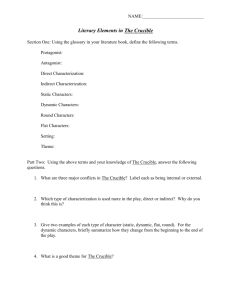

BS EN 12592:2014 BS 2000-47:2014 BSI Standards Publication Bitumen and bituminous binders — Determination of solubility BS EN 12592:2014 BRITISH STANDARD National foreword This British Standard is the UK implementation of EN 12592:2014. It supersedes BS EN 12592:2007 which is withdrawn. The UK participation in its preparation was entrusted to Technical Committee PTI/13, Petroleum Testing and Terminology. A list of organizations represented on this committee can be obtained on request to its secretary. This publication does not purport to include all the necessary provisions of a contract. Users are responsible for its correct application. © The British Standards Institution 2014. Published by BSI Standards Limited 2014 ISBN 978 0 580 77112 5 ICS 75.140; 91.100.50 Compliance with a British Standard cannot confer immunity from legal obligations. This British Standard was published under the authority of the Standards Policy and Strategy Committee on 30 November 2014. BS 2000 Series Energy Institute, under the brand of IP, publishes and sells all Parts of BS 2000, and all BS EN and BS ISO petroleum test methods that would be part of BS 2000, both in its annual publication “IP Standard Test Methods for analysis and testing of petroleum and related products, and British Standard 2000 Parts” and individually. Amendments/corrigenda issued since publication Date Text affected EN 12592 EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM November 2014 ICS 75.140; 91.100.50 Supersedes EN 12592:2007 English Version Bitumen and bituminous binders - Determination of solubility Bitumes et liants bitumineux - Détermination de la solubilité Bitumen und bitumenhaltige Bindemittel - Bestimmung der Löslichkeit This European Standard was approved by CEN on 16 August 2014. CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member. This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions. CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom. EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12592:2014 E BS EN 12592:2014 EN 12592:2014 (E) Contents Page Foreword ..............................................................................................................................................................3 1 Scope ......................................................................................................................................................4 2 Normative references ............................................................................................................................4 3 Terms and definitions ...........................................................................................................................4 4 Principle ..................................................................................................................................................4 5 Reagents and materials ........................................................................................................................4 6 Apparatus ...............................................................................................................................................5 7 Sampling .................................................................................................................................................5 8 8.1 8.2 8.3 Procedure ...............................................................................................................................................5 Test conditions ......................................................................................................................................5 Preparation of crucible ..........................................................................................................................6 Test method............................................................................................................................................6 9 Calculation ..............................................................................................................................................6 10 Expression of results ............................................................................................................................7 11 11.1 11.2 Precision .................................................................................................................................................7 Repeatability...........................................................................................................................................7 Reproducibility .......................................................................................................................................7 12 Test report ..............................................................................................................................................7 Bibliography ........................................................................................................................................................9 2 BS EN 12592:2014 EN 12592:2014 (E) Foreword This document (EN 12592:2014) has been prepared by Technical Committee CEN/TC 336 “Bituminous binders”, the secretariat of which is held by AFNOR. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by May 2015 and conflicting national standards shall be withdrawn at the latest by May 2015. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 12592:2007. In comparison with EN 12592:2007, the following significant changes have been made: — changed/added wording of the Warning in the Scope; — the function of the powdered glass (subclause 6.1.2) as filter aid has been highlighted in the standard; — preparation of the test sample according to EN 12594 in subclause 8.3 has been added. According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. 