N09505211

ARNE OLAV FREOHEIM

NEI-NCJ--563

THERMAL DESIGN OF COIL-WOUND

LNG HEAT EXCHANGERS

SHELL-S:OE HEAT TRANSFER AND

PRESSURE DROP

DOKTOR INGENl0RAVHANDLING 1994:15

INSTITUTI FOR KULDETr.KNlKK

TRONDHEIM

DISTfliBlJTlON OF THIS DOCUMENT IS UNUMiTEO

Thermal Design of Coil-Wound LNG Heat

Exchangers

Shell-Side Heat Transfer and Pressure Drop

by

Arne Olav Fredheim

A Thesis Submitted for the Degree of

Doktor ingeni0r

The Uni~e:rsity of Trondheim.

The Norwegian Institute of Technology

Department of Refrigeration Engineering

February 1994

MASTER

DISTRIBUTION OF THIS

UOCUM~NT

IS UNLIMITED

}tct

1

Summary

The main objectives for the work presented in this thesis has been to develop

calculation models for LNG heat exchangers and LNG liquefaction cycles, in

order to do realistic simulations of LNG plants.

The thesis consists of three different parts :

• Description of procedures for thermal design of LNG heat exchanger

• Description of a test facility for measurements of heat transfer and

pressure drop in a coil-wound heat exchanger

• Presentation of measured data and models foi' calculation of heat transfer and pressure drop

A detailed model for thermal design of a multi-stream heat exchanger is

given. The mcdel is based on a step-by-step integration procedure, in order

to establish the temperature profile in the heat exchanger. The minimum

temperature difference is adjusted by variation of the shell-side pressure.

Different criteria for calcuiation of split point between the cold a.nd the warm

hea.t exchanger bundle are given given. A procedure for calculation of lay-out

parameters on the shell-side is presented, with a review of different methods

for calculation of minimum flow area. A brief description of different methods

for calculation of thern:J.~physical properties is also given.

The test fa.cility consists of a small test heat exchanger, where the heat transfer coefficient and pressure drop are measured in evaporating down flow.

Parameters such as flow rate, vapour quality, pressure and composition are

varied. The geometrical parameters and the instrumentation are described in

addition to data acquisition, data reduction and treatment of measurement

uncertainty. Heat transfer and pressure drop are measured in superheated

vapour flow, film flow and shear flow. The onset point for nucleate boiling is

also measured. The measured data are compared to methods from reference

literature, and some parameters have been adjusted to own measurements.

Acknowledgments

This thesis sum up some of the results from a research project carried out.

at The Division of Refrigeration Engineering, at the Norwegian Institute of

Technology. The project has been financed by Statoil, and I would like to

thank the responsible project managers who made this work possible.

Professor Einar Brendeng has been my supervisor.

Mr. Bengt O. Neeraas wrote his MSc.-thesis on measurements from a early

version of the test facility, and requirement for reconstruction was identified.

The test facility was ready for operation late 1989. Both the test heatexchanger and part of the instrumentation had been changed. The work on

construction, instrumentation and commissioning have been carried out as

parts of the work on this'thesis. I would like to thank Mr. Havard Rekstad

and the laboratory personnel for excellent assistance during the reconstruction and commissioning period. The measurements used in this thesis have

been carried out in the period from 1989 to 1992. Mr. Harald M;ehlum has

performed the measurements on binary mixtures.

The LNG heat-exchanger model was developed and implemented in CryoPro

in the p~riod from 1990 to 1992. I would like to tank Dr. Geir Owren for his

support during this period.

Mr. Hamid MGehlum and Mr. Havard Rekstad have made the AutoCad

drawings.

I would also thank my family for their patience during a rather long preparation period for this thesis.

ii

Contents

1

Thermal design ::.f LNG heat exchangers

1

1.1

1

Introd uctior

.. . .. .. ..

...............

1.2 Process considerations

2

1.3 Design procedure . . .

6

1.3.1

Basic design principles

1;3.2

Heat exchanger mode::

1.3.3

Optimum split point .

1.3.4

Optimum suction pressure. .

14

..................

18

1.4 Geometrica.lla.y-out

6

..

.........

1.5 Thermodynamic and physical properties

11

24

1.5.1

Selection of calcula".:ion methods

24

1.5.2

Equilibrium da.ta . . . . . . . ..........

27

1.5.3

Thermodynamic properties

28

1.5.4 Physical properties . . . . .

2

7

Test facility for LNG heat exchangers

29

30

Introduction. . . . . . ..

30

2.2 Description of test facility

30

2.3 Test heat exchanger ...

33

2.1

2.4

Estimat.ion and treatment of errors

iii

36

Contents

IV

2.5 Instrumentation, calibration and uncertainty

2.5.1

Tempera.ture

37

2.5.2

Pressure.

40

2.5.3

Flow rate

44

2.5.4

Heat flux

46

2.5.5

Composition

49

2.6 Data acquisition and data reduction

3

37

-. . -

49

49

2.6.1

Data acquisition

2.6.2

Pressure drop in section

49

2.6.3

Fluid temperature in section

50

2.6.4

Wall temperature in section

52

2.6.5

Total flow rate

53

2.6.6

Vapour quality

54

2.6.7

Heat-transfer coefficient

55

Heat transfer and pressure drop

56

3.1

Introduction . . . . . . . .

56

3.2 Su perheated vapour flow .

57

3.2.1

Test conditions ..

57

3.2.2

Heat-transfer coefficient

58

3.2.3

Pressure drop .

61

3.2.4

Heat leakage

64

3.3

Film flow

......

65

3.3.1

Parameters in gravity-controlled flow .

3.3.2

Test c.onditions

. -. -.

67

3.3.3

Heat-transfer coefficient

69

65

Contents

v

3.4

Onset of nucleate boiling.

75

3.5 Shear flow . . . . . . ... .

82

3.5.1

Parameters in shear-controlled flow.

82

3.5.2

Test co!:aitions . . . . .

86

:3.5.3

Heat-transfer coefficient

88

3.5.4

Pressure drop . . . . . .

96

A Thermal desfgD of LNG heat exchangers

107

A.I Geometrical data ..

107

A.2 Reference flow area .

114

A.3 Vapour pressure for pure propane ..

116

A.4 Corresponding state method for density

118

A.5 Corresponding state method for viscosity

...........

B Test facility for heat exchanger

123

B.1 Geometrical data .. __ . . . .

B.2 Estimation and treatment of errors .

121

123

.............

127

..

127

B.2.2 Systematic errors .

129

B.2.3 Propagation and combination of errors _

130

B.2.1

Random errors

B.3 Test for outliers in measurements . .

132

B.4 Student's-t statistics. . . . .

133

B.5 Location ofthermocoupies .

-134

B.6 Thermocouple reference equation

136

B.7 Thermocouple off-site calibration

137

B.8 On-site calibration of thermocouples

140

Contents

VI

B.9 Pressure transmitters . . . . . . . . . . . . . .

141

B.lO GeometricaJ data for the orifice meters .. .

144

B.ll Calibration da.ta. for turbiue meter

145

B.12 Measurement of heat flux ..

148

C Examples of measured data.

150

C.1 Superheated vapour flow . . .

151

C.2 Film flow "

153

C.3 Sh@af flow . .

