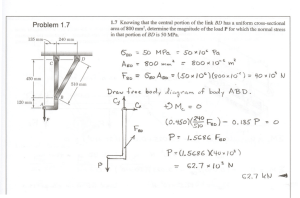

Department of Civil and Environmental Engineering Spring 2023 Instructor: Dr. Hessam Yazdani, PE Solved Select Problems PROBLEM 1.1 Two solid cylindrical rods AB and BC are welded together at B and loaded as shown. Knowing that d1 = 30 mm and d 2 = 50 mm, find the average normal stress at the midsection of (a) rod AB, (b) rod BC. SOLUTION (a) Rod AB: Force: P = 60 103 N tension Area: A= Normal stress: (b) AB = 4 d12 = 4 (30 10−3 )2 = 706.86 10−6 m 2 P 60 103 = = 84.882 106 Pa −6 A 706.86 10 AB = 84.9 MPa Rod BC: Force: P = 60 103 − (2)(125 103 ) = −190 103 N Area: A= Normal stress: BC = 4 d 22 = 4 (50 10−3 ) 2 = 1.96350 10−3 m 2 P −190 103 = = −96.766 106 Pa A 1.96350 10−3 BC = −96.8 MPa 2 PROBLEM 1.2 Two solid cylindrical rods AB and BC are welded together at B and loaded as shown. Knowing that the average normal stress must not exceed 150 MPa in either rod, determine the smallest allowable values of the diameters d1 and d2. SOLUTION (a) Rod AB: Force: P = 60 103 N Stress: AB = 150 106 Pa A= Area: AB 4 d12 4 P P = A= A AB d12 = d12 = P AB 4P AB = (4)(60 103 ) = 509.30 10 −6 m 2 (150 106 ) d1 = 22.568 10−3 m (b) Rod BC: Force: Stress: Area: P = 60 103 − (2)(125 103 ) = −190 103 N BC = −150 106 Pa A= BC d 22 4 P 4P = = A d 22 d 22 = 4P BC = (4)(−190 103 ) = 1.61277 10−3 m 2 (−150 106 ) d 2 = 40.159 10−3 m 3 d1 = 22.6 mm d2 = 40.2 mm PROBLEM 1.14 Two hydraulic cylinders are used to control the position of the robotic arm ABC. Knowing that the control rods attached at A and D each have a 20-mm diameter and happen to be parallel in the position shown, determine the average normal stress in (a) member AE, (b) member DG. SOLUTION Use member ABC as free body. M B = 0: (0.150) 4 FAE − (0.600)(800) = 0 5 FAE = 4 103 N Area of rod in member AE is Stress in rod AE: A= AE = 4 d2 = 4 (20 10−3 ) 2 = 314.16 10−6 m 2 FAE 4 103 = = 12.7324 106 Pa −6 A 314.16 10 (a) AE = 12.73 MPa Use combined members ABC and BFD as free body. 4 4 M F = 0: (0.150) FAE − (0.200) FDG − (1.050 − 0.350)(800) = 0 5 5 FDG = −1500 N Area of rod DG: Stress in rod DG: A= 4 d2 = DG = 4 (20 10−3 )2 = 314.16 10−6 m 2 FDG −1500 = = −4.7746 106 Pa A 3.1416 10−6 (b) 4 DG = −4.77 MPa PROBLEM 1.25 Knowing that a force P of magnitude 750 N is applied to the pedal shown, determine (a) the diameter of the pin at C for which the average shearing stress in the pin is 40 MPa, (b) the corresponding bearing stress in the pedal at C, (c) the corresponding bearing stress in each support bracket at C. SOLUTION Since BCD is a 3-force member, the reaction at C is directed toward E, the intersection of the lines of action of the other two forces. CE = 3002 + 1252 = 325 mm From geometry, From the free body diagram of BCD, Fy = 0 : pin (a) 125 C−P=0 325 C = 2.6 P = 2.6 ( 750 N ) = 1950 N 1 1 C C 2C 2 = = 2 = 2 d2 AP d 4 2C d = pin = 2 (1950 N ) ( 40 106 Pa ) = 5.57 10−3 m d = 5.57 mm (b) b = (1950 ) C C = = = 38.9 106 Pa −3 −3 Ab dt 5.57 10 9 10 ( )( ) b = 38.9 MPa (c) 5 1 C (1950 ) C b = 2 = = = 35.0 106 Pa Ab 2dt 2 5.57 10−3 5 10−3 ( )( ) b = 35.0 MPa PROBLEM 1.32 Two wooden members of uniform cross section are joined by the simple scarf splice shown. Knowing that the maximum allowable tensile stress in the glued splice is 75 psi, determine (a) the largest load P that can be safely supported, (b) the corresponding shearing stress in the splice. SOLUTION A0 = (5.0)(3.0) = 15 in 2 = 90 − 60 = 30 6 = P cos 2 A0 (a) P= A0 (75)(15) = = 1500 lb 2 cos cos 2 30 (b) = P sin 2 (1500)sin 60 = 2 A0 (2)(15) P = 1.500 kips = 43.3 psi PROBLEM 1.43 Two wooden members are joined by plywood splice plates that are fully