Commercial Building Construction Project Report - Pantheon Bhuj

advertisement

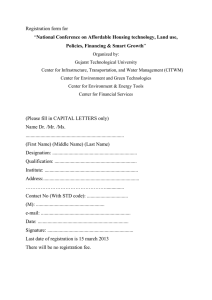

293569 “Planning, Designing and Construction of Commercial Building at Pantheon Bhuj” A PROJECT REPORT Submitted by SUTHAR RAJESHKUMAR BACHUBHAI 190150106050 In partial fulfillment for the award of the degree of BACHELOR OF ENGINEERING In CIVIL ENGINEERING GOVERNMENT ENGINEERING COLLEGE BHUJ UNDER THE GUIDANCE OF Prof. DEVANG MAJITHIYA (ASSISTANT PROFESSOR) Civil Engineering Department CIVIL ENGINEERING DEPARTMENT GOVERNMENT ENGINEERING COLLEGE, BHUJ (INDIA) -370001 2022-2023 i Gujarat Technological University GEC BHUJ 293569 CERTIFICATE This is to certify that the Internship entitled "Planning, Designing and Construction of Commercial Building at Pantheon Bhuj " submitted by SUTHAR RAJESHKUMAR BACHUBHAI (190150106050) in partial fulfillment of the requirements for the award of the degree of "Bachelor of Engineering” in Civil Engineering during the academic year 2022-23 (8th Semester), of the Government Engineering College, Bhuj is record of his own work carried out under our supervision and guidance and matter embodied in this report has not been submitted to any other University or Institution for award of any degree. Prof. DEVANG MAJITHIYA Internal Guide Head of Department Civil Engineering Department Government Engineering College, Bhuj (India) -370001 ii Gujarat Technological University GEC BHUJ 293569 iii Gujarat Technological University GEC BHUJ 293569 iv Gujarat Technological University GEC BHUJ 293569 CIVIL ENGINEERING DEPARTMENT GOVERNMENT ENGINEERING COLLEGE, BHUJ (INDIA) -370001 2022-2023 DECLARATION We hereby declare that the Internship / Project report submitted along with the Internship / Project entitled “Planning, Designing and Construction of Commercial Building at Pantheon Bhuj” submitted in partial fulfilment for the degree of Bachelor of Engineering in civil to Gujarat Technological University, Ahmedabad, is a bonafide record of original project work carried out by me / us at space consultancy. under the supervision of Mr. Hitesh Donga and that no part of this report has been directly copied from any students’ reports or taken from any other source, without providing due reference. Name of the Student Sign of Student Suthar Rajeshkumar Bachubhai _______________ v Gujarat Technological University GEC BHUJ 293569 ACKNOWLEDGEMENT Apart from my effort, the success of this report depends on the encouragement and guidelines by all the faculty member of the Civil Engineering Department. I take this opportunity to thank all the faculty of the Department which helped me to complete this task. I wish to express our sincere gratitude to our Internal Guide Prof. DEVANG MAJITHIYA for helping us through our internship by giving me the necessary suggestions and advices along with their valuable co-ordination in completing this internship. I would like to thank Mr. Hitesh Donga (MIGHTY SCALES INFRA LLP) for giving us this opportunity to work in the organization. Thus, in conclusion to the above said, I once again thank the staff members of "MIGHTY SCALES INFRA LLP" for their valuable support in completion of the project. Sincerely, SUTHAR RAJESH B. 190150106050 vi Gujarat Technological University GEC BHUJ 293569 ABSTRACT The purpose of Training is to expose students to real work of environment experience and at the same time, to gain the knowledge through hands on observation and job execution. Moreover, this practical training program allows students to relate theoretical from the industrial training, the students will also develop skills in work ethics, communication, management and others. knowledge with its application in the manufacturing industry. The objectives of industrial training are: • To provide students the opportunity to test their interest in a particular career before permanent commitments are made. • To develop skills in the application of theory to practical work situations. • To develop skills and techniques directly applicable to their careers. • To expose students to real work environment experience, gain knowledge in writing report in technical works/projects vii Gujarat Technological University GEC BHUJ 293569 List of Figure --------------------------------------------------------------------------------Fig 2.1: Location Map 2 Fig 3.1: Methodology 7 Fig 4.1: Excavation 12 Fig 4.2: Laying PCC 14 Fig 5.1: Footing 15 Fig5.2: Footing Plan 15 Fig 5.3: Column Footing 16 Fig 5.4: Reinforcement of Column 18 Fig 5.5: Combined Footing 19 Fig 5.6: Step Footing 19 Fig 6.1: Plinth Beam 21 Fig 7.1: Stirrups and Bars 24 Fig 8.1: FOUNDATION LAYOUT 26 Fig 8.2: TYPE OF ISOLATED PAD FOOTING 27 Fig 8.3: COLUMN SCHEDULE 27 Fig 9.1: Centring 34 Fig10.1: Slab Formwork 35 Fig10.2: Slab Formwork 36 viii Gujarat Technological University GEC BHUJ 293569 List of Table --------------------------------------------------------------------------------Table 2.1 Student Details 5 Table 4.1 Comparative Analysis of IS Code Criteria 10 Table 4.2 Comparative Analysis of IS Code Criteria 12 Table 4.3 Comparative Analysis of IS Code Criteria 13 Table 5.1 Comparative Analysis of IS Code Criteria 16 