Multi-f unction Protection Relay

for Motors, Transformers, Blow-out Coils, Cables and Overhead Lines

-

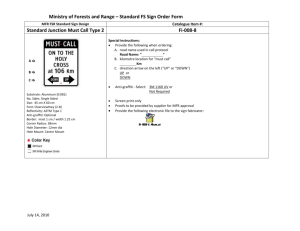

Figure 1

-

Order No. G88700-C3527-07-7600

instruction Manual

illustration of the multi-function protection relay MFR 7SJ551

O Siemens Nederland N.V. 1998 Version R03-03

1

,

,

MFR7SJ551

Introduction

Certificate of Conformity

This product is in conformity with the directive of the Council of the European Communities on the

harmonisation of the laws of the Member States relating to electromagnetic compatibility (EMC Council

Directive 89/336/EEC).

Conformity is proved by tests that have been performed according to article 10 of the Council Directive in

accordance with the generic standards EN 50081-2 and EN 50082-2 by Siemens Nederland N.V.

The device is designed and manufactured for application in industrial environment.

The device is designed in accordance with the standards of IEC 255 and VDE 0435 part 303.

MFR 7SJ551

Introduction

contents

1 introduction

.......................................................................................................................8

.............................................................................................................................................

.................................................................................................................................................

1.1 Application

8

..

1.2 Features

8

1.3 Implemented functions .........................................................................................................................

10

2 Design

2.1

2.2

2.3

............................................................................................................................I 1

............................

.

.

..............................................................................................

....................................................................................................................................

.................................................................................................................................

Arrangements

11

.

Dimensions

13

Ordering data

16

2.3.1 Protection unit ................................................................................................................................

16

2.3.2 Interface unit...................................................................................................................................

I6

17

2.3.3 Operation and evaluation software.................................................................................................

17

2.3.4 Spare parts ....................................................... ..............................................................................

2.3.5 Surface mounting bracket ..............................................................................................................

17

2.3.6.0ptical cable...................................................................................................................................17

3 Technical data ...............................................................................................................

18

3.1

...................................................................................................................................

General data

18

3.1 .1 Inputs / outputs ...............................................................................................................................

18

3.1.2 Electrical tests .........................

.

....................................................................................................

22

3.1.3 Mechanical stress test ....................................................................................................................

24

3.1.4 Climatic stress tests .......................................................................................................................

24

3.1.5 Service conditions ..........................................................................................................................25

3.1.6 Interchangeability........................................................................................................................... 25

3.1.7 Design ............................................................................................................................................

25

3.2

Component data ............................................................................................................................26

3.3

Thermal overload protection

26

26

3.3.1 Rotor thermal overload protection ..................................................................................................

3.3.2 Stator thermal overload protection .................................................................................................28

3.3.3 Thermal overload protection of non-rotating objects ......................................................................

29

30

Ambient temperature biasing (optional)

3.4

3.5

Start inhibit

31

3.6

Locked rotor protection

32

32

3.7

Zero speed protection

3.8

Unbalance protection

33

3.9

Undercurrent protection ......................;........................................................................................

34

3.1 0

Overtemperature protection (optional)

35

3.1 1

Low set overcurrent protection

36

3.1 1.1 Definite time overcurrent protection .............................................................................................

36

3.1 1.2 Inverse time overcurrent protection.............................................................................................. 37

3.1 1.3 Custom curve overcurrent protection ...........................................................................................

39

40

High set overcurrent protection

3.12

Curve switch

41

3.1 3

Directional earthfault protection (optional)

42

3.14

Undervoltage protection (optional)

44

3.1 5

3.1 6

Overvoltage protection (optional)

45

3.1 7

Breaker failure trip

46

3.1 8

Block ...............................................................................................................................................

46

3.1 9

External command

47

3.20

Ancillary functions

47

....................................................................................................

.....................................................................................

.....................................................................................................................................

................................................................................................................

...................................................................................................................

....................................................................................................................

.....................................................................................

.................................................................................................

...................................................................................................

................................................................................................................................

................................................................................

.............................................................................................

...............................................................................................

.........................................................................................................................

......................................................................................................................

........................................................................................................................

MFR 7SJ551

Introduction

4 Method of operation

1

........................................................................................................49

................................................................................................

....................................................................................................

4.1

4.2

Operation of the complete unit

4 9

Thermal overload protection

50

4.2.1 Theoretical background .................................................................................................................

50

4.2.1.1 Single-body thermal overload model ..................................................................................

50

4.2.1.2 Two-body thermal overload model......................................................................................

53

4.2.2 Rotor thermal overload protection .................................................................................................

54

4.2.3 Stator thermal overload protection ................................................................................................

55

4.2.4 Thermal overload protection of transformers, blow-out coils and cables ......................................56

4.3

Ambient temperature biasing (optional)

57

4.4

Start inhibit

58

4.5

Emergency restart

59

4.6

Locked rotor protection

59

4.7

Zero speed protection

60

4.8

Motor start-up protection

60

4.9

Unbalance protection

62

4.9.1 General ..........................................................................................................................................62

4.9.2 Unbalance protection of motors ................................................................................................... 63

4.1 0

Undercurrent protection

63

4.10.1 General ........................................................................................................................................

63

4.1 0.2 Motor undercurrent protection ..................................................................................................... 64

4.1 1

Overtemperature protection (optional)

64

4.12

Low set overcurrent protection

65

4.12.1 Definite time overcurrent protection .............................................................................................

65

4.12.2 Inverse time overcurrent protection .............................................................................................

65

4.12.3 Custom curve overcurrent protection ..........................................................................................

66

4.13

High set overcurrent protection

66

4.1 3.1 Fast busbar protection using the reverse interlock scheme ........................................................ 67

4.14

Curve switch

67

4.15

Directional earth fault protection (optional)

67

4.1 5.1 Cos f determination .....................................................................................................................

68

4.1 5.2 Sin f determination.......................................................................................................................69

4.1 5.3 Sensitivity emprovement by shifting the symmetry axis ..............................................................

69

4.1 5.4 Correcting the angular error of the core balance transformer .....................................................69

4.1 5.5 Earth fault location .......................................................................................................................

70

4.1 6

Undervoltage protection (optional)

70

4.17

Overvoltage protection (optional)

71

71

4.18

Breaker failure trip

4.19

Block

72

4.20

External command

72

4.21

Circuit breaker position

72 .

