-state[3] • Has well-documented conductivity[1-2] • Question: What effects will doping PTMA with EBSA have on its conductivity, Seebeck coefficient, and thermoelectric power factor? 1. 2. 3. 4. Introduction (4 of 4) Methods (2) Results (1) Conclusion (1) From Solution to Device Prepare solution • Mass compounds • Add solvent Apply solution to substrate • Stir until dissolved Paint silver contacts on 1. 2. 3. 4. Introduction (4) Methods (1 of 2) Results (1) Conclusion (1) Heat to evaporate solvent Conductivity and Seebeck Testing Current ΔT 40˚C Voltage Voltage THot 1. 2. 3. 4. Introduction (4) Methods (2 of 2) Results (1) Conclusion (1) TCold Results Mass Percent EBSA vs Conductivity 1. 2. 3. 4. Introduction (4) Methods (2) Results (1 of 1) Conclusion (1) Conclusions and Future Work • Conductivity increases with larger mass percent of EBSA • Seebeck data necessary to determine power factor of devices Percent EBSA vs Seebeck and Power Factor (Example Data) 1. 2. 3. 4. Introduction (4) Methods (2) Results (1) Conclusion (1 of 1) References 1. Rostro, L.; Baradwaj, A. G.; Boudouris, B. W. ACS Appl. Mater. Interfaces 2013, 5, 9896–9901. 2. Rostro, L.; Wong, S. H.; Boudouris, B. W. Macromolecules 2014, 47, 3713–3719. 3. Yonekuta, Y.; Susuki, K.; Oyaizu, K.; Honda, K.; Nishide, H. J. Am. Chem. Soc. 2007, 129, 14128–14129. Acknowledgements