glued on the contact surfaces. Knowing that the clearance between the ends of the members is 6 mm and that the ultimate shearing stress in the glued joint is 2.5 MPa, determine the length L for which the factor of safety is 2.75 for the loading shown. SOLUTION all = 2.5 MPa = 0.90909 MPa 2.75 On one face of the upper contact surface, A= L − 0.006 m (0.125 m) 2 Since there are 2 contact surfaces, all = 0.90909 106 = P 2A 16 103 ( L − 0.006)(0.125) L = 0.14680 m 7 146.8 mm PROBLEM 1.44 For the joint and loading of Prob. 1.43, determine the factor of safety when L = 180 mm. PROBLEM 1.43 Two wooden members are joined by plywood splice plates that are fully glued on the contact surfaces. Knowing that the clearance between the ends of the members is 6 mm and that the ultimate shearing stress in the glued joint is 2.5 MPa, determine the length L for which the factor of safety is 2.75 for the loading shown. SOLUTION Area of one face of upper contact surface: A= 0.180 m − 0.006 m (0.125 m) 2 A = 10.8750 10−3 m 2 Since there are two surfaces, all = P 16 103 N = 2 A 2(10.8750 10−3 m 2 ) all = 0.73563 MPa F.S. = 8 u 2.5 MPa = = 3.40 all 0.73563 MPa PROBLEM 1.61 For the assembly and loading of Prob. 1.60, determine (a) the average shearing stress in the pin at C, (b) the average bearing stress at C in member BC, (c) the average bearing stress at B in member BC. PROBLEM 1.60 Two horizontal 5-kip forces are applied to pin B of the assembly shown. Knowing that a pin of 0.8-in. diameter is used at each connection, determine the maximum value of the average normal stress (a) in link AB, (b) in link BC. SOLUTION Use joint B as free body. Law of Sines: FAB FBC 10 = = sin 45 sin 60 sin 95 (a) Shearing stress in pin at C. = AP = FBC = 8.9658 kips FBC 2 AP d2 = (0.8) 2 = 0.5026 in 2 4 8.9658 = = 8.92 (2)(0.5026) 9 4 = 8.92 ksi PROBLEM 1.61 (Continued) (b) Bearing stress at C in member BC. b = FBC A A = td = (0.5)(0.8) = 0.4 in 2 b = (c) Bearing stress at B in member BC. b = 8.9658 = 22.4 0.4 b = 22.4 ksi FBC A A = 2td = 2(0.5)(0.8) = 0.8 in 2 b = 10 8.9658 = 11.21 0.8 b = 11.21 ksi PROBLEM 2.2 A control rod made of yellow brass must not stretch more than 18 in. when the tension in the wire is 800 lb. Knowing that E = 15 106 psi and that the maximum allowable normal stress is 32 ksi, determine (a) the smallest diameter rod that should be used, (b) the corresponding maximum length of the rod. SOLUTION (a) Stress: Area: = A= P , or A d2 4 , or A= P d= = 800 lb = 25 10−3 in 2 3 2 32 10 lb/in 4A = 4(25 10−3 in 2 ) = 0.178412 in. = 0.1784 in. (b) Strain: PL = , or AE ( )( ) 25 10−3 in 2 15 106 lb/in 2 ( 0.125 in.) AE L= = P 800 lb L = 58.6 in. 11 PROBLEM 2.13 Rod BD is made of steel ( E = 29 106 psi) and is used to brace the axially compressed member ABC. The maximum force that can be developed in member BD is 0.02P. If the stress must not exceed 18 ksi and the maximum change in length of BD must not exceed 0.001 times the length of ABC, determine the smallestdiameter rod that can be used for member BD. SOLUTION FBD = 0.02P = (0.02)(130) = 2.6 kips = 2.6 103 lb Considering stress, = 18 ksi = 18 103 psi = FBD A A= FBD = 2.6 = 0.14444 in 2 18 Considering deformation, = (0.001)(144) = 0.144 in. = FBD LBD AE A= FBD LBD (2.6 103 )(54) = = 0.03362 in 2 E (29 106 )(0.144) Larger area governs. A = 0.14444 in 2 A= 12 4 d2 d= 4A = (4)(0.14444) d = 0.429 in. PROBLEM 2.14 The 4-mm-diameter cable BC is made of a steel with E = 200 GPa. Knowing that the maximum stress in the cable must not exceed 190 MPa and that the elongation of the cable must not exceed 6 mm, find the maximum load P that can be applied as