4.22

Ancillary functions

72

4.22.1 Processing of annunciations........................................................................................................

72

4.22.2 Fault event data storage and transmission (optional)..................................................................73

4.22.3 Operational value measurements ................................................................................................

74

4.22.4 Demand ampere meter ...............................................................................................................

74

74

4.22.5 Test facilities ................................................................................................................................

4.22.6 Hardware monitoring ...................................................................................................................

74

.....................................................................................

....................................................................................................................................

........................................................................................................................

...............................................................................................................

..................................................................................................................

.............................................................................................................

...................................................................................................................

..............................................................................................................

....................................................................................

...................................................................................................

.............................................................................................

...........................................................................................................................

...............................................................................

.............................................................................................

...............................................................................................

........................................................................................................................

........................................................................................................................................

........................................................................................................................

...............................................................................................................

...................................................................................................................

..................................................................................................76

5 installation instructions

5.1

5.2

.........................................................................................................

..................................................................................................................................

Unpacking and repacking

76

Preparations

76

5.2.1 Mounting and connections .............................................................................................................

77

77

5.2.2 Checking the rated data ..............................................................................................................

5.2.3 Checking the (optional)

interface unit transmission link ................................................................ 77

. .

5.2.4 connections .................................................................................................................................... 7 8

5.2.5 Checking the connections .......................................................................................................78

~

1

Introduction

MFR 7SJ551

Operating ia7istrwctiorms

6

......................................................................................80

........................................................................................................................

.................................................................................................................

6.1

6.2

Safety precautions

80

Dialogue with the relay

80

6.2.1 Display panel ..................................................................................................................................

80

6.2.2 Keyboard ........................................................................................................................................80

81

6.2.3 LED indicators ................................................................................................................................

81

6.2.4 Operation with a personal computer ..............................................................................................

6.2.5 Front view of the relay ....................................................................................................................

82

6.3

Parameterizing procedure

83

6.3.1 Menu structure ...............................................................................................................................

83

6.3.2 Initial display ...................................................................................................................................

84

6.4

Main menu (OFF LINE)

84

6.5

SETTINGS menu

85

6.6

Settings for DEVICE DATA

86

6.6.1 Non-rotating device ........................................................................................................................

87

6.6.2 Rotating device...............................................................................................................................

87

6.7

Settings for CHANNELS

89

6.8

Settings for PROTECTIONS

93

6.8.1 THERMAL OVERLOAD protection ................................................................................................ 94

6.8.1.1 Thermal overload protection for rotating objects .................................................................

94

6.8.1.2 Thermal overload protection for non-rotating objects ..........................................................

97

6.8.2 AMBIENT TEMPERATURE BIASING (optional) ...........................................................................99

6.8.3 START INHIBIT ............................................................................................................................ 100

102

6.8.4 EMERGENCY RESTART ...........................................................................................................

6.8.5 OVERTEMPERATURE protection (optional) ...............................................................................

103

6.8.6 UNDERCURRENT protection ......................................................................................................

104

6.8.7 LOW SET OVERCURRENT protection .......................................................................................

105

6.8.7.1 Definite time phase fault overcurrent protection ................................................................

106

6.8.7.2 Definite time earth fault overcurrent protection .................................................................

108

6.8.7.3 Inverse time phase fault overcurrent protection ................................................................ 109

6.8.7.4 Inverse time.earth fault overcurrent protection ..................................................................110

6.8.7.5 Custom curve overcurrent protection ................................................................................111

6.8.8 HIGH SET OVERCURRENT protection.......................................................................................113

114

6.8.9 UNBALANCE protection .............................................................................................................

6.8.1 0 DIRECTIONAL EARTHFAULT protection (optional) ..................................................................

115

6.8.1 1 LOCKED ROTOR protection.............:........................................................................................

118

6.8.12 ZERO SPEED protection ............................................................................................................

118

6.8.1 3 UNDERVOLTAGE protection (optional) .....................................................................................

119

6.8.1 4 OVERVOLTAGE protection (optional) ...................................................................................I19

6.8.1 5 BREAKER FAILURE TRIP .........................................................................................................

120

6.8.16 CURVE SWITCH .......................................................................................................................122

6.8.17 BLOCK .......................................................................................................................................

123

6.8.1 8 EXTERNAL COMMAND ............................................................................................................

125

125

6.8.1 9 CIRCUIT BREAKER POSITION ................................................................................................

6.9

Settings for TRANSIENT DATA

127

6.10

Settings for the REAL TIME CLOCK

127

6.11

MARSHALLING of binary inputs, binary outputs and LED indicators

128

6.1 1 1 General .......................................................................................................................................

128

6.1 1.2 Marshalling of the BINARY INPUTS ..........................................................................................129

6.1 1.3 Marshalling of the OUTPUT RELAYS ........................................................................................

132

6.1 1.4 Marshalling of the LED INDICATORS (optional) ........................................................................

136

6.12

Settings for SERIAL COMMUNICATION (optional)

137

6.13

Putting the relay into operative mode (ON LINE)

139

6.14

Annunciations

140

6.14.1 Introduction.................................................................................................................................

140

6.14.2 MEASURED VALUES ................................................................................................................ 141

6.14.3 COUNTERS ...............................................................................................................................4 3

6.14.4ALARM /TRIP DATA .................................................................................................................143

6.1 4.5 DEMAND AMPERE METER ....................................................................................................

146

6.14.6 RUNNING HOURS ....................................................................................................................147

............................................................................................................

..................................................................................................................

............................................................................................................................

...........................................................................................................

................................................................................................................

.........................................................................................................

.

..................................................................................................

..........................................................................................

...................................

..................................................................

....................................................................

..............................................................................................................................

I

...

Introduction

MFR 7SJ551

I

6.1 4.7 MANUFACTURER DATA ..........................................................................................................

148

Resetting all settings t o factory settings

149

6.15

Testing and commissioning

151

6.16

6.16.1 General .......................................................................................................................................

151

6.1 6.2 Testing the measurement of operational values .......................................................................

152

6.1,6.3 Testing the motor status ............................................................................................................

153

153

6.1 6.4 Testing the rotor thermal overload protection ............................................................................

