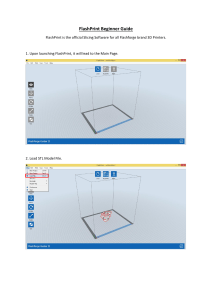

The first step is modelling, using 3D drawing software such as AutoCAD, 3Dsmax, Solidworks, etc., which can be output or converted to STL format. Then add the model in STL format to the slicing software, place the model reasonably in the centre of the printer plate from the preview, and set the print setting, and the following recommendation as follow: Layer height: for different qualities that will impact the time duration, the standard print quality is 0.2mm preferred. Infill: Infill with density (10-15%) and pattern usually use cubic. Material: Printing temperature (200℃) and build plate temperature (60℃). Print speed: Most use 40-70mm/s. Support: The software will automatically add support from the overhang angle setting. Build plate adhesion: best use raft type. After the print setting, estimate the time it will take by software, and reject the set to a suitable time, and we can preview the whole printing process in the software. Finally, insert the slice model into the printer via SD card. Then navigate to the first layer calibration and adjust the z axial to make the test pattern stick on the plate uniformly. And use alcohol clean and start printing! And make sure someone is still around to supervise it. After the model print, we need to polish and assemble the parts to form a finished product.