Table 6.1 Comparative Analysis of IS Code Criteria 22 Table 7.1 Comparative Analysis of IS Code Criteria 25 Table 8.1 Estimation of Footing Casting 29 Table 8.2 Estimation of Footing JALI 31 Table 8.2 Estimation Site 32 Table 10.1 Comparative Analysis of IS Code Criteria 37 ix Gujarat Technological University GEC BHUJ 293569 TABLE OF CONTENT ------------------------------------------------------------------------------DECLARATION Acknowledgement Abstract List of Figures List of Table iv v vi vii viii CHAPTER 1: Company Profile 1 1.1 Mission Of Company and Projects 2.1Mission of Company 3.1 Head office 1 1 1 CHAPTER 2: INTRODUCTION 2.1 SITE LOCATION 2.2 OBJECTIVES 2.3 SEQUENCE OF STRUCTURE WORK 2.4 LITERAURE REVIEW 2.5 Aim and Objective of the Internship 2.6 My Roles and Responsibilities 2-6 2 2 3 3 5 6 CHAPTER 3: METHODOLOGY 3.1 PLANNING 3.2 DETAILS DESCRIPTION OF PLANNING 3.3 PLANNING 7-9 8 8 8 CHAPTER 4: Methodology of Work 4.1 Site Clearance 4.2 Excavation 4.3 Laying of P.C.C. (Plain Cement Concrete) 10-14 10 11 12 CHAPTER 5: FOOTING 5.1 Footing 5.2 CASTING OF COLUMN STARTER 5.3 REINFORCEMENT OF COLUMN 5.4 COMBINED FOOTING 5.5 STEP FOOTING 15-20 15 17 17 18 19 CHAPTER 6: PLINTH BEAM 6.1 PLINTH BEAM AND THEIR FORM WORK 21-23 21 CHAPTER 7: STIRRUPS AND LATERAL TIES 24-25 CHAPTER 8: ESTIMATION 26-32 CHAPTER 9: TEMPORARY STRUCTURE 33-34 x Gujarat Technological University GEC BHUJ 293569 9.1 SCAFFOLDING 9.2 R.C.C FORMWORK 9.3 CENTERING 33 33 34 CHAPTER 10: CASTING SLAB AND BEAM 10.1 MANAGEMENT FOR CASTING SLAB AND BEAM35 35-37 CHAPTER 11: CONCLUSION 38 CHAPTER 11: Bibliography xi Gujarat Technological University GEC BHUJ 293569 COMPANY PROFILE CHAPTER 1: COMPANY PROFILE 1.1 Mission of Company and Projects Mighty Scales Infra LLP is a Limited Liability Partnership firm incorporated on 27 January 2021. It is registered at Registrar of Companies, Mumbai. Its total obligation of contribution is Rs. 7,000,000. with their commitments and quality assurance, they have ranked to be the best in their industry. Their expertise in real estate development ensures the best investment for our needs. Their team is highly experienced having tenured and creative professionals. Designated Partners of Mighty Scales Infra LLP are Breeze Jayant Thacker, Nilesh Sureshchandra Doshi, Monil Hitenbhai Zota, Dharmendra Shantilal Parekh, Arvindkumar Jaysukhlal Morabia, Dhiren Rameshchandra Doshi, Vipulkumar Kantilal. 1.2 Mission of Company: Mighty Scales Infra LLP mission to perform for their customers the highest level of quality construction services at fair and market competitive prices and to maintain the highest level of professionalism, integrity, honesty and fairness in Their suppliers relationship with their suppliers, subcontractors, professional associates and customers. 1.3 Head Office Mighty Scales Infra LLP Identification Number is (LLPIN)AAV-6079. Its Email address is contact@msillp.com and its registered address is GC 2 Mazzenine floor, Ground floor,Karma stambh, L.B.S Marg,Vik hroli. West Mumbai, Maharashtra 400086 1 Gujarat Technological University GEC BHUJ 293569 INTRODUCTION CHAPTER 2: INTRODUCTION Commercial buildings are an important part of doing business, both for those who own them and for those who rent them. A commercial building could contain one or more of many types of businesses, including retailers, restaurants, offices or manufacturing. Commercial buildings are buildings where commercial activities take place. It include office buildings, retail space, warehouses, restaurant, hotels, healthcare and multiuse. 2.1 SITE LOCATION: Name of the Project: Pantheon Bhuj Location: Commercial Building Construction Owner: Mighty Scales Infra LLP Purpose of Project: Commercial Building Construction Total Area of Construction: 2.5 Acers FIG: 2.1 SITE LOCATION 2.2 OBJECTIVES: 1. Experiencing and learning more about construction site environment. 2. Plan should include construction methods to be adopted for different construction activities. 3. Learning about basic process of construction by observing and comparing topics that taught by lectures at college. 4. Construction Projects are executed based on the drawing and specifications. 2 Gujarat Technological University GEC BHUJ 293569 INTRODUCTION 5. Asking questions from supervisors and people working at construction site to gain more information and learn from their exeperience. 2.3 SEQUENCE OF STRUCTURE WORK 1. Site clearance 2. Boundary of Site 3. Positioning of Central Coordinate 4. Excavation 5. Laying of PCC 6. Bar Binding and placement of foundation steel 7. Shuttering and Scaffolding 8. Concreting 9. Electrical and Plumbing 10. De- shuttering 11. Brick Work or Stone Work 12. Plastering 13. Flooring 14. Painting 2.4 LITERAURE REVIEW Hemsworth Martinez-Lorente Clavel et al. (2006) stated that Standardization of materials is one important purchasing department decision. The primary objective of this study is to examine empirically the impact of standardization of materials and purchasing procedures on purchasing and business performance. The results of this research indicate that standardization in purchasing has a significant positive effect on both purchasing and