6.1 6.5 Testing the stator thermal overload protection ........................................................................156

6.1 6.6 Testing the thermal overload protection of non-rotating objects ............................................... 159

161

6.1 6.7 Testing the ambient temperature biasing ..................................................................................

162

6.1 6.8 Testing the start inhibit .........;....................................................................................................

163

6.1 6.9. Testing the emergency restart ..................................................................................................

163

6.1 6.10 Testing the overtemperature protection ...................................................................................

163

6.1 6.1 1 Testing the undercurrent protection.........................................................................................

6.1 6.1 2 Testing the low set overcurrent protection...............................................................................

164

6.16.1 2.1 Testing the definite time overcurrent protection............................................................

164

165

6.1 6.12.2 Testing the inverse time overcurrent protection............................................................

6.1 6.1 2.3 Testing the custom curve overcurrent protection ........................................................

165

166

6.1 6.1 3 Testing the high set overcurrent protection .............................................................................

166

6.16.1 4 Testing the unbalance protection ............................................................................................

167

6.1 6.1 5 Testing the locked rotor protection ..........................................................................................

168

6.1 6.1 6 Testing the zero speed protection ...........................................................................................

6.1 6.1 7 Testing the directional earthfault protection........................................................................ 168

169

6.16.1 8 Testing the undervoltage protection .....................................................................................

;.............169

6.1 6.1 9 Testing the overvoltage protection ............................................................................

6.1 6.20 Testing the breaker failure trip ............................................................................................ 170

6.1 6.21 Testing the curve switch ....................................................................................................... 170

172

6.1 6.22 Testing the block function ........................................................................................................

173

6.1 6.23 Testing the external command ............................................................................................

173

6.1 6.24 Testing the circuit breaker position ..........................................................................................

6.17

Commissioning using primary tests

174

6.1 7.1 Current circuit checks .................................................................................................................

174

6.17.2 Checking the reverse interlock scheme (if used) ...................................................................... 174

175

6.17.3 Testing the switching of binary inputs and outputs ....................................................................

176

6.17.4 Tripping test including circuit breaker ........................................................................................

6.1 7.5 Putting the relay into operation ..................................................................................................176

.................................................................................

....................................................................................................

..

.......................................................................................

1

Maintenance and trouble shooting

7

I

7.1

7.2

7.3

7.4

7.5

7.6

................................................................177

.........................................................................................................................................177

Self test ........................................................................................................................................177

Replacing the real time clock module ................................................................................... 178

Power failure test ........................................................................................................................179

General

Routine checks .................................................................................................................. 1 7 7

Trouble shooting ........................................................................................... .........................176

7.6.1 Replacing the mini-fuse ............................................................................................................... 180

Repairs .............................................................................................................182

Storage .............................................................................................................183

~

I

Appendix

.

.

.

.

A

B

C

D

E.

................................................................................................................................ 184I

............................... ...........................................................................

.............................................................................................................

....................................................................................................

.............................................................................................................................

General diagrams

185

Typical wiring diagrams

190

Motor application example

192

Default values

199

Setting tables .......................................................................................................................

204

I

"

'

MFR 7SJ551

F.

Introduction

Advice of return 7SJ55 ................................................................................................................

224

NOTE:

This instruction manual does not intend to cover ail

details in equipment, nor to provide for every

possible contingency occurring in connection with

installation, operation or maintenance.

a

-

Should further information be desired or should

particular problems arise which are not covered

sufficiently for the purchaser's purpose, the matter

should be referred to the local Siemens sales

office.

The contents of this instruction manual shall not

become part nor modify any prior or existing

agreement, commitment or relationship. The sales

contract contains the entire obligations of Siemens.

The warranty contained in the contract between the

parties is the sole warranty of Siemens. Any

statements contained herein do not create new

warranties nor modify the existing warranty.

1

1

" ,

Introduction

MFR 7SJ551

I

Introduction

1.I

Application

The relay MFR 7SJ551 is a modern protection unit

for low, medium and high voltage electricity

network components like motors, transformers,

blow-out coils, cables, overhead lines and capacitor

banks. The treatment of the electricity network star

point is oi no concern. The main applications of

MFR 7SJ551 are:

- protection against too high temperature

- protection against short circuit situations.

Too high temperatures in electric components

cause isolation ageing, which leads to lifetime

shortening of the component. Temperature

protection is accompanied with relatively low

currents and long time settings. Excessive

temperature rising can appear because of:

- overload

- asymmetrical load or phase loss

- underload (fans and pumps)

- stalled rotor

- multiple starting and tripping

- starting too long.

Short-circuits in electric components are

characterised by very high currents. These currents

1.2

Besides phase and earth short-circuit protection

MFR 7SJ551 is used as earth fault direction

protection for isolated, compensated and highohmic earthed networks.

Furthermore MFR 7SJ551 can be put on as backup protection for differential protection (for

generators, motors, transformers, lines or bus

bars) and distance protection.

MFR 7SJ551 provides a complete statistical record

of the protected electric component. The number of

alarms and trips is recorded in a memory. All

relevant alarm and trip data such as origin, day and

time, duration and trip levels can be read off on the

display. During an alarm or trip event the

magnitudes of the instantaneous values are stored

for a period of 3 seconds. This information can be

visualized with a PC connected to either the RS485 or the fibre optic interface. Furthermore, the

serial interfaces can be used for incorporating MFR

7SJ551 in a substation management system. For

data transmission an standardized protocol is used

in accordance with IEC 870-5.