shown. SOLUTION LBC = 62 + 42 = 7.2111 m Use bar AB as a free body. 4 3.5P − (6) FBC = 0 7.2111 P = 0.9509 FBC M A = 0: Considering allowable stress, = 190 106 Pa A= d2 = 4 FBC = A 4 (0.004)2 = 12.566 10−6 m 2 FBC = A = (190 106 )(12.566 10−6 ) = 2.388 103 N Considering allowable elongation, = 6 10−3 m = FBC LBC AE FBC = AE (12.566 10−6 )(200 109 )(6 10−3 ) = = 2.091 103 N LBC 7.2111 Smaller value governs. FBC = 2.091 103 N P = 0.9509 FBC = (0.9509)(2.091 103 ) = 1.988 103 N 13 P = 1.988 kN PROBLEM 2.29 A homogeneous cable of length L and uniform cross section is suspended from one end. (a) Denoting by the density (mass per unit volume) of the cable and by E its modulus of elasticity, determine the elongation of the cable due to its own weight. (b) Show that the same elongation would be obtained if the cable were horizontal and if a force equal to half of its weight were applied at each end. SOLUTION (a) For element at point identified by coordinate y, P = weight of portion below the point = gA(L − y ) Pdy gA( L − y )dy g ( L − y ) d = = = dy EA EA E = L Total weight: dy = g L 1 Ly − y 2 E 2 0 g 2 L 2 L − E 2 = 1 gL2 2 E W = gAL F= 14 E 0 = (b) g (L − y) EA EA 1 gL2 1 = = gAL L L 2 E 2 1 F= W 2 PROBLEM 2.30 A vertical load P is applied at the center A of the upper section of a homogeneous frustum of a circular cone of height h, minimum radius a, and maximum radius b. Denoting by E the modulus of elasticity of the material and neglecting the effect of its weight, determine the deflection of point A. SOLUTION Extend the slant sides of the cone to meet at a point O and place the origin of the coordinate system there. tan = From geometry, a1 = b−a h a b , b1 = , tan tan r = y tan At coordinate point y, A = r 2 Deformation of element of height dy: d = Pdy AE d = P dy P dy = 2 2 E r E tan y 2 Total deformation: P A = E tan 2 b1 a1 b1 1 dy P P = − = 2 2 y E tan y a E tan 2 1 = 15 b1 − a1 P (b1 − a1 ) P = 2 Eab E tan a1b1 1 1 − a1 b1 A = Ph Eab PROBLEM 2.70 The block shown is made of a magnesium alloy, for which E = 45 GPa and v = 0.35. Knowing that x = −180 MPa, determine (a) the magnitude of y for which the change in the height of the block will be zero, (b) the corresponding change in the area of the face ABCD, (c) the corresponding change in the volume of the block. SOLUTION (a) y = 0 y = 0 z = 0 1 ( x − v y − v z ) E y = v x = (0.35)(−180 106 ) y = = −63 106 Pa y = −63.0 MPa 1 v (0.35)(−243 106 ) ( z − v x − v y ) = − ( x + y ) = − = +1.890 10−3 E E 45 109 x − v y 1 157.95 106 x = ( x − v y − v Z ) = =− = −3.510 10−3 9 E E 45 10 z = (b) A0 = Lx Lz A = Lx (1 + x ) Lz (1 + z ) = Lx Lz (1 + x + z + x z ) A = A − A0 = Lx Lz ( x + z + x z ) Lx Lz ( x + z ) A = (100 mm)(25 mm)(−3.510 10−3 + 1.890 10−3 ) (c) A = −4.05 mm2 V0 = Lx Ly Lz V = Lx (1 + x ) Ly (1 + y ) Lz (1 + z ) = Lx Ly Lz (1 + x + y + z + x y + y z + z x + x y z ) V = V − V0 = Lx Ly Lz ( x + y + z + small terms) V = (100)(40)(25)(−3.510 10−3 + 0 + 1.890 10 −3 ) 16 V = −162.0 mm3 PROBLEM 2.74 In many situations, physical constraints prevent strain from occurring in a given direction. For example, z = 0 in the case shown, where longitudinal movement of the long prism is prevented at every point. Plane sections perpendicular to the longitudinal axis remain plane and the same distance apart. Show that for this situation, which is known as plane strain, we can express z , x , and y as follows: z = v( x + y ) 1 [(1 − v 2 ) x − v(1 + v) y ] E 1 y = [(1 − v 2 ) y − v(1 + v) x ] E x = SOLUTION z = 0 = 1 (−v x − v y + z ) or z = v( x + y ) E 1 ( x − v y − v z ) E 1 = [ x − v y − v 2 ( x + y )] E 1 = [(1 − v 2 ) x − v(1 + v) y ] E x = 1 (−v