business performance. They gave some points for a better understanding of how standardization in purchasing, operationalized as standardization of materials and purchasing procedures, can impact a firm’s purchasing and business performance. Thus, standardizing materials and purchasing procedures is important and may help firms to meet their materials expenditure targets, and increase the quality of materials, on-time delivery from suppliers, and inventory performance. (10) Ashokkumar et al. (2014) stated that the development of construction industry depends on the quality of construction projects. Quality is one of the critical factors in the success of construction projects. This project mainly focuses the importance and factors that affects the quality management in the execution (construction) phase. He concluded that the main factors, which affect the construction quality and increase in cost of construction due to quality defect. This study will create the quality management awareness to all level construction companies’ especially small-scale companies. He get the major factors and issues which affects the construction quality and that create a chance for find out the 3 Gujarat Technological University GEC BHUJ 293569 INTRODUCTION remedial measure. This thesis is useful for minimize the material wastage, workmanship wastage, time wastage and indirect cost. (7) Krishna Satyanarayana Rao et al. (2017) stated that Materials are basic core organs of any product it occupies around 60 to 70% of total cost of production. Materials management will attempt resolve the issues viz., materials shortages, delays in supply, price fluctuations, damage and wastage, and lack of storage space. After analysis, they concluded that the materials are managed in a series of stages such as procurement, transportation, Shipping, grading, storage, warehouse maintenance, supplying to production centres Etc. Minimising the risk at all the above levels give management not only better utilization of resources but also serves as competitive advantage. (20) Gulghane Khandve et al. (2015) stated that the total cost of materials may be up to 60% or more of the total cost incurred in construction project dependent upon the type of project. This give light to the fact that pre-planning and material procurement are equally important in controlling the total project cost. It reveals that the minimization of materials wastage during the construction phases is important in order to avoid loss of profits. It is observed that considerable research has been conducted to investigate individual construction waste management strategies at a specific stage of a construction project. (9) 4 Gujarat Technological University GEC BHUJ 293569 INTRODUCTION Student Details Student Name Suthar Rajeshkumar Bachubhai Enr. Number 190150106050 Semester 7 Email Address Sutharrajesh988@gmail.com Phone No (M) 6354314205 Date Of Reporting 23/01/2023 Project Details Project Title Offline Internship Project Duration 12 Weeks Organization Details Organization Mighty Scales Infra LLP Name Full postal GC 2 Mazzenine floor, Ground floor, Karma stambh, L.B.S address Marg,Vikhroli. West Mumbai, Maharashtra 400086 with pin code Email address contact@msillp.com Dy. General Manger Details Dy. General Manager Name Designation Email address Er. Hitesh Donga Site Engineer - Phone No(M) +91 97143 76492 Internal Guide Details Faculty Name Full contact address With pin code Email address Prof. DEVANG MAJITHIYA Government Engineering College Bhuj-370001 dev_engg2000@yahoo.com Phone No (M) Table 2.1: Student Details 9512450050 2.5 Aim and Objective of the Internship An internship is a purposeful activity of the student set in a work environment in order to obtain learning outcomes within their curriculum. During the internship, the knowledge, skills, and attitudes learned in the programme can be applied. 5 Gujarat Technological University GEC BHUJ 293569 INTRODUCTION The aim of the internship provides a direction to activities, helps to focus on a result, and to assess the result achieved. Before going on the internship, two important factors guiding your development should be taken into account when formulating the aim: • • • • Connecting what you have learned (theoretical and practical knowledge on your subject field) with actual work experience, in order to complement your field specific skills and learn new ones. Apply and Analysis at least one future skill (Future Skills 2025) There can be one or two aims, but both development o field specific skills as well as future skills have to be represented. Proceeding from the established aim (aims), you will set tasks. 