Features

- Controller system with powerful microcontroller;

-

are acceptable only for short periods of time

because of the acting short-circuit strengths.

completely digitally measured value processing

and control from data acquisition and digitizing

of the measured values up to the trip and close

decision for the circuit breaker;

-

complete scope of functions required for the

protection of motors, transformers and cables;

- separate setting tables for the protection of

rotating and non-rotating network components;

- all current and voltage protection functions

(except thermal overload protection which is

based on True RMS measurement) based on

the values of the nominal frequency (digital

Fourier filtering); the direct current component

and the higher harmonic components are

suppressed and do not disturb the protection

functions;

- complete galvanic and reliable separation of the

internal processing circuits from the

measurement, control and supply circuits of the

system, with screened analogue input

transducers, binary input and output modules

and DC converter;

- thermal overload protection of rotating devices:

separate thermal replica for stator and rotor

based on True RMS current measurement

up to 2 heating time constants for the stator

thermal replica

separate cooling time constants for stator

and rotor thermal replica

ambient temperature biasing of thermal

replica

incorporation of additional heating effects of

asymmetrical currents;

"

I

MFR 7SJ551

- thermal overload protection of non-rotating

devices:

up to 2 heating time constants with extremely

wide setting ranges for optimal thermal

protection of cables and transformers

s externally adjustable time constant

ambient temperature biasing of thermal

replica;

Introduction

-

curve switch and blocking functions offering an

adaptive feature to change the relay

characteristics according to prevailing system

conditions (like motor status 'start' or 'running');

-

equipped with highly sophisticated protection

algorithms which offer optimal flexibility in

grading with other protection relays and with the

thermal limit curves of primary components;

-

software matrix for signalling and tripping relays;

-

real time clock: last 3 events are stored with real

time stamps of alarm and trip data;

-

continuous monitoring of the measured values

and the hardware and software of the relay;

-

storage of fault data, storage of instantaneous

values during a fault for fault recording;

-

communication with a PC or a substation

management system through an RS485

interface or a fibre optic interface (optional)

using an IEC 870-5-103 protocol.

- connection of up to 8 temperature sensors

(optional);

- multi-curve overcurrent and earth fault

protection:

e

insensitive for transients and DC

components

e

separate two-stage tripping characteristics

for phase and earth elements

four selectable internationally standardized

(BS 142, IEC 255-4) tripping characteristics

for phase elements: normally inverse, very

inverse, extremely inverse and definite time

e two additional tripping characteristics for the

earth element: long time earth fauit and

residual dependent time;

custom curves instead of standard curves

can be programmed to offer optimal flexibility

for both phase and earth elements;

"

6

MFR 7SJ551

1.3

Introduction

Implemented functions

MFR 7SJ551 contains the following functions.

Protection of motors

ANSI Protection of transformers

blow-out coils

cables

overhead lines

capacitor banks

Rotor thermal overload protection

Stator thermal overload protection

Ambient temperature biasing (optional)

Start inhibit

Emergency restart

Locked rotor protection (failure to accelerate)

Zero speed protection

Unbalance protection

Undercurrent protection

Overtemperature protection (optional)

Definite time overcurrent protection

49R

49

Inverse time overcurrent protection

Custom curve overcurrent protection

High set overcurrent protection

Curve switch

Directional earth fault protection (optional)

Undervoltage protection (optional)

Overvoltage protection (optional)

Breaker failure trip

Block

External command

Circuit breaker position

Self-monitoring

Real time clock

Event recording

Fault recording

Motor statistical data

LED indication

Operational values measurement

Running hours counter

PC programming possibility (optional)

Substation management system connection

(optional)

ANSI

Thermal overload protection

Ambient temperature biasing (optional)

49

Unbalance protection

Undercurrent protection

Overtemperature protection (optional)

Definite time overcurrent protection

46

37

86

48

14

46

37

51

51G

51 N

51

51 G

51 N

50

50G

67N

27

59

For a detailed description please refer to chapter 4.

Inverse time overcurrent protection

Custom curve overcurrent protection

High set overcurrent protection

Curve switch

Directional earth fault protection (optional)

Undervoltage protection (optional)

Overvoltage protection (optional)

Breaker failure trip

Block

External command

Circuit breaker position

Self-monitoring

Real time clock

Event recording

Fault recording

Component statistical data

LED indication

Operational values measurement

PC programming possibility (optional)

Substation management system connection

(optional)

51

51 G

51 N

51

51G

51N

50

50G

67N

27

59

MFR 7SJ551

1)

2

Design

2.1

Arrangements

The complete relay is fitted in a draw-out module of

Double Europe Format. This module is installed in

a housing 7XP20.

The optional interface unit (see figure 2.1)

provides:

- 8 x 3 screw terminals for up to 8 temperature

sensors;

- 9 pole female connector for the RS-485;

- a transceiver and a transmitter fibre optic

interface.

Two types of housings can be delivered:

- 7SJ551*-*A***- in horizontal housing 7XP20 for

-

panel flush mounting or cubicle installation.

7SJ5.51*-*B***- in vertical housing 7XP20 for

panel flush mounting or cubicle installation.

The housing has full sheet-metal covers as well as

a removable front cover with transparent plastic

window for panel mounting.

Guide rails are built in for the support of the plug-in

module. On the top and bottom plates of the

housing, contact areas which are electrically

connected to the housing are installed to mate with

the earthing springs of the module. Connection to

earth is made before the plugs make contact. An

Design

earth screw has been provided on the back of the

housing.

The heavy-duty current plug connectors provide

automatic shorting of the current transformer

circuits whenever the module is withdrawn.

All external signals are connected to combined

screw snap-on terminals on the backside of the

housing. For field wiring, the use of the screwed

terminals is recommended; snap-in connection

requires special tools. See figure 2.2.

The plug modules are labelled according to their

mounting position by means of a grid system (e.g.

XE-IV.2). The individual connections within a

module are numbered consecutively from left to

right (when viewed from the back).

The degree of protection for the housing is IP51,

for the terminals IP21.

For dimensions please refer to figure 2.3.

For surface mounting, surface mounting brackets

are deliverable in two sizes. The short one (depth

271 mm) is used for protection units without

mounted interface module. The long one (depth

288 mm) is used with mounted interface module.

MFR 7SJ551

Figure 2.1

Design

Interface unit

I

Figure 2 . % U N m h M B n ~ ~ r c ! & i M f S w ~ i ~ w )

1

1

MFR 7SJ551

$

2.2

Design

Dimensions

Figure 2.3 shows the dimensions of the housing.

7SJ551 housing for panel flush mounting or cubicle installation 7XP20

interface unit (optional)

recess hole (4 x)

1,

86.4

mounting hole (4

interface unit (optional)

Heavy-current connectors:

Screwed terminal for maximum 4 mm2.

Twin spring crimp connector in parallel for maximum 2.5 mm2.

Further connectors:

Screwed terminal for maximum 1.5 mm2.

Twin spring crimp connector in parallel for maximum 1.5 mm2.