155

Nomenclature

vii

Nomenclature

Latin

All

Ah.e

B

Cp

dX

D

DP

E

E

f

Fr

g

h

K

m

m

M

M

n

N

N

Nu

P

Pr

Pr

PI

q

Q

R

Ru

-Re

S

5

S

t ...,P

T

Flow area

Heat transfer surface

Estimated uncertainty from systematic error

Specific heat capacity

Longitudinal element

Diameter

Pressure difference in test facility

Electrical potential

Exergy loss

Fugacity

Froude number

Acceleration due to gra.vity

Enthalpy

Equilibrium constant (K-V<Ilue)

Number for last tube layer

Mass flow velocity

Mass flow rate

Number of set of measurements

Number for first tube layer

Number of items ( general )

Number of replicated readings

Nusselt number

Pressure

Radial distance between tube centers

Prandtl number

Longitudinal distance between tube centeiS

Heat flux

Heat transferred to fluid

Resistance

Universal gas constant

Reynolds number

Distance between tubes

Slip factor

Standard deviationStudent-t vab.e

Temperature

m2

m2

J/kgK

m

m

Pa

V

W

Pa

m/s2

J/kg

kg/m 2s

kg/s

Pa

m

m

W/m2

W

n

Nm/kgK

m

°C orK

Nomenclature

VIll

Velocity

Total heat-transfer coefficient

Est~mated total uncertainty interval

Wattmeter signal

Length

Vapour quality

Liquid _composition array

Vapour composition array

Total composition array

mjs

W/m 2 K

W/m 2 K

8

8

Heat-transfer coefficient

Inclination angle for all tubes

True uncertainty from systematic error

Film thickness

Heat of evaporation

Increase in number of tubes

Temperature difference

Step length for integration

Angle between identical configurations

True uncertainty from random error

Void fraction

Mass flow rate pr _ unit length

Thermal conductivity

True mean value for a normal distribution

Dynamic ~osity

Degree of freedom

Kinematic viscosity

Density

Surface teusion ccC::

Peripherical angle' Fugacity coefficient

Subscript

a

bu

calib

cb

Acceleration

Bundle

Calibrated -..alue

Cold b!i.ndle

u

U

VI

W

X

i

X

y

Z

W

m

Greek

Q

Q

f)

0

LlhLV

LlNT

LlT

LlX

Ll(}

E

e

r

).

J.£

J.£

v

v

p

(j

0

!D

J/kg

K

m

0

kg/ms

WjmK

Ns/m 2

m 2 /s

kg/m3

N/m

0

Nomenclature

co

com

cs

f

g

iJ

i-I

In

lam

lay

10

Is

L

m

n

oh

onb

or

P

ref

sat

sh

st

tp

tu

tui

vo

vs

V

w

wb

ws

Core

Component

Cold strea~

Friction and drag force

Static head or gravity

General number

Relative value between stream i and stream 1In-lirl.o:cuutiguratlon

Laminar

Layer

Liquid only

Liquid superficial

Liquid phase

Measured

Step number

Superheated

Onset of nucleate boiling

Orifice

Probability

Reference value

Saturated

Shell or jacket

Staggered con1iguration

Twcr-phase

Tube

Inside t'!!be

Vapour only

Vapour superficial

Vapour phase

VVall

VVarm l-n"dle

VVarm ~t.ream

IX

x

Nomenclature

Mathematical

Function parenthesis

()

Gradient of X with respect to Y

4X/dY

Acronym

SRK-EOS

PR-EOS

G-EOS

CSP

GPA

CWHX

MCR

LNG

MITA

PTFE

EMF

IPTS-68

Soave-Redlich-K wcng equation-of-state

Peng-Robinson equation-of-state

Cubic eq~atioD-of-state

Corresponding state principle

Gas processors association

COil-WOUD_d heat excha.nger

M ultico.:D p-cilent refrigerant

Liquefied natural gas

Minimum temperature approach

Teflon

Electromotive force

The International Practical: Temperature '5cale of 1968

1 Thermal design of LNG heat

exchangers

1.1 Introduction

Coil-wound heat exchangers ( CWHX ) have been used as main heat exchangers i:J. most of the LNG production plants built until now. The main

application areas for CWHX are as natural gas condensers in LNG production

plants, as steam boilers in nuclea.r power production plants and occasionally

as heat exchangers in petrochemical. or cryog€nic plants. Use of CWHX

in !:!'fG plants is based on the advantages of multist~eam capability, high

compactness, efficient heat transfer, high flexibility with regard to design

temperature and pressure and robustness with regard to rapid changes in

temperature and pressure.

CWHX may be constructed with one or several tube-side streams. Two

or three tube-side streams ue normal for LNG application. These streams

exchange heat with a common shell-side stream. The fluid ma.y be in onephase flow or in two-phase flow, both on the tube-side and on the shell-side.

The shell-side stream for the Ll'iG application is a.n evaporating multicomponent mixture which produces cooling duty for the condensing and subcooling

streams on the tube-side. The two-phase flow on the shell side is limited to

the cryogenic LNG application. The design pressures may be up to over 200

Bar on tube-side, but a normal design pressure for LNG appliC<'.tion is in

the range of 30-50 Bar on tube side and 2-10 Bar on shell-side. The areato-volume ratio is in the range of 150 to 250 m2 /m 3 in t!:.e heat exchanger

bundle, depending on tube diameter and radial and longitudinal tube spacing. High compactness combined with efficient heat transft:r due to local

cross-flow and total counter-current flow, make it possible to build la...rge heat

exchanger units, which are utilized in LNG plants.

1

2

1 Thermal design of LNG heat exchangers

The direct capital cost for the main neat exchanger may be about 30 % of tne

total investment cost pro liquefaction train [1], [2J. The energy consumption

<j.ue to exergy loss :n the main heat exchanger could be about 25 % of the

total energy consumption pro liquefaction train. Optim~J design of the main

heat exchanger is therefore important with regard to investment costs and

energy consumption during operation.

A simulation program, CryoPro, has been developed in order to carry out

thermal design and simulation of the liquefaction cycle and the main heat

e.'(changer in an LNG plant. The computer program was developed at The

Division of Refrigeration Engineering, at the Norwegian Institute of Technology, with financial support from StatoiL The design procedure for LNG

heat exchangers, described in this chapter, have also been implemented in

CryoPro.

1.2 Process considerations

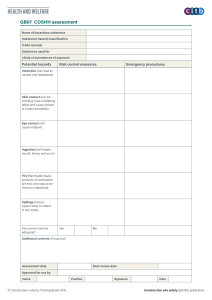

Figure 1.1 shows a flow diagram for a natural gas liquefaction process. The

process is a propane precooled MCRI process, the most widely-u~ process

for LNG production worldwide.

A complete description of the process is given by Newton et al. in references

[3], [4], [5]. The process consists of a pretreatment system, a liquefaction sys,tem and a compressor/driver system. Heavy hydrocarbons, water, CO 2 , HzS

and Hg are removed down to a specified limi.t in the pretreatment system.

The limits for maximum content of these components are normally given in

order to prevent freeze-out and blocking in the main heat exchanger. The

design specification for the fractioning system would be given by the inlet

composition of the natural gas and the freeze out limit in the main heatsxchanger. The liquefaction system consists of a PI':COCling system which uses

a propane cycle or a binary-fluid cycle (Dual-mix), aud a main liquaaction

system which uses an MCR cycle. The pretreatment system and tha precooling system are normally incorporated into the same process block. The main

heat exchanger consists of two bundles built together in one shelL The two

bundles are called the warm bundle and the cold bundle respectively.

The natural gas and the MCR mixture are precooled before they are conI

Multi Component Refrigerant

3

1 Thermal design cif LNG heat exchangers

_-

..........

-

-

rrr~

I

II

I

(

Figure 1.1: Flow diagram for a na.tural gas liquefaction process [3).

4

1 Thermal design of LNG heat exchangers

dense<! in the warm bundle and subcooled in the r.old bundle. The MeR

fluid is separated into liquid and gas, before entering the warm bundle, in

()rder to obtain different compositions of the evaporating fluid in the warm

and the cold bundle. The MeR mixture is totally evaporated in the warm

bundle before being compressed and recondensed again. The natural gas and

the MeR are multicomponent mixtures, and will therefore condense at decreasing temperature. The MeR mixtures will also evaporate at increasing

temperature.

The natural gas enters the main heat exchanger with specified composition,

flow rate and pressure. The flow rata of the fuel gas is specified from the

total demand in the plan'!;. The natural gas temperature at the outlet of the

cold end in the main heat exchanger will be a function of this fuel-rate.