2.6 My Roles and Responsibilities • • • • • • • • • • Site Observation and Excavation Checking the column center line. Safety Aspect Mange the concrete grade (M-15, M-25, M-30) Management of the proper curing. Reading of drawing for various type structures Testing Materials Solve the Technical Problems Work with Group Management of Construction Site 6 Gujarat Technological University GEC BHUJ 293569 METHODOLOGY CHAPTER 3: METHODOLOGY Collection of Data Analysis and comparing specification given in IS C Drawing reading ode practically at site Learn about basic process of construction Analysis and comparing specification given in GUIDELINES practically at site Conclusion Fig 3.1: Methodology The methodology of construction of a commercial building can vary depending on the project's specific requirements, size, and complexity. However, some general steps are commonly followed in most commercial building construction projects. These steps include: 1. Pre-Construction Phase 2. Site Preparation 3. Foundation 4. Structural Framing 5. Exterior Work 6. Mechanical and Electrical Systems 7 Gujarat Technological University GEC BHUJ 293569 METHODOLOGY 7. Interior Work 8. Finishing Work 9. Final Inspection 10. Handover 3.1 PLANNING Aspect Building planning is a crucial aspect of the construction of a commercial building. The planning stage involves developing a comprehensive plan for the building that considers various factors such as the intended use of the building, budget, local building codes and regulations, and sustainability goals. 3.2 DETAILS DESCRIPTION OF PLANNING Road-facing Showrooms of G + 1 Level for Pan-India Brands & Designer Labels. Truly, one can expect greater customer connect at Pantheon’s Retail spaces. A limited edition of road facing retail stores with promenade that beckons a choosen few to grab maximum eyeballs. The following are some of the key steps involved in the building planning process: 1. 2. 3. 4. 5. 6. 7. 8. Determining the Purpose and Scope of the Building Site Analysis: Conceptual Design Cost Estimation Finalizing the Design Obtaining Permits and Approvals Sustainability Considerations Construction Management Plan In conclusion, building planning is a critical aspect of the construction of a commercial building. It involves developing a comprehensive plan that considers various factors such as the intended use of the building, budget, local building codes and regulations, and sustainability goals. The success of the construction project largely depends on the quality of the building planning process. 3.3 PLANNING Designing is an essential aspect of the construction of a commercial building. The design phase involves creating a detailed plan for the building's layout, structure, and aesthetics. The following are some of the key steps involved in the designing of a commercial building: 8 Gujarat Technological University GEC BHUJ 293569 1. 2. 3. 4. 5. 6. 7. 8. 9. METHODOLOGY Developing a Design Brief Site Analysis Conceptual Design Detailed Design Sustainability Considerations Cost Estimation Interior Design landscaping Building Information Modeling (BIM) In conclusion, designing is a critical aspect of the construction of a commercial building. It involves creating a detailed plan for the building's layout, structure, and aesthetics. The success of the construction project largely depends on the quality of the designing process. 9 Gujarat Technological University GEC BHUJ 293569 Methodology of Work CHAPTER 4: Methodology of Work 4.1 Site Clearance Site clearance is an important aspect of the construction of a commercial building. It involves clearing the construction site of any existing structures, debris, or other obstructions that may interfere with the construction process. The following are some of the key steps involved in site clearance for a commercial building: Site Inspection Demolition Tree Felling Excavation Waste Disposal Site Security Environmental Considerations Sr. IS Code, Clause/Table 1 IS1200-1(1992) Clause 2.6 Page No. 1 Criteria for site Provided clearance as per IS Code removal of grass and vegetation YES Remark OK Table 4.1: Comparative Analysis of IS Code Criteria Table 4.1: Comparative Analysis of IS Code Criteria 10 Gujarat Technological University GEC BHUJ 293569 Methodology of Work In conclusion, site clearance is a critical aspect of the construction of a commercial building. It involves clearing the site of any existing structures, debris, or other obstructions that may interfere with the construction process. The success of the construction project largely depends on the quality of the site clearance process. 4.2 Excavation Excavation was carried out both manually as well as mechanically. When a small area or depth of footing is less than 4’ or constructed a single home excavation there required a worker excavation. Where a large area more than 5’or number of more column footing are available and residential construction working that place required a mechanically excavation. Adequate precaution is taken to see that the excavation operation does not damage the adjoining structures. Excavation is carried out providing adequate side slopes and dressing of the excavation bottom. The soil present beneath the surface was too clayey so it was dumped and was not used for black filling. the filling is done in layer not exceeding 20cm layer and then it’s compacted. Depth of excavation 2.0 meter from ground level. Table 4.2: Comparative Analysis of IS Code Crite 11 Gujarat Technological University GEC BHUJ 293569 Methodology of Work Sr. IS Code, Clause/Table 1 IS 3764:1992 Clause 5.1.2 ,5.1.3 Page No. 2 Criteria for excavation Provided Remark as per IS Code All trenches in soil more than 1.5m deep shall securely shored and timbered. 