Dimensions in mm

Figure 2.3

Dimensions for housing 7XP20 for panel flush mounting or cubicle installation

cl

MFR 7SJ551

Figure 2.4 shows the surface mounting bracket.

Figure 2.4

Dimensions for suriace mounting bracket for panel surface mounting

~esign'

"

I

MFR 7SJ551

I)

MFR 7SJ.551 can be mounted in standard 19 inch double height racks. Figure 2.5 shows the relevant

dimensions.

Figure 2.5

Mounting of MFR 7SJ.551 in standard 19"racks

Design

1

MFR7SJ551

2.3

Ordering data

2.3.1

Protection unit

[ Multi-Function Protection Relay

Rated current: rated freoluencv

Auxiilarv voltaae

Construction

I in horizontal housing 7XP20 for panel flush mounting or

cubicle mounting

in vertical housing 7XP20 for panel flush mounting or

cubicle mountina

Operating language

English

German

Connections

1 standard version

Desian

1

7SJ551 1

7

8

j

9

[a1

11

-

0

1

14

10 1

extended input / output: 3 extra inputs, 2 extra outputs,

4 extra LED indicators

extended input Ioutput: 3 extra inputs, 2 extra outputs,

4 extra LED indicators + voltage functions (single

phase)

2

extended input loutput: 3 extra inputs, 2 extra outputs,

4 extra LED indicators + voltage functions (single

phase) earth fault direction

(only in combination with e,,,,,iv, 1 A)

3

Interface module

15

1 without

RS485 + optical FSMA-interface

RS485 + optical FSMA-interface + connection for 2 RTD

elements ,

RS485 + optical FSMA-interface + connection for 8 RTD

elements

B

C

D

MFR 7SJ551

2.3.2

Design

interface unit

The interface unit can be ordered separately with the following ordering numbers. It is always possible to equip

the protection unit with the interface unit later on.

RS-485 + optical FSMA-interface ...................................................

RS-485 + optical FSMA-interface + connection for 2 RTD elements ..

RS-485 + optical FSMA-interface + connection for 8 RTD elements ..

2.3.3

Operation and evaluation software

Operation and evaluation software 7SJ551 Communication Utility

English ........................................................................................

German ....................................................... i....................... .......

@

2.3.4

G88700-C3526-L130

G88700-C3526-L131

G88700-C3526-L132

688700-M3587-R100

G88700-H3587-R200

Spare pans

Complete housing for panel flush mounting or cubicle installation .......

Front cap .....................................................................................

Enbedded software English 1) .........................................................

Enbedded software German 1) ........................................................

G88700-63526-b153

G88080-W-350-b110

G88080-C3526-L9X1

688080-C3526-L9XO

1) By ordering software please give the serienumber of the relay

2.3.5

Surface mounting bracket

Surface mounting bracket long (depth 288 mm) ...............................

Surface mounting bracket short (depth 271 mm) ..............................

2.3.6

Optical cable

Optical cable complete (5 meter).....................................................

Notebook connector ....................................................................

G88700-C3526-L154

G88080-X504-Lf 10

MFR 7SJ551

Technical data

I)

Technical data

3.1.1

laputs / outputs

Setting ranges

Full scale phase current

Full scale regular earth current

Full scale sensitive earth current

Irn,~

,,I

I, ,

,

Current transformer ratio

?

.age transformer ratio

Measuring circuits

Rated current I,

(3 x Iph+1 x 1),

Rated current I, ,,,itive

1A

Rated voltage U,

(1 x U)

100 V o r 110V

Rated frequency f ,

50 Hz or 60 Hz (selectable)

Burden at I, I U,

- 1 A current inputs

- 5 A current inputs

- 1 A sensitive earth current input

voltage input

capability phase current and regular earth

current path

- thermal (RMS)

10.05

VA

100

x I,

XI,

x I,

x I,

for 1 s

for10s

continuous

one half cycle

x I,

x I,

x I,

x I,

for 1 s

for 10 s

continuous

one half cycle

30

6

-

dynamic (pulse current)

Overload capability sensitive earth current path

thermal (RMS)

-

dynamic (pulse current)

250

75

20

4

200

''

MFR 7SJ551

i

Technical data

0

Accuracy

Phase currents and regular earth currents

for full scale current

,,I =

7

x ,I

0

0.05

to 0.5

X In

0

0.5

to 7

X ,1

- for full scale current

,,I =

14

x I,

0

0.1

to

1

X In

0

1

to 14

X In

- for full scale current, , I =

28

x In

0.2

to 2

X In

0

2

to 28

X 1,

-

Sensitive earth current

- for full scale current I,

,

,

= 0.35

0.003

to0.025

x I,

0

0.025

t00.35

X in

- for full scale current

,,,I

= 0.7

0.005

t00.05

X In

0

0.05

to 0.7

X In

- for full scale current I, ,

,= 1.4

* 0.01

x In

to 0.1

* 0.1

to 1.4

X In

X

50.025

I5

X

In

% of setting value

10.05

I 5

o/'

In

of setting value

50.1

I 5

X

In

10.00125

5 5

x I,

% of setting value

10.0025

I5

X

10.005

5 5

X

S0.0005

I 5

X

X

% of setting value

In

0

X

X

In

In

% of setting value

In

In

% of setting value

Voltage

0.005

0.01

t00.01

to 1.2

X

Un

x

un

Un

% of setting value

Auxiliary supply voltage

Power supply via integrated AC/DC or DCIDC

converter

Rated auxiliary voltage Uh

Permissible variations

-60VDC

24

19.2 - 7 2 V D C

Superimposed AC voltage,

peak to peak

I 12

6

%

%

at rated voltage

at limits of admissible voltage

Power consumption

quiescent

energized

picked up

-

Bridging time during failure or short circuit of auxiliary

voltage

20 ms at

500 ms at

40msat

500 rns at

40rnsat

500 rns at

I

110-250VDC

110-230VAC

8 8 - 3 0 0 ( ~ ~8 8~- 2 5 6 V A C

24 V DC

60 V DC

110VDC

250 V DC

110VAC

230 V AC

Technical data

MFR 7SJ551

vy duty command and signal contacts

Command (trip) and signal relays

basic version

e number

-

contacts per relay

- version with extended 1/0

number

contacts per relay

Switching capacity

MAKE

BREAK

DC

AC

4 command or signal relays

1 monitor relay

output 1 - 4 : 1 NO

monitor

: 1 NC

6 command or signal relays

1 monitor relay

: 2N0

output 1

output 2 - 5 : 1 NO

monitor

: 1 NC

1000 W N A

30 W150 VA

300 V

250 V

5 A continuous

30 A for 0.5 sec

Binary control inputs, number

-

basic version

- version with extended I/O

2 (can be marshalled)