3 BS EN 12592:2014 EN 12592:2014 (E) 1 Scope This European Standard specifies a method for determining the degree of solubility of bituminous binders having little or no mineral matter other than recovered bituminous binders from asphalt mixes, in a specific solvent. Toluene is used as the solvent for reference tests. NOTE Bituminous binders will have varying solubility in different solvents. WARNING — Use of this European Standard can involve hazardous materials, operations and equipment. This European Standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this European Standard to identify the hazards and assess the risks involved in performing this test method and to implement sufficient control measures to protect individual operators (and the environment). This includes appropriate safety and health practices and determination of the applicability of regulatory limitations prior to use. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 58, Bitumen and bituminous binders — Sampling bituminous binders EN 1425, Bitumen and bituminous binders — Characterization of perceptible properties EN 12594, Bitumen and bituminous binders — Preparation of test samples ISO 4793, Laboratory sintered (fritted) filters — Porosity grading, classification and designation ISO 5272, Toluene for industrial use — Specifications ISO 5280, Xylene for industrial use — Specification 3 Terms and definitions For the purposes of this document, the following term and definition apply. 3.1 solubility portion of material that is soluble in a specific solvent 4 Principle A sample of bituminous binder is dissolved in a solvent. The solution is filtered through a layer of powdered glass in a sintered crucible. The insoluble material is then washed, dried, and weighed. 5 Reagents and materials Examples of specific solvents are given in 5.1 and 5.2. 5.1 4 Toluene, conforming to ISO 5272. BS EN 12592:2014 EN 12592:2014 (E) 5.2 6 Xylene, conforming to ISO 5280. Apparatus Usual laboratory apparatus and glassware, together with the following: 6.1 Filtering apparatus NOTE 6.1.1 Assembled as illustrated in Figure 1. Details of the component parts are as given in 6.1.1 to 6.1.5. Sintered glass crucible, porosity P4 (see ISO 4793), effective diameter approximately 30 mm. 6.1.2 Powdered glass, borosilicate glass powder, particle diameter approximately between 50 µm and 80 µm. The powdered glass functions as filter aid. The granulometry of powdered glass may evolve over time. It is recommended to check the granulometry prior to using the powdered glass, if used. Instead of powdered glass, glass fibre or Whatman filter grade 934 or equivalent may also be used. However, the use of powdered glass is the reference method. When using glass wool or filter as filter aid, a Gooch crucible may also be used. 6.1.3 Filter flask, 250 ml or 500 ml, heavy-wall, with a side tube. 6.1.4 Filter tube, 40 mm to 42 mm inside diameter. 6.1.5 Rubber tubing or adaptor, for holding the crucible on the filter tube. Other suitable assemblies permitting vacuum filtration with a crucible can be used. 6.2 Oven, capable of maintaining a temperature, T, of 15 °C to 25 °C above the boiling temperature of the selected solvent. 6.3 7 Balance, accurate to 0,2 mg and readable to 0,1 mg. Sampling Take the test sample in accordance with EN 58, taking all necessary safety precautions and ensuring that the test sample is representative of the laboratory sample from which it is taken. Ensure that the laboratory sample is homogenous and not contaminated (see EN 1425). If the sample contains water, heat a representative portion of between 100 g and 200 g at a temperature not exceeding 130 °C stirring constantly until the binder ceases to foam. 8 8.1 Procedure Test conditions Normally the temperature at which the test is run is not critical and may be performed at the laboratory air temperature. For reference tests, the flask with the sample in solution shall be placed in a water bath maintained at (25 ± 2) °C for 1 h before filtering. Crystallized paraffins may disturb the analysis of the samples with high wax content. To avoid this, use the higher test temperature of 40 °C. 5 BS EN 12592:2014 EN 12592:2014 (E) 8.2 Preparation of crucible Weigh (3,0 ± 0,1) g of clean dried powdered glass into the crucible. Place the crucible in the filter tube (6.1.4). Wash the powdered glass (6.1.2) with a small portion of the selected solvent (see Clause 5) and filter carefully into the flask with or without vacuum, as necessary. Repeat the washing process several times. Place the crucible on a heater or steam bath for 30 min before placing in the oven (6.2) at the temperature T (see 6.2) for at least 20 min. Remove the crucible from the filter tube and cool in a desiccator for 25 min to 35 min and determine the mass to the nearest 0,1 mg. Repeat the drying and weighing until constant mass is obtained, i.e. the difference between the two weights shall not exceed 0,5 mg. 8.3 Test method Prepare the test sample according to EN 12594 in order to homogenize it and transfer (2 ± 1) g of the dry sample, if necessary, using a warmed knife, into a suitable weighed container, e.g. Erlenmeyer flask. Determine the mass of the container and sample to the nearest 1 mg. Add 100 ml of the selected solvent to the container in small portions with continuous agitation until all lumps disappear and no undissolved sample adheres to the container. For reference testing stopper or cover the container and set aside for at least 15 min (see 8.1). Place the previously prepared and weighed crucible in the filter tube (6.1.4). Wet the powdered glass with a small portion of solvent and filter the solution carefully into the flask through the powdered glass of the crucible with or without vacuum as necessary. If the insoluble matter is appreciable, retain as much of it as possible in the container until the solution has drained through the filter aid. Wash the container with a small amount of solvent and, using a stream of solvent from a wash bottle, transfer all insoluble matter to the crucible. If necessary use a glass rod to remove any insoluble matter adhering to the container and transfer it into the crucible. Thoroughly rinse the glass rod and container and transfer it with the crucible. Wash the insoluble matter in the crucible with solvent until the filtrate flows substantially colourless, then apply strong vacuum to remove the remaining solvent or place the crucible into a vacuum desiccator. Remove the crucible from the tube or desiccator, wash the bottom free of any dissolved matter, and place the crucible on a heater or a steam bath for 30 min. Place in an oven at the temperature T (see 6.2) for at least 20 min. Remove the crucible from the filter tube and cool in a desiccator for 25 min to 35 min and determine the mass to the nearest 0,1 mg. Repeat the drying and weighing until constant mass is obtained, i.e. the difference between the two weights is not more than 0,5 mg. Repeat the determinations, making at least two valid determinations. Two solubility determinations shall be considered valid if they do not differ by more than 0,2 % mass. 9 Calculation Calculate either the total mass percentage of insoluble matter (xi) or the mass percentage of soluble matter (xs), of the sample in the solvent as follows: x i = mA × 100 m B (1) × 100 xs = 100 − mA m B (2) where xi 6 is the percentage of insoluble matter, in percent; BS EN 12592:2014 EN 12592:2014 (E) xs is the percentage of soluble matter, in percent; mA is the mass of insoluble material, in grams; mB is the mass of the dry sample, in grams. 