1.2 OK Table 4.2: Comparative Analysis of IS Code Criteria For the analysis of above calculation manually and mechanically (JCB) we can see JCB is grate for the excavation and it was faster work compare to worker and completed its work quickly. And JCB total rate of cost is low. Fig 4.1: Excavation 4.3 Laying of P.C.C. (Plain Cement Concrete) After the process of GSB, laying of plain cement concrete that is PCC is done. The level of the PCC is also given in the given in the drawing. The level of PCC is done by mason. Plain concrete is vibrated to achieve full compaction. Concrete placed below ground should be protected from falling earth during and after placing. When joint in a layer of concrete are unavoidable, and end is sloped at an angle of 30 and junctions of different layer break joint in laying upper layer of concrete. The lower surface is made rough and clean water before upper layer is laid. 12 Gujarat Technological University GEC BHUJ 293569 Methodology of Work Sr. IS Code, Clause/Table Page No. Criteria for Footing as per IS Provided Remark Code 1 IS 456:200 Clause 26.4.2.2 46 For Footings Minimum cover shall be 50mm 50mm OK 2 IS 456:2000 Clause5.1 13 53 Grade ordinary Portland cement conforming to IS 12269 53 Grade OK 3 IS 456:2000 Table5 20 Min. Grade of concrete for mild exposure (for PCC work): M30 M30 4 IS 456:2000 Table5 IS 456:2000 Clause 34.3.1 20 Min. Grade of concrete for mild exposure (for RCC work): M30 In one-way reinforced footing, the reinforcement extending in each direction shall be distributed uniformly across the full width of the footing OK In site use the M15 ratio for PCC OK OK OK 5 65 Table 4.3: Comparative Analysis of IS Code Criteria 13 Gujarat Technological University GEC BHUJ 293569 Methodology of Work CONCLUSION: • From the analysis of above data it can be concluded that the parameters like cover of footing, width of footing reinforcement, one way slab, grade of concrete matched with the IS Code while the grade of concrete for mild exposure used at site M30 which was mention in IS Code. Fig 4.2: Laying PCC GRADE: M15 OBSERVATION: • From the analysis of above data, it can be concluded that the parameters like cover of footing, width of footing reinforcement, one way slab, grade of concrete matched with the IS Code while the grade of concrete for mild exposure used at site M15 which was mention in IS Code. 14 Gujarat Technological University GEC BHUJ 293569 FOOTING CHAPTER 5: FOOTING 5.1 Footing After completion of the PCC, we had done the footing as per the drawing. In the footing the bottom has is and top has. Between the bottom and top there is ‘chair’. Which is use for spacing between bottom and top. The chair’s height is calculated as per drawing Fig 5.1: Footing Fig5.2: Footing Plan 15 Gujarat Technological University GEC BHUJ 293569 FOOTING Sr. IS Code, Clause/Table Page No. Criteria for Column as per IS Code Provided 1 IS 456:200 Clause 25.1.1 41 Effective length exceeds three times the least lateral dimension OK 2 IS 456:200 Clause 25.1.2 41 3 4 5 Remark A compression member may OK be considered as short when both the slenderness ratio and are less than 12 IS 456:2000 48 The maximum longitudinal OK Clause 26.5.3.1(a) steel reinforcement for the column is 6% of the gross column area IS 456:2000 48 The bar shall not be less than OK Clause 26.5.3.1(d) 12mm I diameter IS 456:2000 48 Minimum numbers of bar for OK Clause 26.5.3.1(c) rectangular = 4 Table 5.1: Comparative Analysis of IS Code Criteria 6.1.2 CLOUMN FOOTING: Fig 5.3: Column Footing GRADE: M30 5.2 R.C.C COLUMN 16 Gujarat Technological University GEC BHUJ 293569 FOOTING R.C.C. Column is the vertical structural member in compression, which carries an axial load coming from beams and slabs & transfer it to the foundation & ultimately to the soil the various constructional activities related to the column area as follow • Casting of starters • Reinforcement of column • Formwork of column. • Concreting of column • Stripping work • Curing work of column 5.3 CASTING OF COLUMN STARTER: • • • • • • • Line string is fixed at outer side of slab top and then diagonals are checked as per center line plan, before starter sides are fixed. After fixing of starter sides, all the distances are checked and measured According to the centre line plan & column drawings. Line, right angle & plumb bob are also checked of every individual starter and also measurements are checked of every column starter according to column size at the respective floor. Check proper covering given or not. 5.4 REINFORCEMENT OF COLUMN: • • • • • • Longitudinal reinforcement is tied to columns as per structural drawing details columns at that respective floor. Lap length should be provided to all the longitudinal reinforcement of column. In my site, Lap length For 12 mm bar 600 mm Cover blocks are tied up to stirrups at bottom, middle & top position. Clear cover should be 45mm from stirrups of column. After tying of reinforcement & stirrups, diameter of bars & number of bar as per structural drawing. o Supports provided for shuttering should rest on firm ground or base. Supporting is done with the help of props, clamps & joist. o After tying of longitudinal, stirrups are tied to columns as per given in structural drawing of columns. At my site, stirrups are of 8mm diameter provided following C/C spacing. 