5 (can be marshalled)

Current consumption

24 - 250 V DC

110- 230VAC

approx. 3 mA, independent of the operating voltage

Minimum signal time

2

5 ms

Detection time

5

10ms

Operating voltage

Interface module

0

RS485 serial interface

Floating interface for data communication

with PC or substation management system

Protocol standards

o

Transmission speed

Hamming distance

Connection

Transmission distance

Test voltage

isolated by opto-couplers

IEC 870-5 with VDEWIZVEI recommendation or

protocol DIN 19244

2400 Baud

4800 Baud

9600 Baud

19200 Baud

38400 Baud

d=4

9 pole female D connector

I 1000 m

500 V DC, 2 kV with rated frequency for 1 min.

I

MFR 7SJ551

Technical data

Fibre optic serial interface

e Floating interface for data communication with a isolated according IEC 874-2

control centre

IEC 870-5 with VDEWRVEI recommendation or

e Protocol standards

protocol DIN 19244

2400 Baud

Transmission speed

4800 Baud

9600 Baud

19200 Baud

38400 Baud

d=4

Hamming distance

integrated F-SMA connector for direct optical fibre

Connection

connection e.g. glass fibre 62.5/125 ym

820 nm

0

Optical wave length

ma%.8 dB

o Permissible line attenuation

2 km

8

Transmission distance

factory setting 'light off' (configurable with 2 jumpers)

Signal setting

Temperature sensors

o Floating interface isolated from the main relay

and the serial interfaces

o Number of temperature sensors

Type

9

Temperature range

Connection terminals

Distance

Cable resistance

Accuracy

2 or 8

Pt100 or

Nil 00 or

Nil20

0 to 200°C

3 for each sensor

r 150 m

r 25 S2 pro wire

<

3 "C

I

MFR 7SJ551

1

# .2

Technical data

Electrical tests

Standards for general product testing

- Test standards

EN 5501 1

EN 68-2

IEC 255-5

IEC 255-22-1

IEC 255-6

IEC 801-2

IEC 801-3

IEC 801 -4

IEC 801-5

VDE 0435 part 303

DIN 40040

DIN 40048-8

Insulation tests

@High

voltage test (routine test)

injecting 50 Hz, 2 kV AC. for 1 minute between the

housing and one pair of shortened circuit terminals

(auxiliary power, current inputs, voltage input, external

control inputs and output contacts); all the other pairs

of circuit terminals are connected to the housing; this

successively for &I pairs of circuit terminals

- Measurement of insulation resistance

test voltage 500 V DC

- Impulse voltage test (type test)

injecting 3 positive and 3 negative 5 kV impulse

voltages both common mode and differential mode

(1.2150 ps between tested circuit and earth)

test voltage 500 V DC

-

Repeated measurement of isolation resistance

-

Conclusions

no flash-over or break-down between tested circuit

and earth or between tested circuit and any other

terminal; isolation resistance in all cases exceeded

100 Ms2

turbance immunity tests for the auxiliary supply voltage

- Proper operation range of input voltages

24

110

110

-

-

60 V DC

25OVDC

230VAC

19.2

88

88

-

Spike test (recommended by KEMA)

-

Rise time

Half amplitude width

R,

Differential mode voltage on auxiliary supply

voltage terminal

150 ns

50 ps

5Q

1 kV

72 V DC

300 V DC

276 V AC

MFR 7SJ551

I

Technical data

Disturbance immunity of the current and voltage frequency

-

Maintenance of accuracy

e for the 50 Hz model

for the 60 Hz model

Harmonic immunity

Immunity level to high frequency harmonic current

waveforms

- 10% 3th harmonic

- 10% 5th harmonic

influence on operating current c 1%

influence on operating current < 1%

High frequency disturbance test

- Standard

-

Test frequency

- Ri

- Repetition rate

-

Test duration

IEC 256-6/255-22-1

1 MHz

200 n

400 shotsls

2s

- Common mode voltage

- Differential mode voltage

Electrostatic discharge test

- Standard

- Level

-

Discharge voltage

IEC 801 -2

3

4 kV

Radiated electromagnetic fields test

- Standard

-

Level

- Test frequency

- Magnetic field strength

- Directions

IEC 801-3

3

0.1 5 - 300 Mhz

10 V/m

front, top and side

0

Electrical fast transient test

lmmunity to noise generated from high energy

transient generator

Standard

- Level

Rise time

- Half amplitude width

Ri

- Repetition rate

Burst duration

- Burst period

- Test duration

- Common mode voltage

between circuit and case

between auxiliary supply and case

-

IEC 801-4

3

5 ns

50 ns

50 R

5 kHz

15 ms

300 ms

10 s

MFR 7SJ551

Technical data

io frequency interference test

-

Standard

-

Radiation

- Line interference on all terminals

Surge test

- Standard

3.1.3

Mechanical stress test

Amplitude

- Acceleration

- Repetition rate

3.1.4

IEC 801-5

IEC 68-2-6 and DIN 40048-8

1 0 - 5 5 HZ

15 mm

2G

20 sweeps in 3 directions

Climatic stress tests

Permissible ambient temperature

-

During service

- During storage

- During transport

- Storage and transport

-10 "C to +55 "C

-25 "C to +70 "C

-25 "C to +55 "C

standard works packing

Humidity class

DIN 40040, Class F

IEC 68-2-30

Cyclic damp heat test

- Standards

-

Cycle number

- Temperature range

- Relative humidity

DIN 40040, Class F

IEC 68-2-30

6

25 "C to 55 "C

95%

Storage test (recommended by KEMA)

- Duration

16 hours at

16 hours at

-25 "C and

1.70 "C

We recommend that all units are installed such that they are not subjected to direct sunlight, nor to large

temperature fluctuations which may give rise to condensation.