x + y − v z ) E 1 = [−v x + y − v 2 ( x + y )] E 1 = [(1 − v 2 ) y − v(1 + v) x ] E y = 17 PROBLEM 3.3 A 1.75-kN · m torque is applied to the solid cylinder shown. Determine (a) the maximum shearing stress, (b) the percent of the torque carried by the inner 25-mm-diameter core. SOLUTION (a) max = Given shaft: max = Tc J (1.75 103 N m)(0.025 m) 2 ( 0.025 m ) 4 = 71.301 106 Pa max = 71.3 MPa (b) At surface of core: 1 m 2 1 = 71.301 106 2 = ( ) = 35.651 106 Pa Corresponding torque: c4 3 T= = 2 = c3 = 35.651 106 Pa ( 0.0125 m ) c c 2 2 J ( ) T = 109.376 N m %T = 109.376 N m (100 ) 1750 N m 6.25% 18 PROBLEM 3.7 The solid spindle AB is made of a steel with an allowable shearing stress of 12 ksi, and sleeve CD is made of a brass with an allowable shearing stress of 7 ksi. Determine (a) the largest torque T that can be applied at A if the allowable shearing stress is not to be exceeded in sleeve CD, (b) the corresponding required value of the diameter d s of spindle AB. SOLUTION (a) Analysis of sleeve CD: 1 1 d o = (3) = 1.5 in. 2 2 c1 = c2 − t = 1.5 − 0.25 = 1.25 in. c2 = J= T= (c 2 4 2 ) − c14 = 2 (1.54 − 1.254 ) = 4.1172 in 4 J (4.1172)(7 103 ) = = 19.21 103 lb in. c2 1.5 T = 19.21 kip in. (b) Analysis of solid spindle AB: = Tc J J T 19.21 103 = c3 = = = 1.601 in 3 3 c 2 12 10 c=3 (2)(1.601) = 1.006 in. d s = 2c d = 2.01 in. 19 PROBLEM 3.40 The solid spindle AB has a diameter d s = 1.5 in. and is made of a steel with G = 11.2 106 psi and all = 12 ksi, while sleeve CD is made of a brass with G = 5.6 106 psi and all = 7 ksi. Determine the angle through which end A can be rotated. SOLUTION Stress analysis of solid spindle AB: c= 1 ds = 0.75 in. 2 = Tc J T = Stress analysis of sleeve CD: T = Deformation of spindle AB: (c 2 4 2 ) − c14 = 2 (1.54 − 1.254 ) = 4.1172 in 4 J (4.1172)(7 10−3 ) = = 19.21 103 lb in. c2 1.5 2 c 4 = 0.49701 in 4 , L = 12 in., G = 11.2 106 psi TL (7.95 103 )(12) = = 0.017138 radians GJ (11.2 106 )(0.49701) J = 4.1172 in 4 , L = 8 in., G = 5.6 106 psi CD = 20 c = 0.75 in. AB = Total angle of twist: (12 103 )(0.75)3 = 7.95 103 lb in. T = 7.95 103 lb in. J = Deformation of sleeve CD: J = c3 c 2 2 1 1 c2 = d o = (3) = 1.5 in. 2 2 c1 = c2 − t = 1.5 − 0.25 = 1.25 in. J = The smaller torque governs. T = TL (7.95 103 )(8) = = 0.002758 radians GJ (5.6 106 )(4.1172) AD = AB + CD = 0.019896 radians AD = 1.140 PROBLEM 3.55 Two solid steel shafts (G = 77.2 GPa) are connected to a coupling disk B and to fixed supports at A and C. For the loading shown, determine (a) the reaction at each support, (b) the maximum shearing stress in shaft AB, (c) the maximum shearing stress in shaft BC. SOLUTION Shaft AB: 1 d = 25 mm = 0.025 m 2 T L = c 4 = (0.025)4 = 613.59 10−9 m 4 B = AB AB 2 2 GJ AB T = TAB , LAB = 0.200 m, c = J AB TAB = Shaft BC: GJ AB (77.2 109 )(613.59 10−9 ) B = B = 236.847 103 B LAB 0.200 1 d = 19 mm = 0.019 m 2 T L = c 4 = (0.019)4 = 204.71 10−9 m 4 B = BC BC 2 2 GJ BC T = TBC , LBC = 0.250 m, c = J BC TBC = GJ BC (77.2 109 )(204.71 10−9 ) B = = 63.214 103 B LBC 0.250 Equilibrium of coupling disk. T = TAB + TBC 1.4 103 = 236.847 103 B + 63.214 103 B B = 4.6657 10−3 rad TAB = (236.847 103 )(4.6657 10−3 ) = 1.10506 103 N m TBC = (63.214 103 )(4.6657 10−3 ) = 294.94 N m (a) TA = TAB = 1105 N m Reactions at supports. TC = TBC = 295 N m (b) Maximum shearing stress in AB. AB = (c) AB = 45.0 MPa Maximum shearing stress in BC. BC = 21 TABc (1.10506 103 )(0.025) = = 45.0 106 Pa J AB 613.59 10−9 TBC c (294.94)(0.019) = = 27.4 106 Pa J BC 204.71 10−9 BC = 27.4 MPa PROBLEM 3.60 A torque T is applied as shown to a solid tapered shaft AB. Show by integration that the angle of twist