The selection of the remaining process parameters for the MeR refrigerant

has to ~ done in close ccnnectir,m with the thermal design of the liquefaction cycle and the main heat exchanger. These process parameters could be

summarized. as :

• Composition of the MeR fluid

• In!et temperature to the

wan::J.

end of the heat exchanger

• Suction and delivery pressure for the MeR compressors

• Pressure drop on each stream in the heat exchanger

• Temperature at the split point between the warm and the cold bundle

•

US(;

of expander as throttle device

The inlet temperature to the warm end of the heat exchanger is a function

of the temperature in the precooling loop. If a propane cycle is used, this

temperature may only vary v.ithin a narrow range. If a duel-mixture cycle

is used the flexibility will be much greater with respect to selection of inlet temperature and distribution of cooling duty and driver capacity in the

precooling cycle and the MeR cycle.

The exergy loss in the liquefaction loop may always be minimized by changing

the MeR composition. The local exergy loss due to heat tIG.!'!.sfer of a duty

Q between a warm and a cold stream with temperatures Tws and Tes may

1 Thennal design of LNG heat excha:agers

5

be calculated from Equation 1.1. The temperature is assumed to be constant

for both streams. Tref !s the reference temperature for exergy.

E

Tref

[T

"' ]

Q = Tcs. Tws· ws -.L cs

(1.1)

The loss is an inverse function of the stream temperature and a function of

the temperature difference between the warm and the cold stream. Equation 1.1 is used to calculate the temperature difference for a constant relative

exergy loss of 0.05 as function of temperature. The result is given in Table

1.1. The MCR composition should be optimized in such a way that temperature profiles in the heating and the cooling curves are similar to each other,

with decreasing temperature difference at decreasing temperature, in order

to obtain a constant, relative exergy loss.

Table 1.1: Temperature difference as function of temperature with a

relative exergy loss of 0.05.

Tes [K]

240.0

200.0

150.0

100.0

T uts

-

con~tant

T es [K]

10.00

6.89

3.85

1.69

The exergy loss in the main heat exchanger will also be a function of the

delivery pressure from the MeR compressors. Expanders may also be used

as throttle devices for the natural gas stream and the two MCR streams, in

the main heat exchanger. Use of expanders entails a reduction in exergy loss

in the liquefaction unit.

6

1 Thermal design of LNG heat exchangers

1.3 Design procedure

1.3.1 Basic design principles

The design procedure for the main heat exchanger is based on two main

principles.

• The total surface in the main heat exchanger will depend on the location

of the split point between the warm and the cold bundle. The location

will always have an optimum solution .

• A specified minimum temperature in the main heat exchanger can always be obtained by cha.nging the pressure on the shell side.'

The first statement is only valid for design purpose, where the geometrical

lay-out has to be established. The last statement may be used both for design

and for simulation.

A design procedure for the main heat exchanger is summarized in Figure 1.2.

The specification contains process parameters for the inlet natural gas stream

and the outlet LNG product, specified minimum temperature difference in

the heat exchanger, specified temperature difference in the warm end of the

heat exchanger and an object function for the optimization. The object

function could, for iI!stance, be exergy loss, investment cost or a combination

of investment cost and operational costs.

The design starts with a heat balance around the main heat exchanger with

given process conditions in order to calculate MeR flow rate. The hea.t

exchanger length is estimated by use of a step-by-step calcula.tion from the

warm to the cold end, with a heat balance on each step. The length of the

warm bundle is settled by use of a. split criterion, and the specified minimum

temperature difference is obtained by control of suction pressure. A new

total heat balance and a new ftow rate are calculated every time the suction

pressure is updated. The change of suction pressure and the location of split

point, and tile calculation of surface in the heat excilanger bundle will be

described in detail.

A procedure for simulation of the main neat excha.nger is given in Figure

1.3. The heat transfer area is fixed, and the operational conditions, such as

natural gas :flow rate and gas composition may be varied. MeR :flow ra.te

1 Thermal design of LNG heat exchangers

7

With given process specifications and object junction

Change MeR composition and delivery pressure

Change MeR ·suction pressure

Change location of split point between warm and cold bundle

Calculate surface in warm and cold bundle

TJ ntil optimum location is reached

U uti! specified minimum temperatu1'C difference is reached

Until optimum design solution is rmched

Figure 1.2: Ba.sic procedure for design of the main heat exchanger.

and high pressure is established by the compressor. Such simulations could.

be used in order to achieve optimum operation conditions. The procedure

described in Figure 1.3 uses a shooting technique on the temperature of the

low-pressure refrigerant in the warm end and on the suction pressure. The

optimum control of the MeR compressor is not considered in the procedure.

With given process specifications and object junction

Change MCR composition.

Change MCR S1.lCtior. pressure

Change refrigerant temperature out of warm. end

Calculate warm and cold bu.ndle

Until total heat balance is reached

Until specified LNG conditions is reached

Until minimum power input is reached

Figure L3: Basic procedure for simulation of the main heat exchanger.

1.3.2 Heat exchanger model

Figure 1.4 shows a simplified sketch of a multistream heat-exchanger bundle

with N st number of streams. The first stream is the shell-side stream and

the (N st-1) tube-side streams exchange heat with the shell-side stream only.

1 Thermal design of LNG heat exchangers

8

.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

·

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

,

I

I

I

.

I

I

I

I

I

I

··

·, ·,,

·

···

. , ·,

I dX I

Len gt hO

I

I

I

I

I

I

I

I

Stream Nst

Stream·· .

Stream 2

•,

I

I

Stream 1

I

I

Len gt.h

X

Figure 1.4: Simplified sketch of a 1X.ultistream. heat exchanger with N st

streams.

A steady-state heat balance for a small longitudinal element dX, between a

tube-side stream, i, and the shell-side stream, 1, leads to Equation 1.2 and

1.3. The longitudinal heat conduction is ignored in this heat balance.

i

dh

N~, dh

M·

dX

;=2 dX

Ml

= 2···Ns i.

(1.2)

[-h=2,)-k-'

(1.3)

A. momentum balance over a longitudinal element dX leads to Equation 1.4.

i= l···Nst

(1.4)

51, S2 and 52 are integer constants with values of -lor 1 depending on integration direction, flow direction and direction of phase change. An adiabatic

1 Thermal design of LNG heat exchangers

9

flash method for calculation of temperature as function of enthalpy and pressure for a given composition is also needed as given by Equation 1.5, in order

to obtain a closed equati~n system.

i=1···Nst

(1.5)

Equations 1.2 to 1.4 express the enthalpy and the pressure for each stream

through the heat-exchanger bundle by first-order differential equations. The

right-hand side of the equations has to be calcdated from a set of algebraic

equations and constants. The constants are given by the geometrical layout such as heat transfer area pro unit length and cross-sectional area for

each stream. The algebraic equations, sach as heat-transfer coefficient for

each stream and pressure gradient for each stream will vary through the heat

exchanger, as the temperature and pressure vary. The total heat-transfer

coefficient is calculated from the local heat-transfer coefficients by the same

method as for a shell and tube heat exchanger [6].

The total mathematical model consists of (2· Nst - 1) independent differential

equations and a set of independent algebraic equations. A solving procedure

for the equations is given in Figure 1.5. The geometrical lay-out refers to

parameters such as radial and longitudinal tube spacing, number oftubes for

each stream and tube length. .

With given stream data and design limitations

Change geometrical lay-out

Change guessed values at length 0.0

Change for next step by integration

Enthalpy, pressure and temperature.

Heat-transfer coefficient and total surface

Until stop criterion is reached

Until residuals at length X are minimized

U nti! optimum design is obtained

Figure 1.5: Solution procedure for a bundle in a multistream heat exchanger.

..I\.s described in Chapter 1.3.1. all of the input streams to the heat exchanger

are known or guessed in the wa.rm end. These streams are considered as

10

1 Thermal design of LNG heat exchangers

specified input values. There will also be design limitations such as ma.ximum

pressure drop, maximum length and so on. These limits could be based on

J;Danufa.cturing, transport, or process considerations. The design starts ,..lith

a choice of geometrical lay-out for the bundle. k soon as these values are

established the heat transfer area pro unit length and the cross-sectional area

for each stream can be calculated. The geometrical parameters are constant

throughout the heat exchanger bundle.

