NFPA 61: Fire & Dust Explosion Prevention in Agriculture

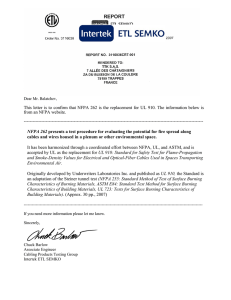

advertisement