at A is = 7TL 12 Gc 4 SOLUTION Introduce coordinate y as shown. r = cy L Twist in length dy: d = Tdy Tdy 2TL4dy = = GJ Gc 4 y 4 G r4 2 = L 2L 2TL4 dy 2TL 2 L dy = 4 4 Gc y Gc 4 L y 4 2L 2TL4 1 2TL4 1 1 = − = − + 3 4 3 4 3 Gc 3 y L Gc 24L 3L = 2TL4 7 7TL = 4 3 Gc 24 L 12 Gc 4 22 PROBLEM 3.74 Three shafts and four gears are used to form a gear train that will transmit power from the motor at A to a machine tool at F. (Bearings for the shafts are omitted in the sketch.) The diameter of each shaft is as follows: d AB =16 mm, dCD = 20 mm, d EF = 28mm. Knowing that the frequency of the motor is 24 Hz and that the allowable shearing stress for each shaft is 75 MPa, determine the maximum power that can be transmitted. SOLUTION all = 75 MPa = 75 106 Pa Shaft AB: c AB = Tall = 1 d AB = 0.008 m 2 2 c3AB all = 2 = Tc AB 2T = J AB c3AB (0.008)3 (75 106 ) = 60.319 N m f AB = 24 Hz Pall = 2 f ABTall = 2 (24)(60.319) = 9.10 103 W Shaft CD: 1 dCD = 0.010 m 2 Tc 2T 3 = CD = 3 Tall = cCD all = (0.010)3 (75 106 ) = 117.81 N m J CD 2 2 cCD cCD = fCD = Shaft EF: rB 60 f AB = (24) = 9.6 Hz rC 150 cEF = Tall = Pall = 2 fCDTall = 2 (9.6)(117.81) = 7.11 103 W 1 d EF = 0.014 m 2 3 cEF all = (0.014)3 (75 106 ) = 323.27 N m 2 2 r 60 f EF = D fCD = (9.6) = 3.84 Hz rE 150 Pall = 2 f EF Tall = 2 (3.84)(323.27) = 7.80 103 W Maximum allowable power is the smallest value. 23 Pall = 7.11 103 W = 7.11 kW PROBLEM 3.86 Knowing that the stepped shaft shown transmits a torque of magnitude T = 2.50 kip in., determine the maximum shearing stress in the shaft when the radius of the fillet is (a) r = 18 in., (b) r = 163 in. SOLUTION D 2 = = 1.33 d 1.5 D = 2 in. d = 1.5 in. 1 d = 0.75 in. T = 2.5 kip in. 2 Tc 2T (2)(2.5) = = = 3.773 ksi 3 J c (0.75)3 c= (a) r = 1 in. r = 0.125 in. 8 r 0.125 = = 0.0833 d 1.5 K = 1.42 From Fig. 3.28, max = K (b) r = Tc = (1.42)(3.773) J 3 in. 16 max = 5.36 ksi r = 0.1875 in. r 0.1875 = = 0.125 d 1.5 From Fig. 3.28, max = K 24 K = 1.33 Tc = (1.33)(3.773) J max = 5.02 ksi PROBLEM 4.1 Knowing that the couple shown acts in a vertical plane, determine the stress at (a) point A, (b) point B. SOLUTION I = (r 4 o 4 ) − ri 4 = 4 ( 20 4 ) − 154 = 85.903 103 mm 4 I = 85.903 10−9 m 4 (a) y A = 20 mm = 0.020 m A = − My A (500 N m)(0.020 m) =− = −116.4 106 Pa I 85.903 10−9 m 4 A = −116.4 MPa (b) yB = 15 mm = 0.015 m B = − MyB (500 N m)(0.015 m) =− = 87.3 106 Pa I 85.903 10−9 m 4 B = −87.3 MPa 25 PROBLEM 4.2 Knowing that the couple shown acts in a vertical plazne, determine the stress at (a) point A, (b) point B. SOLUTION For rectangle: I1 = For one circular cutout: 1 3 1 3 bh = ( 4.8 )( 2.4 ) = 5.5296 in 4 12 12 I2 = 4 d4 = 4 ( 0.75 )4 = 0.24850 in 4 For cross sectional area: I = I1 − 2I 2 = 5.5296 − 2 ( 0.24850 ) = 5.0326 in 4 (a) y A = 1.2 in. (b) yB = −0.75 in. 26 A = − B = − My A (25 kip in.)(1.2 in.) =− I 5.0326 in 4 MyB (25 kip in.)(−0.75 in.) =− I 5.0326 in 4 A = −5.96 ksi 𝜎𝐵 = −3.73 ksi PROBLEM 4.3 Using an allowable stress of 155 MPa, determine the largest bending moment M that can be applied to the wide-flange beam shown. Neglect the effect of fillets. SOLUTION Moment of inertia about x-axis: I1 = 1 (200)(12)3 + (200)(12)(104) 2 12 = 25.9872 106 mm 4 I2 = 1 (8)(196)3 = 5.0197 106 mm 4 12 I 3 = I1 = 25.9872 106 mm 4 I = I1 + I 2 + I 3 = 56.944 106 mm 4 = 56.944 10−6 m 4 Mc 1 with c = (220) = 110 mm = 0.110 m I 2 I M = with = 155 106 Pa c = Mx = (56.944 10−6 )(155 106 ) = 80.2 103 N m 0.110 M x = 80.2 kN m 27 PROBLEM 4.8 Two W4 13 rolled sections are welded together as shown. Knowing that for the steel alloy used U = 58 ksi and using a factor of safety of 3.0, determine the largest couple that can be applied when the assembly is bent about the z axis. SOLUTION Properties of W4 13 rolled section. (See Appendix E.) Area = 3.83 in 2 Depth = 4.16 in. I x = 11.3 in 4 For one rolled section, moment of inertia about axis a-a is I a = I x + Ad 2 = 11.3 + (3.83)(2.08)2 = 27.87 in 4 For both sections, I z = 2 I a = 55.74 in 4 c = depth = 4.16 in. M all 28 U 58 = 19.333 ksi F .S . 