The solution of Equation 1.2 to Equation 1.4 is based on a numerical integration of the differential equations from length 0 to length X of the heat

exchanger. Different numerical methods may be used to integrate equations

1.2 to 1.4. The simple first-order Euler method is given by Equation 1.6. The

method is a. step-by-step method, where 11. refers to integration step number

and i refers to stream numb~r. LlX is the length of each integration step.

The pressure and the enthalpy at the next integration step are calcula.ted

from equations 1.2, 1.3 and 1.4. The temperature is calculated from Equation 1.5 and the rigbt-hand sides of equa.tions 1.2 to 1.4 a.re updated in order

to calculate yet another integration step.

(1.6)

The integration proceeds until a specified stop criterion is reached. Specified

length or specined temperature and pres'Oure on an output stream may be

used as stop criterion. The procedure is generalized to solve the situation

where some of the input streams have unknown values at length 0 and known

values at length X. The residuals are defined as the difference betw~ the calcula.ted stream temperature a.nd pressure at length X and the known stream

temperature and pressure at length X. The guessed values at length 0 are

changed in order to minimize these residuals. In the last part of the design,

the geometrical lay-out may be changed in order to meet the design-limits

given at the start of the calculation.

A simplined solution may also be obtained for Equation 1.2 to Equation 1.47

by assur::ling that all of the warm streams follow the same temperature profile

thro1igh the heat exchanger. The total cooling curve may then be divided into

a number of grid points or section:;, where the temperature for the sa ell-side

1 Thermal design of LNG heat exchangers

11

stream is estimated by use of a heat balance. This gives a faster calculation

and the U . Aile value is then post-calculated for each stream and each grid

point. Such an approach. may be used for preliminary studies of the design

and the process parameters.

The accuracy of the design depends on many parameters, such as adiabatic~

l1ash calculation and correlations for calculation of heat-transfer coefficients

and pressure drop. The temperature difference in an LNG heat exchanger

may be as low as 2 to 3 K at the pinch point. Accurate prediction of temperature from specified enthalpy and pressure values is therefore important.

The total calculated surface is also sensitive to the pressure on the shell-side.

The prediction of the pressure drop may therefore affect the prediction of the

temperature difference and the total surface.

1.3.3 Optimum split point

Different design criteria may be used in order to establish the split point

between the warm and the cold bundle. Figure 1.6 shows an example on the

temperature difference in the warm and the cold bundle as a function of relative length. The split point must be within the range of relative length where

both the warm and the cold bu~dle have a positive temperature difference.

This range will vary with composition and suction pressure. The profile is

generated with the assumption of equal temperature on each warm. stream

at each grid point.

Different criteria for detection of split point may be :

L Given length of warm bundle or temperature of one stream out of warm

bundle

2. Minimizing surface in heat exchanger

3. Maximizing

~T

in the split point

The first criterion may not be obtainable due to the actual range with positive

temperature differences for both bundles.

Figure 1.7 shows an example for the total heat transfer surface in a main heat

exchange!" as a function of the relative length at the split point between the

warm and cold bundles. A decrease in the warm bundle length will reduce

12

1 Thermal design of LNG heat exchangers

::.::

8.0

OJ

Warm bundle - - •

{J

C

OJ

1-1

OJ

Cold bundle ___ .

6.0

I

"-l

"-l

-rI

'0

I

'.

4.0

I.

OJ

1-1

:l

J.J

<0

1-1

~- .....

,,

I"

'

I

,

"I

,

.... J

I

,

I

2.0

,

\,I

I

OJ

0.0

~

QI

E-t

0.7

0.8

0.9

1.0

Relative length [-]

Figure 1.6: Temperature djfferences in the warm and cold bundle.

the total surface because the total heat transferred is reduced due to the

fact that there are more streams in the warmb-undle than in the cold bundle

and because the temperature difference in the warm bundle is increased. The

surface in the cold bundle will increase at the same time since the temperature

difference is reduced. The minimum surface will be at a length where these

two effects balance each other. The possible split range is narrow for this case

and the temperature difference in the cold bundle increases very rapidly with

respect to relative length. The split point for minimum surface is therefore

located very close to the lowest range limit. The criteria for minimum surface

is set up in Equation 1.7. The optimum po!nt for minimum surface is given

in Figure 1.7.

(1.7)

The use cf the minimum surface criterion PN~UCes a lower Ll T for the cold

bundle than for warm bundle. If the pinch point for the heat exchanger is

located in the split point, the suction pressure will have to be kept lower

than necessary in crder to obtain the specified, minimum pi.nch point. The

13

1 Thermal design of LNG heat exchangers

40000

r---~r-r---...,...----"----'

N

I

E

•

~

~

36000

ItS

""':II-<

til

32000

Surface - Minim1.lJ.iI ---Max_ DT ----

2800 0

'--_---J~

0.85

_ _.....J,..._ ___L_ _

0_87

0.89

0_91

~

0.93

Relative length [-]

Figure 1.7: Total h eat- transfer surface as a. fun ctian of th e split pai:Jt between

the warm and coid bundle.

14

1 Thermal design of LNG heat exchangers

maximum obtainable ~ T in the split point wi.ll be for relative length where

temperature difference is equal for the warm and the cold bundle, as

given in Equation 1.8.

th~

(1.8)

The optimum point for maximum temperature difference is also given in

Figure 1.7. The variation in minimum temperature difference between the

two different split points is about 0.4 °C in Figure 1.7. The optimum curve

is :fiat in this region, so the increase in surface between the two split points

is small compared to the change in temperature difference and, eventua.lly,

suction pressura, for this case.

All of the three methods are im plemented in CryoPro, but the method which

maximizing the !!J. T is used in most cases.

1.3.4 OptimUm suction pressure

Figure 1.8 shows the temperature difference through the heat exchanger as a.

function of relative length at different specifications for minimum temperature approach (MITA ). The split point between the warm and cold bundle is

ca.Iculated from the criterion of maximum temperature-difference in the split

point. The profiles are generated with the assumption of equal. temperature

on each warm stream. The change in MITA specification creates a. change

in suction pressuro:;. The different temperature ?rofiles have a parallel displacement to each othe:.r with respect to change in suction pressure or MITA

specification. There are six different pinch points in this example, four-in the

warm bundle and two in the cold bundle. The last one in the warm :,undle

and the first one in the cold bundle are located in the split point. These two

are similar due the specification of maximum temperature difference. Two

of the different pinch points are in position to be a MITA point.

Figure 1.9 shows a trace of the different pinch points as a function of suction

pressure. The pinch points are detected from the definition given in Equation

1.-9.

dT

[dXbu];

= 0.0

(1.9)

15

1 Thermal design of LNG heat exchangers

::.::

~

10.0

MITA

(!)

u

t:

(!)

8.0

l-l

(!)

....,

...., 6.0

"'-- ..

.

= 1.5

= 2.5

= 3.5

I

I

"

•

•

.

.,.,j

'0

4.0

0.0

0.0

0.2

0.4

0.6

D.B

1.0

Relative length [-]

Figure 1.8: Temperature profile as a function of specified MITA.

The MITA specification is located at the pinch point which gives the lowest

suction pressure. Each of the pinch points has to be traced during iteration

on suction pressure due to the fact that the MITA point jumps from one pinch

point to another when the pressure is varied. At a given suction. pressure,

the MITA point is located at two different pinch points.

The slo.,-.a of the dinerznt pinch traces is a strong function of pressure drop

on the shell side. If the eqQations are solved without the assumption of equal

temperature on each v;ann stream, the number of pinch points increase:::, as

shov.,,!!jn Figure 1.10. The total heat-transfer coefficient is assumed to be

constant for each stream through the heat exchanger in this example. There

are about 10 different pinch points in the figure.

Heating and cooling curves for the main heat exchanger in an MeR,

precooled, liquefaction system are given in figure l.li.

propa.n~

Figure 1.12 shows the total heat transfer surface and the exergy loss in an

LNG heat exc.h.ar.ger as a function of the suction pressure to the MeR compressor. A change of ~:uction pressure will lead to a pa.rallel displacement of

the heating and cooling curves in figure L 11. The optimum solution has to

16

1 Thermal design of LNG heat exchangers

~

~

10.0

(!)