17 Gujarat Technological University GEC BHUJ 293569 FOOTING Fig 5.4: Reinforcement of Column GRADE: M30 5.5 COMBINED FOOTING: Combined footing is constructed for two or more column when they are close to each other and their foundations overlap. Design of combined footings with examples is discussed. The function of a footing or a foundation is to transmit the load from the structure to the underlying soil. 18 Gujarat Technological University GEC BHUJ 293569 FOOTING Fig 5.5: Combined Footing GRADE: M30 5.6 STEP FOOTING: The main purpose of using stepped footing is to keep the metal columns away from direct contact with soil to save them from corrosive effect. They are used to carry the load of metal columns and transmit this load t the below ground Fig 5.6: Step Footing GRADE: M30 19 Gujarat Technological University GEC BHUJ 293569 FOOTING QUANTITY CALCULATION COLUMN SIZE Column Nos. C71,C72,C76 C35,C40,C66,C76 C18,C21 Length 450mm 450mm 750mm Breadth 450mm 750mm 750mm Height 2.28m 2.28m 2.28m 20 Gujarat Technological University GEC BHUJ 293569 PLINTH BEAM CHAPTER 6: PLINTH BEAM 6.1: PLINTH BEAM AND THEIR FORM WORK Fig 6.1: Plinth Beam GRADE:M30 o Plinth beam is a reinforced concrete beam constructed between the wall and its foundation. Plinth beam is provided to prevent the extension or propagation of cracks from the foundation into the wall above when the foundation suffers from settlement. o The main function for the plinth in construction is to distribute the load of the columns over the foundation evenly. o Concrete blocks ae used from work of plinth beam. The purpose of the concrete block used in form work is no need to remove after casting. o The size of the plinth beam is 300*450mm, bars are 16mm and stirrups are 8mm and their spacing is 125mm. o The concrete is used M-30 Grade. Sr. IS Code, Clause/Table Pag e No. 3 1 IS 13920:1993 Clause 6.1.2 2 IS 2502:1963 Clause 3.2.1 5 Criteria for plinth beam as per IS Code Provided Rema rk The Beam shall preferably have a width-to-depth ratio of more than 0.3 Standard length of hook for 135 degrees for stirrups = 24d 0.3 OK 135 OK 21 Gujarat Technological University GEC BHUJ 293569 3 4 5 6 7 8 IS 13920:1993 Clause 6.1.3 IS 13920:1993 Clause 6.1.4 IS 13920:1993 Clause 6.3.2 IS 13920:1993 Clause 6.2.6.1 IS 456:2000 Clause 26.4 PLINTH BEAM 3 The width of the beam shall not be less than 200mm 3 Beam shall not have D more than ¼ of the clear span 4 The minimum diameter of shall be 8 mm 3 At a splicing junction, spacing of links shall not exceed 150mm 46 For beam Minimum cover shall be 25mm IS 456:2000 Clause 6.3.2 3 The minimum diameter of the bar forming a hoop shall be 6mm. Table 6.1: Comparative Analysis of IS Code Criteria 300 OK 450 OK 8mm OK 150mm OK 25mm OK 8mm OK 22 Gujarat Technological University GEC BHUJ 293569 PLINTH BEAM OBSERVATION: o From the analysis of above data it can be concluded that the parameters like cover of footing, width of footing reinforcement, grade of concrete matched with IS Code while the concrete for mild exposure used at site M30 which was mentioned in IS Code. 23 Gujarat Technological University GEC BHUJ 293569 STIRRUPS AND LATERAL TIES CHAPTER 7: STIRRUPS AND LATERAL TIES Fig 7.1: Stirrups and Bars GRADE:M30 7.1: stirrups and lateral ties (various dimension) • There are following dimension of the stirrups and lateral tis are used: 1. 150*150mm 2. 150*200mm 3. 150*300mm 4. 150*380mm Sr. IS Code, Clause/Table Page Criteria for Lateral ties as no. per IS Code Provided Remark 24 Gujarat Technological University GEC BHUJ 293569 1 2 3 STIRRUPS AND LATERAL TIES IS 456:2000 Clause 26.5.3.2(c) IS 456:2000 Clause 26.5.3.2(c) 49 IS 456:2000 Clause 26.5.3.2(c) 49 49 The least lateral dimension of the compression members Sixteen times the smallest diameter of the longitudinal reinforcement bar to be tied Diameter-The diameter of the polygonal links or lateral ties shall be not less than one- fourth of the diameter of the largest longitudinal bar. and in no case less than 16mm OK OK OK Table 8.1: Comparative Analysis of IS Code Criteria OBSERVATION: o It is concluded that the above analyzed data is correct criteria for lateral ties as per IS Code to be considered at construction site. 7.2 REINFORCEMENT OF BEAM AND SLAB • • • Longitudinal reinforcement at tension and compression face. Shear reinforcements in the form of vertical stirrups and or bent up longitudinal bars. Structural reinforcement is typically placed in the bottom portion of the slab thickness to increase the slab's load capacity. In IS 456:2000, the minimum steel requirement of slabs is prescribed in Clause 26.5. 