3.0 I (19.333)(55.74) = all = c 4.16 all = = = Mc I M all = 259 kip in. PROBLEM 4.7 Two W4 13 rolled sections are welded together as shown. Knowing that for the steel alloy used Y = 36 ksi and U = 58 ksi and using a factor of safety of 3.0, determine the largest couple that can be applied when the assembly is bent about the z axis. SOLUTION Properties of W4 13 rolled section. (See Appendix E.) Area = 3.83 in 2 Width = 4.060 in. I y = 3.86 in 4 For one rolled section, moment of inertia about axis b-b is I b = I y + Ad 2 = 3.86 + (3.83)(2.030)2 = 19.643 in 4 For both sections, I z = 2 I b = 39.286 in 4 c = width = 4.060 in. M all 29 U 58 = 19.333 ksi F .S . 3.0 I (19.333)(39.286) = all = c 4.060 all = = = Mc I M all = 187.1 kip in. PROBLEM 4.10 Two vertical forces are applied to a beam of the cross section shown. Determine the maximum tensile and compressive stresses in portion BC of the beam. SOLUTION A y0 A y0 8 7.5 60 6 4 24 4 0.5 18 Yo = 2 86 86 = 4.778 in. 18 Neutral axis lies 4.778 in. above the base. 1 1 b1h13 + A1d12 = (8)(1)3 + (8)(2.772) 2 = 59.94 in 4 12 12 1 1 3 2 I 2 = b2 h2 + A2 d 2 = (1)(6)3 + (6)(0.778) 2 = 21.63 in 4 12 12 1 1 I 3 = b3 h33 + A3 d32 = (4)(1)3 + (4)(4.278) 2 = 73.54 in 4 12 12 I = I1 + I 2 + I 3 = 59.94 + 21.63 + 73.57 = 155.16 in 4 ytop = 3.222 in. ybot = −4.778 in. I1 = M − Pa = 0 M = Pa = (25)(20) = 500 kip in. top = − bot = − 30 Mytop I =− (500)(3.222) 155.16 Mybot (500)(−4.778) =− I 155.16 top = −10.38 ksi (compression) bot = 15.40 ksi (tension) PROBLEM 4.39 A copper strip (Ec = 105 GPa) and an aluminum strip (Ea = 75 GPa) are bonded together to form the composite beam shown. Knowing that the beam is bent about a horizontal axis by a couple of moment M = 35 N m, determine the maximum stress in (a) the aluminum strip, (b) the copper strip. SOLUTION Use aluminum as the reference material. n = 1.0 in aluminum n = Ec /Ea = 105/75 = 1.4 in copper Transformed section: A, mm2 nA, mm2 y0 , mm nA y0 , mm 3 144 144 9 1296 144 201.6 3 Σ Y0 = 345.6 604.8 1900.8 1900.8 = 5.50 mm 345.6 The neutral axis lies 5.50 mm above the bottom. n1 1.0 b1h13 + n1 A1d12 = (24)(6)3 + (1.0)(24)(6)(3.5) 2 = 2196 mm 4 12 12 n2 1.4 3 2 I 2 = b2 h2 + n2 A2 d 2 = (24)(6)3 + (1.4)(24)(6)(2.5) 2 = 1864.8 mm 4 12 12 I = I1 + I 2 = 4060.8 mm 4 = 4.0608 10−9 m 4 I1 = (a) Aluminum: n = 1.0, =− y = 12 − 5.5 = 6.5 mm = 0.0065 m nMy (1.0)(35)(0.0065) =− = −56.0 106 Pa = −56.0 MPa −9 I 4.0608 10 = −56.0 MPa (b) Copper: n = 1.4, =− y = −5.5 mm = −0.0055 m nMy (1.4)(35)(−0.0055) =− = 66.4 106 Pa = 66.4 MPa I 4.0608 10−9 = 66.4 MPa 31 PROBLEM 4.42 The 6 12-in. timber beam has been strengthened by bolting to it the steel reinforcement shown. The modulus of elasticity for wood is 1.8 106 psi and for steel is 29 106 psi. Knowing that the beam is bent about a horizontal axis by a couple of moment M = 450 kipin., determine the maximum stress in (a) the wood, (b) the steel. SOLUTION Use wood as the reference material. For wood, n =1 For steel, n= Es 29 106 = = 16.1111 Ew 1.8 106 For C8 11.5 channel section (see the screenshot taken from Appendix E on the next page), A = 3.38 in 2 , tw = 0.220 in., x = 0.571 in., I y = 1.32 in 4 For the composite section, the centroid of the channel (part 1) lies 0.571 in. above the bottom