()

Split point pinch

Warm #1

,

Warm *2

' • .c:-.-".",

Warm #3

, .............------,'::.~

Cold #::!.

....-:::........

....~---

W 8.0

1-1

(!)

:!j 6.0

• ..-1

'0

(!)

J..J

ItS

----

-:::-............... ---..:::--..

4.0

.......

1-1

;:!

.-.-.-.:~:::~

.

2.0

.

>-I

(!)

0:

e:Q}

8

0.0

I

L

1.9

2.1

2.3

2.7

2.5

2.9

Suction pressure [Bar]

Figure 1.9: Pinch trace as a function of specified MITA.

~

~

15.0

(!)

()

liquid. - vapour ----

!1CR

MCR

W12.0

Natural gas

1-1

..' ,,

Q}

I

::::

9.0

,

• ..-1

\,

"

'0

"

6.0

0.0

0.0

0.2

0.4

0.6

0.8

1.0

Relative length [-]

Figure 1.10: Temperature profiles in an LNG heat exchangel".

17

1 Thermal design of LNG heat exchangers

Temp=mre [KJ

240.00

230.00

,

1\\.

I

I

I

~, I

~

220.00

I

I

I

I

200.00

I~,

190.00

I

II~-,-

I

180.00

I

I

170.00

i

I

~ ~\.

I

I

I

150.00

140.00

I

130.00

II

I

120.00

I

I

110.00

I

0.00

0.20

II

I~\

I

I

I

I

I

I

"\ 1

\.1

\l\

I

160.00

HotTii~-­

ColdSbCilPaSs - .

coidTiibcPaSSC

CcldTuiid'iSsr

I

I

HotSheIlFass

HotTlibePassl

HOlTi!beP"aSSi---

!

I

I

I

210.00

I

!

I

1

I

I

I

I

I

0.40

0.60

0.80

I

\\ I

\'

';~

\1

1

I

Re1:uive Length [-]

1.00

Figure 1.11: Heating and cooling curve for for the main heat exchanger in

an MeR, propane precooled, liquefaction process.

18

1 Thermal design of LNG heat exchangers

be based on economical considerations.

til

til

o

.-l

60

50

Area

Exergy loss

40

30

20

M

E

10

o ~----~------~----~----~

1.0

1.5

2.0

2.5

Suction pressure [Bar]

Figure 1.12: Total heat transfer surface and exergy loss as a functioD. of

suction pressure.

1.4 Geometricallay--out

A sk~-:-~h of a CWHX bundle is shown in Figure 1.13. The heat exchanger

consists of tubes coiled in layers around a cylindrical core. The coiling direction alternates for each la.yer and the number of parallel tub~ in each layer

increases by a constant number from layer to layer toward the outside of the

heat exchanger. The radial distance between each layer is held constant by

use of longitudinal space bars.

The longitudinal distance between tubes in one layer and the tube inclination are also kept constant for all the layers. All of the tubes in one bundle

have equal length because of the constant distances in the radial and longitudinal directions and the constant inclination. The tubes are connected to

tubesheets at each end of the heat exchanger_ The ratios of tubes from all

of the different streams are constant for each layer in order to avoid maldistribution for the :fluid Oil the shell side introduced by differences in heat load

1 Thermal design of LNG heat exchangers

19

ELEMENTS 0" CONSTRUCTION

t-'1t.-:~_--

8

I. CD!L

2. MANDREL,3. TuBE L~Y:RS

4. SPACER5

5. JACKET

6.. PIGTA:L-ENDS

7. TuBE-SHEET

~. NOZZLES

«. ':''I£LL

USUALLY COUNTER-CURRENT

RANGE 0, BUllT UNITS

AREA

;.ElGHT

DIAMETER

WElGH'

,

0.3 -

11000 m 2

0.6 - 20m

I

o ;: -

201:'

0.0-4- 150 'tons

A-A SHELL SIDE FLOW

B

B-B 1. TUBE SIDE ~LOW

C-C 2. TUBE SIDE FLOW

0-0 TUBE SlOE FLOW

Figure 1.13: Sketch of a .:oil-wound hea.t exchanger bundle OYith four streams,

LINDE A.G. [8}

20

1 Thermal design of LNG heat exchangers

for each stream. The bundle is covered by a. jacket on the outside in order to

avoid a by-pass stream on the shell side.

A uniform two-phase flow distribution on {;he shell-side is crucial in a heat

exchanger used for LNG production in order to achieve constant temperature on each layer at a given length. Maldistribution may result in reduced

production capacity or increased power consumption.

The distribution system in a heat exchanger used for LNG production may

be constructed as given in Figure 1.14 as a separator and a perforated plate

spray tower [7]. The liquid phase is distributed over the entire CfO<:S section

ofthe tube bundle by gravity force, through the perforated plates; and :8.ows

as a thin film on the tube wall. The vapour is distributed in between the

liquid phase by pressure differences. The liquid and the vapour are in thermal

equilibrium a.t the top of the bundle, downstream the distribution system.

INTEIUUU.

SEPJlRATOR

DISTRIBUTOR TRATS

FOR UQU\D

Figure 1.14: Two-phase :Bow distribution system for a CWHX, Bukacek [7}

Description of a. the geometrical lay-out, performance and manufacturing of

1 Thermal design of LNG heat exchangers

21

coil-wound heat exchangers are also given ir. references [3], [7] and [9].

The main objective for the geometrical calculations in CryoPro is to establish

the bundle geometry, and to calculate variables which influence on the heat

transfer and the pressure drop. The geometrical data are classified in three

different categories, given in Table 1.2. The input data which have an initial

estimate may be changed during the calculation.

Table 1.2: Geometrical data for the main heat exchanger in CryoPro.

Fixed input data

Inside and outside tube diameter

Radial tube pitch

Longitudinal tube pitch

Input data with initial estimate

Core diameter

Number of tubes for each stream

Output data

Shell diameter

Bundle length

Heat transfer surface for each stream

Flow area for each stream

Number of layers

Tube inclination

The shell-side configuration varies continuously between in-line and staggered

as a function of position. Figure 1.15 shows the tube configuration between

four different layers at peripherical angle 0, 20 and 40 degrees. All of the

layers have in-line configuration at the starting position, (J = 0.0. The second

and the fourth layer are coiled in the right direction, and the other layers are

coiled in the left direction. The calculation of geometrical data is reviewed

in Appendix A.I.

Two of the most important parameters for calculation of heat transfer and

pressure drop are the characteristic flow area, and th,! characteristic radial

distance between neighboring tubes. The flow area for a tube side stream, j,

22

1 Thermal design of LNG heat exchangers

40

0000

0000

0000

degrees

s::

....0

"'u"'

Q)

....'0

l-;

.....

60 degrees

0°00

00

00°0

400

6

III

....'0s::

::s

...."'"'

OJ

s::

0

..J

o

degrees

20 degrees

0000

0000

0000

o 00

0°0

0~08

Radial direction

Figure 1.15: Local tube configuration at different periphe;-ical angles.

23

1 Thermal design of LNG heat exchangers

may be calculated from Equation LID.

(LID)

The cross-flow area on the shell-side may be calculated from Equation 1.11,

where SreJ is the radial reference distance between to neighboring tubes,

calculated from one of the different methods reviewed in Appendix A.2.

(Lll)

The different methods calculate different values for the reference distance

and the lIow area. Comparisons between the methods are given in Table 1.3,

for four different cases. The methods are compared on a relative basis with

respect to the in-line flow area for given values of Pr, PI and Dt... These

parameters are also given in Table 1.3 and represent a reasonable range of

choice with respect to geometrical data in an LNG heat exchanger.

Table L3: Rel:;,:'ive Bow area on shell side, calculated by four different methods.

Case 1 : D tu = 10.0 mm, Pr = 13.0 mm, PI = 12.D mm

Case 2: D tu = 10.0 mm, Pr 13.0 mm, PI

11.0 mm

Case 3 : Dtu = 10.0 mm, Pr = 15.0 mm, PI = 12.0 mm

Case 4 : Dt'OL = 10.0 mm, Pr 15.0 mm, PI = 11.0 mID.