2.1 as 0.15% of the gross cross-sectional area for mild steel reinforcement and 0.12% for high-strength deformed bars. 25 Gujarat Technological University GEC BHUJ 293569 ESTIMATION CHAPTER 8: ESTIMATION Fig 8.1: FOUNDATION LAYOUT 26 Gujarat Technological University GEC BHUJ 293569 ESTIMATION Fig 8.2: TYPE OF ISOLATED PAD FOOTING Fig 8.3: COLUMN SCHEDULE SR No. Iteam Description No. length Width Height Quantity Unit 27 Gujarat Technological University GEC BHUJ 293569 1 ESTIMATION Footing Casting M25 F1 Step 1 8 1.95 1.65 0.60 15.44 F2 Step 1 Step2 2 2 2.40 1.50 2.10 1.20 0..45 0.45 4.53 1.62 F3 Step 1 Step2 9 9 2.25 1.20 2.25 1.20 0.45 0.45 20.50 5.83 F4 Step 1 Step2 1 1 3.00 1.80 2.40 1.50 0.45 0.45 3.24 1.21 F5 Step 1 Step2 8 8 3.00 2.10 2.30 1.80 0.45 0.60 29.16 18.14 F6 Step 1 Step2 2 2 3.00 1.80 3.00 1.80 0.45 0.60 8.10 3.86 F7 Step 1 Step2 2 2 3.15 1.80 3.15 1.80 0.45 0.60 8.93 3.86 F8 Step 1 Step2 5 5 3.45 2.10 3.30 1.80 0.60 0.60 34.15 11.34 F9 Step 1 Step2 6 6 3.90 2.55 3.90 2.55 0.60 0.75 54.75 29.26 F10 Step 1 Step2 6 6 4.50 2.25 3.45 1.65 0.60 0.75 55.89 16.70 Cu m F11 28 Gujarat Technological University GEC BHUJ 293569 ESTIMATION Step 1 Step2 2 2 4.95 4.95 2.70 1.50 0.15 0.60 12.02 8.91 F12 Step 1 Step2 1 1 5.85 5.85 3.45 2.10 0.45 0.45 8.67 5.55 F13 Step 1 Step2 1 1 3.90 3.15 6.45 3.15 0.60 0.60 Total Qty= 15.09 5.95 382.7 Cu m Table 8.1: Estimation of Footing Casting SR No. Iteams Description 1 Footing Jali 1 2 3 No. length Steel (Kg) 8mm F1 Bottom steel (10d-125c/c) Short bar (16) Long bar (13) 8 8 2.55 2.85 Top Steel (8d-230c/c) Short bar (9) Long bar (7) 8 8 2.55 2.85 F2 Bottom steel (10d-125c/c) Short bar (19) Long bar (17) 2 2 2.3 2 Top Steel (8d-230c/c) Short bar (17) Long bar (9) 2 2 2.3 2 F3 Bottom steel (10d-125c/c) Short bar (18) Long bar (18) 9 9 2.15 2.15 Top Steel (8d-230c/c) Short bar (10) Long bar (10) 9 9 2.15 2.15 10mm 12mm 16mm 20mm 326 296 183 159 87 68 51 36 348 348 193 193 29 Gujarat Technological University GEC BHUJ 25mm 293569 4 5 6 7 8 ESTIMATION F4 Bottom steel (12d-150c/c) Short bar (20) Long bar (16) 1 1 2.9 2.3 Top Steel (8d-230c/c) Short bar (13) Long bar (10) 1 1 2.9 2.3 F5 Bottom steel (12d-125c/c) Short bar (24) Long bar (22) 8 8 2.9 2.6 Top Steel (10d-230c/c) Short bar (13) Long bar (12) 8 8 2.9 2.6 F6 Bottom steel (12d-150c/c) Short bar (20) Long bar (20) 2 2 2.9 2.9 Top Steel (10d-230c/c) Short bar (13) Long bar (13) 2 2 2.9 2.9 F7 Bottom steel (12d-125c/c) Short bar (25) Long bar (25) 2 2 3.05 3.05 Top Steel (10d-230c/c) Short bar (14) Long bar (14) 2 2 3.05 3.05 F8 Bottom steel (12d-125c/c) Short bar (28) Long bar (26) 5 5 3.35 3.2 58 36 37 23 556 457 301 250 116 116 75 75 152 152 85 85 469 416 Top Steel (10d-230c/c) 30 Gujarat Technological University GEC BHUJ 293569 9 10 11 ESTIMATION Short bar (15) Long bar (14) 5 5 3.35 3.2 251 224 F9 Bottom steel (16d-125c/c) Short bar (31) Long bar (31) 6 6 3.8 3.8 Top Steel (12d-230c/c) Short bar (17) Long bar (17) 6 6 3.8 3.8 F10 Bottom steel (16d-125c/c) Short bar (36) Long bar (28) 6 6 4.4 3.35 Top Steel (12d-230c/c) Short bar (20) Long bar (15) 6 6 4.4 3.35 528 301 F11 Bottom steel (12d-150c/c) Short bar (33) Long bar (18) 2 2 4.85 2.6 320 93 Top Steel (12d-230c/c) Short bar (33) Long bar (18) 2 2 4.85 2.6 320 93 707 707 388 388 950 563 Total Qty= 875 2819 Total Qty=11580 Kg 4959 2927 Table 8.2: Estimation of Footing JALI SR No. Iteam Description 1 Excavation Footing F1 F2 F3 F4 F5 No. length Width 8.00 2.00 9.00 1.00 8.00 2.55 3.00 2.85 3.60 3.60 2.55 2.70 2.85 3.00 3.30 Height Quantity 1.80 1.80 1.80 1.80 1.80 82.62 29.16 131.58 19.44 171.07 Unit Cu.m 31 Gujarat Technological University GEC BHUJ 293569 ESTIMATION F6 F7 F8 F9 F10 F11 F12 F13 2 Footing P.C.C F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 F13 2.00 2.00 5.00 6.00 6.00 2.00 1.00 1.00 3.60 3.75 4.05 4.50 5.10 5.50 6.40 4.50 8.00 2.00 9.00 1.00 8.00 2.00 2.00 5.00 6.00 6.00 2.00 1.00 1.00 2.55 3.00 2.85 3.60 3.60 3.60 3.75 4.05 4.50 5.10 5.50 6.40 4.50 3.60 3.75 3.90 4.50 4.05 3.30 4.05 7.05 2.55 2.70 2.85 3.00 3.30 3.60 3.75 3.90 4.50 4.05 3.30 4.05 7.05 1.80 1.80 1.80 1.80 1.80 1.80 1.80 1.80 Total Qty= 46.65 50.62 142.15 218.7 223.07 65.93 46.65 57.1 1350.68 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.10 Total Qty= 4.59 1.62 7.31 1.08 8.64 2.59 2.81 7.89 12.15 12.39 3.63 2.59 3.17 70.46 Cu.m Cu.m Cu.m Table 8.3: Estimation Site 32 Gujarat Technological University GEC BHUJ 293569 TEMPORARY STRUCTURE CHAPTER 9: TEMPORARY STRUCTURE 9.1 SCAFFOLDING: • Scaffolding, also called scaffold or staging, is a temporary structure used to support a work crew and materials to aid in the construction, maintenance and repair of buildings, bridges and all other man-made structures. Types of scaffolding or scaffold• Single scaffolding • Double scaffolding Ladder scaffolding • Cantilever scaffolding Steel scaffolding • Suspended scaffolding • Trestle scaffolding • Wooden gantries 9.2 R.C.C FORMWORK: • Formwork (shuttering) is a temporary mould to provide support to fresh concrete when placed in structural member until the concrete has set. This helps the structural member to gain sufficient strength to carry its self-load and load from other members. Requirements of Good Formwork: 1. It should be carefully designed, so as to be strong enough to resist the pressure of fresh concrete and the super-imposed loads due to men, materials and Equipment etc. 2. It should be rigid enough to retain its original shape without undue deformation which is normally restricted to 1/300 the of span in normal cases. 