of the section. The centroid of the wood (part 2) lies 0.220 + 6.00 = 6.22 in. above the bottom. Transformed section: A, in2 3.38 Part 1 72 2 Y0 = nA, in2 54.456 y , in. 0.571 72 6.22 31.091 447.84 d, in. 3.216 2.433 478.93 126.456 478.93 in 3 = 3.787 in. 126.456 in 2 nAy , in 3 d = y0 − Y0 The neutral axis lies 3.787 in. above the bottom of the section. I1 = n1 I1 + n1 A1d12 = (16.1111)(1.32) + (54.456)(3.216)2 = 584.49 in 4 n2 1 b2 h23 + n2 A2 d 22 = (6)(12)3 + (72)(2.433)2 = 1290.20 in 4 12 12 4 I = I1 + I 2 = 1874.69 in I2 = M = 450 kip in (a) Wood: n = 1, w = − (b) Steel: (1)(450)(8.433) = −2.02 ksi 1874.69 n = 16.1111, s = − 32 n My I y = 12 + 0.220 − 3.787 = 8.433 in. =− w = −2.02 ksi y = −3.787 in. (16.1111)(450)(−3.787) = 14.65 ksi 1874.67 s = 14.65 ksi 33 PROBLEM 4.51 Knowing that the bending moment in the reinforced concrete beam is +100 kip ft and that the modulus of elasticity is 3.625 106 psi for the concrete and 29 106 psi for the steel, determine (a) the stress in the steel, (b) the maximum stress in the concrete. SOLUTION n= Es 29 106 = = 8.0 Ec 3.625 106 As = (4) (1)2 = 3.1416 in 2 4 nAs = 25.133 in 2 Locate the neutral axis. x (24)(4)( x + 2) + (12 x) − (25.133)(17.5 − 4 − x) = 0 2 96 x + 192 + 6 x 2 − 339.3 + 25.133x = 0 x= Solve for x. or 6 x 2 + 121.133x − 147.3 = 0 −121.133 + (121.133)2 + (4)(6)(147.3) = 1.150 in. (2)(6) d3 = 17.5 − 4 − x = 12.350 in. 1 1 b1h13 + A1d12 = (24)(4)3 + (24)(4)(3.150) 2 = 1080.6 in 4 12 12 1 1 I 2 = b2 x3 = (12)(1.150)3 = 6.1 in 4 3 3 I1 = I3 = nA3d32 = (25.133)(12.350)2 = 3833.3 in 4 I = I1 + I 2 + I 3 = 4920 in 4 =− (a) Steel: nMy I where M = 100 kip ft = 1200 kip in. y = −12.350 in. n = 8.0 s = − (b) Concrete: s = 24.1 ksi n = 1.0, y = 4 + 1.150 = 5.150 in. c = − 34 (8.0)(1200)(−12.350) 4920 (1.0)(1200)(5.150) 4920 c = −1.256 ksi PROBLEM 4.55 Five metal strips, each a 0.5 × 1.5-in. cross section, are bonded together to form the composite beam shown. The modulus of elasticity is 30 × 106 psi for the steel, 15 × 106 psi for the brass, and 10 × 106 psi for the aluminum. Knowing that the beam is bent about a horizontal axis by a couple of moment 12 kip in., determine (a) the maximum stress in each of the three metals, (b) the radius of curvature of the composite beam. SOLUTION Use aluminum as the reference material. n= Es 30 106 = = 3.0 in steel Ea 10 106 Eb 15 106 = = 1.5 in brass Ea 10 106 n = 1.0 in aluminum n= For the transformed section, n1 1 b1h13 + n1 A1d12 = (1.5)(0.5)3 + (0.75)(1.0)2 12 12 4 = 0.7656 in I1 = n2 1.5 b2 h23 + n2 A2 d 22 = (1.5)(0.5)3 + (1.5)(0.75)(0.5)2 = 0.3047 in 4 12 12 n3 3.0 3 I 3 = b3 h3 = (1.5)(0.5)3 = 0.0469 in 4 12 12 I 4 = I 2 = 0.3047 in 4 I 5 = I1 = 0.7656 in 4 I2 = I= 5 I i = 2.1875 in 4 1 (a) Aluminum: = nMy (1.0)(12)(1.25) = = 6.86 ksi I 2.1875 Brass: = nMy (1.5)(12)(0.75) = = 6.17 ksi I 2.1875 Steel: = nMy (3.0)(12)(0.25) = = 4.11 ksi I 2.1875 1 M 12 103 = = 548.57 10−6 in.−1 6 Ea I (10 10 )(2.1875) (b) 35 = = 1823 in. = 151.9 ft PROBLEM 4.64 Semicircular grooves of radius r must be milled as shown in the top and bottom portions of a steel member. Using an allowable stress of 10 ksi, determine the largest bending moment that can be applied to the member when (a) r = 0.25 in., (b) r = 0.5 in. SOLUTION (a) d = D − 2r = 3 − 0.5 = 2.50 in. D 3 = = 1.20 d 2.50 From Fig. 4.25, I = r 0.25 = = 0.10 d 2.55 K = 2.07 1 3 1 ( ) bh = 1 (2.5)3 = 1.30208 in 4 12 12 =K Mc I M = I Kc = (10 ksi)(1.30208 in 4 ) (2.07)(1.25 in.) = 5.03 kip in. (b) From Fig. 4.25, K = 1.60 M = 36 D 3 = = 1.50 d 2.0 d = D − 2r = 3 − 2 ( 0.5 ) = 2.0 in. I Kc I = = r 0.5 = = 0.25 d 2.0 1 3 1( ) bh = 1 (2.0)3 = 0.66667 in 4 12 