~

I

Technical data

MFR 7SJ551

3.1.5

MFR 7SJ551 is designed for use in industrial

environment, for installation in standard relay

rooms and compartments so that with proper

installation electro-magnetic compatibility (EMC)

is ensured. The following should also be heeded:

-

All contactors and relays which operate in the

same cubicle or on the same relay panel as the

MFR 785551 should, as a rule, be fitted with

suitable spike quenching elements.

-

All external connection leads in substations

from 100 kV upwards should be screened with a

screen capable of carrying power currents and

should be earthed at both sides. No special

measures are normally necessary for

- Devices:

M F R 7SJ551 protective devices in housings or

in factory fitted subracks are always tested as

complete units and are interchangeable as

complete units without restrictions.

-

0

Service conditions

substations of lower voltages.

-

It is not permissible to withdraw or insert

individual modules under voltage. In the

withdrawn condition, some components are

electrostatically endangered; during handling

the standards for electrostatically endangered

components must be observed. The modules

are not endangered when plugged in.

WARNING! The relay is not designed for use in

residential, commercial or light-industrial

environment as defined in EN 50081.

When it is necessary to exchange a device or

module, the complete parameter assignment

should be repeated. Respective notes are

contained in Chapters 5 and 6.

Modules:

MFR 7SJ551 plug-in modules are

interchangeable.

3.1.7

Design

Housing

7XP20; refer to section 2.1

Dimension

refer to section 2.2

Weight

protection unit

- interface unit

approximately 4

approximately 0.5

-

Degree of protection according to DIN 40050

- Housing

-

Terminals

IPS1

IP21

kg

kg

0

MFR 7SJ551

l3l.i2

,

Technical data

Component data

Setting ranges Isteps

Full load current

- Setting range

- Steps

e

0

*

0.05

1

10

IIflc/ln

li~c/ln

<

5 IflCn <

5I c n 5

1

10

28

0.05

to

28

to

1

to

10

0.001

0.01

0.1

No load current (motors)

- Setting range

Ino ioad/ln

)S

Thermal overload protection

3.3.1

Rotor thermal overload protection

0.05

Setting ranges 1 steps

Permissible start-up current

- Setting range

- Steps

* 0.05

5 lstan/ln <

*

1

5I a n <

10

5I a n S

Istartfln

1

10

28

Permissible start-up time

- Setting range

- Steps

*

1

I

tstan

-

tstart

<

10 s

'ermissible number of starts

- from warm motor condition

-

from cold motor condition

,,,n

%old

Unbalance factor

kin"

Cooling down factor rotor

Cstop,rotor

1

(steps 0.001)

~

MFR 7SJ551

Technical data

@

Trip time calculation

2

2

fh,rotor (t) = loeating + [Itn,rotor(t = 0)-

!Latins

I. exP(+)

rot or

krotor

Trotor

1flc

lheating

!normal

Iinverse

Ith,rotor

eth,rotor

tirip

I

Accuracy trip time

overload factor rotor

thermal time constant rotor

full load current

equivalent heating current

normal component of the phase currents

inverse component of the phase currents '

thermal load current rotor

thermal reserve rotor

trip time

actual symmetric three phase step current

preload current rotor

the higher value of 1 s and 2% of zrot0,

"

MFR 7SJ551

I

Technical data

e.2 Stator thermal overload protection

,

I

Setting ranges / steps

Overload factor stator

b a t

Thermal time constant stator 1

Thermal time constant stator 2

- Steps for 71,stat and 22,stat

T ~ , , ~ ~ ~

a

*

1

10

100

,I

,,t

t

Itsta,

c

<

<

TI,^,,^

10 slminlh

I00 slminlh

999 slmin

Weighing factor

Pweight

Cooling down factor stator

Cstop.stator

&tr;inS

level

Setting range

*

0

o

0

1

10

5, , ,e

1 ow,

18w,,

owam

<

<

<

1 O/o

loO/o

95%

1

to

1.5

to 999 min

to 999 min

switchable between seconds, minutes

and hours

0.01

slminfh

0.1

slminlh

1

slmin

1s

I s

0

to

95

0.001

0.01

0.1

O/O

O/o

O/o

70

Trip time calculation

Ith,stator

thermal load current stator

largest True RMS phase motor current

lTNe

RMS

thermal reserve stator

IR C

full load current

ftnp

trip time

Accuracy trip time

the higher value of 1 s and

2% of [pweight Tl.stat f (1 - ~welght)'

'

72,statI

I

l

"

r

MFR 7SJ551

3.3.3

Technical data" '

Thermal overload protection of non-rotating objects

I

1

Setting ranges / steps

1

Overload factor

k

Thermal time constant 1

Thermal time constant 2

- Steps for 7, and 72

71

72

1

I

I

I

B

1

10

100

It,,,,

5,,t

5,,t

c

<

5

I0 slminlh

100 slminlh

999 slmin

Weighing factor

Pweight

Adjusting factor

Cad]

Warning level

- Setting range

- Steps

1 €Iwam

e

0

,5, , I€

0

1

5,wI€

e

10

1

to

1.5

1 s to 999 min

1 s to 999 min

switchable between seconds, minutes

and hours

0.01

s/rnin/h

0.1

s/min/h

1

slmin

0

to

1

0.01

to

10

0 ~ ~ 7

<

1%

<

5

loO/o

95%

Trip time calculation

t =t,,,

for

€4, =O

Ith

,,,I

RMS

0th

IRC

hip

Accuracy trip time

thermal load current

largest True RMS phase current

thermal reserve

full load current

trip time

the higher value of 1 s and 2% of [pweight

, 71+ (1

weight) ' 2211

-

MFR 7SJ551

Technical data

Ambient temperature biasing (optional)

Setting ranges 1 steps

Maximum ambient temperature , ,T

Nominal ambient temperature

Tmi,

- Steps for, ,T and Tmin

e

0

ST

<

1 "c

0

1

I T

<

10°C

0

10

I T

< I00 "C

0

100

ST

I 200 "C

0

0

0.001

0.01

0.1

1

to

to

200

200

"C

"C

"c

"C

"C

"C

Trip time calculation

@,

bient

-

ambient

'

'

ni,

. k2 . lf,c

Tmax m

.-.i

I

eth = 0

t = t,p

for

NOTE:

This trip time calculation applies to rotor

thermal overload protection, stator thermal

overload protection and thermal overload

protection for non-rotating objects.

