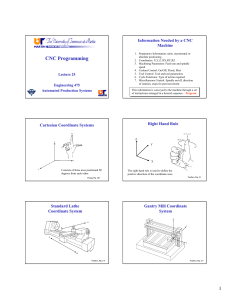

Computer Aided Manufacturing Course Outlines (2nd Term) 1st Term Course Outlines (2nd Term cont.) References Alan Overby , “CNC Machining Handbook Building, Programming, and Implementation ”, Mc Graw Hil, 2011. Peter Smid, “CNC Programming Handbook”, 2nd edition, Industrial press, 2000. Steve Krar and Arthur Gill, “Computer Numerical Control Programming Basics”, 1999. CAD/CAM (MEC 5431) 300 Marks CW : 120 Marks Semester work: 90 Practical Exam : 30 Final Exam :180 Marks Mid Term (20) Assignments (10) 1st term: 45 2nd term: 45 Quizzes (10) Attendance (5) CAD/CAM Course Policies: 1. Homework Submission: Homework solutions should be submitted on the due date. 2. Late homework policy: On time, in the class (100%), same day after class (0%). Lecture Rules Today Lecture 9 1. Reading drawing 2. Programming 3. Input Program 4. Manufacturing 10 CAD Example 11 Process planning simulation 12 Working Drawing 13 Program simulation NC Words General Format of a Block Sequence Preparatory Function # N G Dimension Words X Y Z Example Feed Rate I J K Spindle Speed F Tool Number S T Misc. Function M The following list presents the different types of NC words: N-Word: Sequence No. This is used to identify the block N010 N020 N025 N030 G-Code : Preparatory Word Is used to prepare the controller for instructions G20 – Inch input (in) – G70 G21 –Metric input (mm) – G71 G00 – Rapid positioning mode : Move in a straight line at rapids speed. NOT used for cutting. G01 – Linear Interpolation mode Tool is moved along a straight-line path at programmed rate of speed. G02 – Circular motion clockwise (CW) G03 – Circular motion counter clockwise (CWW) Coordinate Systems Absolute (2,10) 2 Incremental (10,10) 3 1 (-8,8) 2 (10,2) (8,0) 3 1 (10,2) Absolute & incremental coordinates Absolute (G90) : All Points refers to Zero point Incremental (G91) : All Points refers to Previous point Practice pt Abs Inc X-Y-Z Word : Coordinates word G Codes – Arcs Method : Arc with R (R is arc radius) Absolute coordinates N0 G90 ; Absolute coord N5 G00 X1 Y2 ; start N10 G02 X2 Y1 R1 X1Y2 R1 X2Y1 X1Y2 Relative coordinates N0 G91; Relative coord N05 G00 X1 Y2 ; start N10 G02 X1 Y-1 R1 R1 X1Y-1 F-Word : Feed Rate : The feed rate code to move the cutting tool or work piece to the desired position. S-Word : Spindle Speed (rpm) T-Word: Tool number T01, T02,….etc 26 Tool Magazine CNC turret 27 Miscellaneous function M-Code List: that used for decision command like spindle on/off or coolant on/off M02 End of Program M03 Spindle on CW M04 Spindle on CCW M05 Spindle off M06 Tool change M07 Coolant 2 on M08 Coolant 1 on M09 Coolant off M30 End of tape Preparatory function G-Code List: that used to guide the machine tool to carry out machining processes G00 G01 G02 G03 G17 G18 G19 G20 G21 G90 G91 Rapid Linear Interpolation PTP Linear Interpolation Clockwise Circular Interpolation Counter Clockwise Circular Interpolation X-Y Plane Selection Z-X Plane Selection Y-Z Plane Selection Inch Mode Metric Mode Absolute Value Command Incremental Value Command Programming Point N P1 … … Pn G X Y Z I J S F T M Profile milling Profiling is to cut the WP using one side of the cutting tool Practice Write a part programme to machine the following part and list the tool used 50 30 20 80 Dim in mm 10 Solution Y P3 50 P2 30 Tool change Point P0 P4 P5 20 P1 80 P6 X 10 Z Solution N010 G21 G90 N020 G00 X90 Y60 Z5 T01 X0 Y0 S1000 M03 M07 Z-15 F200 M05 M09 N030 N040 G01 N050 Y50 N060 X30 N070 Y20 N080 X80 N090 Y0 N100 X0 N110 Z5 N120 N130 G00 X90 Y60 M30 M06 Tool Description T01 End mill, 10mm Dia. 36 36