10 Expression of results Express the solubility as the percentage of mass of soluble material xs, to the nearest 0,05 %, as the mean of the two valid determinations. 11 Precision 11.1 Repeatability The difference between two test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed 0,10 % absolute in only one case in twenty. 11.2 Reproducibility The difference between two single and independent results obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed 0,15 % absolute in only one case in twenty. These precision data are not automatically applicable to modified bitumen, and for modified bitumen, they should only be used for guidance until criteria data are available. 12 Test report The test report shall contain at least the following information: a) type and complete identification of the sample under test; b) reference to this European Standard; c) solvent used; d) results obtained (see Clause 10); e) any deviation, by agreement or otherwise, from the procedure specified; f) date of the test; g) type of filtrating medium (glass powder, glass fibre, filter) used. 7 BS EN 12592:2014 EN 12592:2014 (E) Key 1 sintered glass crucible 2 rubber tubing 3 filter tube 4 polychloroprene stopper 5 filter flask Figure 1 — Filtering apparatus assembly 8 BS EN 12592:2014 EN 12592:2014 (E) Bibliography [1] ASTM D2042-01, Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene 9 This page deliberately left blank This page deliberately left blank NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW British Standards Institution (BSI) BSI is the national body responsible for preparing British Standards and other standards-related publications, information and services. BSI is incorporated by Royal Charter. British Standards and other standardization products are published by BSI Standards Limited. About us Revisions We bring together business, industry, government, consumers, innovators and others to shape their combined experience and expertise into standards -based solutions. Our British Standards and other publications are updated by amendment or revision. The knowledge embodied in our standards has been carefully assembled in a dependable format and refined through our open consultation process. Organizations of all sizes and across all sectors choose standards to help them achieve their goals. Information on standards We can provide you with the knowledge that your organization needs to succeed. Find out more about British Standards by visiting our website at bsigroup.com/standards or contacting our Customer Services team or Knowledge Centre. Buying standards You can buy and download PDF versions of BSI publications, including British and adopted European and international standards, through our website at bsigroup.com/shop, where hard copies can also be purchased. If you need international and foreign standards from other Standards Development Organizations, hard copies can be ordered from our Customer Services team. Subscriptions Our range of subscription services are designed to make using standards easier for you. For further information on our subscription products go to bsigroup.com/subscriptions. With British Standards Online (BSOL) you’ll have instant access to over 55,000 British and adopted European and international standards from your desktop. It’s available 24/7 and is refreshed daily so you’ll always be up to date. You can keep in touch with standards developments and receive substantial discounts on the purchase price of standards, both in single copy and subscription format, by becoming a BSI Subscribing Member. PLUS is an updating service exclusive to BSI Subscribing Members. You will automatically receive the latest hard copy of your standards when they’re revised or replaced. To find out more about becoming a BSI Subscribing Member and the benefits of membership, please visit bsigroup.com/shop. With a Multi-User Network Licence (MUNL) you are able to host standards publications on your intranet. Licences can cover as few or as many users as you wish. With updates supplied as soon as they’re available, you can be sure your documentation is current. For further information, email bsmusales@bsigroup.com. BSI Group Headquarters 389 Chiswick High Road London W4 4AL UK We continually improve the quality of our products and services to benefit your business. If you find an inaccuracy or ambiguity within a British Standard or other BSI publication please inform the Knowledge Centre. Copyright All the data, software and documentation set out in all British Standards and other BSI publications are the property of and copyrighted by BSI, or some person or entity that owns copyright in the information used (such as the international standardization bodies) and has formally licensed such information to BSI for commercial publication and use. Except as permitted under the Copyright, Designs and Patents Act 1988 no extract may be reproduced, stored in a retrieval system or transmitted in any form or by any means – electronic, photocopying, recording or otherwise – without prior written permission from BSI. Details and advice can be obtained from the Copyright & Licensing Department. Useful Contacts: Customer Services Tel: +44 845 086 9001 Email (orders): orders@bsigroup.com Email (enquiries): cservices@bsigroup.com Subscriptions Tel: +44 845 086 9001 Email: subscriptions@bsigroup.com Knowledge Centre Tel: +44 20 8996 7004 Email: knowledgecentre@bsigroup.com Copyright & Licensing Tel: +44 20 8996 7070 Email: copyright@bsigroup.com