Ith,amblent thermal load current adjusted with

ambient temperature

Ith

thermal load current

thermal load adjustment with ambient

Cambient

temperature

Tarnbient

measured ambient temperature

k

overload factor

I~IC

full load current

8th

thermal reserve

tt ri p

trip time

MFR 7SJ551

Technical data

Start inhibit

3.5

1

Setting ranges / steps

Stator start inhibit level

Setting range

-

estator

Steps

1 8stat,r

1 esta0,

1 es,,o,

0

1

10

e

e

Start inhibit release time

- Setting range

- Steps

<

<

I

1%

10%

100%

tinh

0 s to 166 min

switchable between seconds, minutes

and hours

siminlh

0.001

0.01

s/min/h

0.1

slmin

1

s/m i n

Calculation rotor start inhibit level

krotor =

=rotor

=

d

ncold

- nwarrn

"bold

-"cold

. f start

start

krotor

%old

nwarm

Trotor

tstm

I~IC

QrOtor=

a,:'

c o t or

.

.~

I C

istafi

Qrotor

overload factor rotor

permissible number of starts from cold

motor condition

permissible number of starts from warm

motor condition

thermal time constant rotor

permissible start-up time

full load current

permissible start-up current

rotor start inhibit level

MFR 7SJ551

Technical data

Locked rotor protection

Setting ranges / steps

Permissible locked rotor time

- Setting range

-

tl,

Steps

0

0

a

0

1

10

100

Itl,

I

t,,

Itl,

<tl,

<

<

<

I s

10s

100s

I 200 s

Trip time calculation

ttnp

Istart

I

s 5

Pick-up value

Delay time

3.7

trip time

permissible start-up current

largest phase motor current

% of setting value

maximum from 10 ms and 2% of tl,

Zero speed protection

Setting ranges / steps

Zero speed detection time

- Setting range

- Steps

a

0

1

10

100

I

,,,,t

I

,,,,t

I

,,t

I

,,t

~E,O

<

<

<

1 s/min/h

10 s/min/h

100 slmin

I 166 slmin

0 s to 166 min

switchable between seconds, minutes

and hours

0.001

s/min/h

0.01

s/min/h

0.1

s/min

1

s/min

Tolerances

Delay time

maximum from 10 ms and 2% of,,,,t

MFR 7SJ551

3.8

Technical data

Unbaiance protection

Setting ranges / steps

Unbalance pick-up

Izph

0.03

to

1

(steps 0.001 j

Unbalance time multiplier

Setting range

- Steps

I

tzp

<

Is

a

0

Itzp

<

10s

1

5tZp

I 25s

10

-

Bypass time (only for rotating objects)

Setting range

fbypass

- Steps

0

stzp

<

1S

ItPP

<

10s

0

1

Itzp

< 100s

o

10

I

tap

I 200 s

100

-

Trip time calcuiation

trip

linv

Reset time

trip time

inverse component of the phase currents

approximately 40 ms

Tolerances

Pick-up value

Delay time

% of setting value

maximum from 10 ms and 2% of t,",

I5

Drop off / pick up ratio

Referring to unbalance pick-up value I*,

0.95 zt 0.01

MFR 7SJ551

-

Steps

0

0.025

e

1

Technical data

<

<

5I

5 Iqdln

Time multiplier

- Setting range

- Steps

0

0

It,

e

1

S

1

1.4

~ O P

<

<

I s

10s

normally inverse

very inverse

extremely inverse,

long time earth fault

residual dependent time

custom curve

Characteristics

5% of setting value

Measuring tolerance

Time tolerance

maximum from 10 ms and 2% of time setting value

Drop-off ratio

0.95 h 0.01

Directional determination

Measurement

with Ieand Uo

Measuring principle

active power.(cos $ measurement) or

reactive power (sin 4 measurement)

Directional trip condition

forward or

backward

Rotation angle

- Setting range

- Steps

o

$e

0

S

<

I

1

I

' <

10

10

$

5

45

(negative range similar)

CT angle correction

1,s 100 mA

- 100 mA < 1,s 200 mA

,I > 200 mA

- Steps

56

<

0"

56

<

1"

61

62

53

1"

5"

"

r

Technical data

MFR 7SJ551

Q

Undercurrent protection

Setting ranges / steps

Undercurrent pick-up

Setting range

Steps

0

0.05

I

I

I

e

1

0

10

I

n

-

ldln

<

<

I

Undercurrent delay time

Setting range

Steps

-

&ass

1

10

28

t I<

0 s to 166 rnin

switchable between seconds, minutes

and hours

0.001

s/mi n/h

0.01

s/min/h

0.1

slmin

1

s/min

time (only for rotating objects)

tbypass

- Setting range

- Steps

a

0

1

10

I

t,,

I

t,,

<

<

It,,

<

1s

10s

100s

0

to

0.001

0.01

0.1

100

s

S

S

S

Tolerances

Pick-up value

Delay time

5

% of setting value

maximum from 10 ms and 2% of tl<

I:

Drop off / pick up ratio

Referring to undercurrent pick-up value I<

1.05 i 0.01

Technical data

MFR 7SJ551

3.1 0

Overtemperature protection (optional)

Setting ranges / steps

Type setting temperature sensor

Alarm level

- Setting range

- Steps

8

0

I T

I

IT

10

IT

a

100

ST

Trip level

- Setting range

- Steps

0

ST

a

1

ST

0

10

I T

100

ST

<

<

<

<

<

<

<

I

Pt100 or

Nil 00 or

Nil 20

"c

1

IOOC

100 OC

200 "C

1 "C

10°C

100 "C

200 "C

Tolerance

Pick-up value

5 3

"C

MFR 7SJ551

Technical data

@ )II

Low set overcurrent protection

3.1 1.I

Definite time overcurrent protection

Setting ranges Isteps

Phase overcurrent pick-up

- Setting range

- Steps

e

a

0.05

1

10

5I

I

I

n

n

n

<

<

I

1

10

28

Regular earth overcurrent pick-up

- Setting range

- Steps

le>/ln

Sensitive earth overcurrent pick-up

- Setting range

-

Steps

0.003

1

le>/ln

<

I

Illn

I

I

n

<

1

1.4