=

=

- ..c!'

Method

In-line

Staggered

Glaser [13]

Gilli [14]

=

Relative flow area

Case 2 Case 3 Case 4

1.0000 1.0000 1.0000

1.3719 1.2311 1.1953

1.1206 1.0782 1.0659

1.1961 1.1220 1.1032

Case 1

1.0000

1.4393

1.1493

1.2313

The heat-transfer surface for each stream, j, may be set up as a function of

the shell-side length, as given in Equ ation 1. 12. The total surface is calculated

24

1 Thermal design of LNG heat exchangers

as a sum of the surfaces for each stream.

(1.12)

The total tube length and the total bundle length are calculated as a result

from the integration. The two length parameters are related as given in

Equation 1.13.

Xiru. = sin{o:) . X t ...

(1.13)

1.5 Thermodynamic and physical properties

1.5.1 Selection of calculation methods

Accurate calculation of thermodynamic and physical properties is important

both for the design and simulation of heat-transfer equipment. The main aim

for the review in this section is to describe general methods which may be used

for calculation ofthermodynamic and physical properties in relation to design

and simulation of LNG heat exchangers. The thermo-physical properties are

also of great importance for data reduction and for data modeling in the test

facility, described in Chapter 2 and Chapter 3.

.

The properties and methods used in connection with models for thermal

design of heat exchangers and models for calculation of heat transfer aIid

. pressure drop may be classified into three different grQUPS as given in Table

1.4. A brief description of the different calculation methods is provided.

The thermodynamic and physical properties must be calculated for both

the liquid and vapour phase. The two key parameters used for selection of

calculation methods are the claim for high accuracy and the claim for general

application on mixtures. The main objective is to use the same Calculation

methods both for pure component and for mixtures in o::der to achieve a

smooth transition for the measured properties in the test facility with regard

to composition. The methods are selected for use on light hydrocarbons or

hydrocarbon mixtures. Some special methods are chosen for nitrogen gas in

order to obtain high accuracy in the test facility.

1 Thermal design of LNG heat exchangers

25

Ta.ble ! .4: TherlIlodynamica.l and physical properties used for design of the

main heat exchanger and da.ta. reduction in the test fa.ci1ity.

I Property

Calculation method

Equilibrium. data

Pure component

Vapour pressure or C-EOS

Multicomponent

C-EOS

Solid-liquid

GPA

Thermodynamic properties

Enthalpy

CSP (C-EOS in test facility)

Heat of evapora.tion . CSP (C-EOS in test facility)

Entropy

CSP (C-EOS in test facility)

Heat capacity

CSP (C-EOS in test fwlity)

Density

CSP

Physical properties

Cet>

I

Viscosity

Thermal cond.lcti\"ity

CSP

I Surface tension

CSP

....

26

1 Thermal design of LNG heat exchangers

A review of the chosen methods is given with emphasis on accuracy. The

review is related to the measUi<=lments and the data reduction in the test

f?rility, and is not c')mplete with r,>spect to the different da.ta given in Table

1.4.

A computer program for calcula.tion of thermodynamic and physical properties has been developed at SINTEF, Division of Refrigeration Engineering

[10J. This program, TP-lib, is used as a subsystem in CryoPro. The propert!es are calculated from a given temperature, pressure and composition. A

view of the different layers in TP-lib is given in Figure 1.16.

Enthalpy

APPUcmON LIVEL

t

FIASR CAI.CULUIONS

PHASE SEARCBlNG

ENTBALPY !'l'C..

RESIDUAL

FtlNCl'JONS IDEAL GAS

FOIL

PROPEiTlES

m!"J2Es

ImiNG ~!I

I

I

,CSP~

,.

Entropy

Compositions

'!P.Jib left! 0

BesidlI8l flmctioD

cas flmctiODS

TP_lib left! 1

tIdal

t

1

I

~panmeters

TP.Jib left! 2

Pure eomJlC!ll.ent

parameter!

TP_lib level 3

PtmE COMPONENT

CONDmONS

Figure 1.16: The layers ofTP-lib used for calculation of thermodynamic and

physical properties [10]-

The program consists of different layers and the interface between CryoPro

and TP-lib is on the application level. The system is also used as a basis for

the data reduction in tbe test facilities.

1 Thermal design of LNG heat exchallgers

27

1.5.2 Equilibrium data

The isothermal equilibrium in a vapour-liquid system may be calculated by

us<; ofEqi,iation 1.14, [il]. The equation is solved by iteration, and is applied

to calculate t-he vapc~r quality ~d the composition for each phase.

(1.14)

The equ3tion for adiabatic equilibrium may be obtained by adding a heat

balance around the two phases, as giveli in Equation 1.15. This is a calculated equilibrium with given enthalpy and pressure. This equation may

also be solved by iteration with respect to temperature, in combination with

Equation 1.14.

htp

-

i· hv(T, P, Y) - (1- x) . hL(T, P, X)

= 0.0

(1.15)

The vapour quality is influenced by th~ K-value for each component, which

is the equilibrium constant that describes the distribution of a component

between the two phases. The K-~ues are functions of temperature, pressure

and composition and a.re obtained from the definition of thermodynamic

equilibrium, given in Equation 1.16, where the fugacity for a component, i,

is equal in both phases. The temperature and the pressure are also equal in

the two phases.

fL,i

= IV.i

(1.16)

Different models may be used for calculation of the fugacity, and a G-EOS

is normally used for both phases in light hydrocarbon systems with small

amounts of polar components present. The K-value for a component, i, may

then be calculated from Equation 1.17.

Ki

= Yi = (h,i(T,P,X"r

Xi

BV,i(T, P, Y)

(1.17)

The CWHX design is based on Equations 1.2 to 1.5, and the accuracy in

the calculations depends on the C-EOS model, in turn dependent upon the

28

1 Thermal design of LNG heat exchangers

K-values and the enthalpy-temperature relationship. High accuracy may

be obtained for multicomponent equilibrium by use of binary interaction

parameters.

The same equilibrium model may be chosen for calculation of pure-component

vapour pressure. This gives a smooth transition between a pure component

arid a mixture, which is of importance for the measurements in the test facility. Pure-component vapour pressure for propane is compared with different

calculation methods in Appendix A.3. The deviation for the Peng-Robinson

equation-of-state ( PR-EOS ) is estimated to be within ± 0.2 °C within the

t~IUperature range of 230 K to 350 K. A detailed description of different

ii.&odels for calculation of K-values is given in Reference [11]. Different equations of sta.te for calculation of equilibrium in binary and multicomponent

mlxt)lres have also been reviewed in Reference [15].

.

.

Estimation of freeze-out for C02 and heavy hydrocarbons in LNG heat exchanger:; is an important part of the equilibrium calculations because these

calculations set the limit for the pretreatment system. These calculations

have been reviewed by Owren [12], with given recommendations. The GPA

Cryogenic Solubility program, developed by Kahn and Luks, may be used for

such calculations [12].

1.5.3 Thermodynamic properties

The density for pure or mixed hydrocarbons is calculated by a cCJ."l'esponding

state method as described by Ely et al. [16] and Stephan et aI. :[17]. The

method is based on statistical thermodynamics and relates the properties of

a mixed or pure fluid to the same properties for_a P1J!'e reference fluid by use

of a set of functions. Methane is used as reference fluid, and the density for

pure methane is calculated by a very accurate correlation. The P ..... p - T

data for pure methane may be c:alculateJ by use of a quasi-vinal equation

of state as given by Younglove et aI. [18], [19}. The equation is used both

for saturated and subcooled liqUid and for saturated and superheated gas

and is quoted to be very accurate. Evaluation of uncertaint)~ in calculated

density by the corresponding state method is based. on data for pure and

mixed hydrocarbons. The uncertainty for the calculated density is regarded

to be within ± 2 % for light hydrocarbons. A detailed description of the

comparisons is given in Appendix A.4.