3. It should be tight enough so as not to allow cement and other materials to leak through the joints. 4. The formwork should not warp, bulge, bend or sink and should remain true to the designed size. 5. The inner surface of the formwork should be smooth so as to give pleasing appearance to the finished surface. The inner surface is also applied with mould oil to facilitate its removal 33 Gujarat Technological University GEC BHUJ 293569 TEMPORARY STRUCTURE 9.3 CENTERING: Fig 9.1: Centring DATE: 10/03/2023 TIME:1:00PM GRADE:M30 • Centring is a type of formwork the temporary structure upon which the stones of an arch or vault are laid during construction. Until the keystone is inserted an arch has no strength and needs the centring to keep the vous soirs in their correct relative positions. A simple centring without a truss is called a common centring. The cross piece connecting centring frames are called a lag • The centring is normally made of wood timbers, which was a relatively straightforward structure in a simple arch or vault, but with more complex shapes, involving double curvature, such as a small dome or the bottle-shaped flues of the kitchens of some Normanperiod houses; clay or sand bound by a weak lime mortar mix could be used. 34 Gujarat Technological University GEC BHUJ 293569 CASTING SLAB AND BEAM CHAPTER 10: CASTING SLAB AND BEAM 10.1 MANAGEMENT FOR CASTING SLAB AND BEAM: • • • • The formwork & reinforcement of beams & slab is checked by site engineer one day advance before casting & any remarks suggest by him is get rectified immediately. Arrangement of materials like cement, sand, metals for casting of slab in well advance Arrangement of water, in case of electric failure & labour strength. The concrete mixer, Vibrators, skip and hoist machine is well cleaned by oiling. The slab and beam are well cleaned with water and dust, wooden pieces and solid waste is remaining. Fig10.1: Slab Formwork DATE: 15/03/2023 TIME: 1:00PM GRADE:M30 A vibrator is a mechanical device to generate vibrations. The vibration is often generated by an electric motor with an unbalanced mass on its driveshaft. Different types of vibrator used in commercial construction. Needle vibrator are most commonly used vibrator for concrete. It consists of a steel tube having an eccentric vibrating element inside it. On my site Needle vibrator used in all slab. 35 Gujarat Technological University GEC BHUJ 293569 CASTING SLAB AND BEAM Fig10.2: Slab Formwork DATE: 15/03/2023 Sr. 1 2 3 IS Code, clause/Table Is 456:2000 Clause 26.5.2 Is 456:2000 Clause 26.5.2.2 Sp-34 handbook on concrete TIME: 1:00PM Page Criteria for Slab as per IS code no. 48 For plain barsminimum0.15% of totalcross section area For high strength deformedbars minimum 0.12% oftotal gross section area 48 The diameter of bar shall not exceed 1/8 times total slab thickness For main steelFor plain bar – minimum dia.=10mmFor deformed bar minimum dia =8mmFor distribution steel, Minimum dia =6mm 4 Is 456:2000 Clause 12.3.2 26 5 Is 456:2000 Clause 12.3.2 26 Strength of the Cover block spacers, cover block should be of concrete of same strength or PVC Spacers or chair should be placed at a maximum spacing of 1m and closer spacing may sometimes be necessary Provided Remark Plain bar ok 0.20% And deformed bar 0.18% 10 mm ok Main steel ok is 10 mm and distribution steel is 8mm ok 1m ok 36 Gujarat Technological University GEC BHUJ 293569 CASTING SLAB AND BEAM Table 10.1: Comparative Analysis of IS Code Criteria OBSERVATION It is concluded that the above analysed data is correct criteria for slab as per IS Codes to be considered at construction site. 37 Gujarat Technological University GEC BHUJ 293569 CONCLUSION CHAPTER 11: CONCLUSION Under the guidance of Mr. Hitesh Donga (Site Engineer) as a mentor I have got opportunity to understand the technical and field work aspect of Commercial Building Construction. The main aim of studies within the project was to investigate how as structure is constructed within its desired properties. I got a known about basic and advanced techniques of building construction as well as saw the challenges which a civil engineer has to face during construction i.e. labor problems, cost management, environmental challenges etc. I cleared out many doubts regrading building construction. Overall, it must be said that the construction method and quality control on a Commercial project needs a very good coordination and large quantities of man power, equipment and funds. So, I am grateful to Mighty Scales Infra LLP and college staff for giving us the opportunity to learn and grow. It is concluded that the above analyzed data is correct criteria for column as per IS Codes to be considered at construction site. 38 Gujarat Technological University GEC BHUJ 293569 Bibliography CHAPTER 12: Bibliography • • • • http://bhujada.com/revised-dp-2025/ https://www.bis.gov.in/standards/technical-department/national-building-code/ https://pantheonbhuj.com/ https://www.google.com/maps/place/DREAMS+NAVRATRI+GROUND/@23.2 34876,69.6469243,442m/data=!3m1!1e3!4m5!3m4!1s0x39511e131734d983:0xe9 77fdc00c17bdf4!8m2!3d23.2349868!4d69.6471459 39 Gujarat Technological University GEC BHUJ