1 Thermal design of LNG heat exchangers

29

Density and thermodynamic properties for pure nitrogen gas is calculated

from the same quC!Si-virial equation-of-state used for methane and propane

[18]. The uncertainty ill the calculated density is quoted to be within ±

C.2 % for fluid above critical temperature. This method is used for data

reduction in the test facility, for gas measurements. The uncertainty for the

calculated thermodynamic properties for nitrogen gas above critical temperature is quoted to be within ± 5 % for calculation of specinc heat at constant

pressure or volume, and within ± 1 J/mole for calculation of enthalpy [18].

1.5-4 Physical properties

Viscosity and thermal conductivity for pure or mixed hydrocarbon fluids are

estimated o;>r use of a corresponding state method similar to the method used

for calculation of density. A complete review of the method is given by Ely

et aI. [16]. The method has been implemented in TP-lib as a part of the

work on the thesis.

The uncertainty in calculated dynamic viscosity and thermal conductivity

for pure hydrocarbons and hydrocarbon mbctures is evaluated to be within

± 8 % for this method [16]. A def::illed comparison is performed in Appendix

A.5 for pure component dyna-..lic viscosity. The uncertainty in calculated

dynamic viscosity for pure propane is regarded to be within ± 3 %.

Thermal conductivity and viscosity for a pure component are given by YOllDglove et aI. [18], [19]. The uncertainty for the calculated properties for

nitrogen gas above critical temperature is quoted to be within ± 6 %, both

for viscosity and thermal conductivity.

2

Test facility for LNG heat exchangers

2.1 Introduction

Design- and simulation results for LNG heat exchangers are sensitive to the

loeal heat-transfer coefficient and pressure gradient on the shell side, due to

small temperature differences between warm and coLd streams and a high

~ gradient on the shell side. No commercial computer program is available

to calculate such an exchanger. Information regarding heat transfer and

pressure drop are normally proprietary for manufa...-turers I)f such exchangers.

Two different test facilities have baen built in order to verify and improve

the simulation program CryoPro. The test facility described here is built for

measurement on down-flow evaporation on the shell side.

The local heat transfer coefficient and pressure gradient are measured, and

the whole shell-side range, in an LNG heat exchanger, may be covered by

.::hanging different parameters in the test facility. The test fluid may be

pure or mixed hydrocarbons and the test facility are operated at realistic

pressures and temperatures. Different parameters which affect the measured

heat-transfer and pressure drop are varied.

The construction of the test heat-exchanger, and the commissioning of the

test facility have been performed in connection to this thesis.

2.2 Description of test facility

A flow diagram for the test facility, including the major parts of equipment

and instrumentation, is presented in Figure 2.1. The facility consists of a

test circuit, a propane brine circuit and a methane cooling cirC1!it.

The local hea.t-tra.nsfer coeilicient and the pressure gradient are measured

30

31

2 Test facility for LNG heat exchangers

I

I

I

I

I

I

I

I

I

I

I

I

H~

I

.

_~ __ ~___Lj~~r, ~fl~'"

~

I

)---L~"""J.:T5

-------liliI-L--LrO;- ....

@yI..N

Figure 2.1: Flow diagram for the test facility.

(A)(C)(E)(G)(1)(K)(M)-

Test heat-exchanger

Vapour blower

Vapour cooler

Turbine-meter

Propane pump

Propane cooler

Methane expansion drum

(B)- Sepa.rator

(D)- Orifice-meter

(F)(H)(J)(L)(N)-

Pump

Liquid cooler

Temperature regulator

Propane expansion drum

Philips cryogenerator

32

2 Test facility for LNG heat exchangers

in the test heat exchanger. The test fluid is circulated through the test

heat exchanger as gas- , liquid- or two-phase flow. When measurements are

Rerformed at two-phase conditions, the fluid is separated into a liquid stream

and a vapour stream, after the test heat exchanger. The flow rate and the

composition are measured for the two different phases. The V3.pour stream is

circulated by use of a gas blower and cooled before it is mixeJ with the liquid

in the test he:~,t exchanger. The liquid stream is cooled after the separator

and circulated by use of a pump before it is mixed with the gas in the test

hea.t exchanger again.

The liquid and the vapour streams in the test circuit are cooled against the

propane in the brine ci,rcuit. The propane is circulated by use of a pump

a.nd cooled against evaporating methane in the main cooling circuit. The

brine circuit is branched into three courses; one for cooling of liquid, one

for cooling of vapour and one for recirculation of brine. The main cooling

circuit operates by thermosyphon circulation. The methane is conde!lsed in

a cryogenerator, which is the cold-supplier in the plant.

The vapour- and the liquid flowrates are changed by means of frequency regulation on the gas blower- and the pump motor, and by means of recirculation

of liquid from the pump to the separator. This system provides a smooth

regulation of flow rate through the test heat exchanger. The flow rate in the

brine circuit is changed by means offrequency regulation on the pump motor

and by means of regulation of the split ratio between the different courses.

The brine temperature is set by regulation of the cooling duty in the cryogenerator and by regulation of the electrical heat-input. The temperature in the

test heat exchanger follows the brine t~mperature. The pressure in the test

heat exchanger is a function of the temperature and the total composition of

the nuid in the test circuit.

The test facility may be operated at temperatures from 0 to -150 0 C, and

pressures from 1 to 15 bar. The mass-flow velocity in the test section may

be varied from 20 to 200 kg/m 2 s. The whole quality range from superheated.

vapour flow to liquid film flow may be covered for a particular mixture,

by changing the temperature and the flow rate of liquid and vapour in the

test circuit. Pure-component or mixtures of nitrogen, methane, ethane and

propane would normally be used as test fluid.

2 Test facility for LNG heat exchangers

33

2.3 Test heat exchanger

The test heat exchanger consists of a gas-liquid mixing system, a two-phase flow distribution system and the test section. A sketch of the hea.t exchanger

is gl1T<ln in Figure 2.2.

The liquid- and the vapour strea!:lS have different temperature and composition before mixing into a two-phase fiow. The purpose of the mixing system

is to bring the two-phase flow to thermodynamic equilibrium. The system

consists of series of bends and T junctions.

It is important to obtain uniform distribution of the two-phase flow in the

test heat exchan~er. The :flow distribution system consists of a plate with 30

vertical tubes, placed in a circle over the central coil in test heat exchanger.

Each tube has two slits, 0.5 mm wide and 100 mm long. The two-phase now

is separated by gravity, and the liquid forms a level over the partition pla.te

before it is drained through th.e slits in th.e tubes. The vapour is drained

directly through the center of the tubes, and the two-phase flow forms an

annular flow pattern through the distribution tubes. The expansion at the

outlet of the tubes generates a uniform spray of liquid over the whole flow

area in the test section.

The distribution system and the heat exchanger were tested with air-water

mixtures as test fluid. Visual observations were performed. The flow rate

and the vapour quality were changed over a large range. Dye was added at

different locations in order to observe the iluid :Bow through the d.istributi.on

system and in the heat exchanger. The testing gave satisfactory results, both

for two-phase distribution and for film flow down through the heat e.'Cchanger.

The dye was traced around the whole periphery of the test excha.nger in a.

distance of 6 to 8 rows downstream the injection point. The heat exchanger

is normally operated with light hydrocarbon mixtures, where the density and

the viscosity ra.tios are much smaller than for air and wa.ter. The degree of

mixing and the :Bow distribution will therefore be better for such mixtures.

The test section is a model of a coil-wound hea.t exchanger, and consists of

one central coil and two half-tube coils on the inner and outer walls. The

center coil consists of four parallel tubes and the inner and the outer coils

consist of respectively three and five parallel half-tubes. The half-tabes on

the walls are inserted in order to obtain right flow performance around the

center coil where the heat-transfer coefficient is measured. Tha main layer is

2 Test facility for LNG heat excha'lgers

34

Figure 2.2: Test heat exchanger.

(1)(3)(5)(7)(9)-

Tubes with vertical slits

Outer half-tubes

Flow inlet

Pressure tapping

Partition plate

(2)- Heated palt of test section

(4)- Inner half-tubes

(6)- Flow braker

(8)- Separator plate

35

2 Test facility for LNG heat exchangers

coiled to the right and the two half-tube layers are coiled to the left. Three

longitudinal space bars are inserted between each of the layers. The tubes in

the center coil are also separated by space bars in the longitudinal direction.

The core and the half-tubes on the inner wall are cut on the lathe with high

accuracy, from one piece of metaL Five parallel half-tube hollows with correct

inclination and longitudinal distance were made on the outer walL The tubes

was squeezed down into t:,~ hollows in order to form the ~uter half-tubes

on the walL

The test section consists of a flow stabilization zone, an isothermal zone and

a heated test zone. The total heat exchanger consists of 24 succ~ing tubes

in the flow direction. The flow-stabilizer zone consists of 6 succeeding tUDes

where a correct velocity profile and flow distribution are esta.blished.

The heated zone corresponds to one round for each tube in the coil, which

again corresponds to four succeeding tubes in the flow direction. Outside

tube diameter, heated area, longitudinal tube pitch, radial tube pitch and

tube inclination have been measured directly or calculated from indirect measurements. The geometrical data are used in date reduction and in models for

heat transfer and pressure drop. An uncertainty limit for each of the geometrical parameters is estima.ted. The geometrical data for the test section are

cited in Table 2.1, and reflect a normal geometrical choice for a coil-wound

heat exchanger. The determination of the different geometrical parameters

and the relation between the different parameters are shown in Appendix

B.1.

Table 2.1: Geometrical data for the test heat excha.1ger.

Parameter

Outside tube diameter

Longitudinal distance between tube center

Radial distance between tube center

Winding angle

Heated tubelength

Heated area

Value

12.00 ± 0.05

13.94 ± 0.09

15.91 ± 0.06

7.938 ± 0.06

1688.5 ± 3.00

63655.0 ± 288

mm

mm

mm

0

!Ilm

mm 2

Each of the four aluminium tub~ in the center layer is heated with electrical

heating elements at the center of the tu bes. The heated test zone is separated

36

2 Test fadlity for LN G heat

excha.ng~rs

from the rest Cif the heat exchanger by PTFE plugs in order to prevent heat

leakage. The heat flux from the tubes may be varied from 0 to 10 kW 1m2 •

A mixing chamber is insta.lled after the heated test section in order to bring

the fluid back to isothermal conditions before the temperature is measured.

The mixing chamber consists of saddle pocking, as used in distillation columns.

2.4 Estim.ation and treatment of errors

Measurement and calculation of physical properties involves errors. The main

aim for the error analysis is to estimate uncertainty intervals ror the measured

heat transfer, the measured pressure drop, the parameters used for modelling

purposes and the models used for calcu lation of heat transfer and pressure

drop.

The uncertainty interval, UI, is defined as the range around a mean value,

which can be expected to inclllde the true mean vabe of the property

with a. specified confidence level or probability, P. A result may be stated as

x±Ulp.

x,

Errors are divided into three main groups. Spurious errors, random errors or

precision errors, E, and systematic errors, /3, also called fixed errors or bias

errors. Spurious errors, such as human errors and instrument malfunction,

are not incorporated into the uncertainty intervaL A statistical outlier test is

used in order to detect and reject measurements affected by spurious errors.

The Dixon outlier test [26] is described in Appendix B-3. The total uncertainty interval is estimated by a combination of j3 and E. The error analysis

for the measurements involves ;

L Identification of all independent sources of errors

2. Identification and rejection of spurious errors

3. Estimation of uncertainty associated with systema.tic errors

4. Estimation of uncertainty associated with random errors from repeatoo

measurements a.nd statistical analysis

5. Estimation of uncertainty intervals for the measured results due to

propagation of systematic and random errors

2 Test facility for LNG heat exchangers

37

6. Estimation of uncerta.inty interval for the calculated results due to propagation of errors

The main sources for uncertainty in measured values are calibration, data

acquisition and data reduction. Methods for estimation of errors and uncertainty interval are given in Appendix B.2.

3.5 Instrumentation, calibration and uncertainty

2.5.1 Temperature

The locations of the different points for measurements of temperatures are

shown in Figure 2.1. Fluid temperatures in the test section are measured

at eight different points. All of these points are regarded as isothermaL

Surface temperatures are measured in the tipper and lower parts of the heated

test section, by four thermocouples on each of the four heated tubes. The

location of the wall points and the fluid points are given in Appendix B.S.

Temperatures in the test fluid are measured at three points along the liquid

part of the circuit and at four points in the vapour part of the test circuit.

A description of the different elements is presented in Table 2.2.

The temperatures TIl to T 1., T31 to T~ and all of the surface temperatures

are measured with sheathed and insulated thermocouple elements. The rest

of the temperatures are measured with ba.re thermocouple elements. All of

the thermocouples are of type E made with chromel-constantan wires. An

ice ba.th is used as reference junction.

An instrumentation diagram for the thermocouple element is given in Figure

2.3. The chromel-constantan wires in the thermocouple elements are connected to shielded and twisted copper wires at the reference jUilction. All of

the copper wires from the reference junction are connected to an isothermal

input connector on the data logger. The shield is connected to earth ground.

The shield on the input connector is connected to earth ground through a

100 kQ resistance in order to prevent noise in the measuring chain.

The signals from the thermocouple elements are converted to temperature by

use of Equation 2.1, where the electrical signal is represented as a temperature

38

2 Test facility for LNG heat exchangers

DATAE..OGGER

VOLTMETER

CONNECTOR

MEASUREMENT

+

POINT

G

CONSTANTAN

SHIELD

100 k

Figure 2.3: Instrumentation diagram for temperature measurement.

39

2 Test facility for LNG heat exchangers

Table 2.2: Thermocouple elements in the test circuit.

Identifier

TIl - T14

TSl - T 3•

TZAl - TZAa

T2Bl - T2B8

T4

Ts

'1'6

T7

Ts

T9

TIO

Tn

TI2

Tlcb

Location

Fluid temperatures before the heated test section

Fluid temperatures after the mixing chamber

Wall temperatures in the upper part

Wall temperatures in the lower part

Liquid temperature at the outlet of the separator

Liquid tempera.ture at the outlet of the liquid cooler

Liquid tempera.ture at the inlet of the mixing system

Vapour temperature at the outlet of the separator

Vapour temperature before tr.e orifice meters

Vapour temperature at the inlet of the mixing system

Propane temperature at the outlet of the p'lmp

Propane temperature at the outlet of the liquid cooler

Propane temperature at the inlet of the pl\mp

Laboratory temperature

function.

E(T} = EreJ(T) + Ecalib(T}

(2.1)

Erei is the electromotive force, EMF, calculated from a standard thermocouple reference table. Ecalib is a correction for the EMF based on calibration

data. The reference table is given by an equation in Appendix B.6. Equation

2.1 is solved by iteration. Six of the sheathed elements and the bare wire

are calibrated off-site by a comparison method described in Appendix B.7.

Individual equations for Ecalib are given. Total uncertainty, in EquatioI:. 2.1,

due to off-site calibration of the elements is estiinated to be within ± 0.07

°e, both att~e calibration points and in the int€!"Val between the points.

The calibration curve for the rest of the sheathed elements is estimated by

bulk calibration as described in Appendix B.8. An equation for Eeelib is given.

The elements are also checked on-site by use of isothermal me<lSurement. The

uncertainty due to calibration for these elements is estimated to be v..':ithin ±

0.1 DC. The main error sources in the data acquisition system for temperature

are summarized in Table 2.3.

2 Test facility for LNG heat exehangers

40

Table 2.:3: Error sources for measurement of temperature.

Source

Reference junction

Data logger

Function of reading

Function of resolution

Calibration

Fluid temperature

Wall temperature

Uncertainty

± 0.01 °C

± 0.01

%

± 8.00

p.V

± 0.07 °C

± 0.10 °C

Status

Dependent

Dependent

Independent

Dependent

Dependent

The inaccuracy for the data logger is based on a.n air temperature !n the range

of 15 - 35°C and recalibration of the logger once a year. The total uncertainty

limit for each measured. temperature is estimated by use of Equa.tkl !! B.17