12 (10 ksi)(0.66667 in 4 ) (1.60)(1 in.) = 4.17 kip in. PROBLEM 4.134 The couple M is applied to a beam of the cross section shown in a plane forming an angle with the vertical. Determine the stress at (a) point A, (b) point B, (c) point D. SOLUTION For W310 38.7 rolled steel shape, I z = 84.9 106 mm 4 = 84.9 10−6 m 4 I y = 7.20 106 mm 4 = 7.20 10−6 m 4 1 1 yD = − yE = (310) = 155 mm 2 2 1 z A = z E = − z B = − z D = (165) = 82.5 mm 2 y A = yB = M z = (16 103 ) cos 15 = 15.455 103 N m M y = (16 103 ) sin 15 = 4.1411 103 N m (a) tan = Iz 84.9 10−6 tan = tan 15 = 3.1596 I 7.20 10−6 = 72.4 − 72.4 − 15 = 57.4 (b) Maximum tensile stress occurs at point E. E = − M z yE M y z E (15.455 103 )(−155 10−3 ) (4.1411 103 )(82.5 10−3 ) + =− + Iz Iy 84.9 10−6 7.20 10−6 = 75.7 106 Pa = 75.7 MPa 37 PROBLEM 4.141 The couple M acts in a vertical plane and is applied to a beam oriented as shown. Determine the stress at point A. SOLUTION Using Mohr’s circle, determine the principal axes and principal moments of inertia. Y : (1.894, 0.800) 106 mm 4 Z : (0.614, 0.800) 106 mm 4 E : (1.254, 0) 106 mm 4 2 2 R = EF + FZ = 0.6402 + 0.8002 10−6 = 1.0245 106 mm 4 I v = (1.254 − 1.0245) 106 mm 4 = 0.2295 106 mm 4 = 0.2295 10−6 m 4 I u = (1.254 + 1.0245) 106 mm 4 = 2.2785 106 mm 4 = 2.2785 10−6 m4 FZ 0.800 106 = = 1.25 m = 25.67 FE 0.640 106 M v = M cos m = (1.2 103 ) cos 25.67 = 1.0816 103 N m tan 2 m = M u = − M sin m = −(1.2 103 ) sin 25.67 = −0.5198 103 N m u A = y A cos m − z A sin m = 45 cos 25.67 − 45 sin 25.67 = 21.07 mm v A = z A cos m + y A sin m = 45 cos 25.67 + 45 sin 25.67 = 60.05 mm A = − M v u A M u vA (1.0816 103 )(21.07 10−3 ) (−0.5198 103 )(60.05 10−3 ) + =− + Iv Iu 0.2295 10−6 2.2785 10−6 = 113.0 106 Pa 38 A = 113.0 MPa PROBLEM 4.144 The tube shown has a uniform wall thickness of 12 mm. For the loading given, determine (a) the stress at points A and B, (b) the point where the neutral axis intersects line ABD. SOLUTION Add y- and z-axes as shown. Cross section is a 75 mm 125-mm rectangle with a 51 mm 101-mm rectangular cutout. 1 1 (75)(125)3 − (51)(101)3 = 7.8283 106 mm 4 = 7.8283 10−6 m 4 12 12 1 1 I y = (125)(75)3 − (101)(51)3 = 3.2781 103 mm 4 = 3.2781 10−6 m 4 12 12 A = (75)(125) − (51)(101) = 4.224 103 mm 2 = 4.224 10−3 m 2 Iz = Resultant force and bending couples: P = 14 + 28 + 28 = 70 kN = 70 103 N M z = −(62.5 mm)(14 kN) + (62.5 mm)(28kN) + (62.5 mm)(28 kN) = 2625 N m M y = −(37.5 mm)(14 kN) + (37.5 mm)(28 kN) + (37.5 mm)(28 kN) = −525 N m (a) A = P M z yA M y zA 70 103 (2625)(−0.0625) (−525)(0.0375) − + = − + −3 A Iz Iy 4.224 10 7.8283 10−6 3.2781 10−6 A = 31.5 MPa = 31.524 106 Pa B = P M z yB M y z B 70 103 (2625)(0.0625) (−525)(0.0375) − + = − + −3 A Iz Iy 4.224 10 7.8283 10−6 3.2781 10−6 B = −10.39 MPa = −10.39 106 Pa (b) Let point H be the point where the neutral axis intersects AB. z H = 0.0375 m, 0= yH = ?, H = 0 P M z yH M y z H − + A Iz Iy P Mz H 7.8283 10−6 70 103 (−525)(0.0375) + + = − 3 A I y 2625 3.2781 10−6 4.224 10 = 0.03151 m = 31.51 mm yH = Iz Mz 31.51 + 62.5 = 94.0 mm 39 Answer: 94.0 mm above point A. PROBLEM 4.197 The vertical portion of the press shown consists of a rectangular tube of wall thickness t = 10 mm. Knowing that the press has been tightened on wooden planks being glued together until P = 20 kN, determine the stress at (a) point A, (b) point B. SOLUTION Rectangular cutout is 60 mm 40 mm. A = (80)(60) − (60)(40) = 2.4 103 mm 2 = 2.4 10−3 m 2 I = 1 1 (60)(80)3 − (40)(60)3 = 1.84 106 mm 4 12 12 = 1.84 10−6 m 4 c = 40 mm = 0.040 m e = 200 + 40 = 240 mm = 0.240 m P = 20 103 N M = Pe = (20 103 )(0.240) = 4.8 103 N m (a) A = P Mc 20 103 (4.8 103 )(0.040) + = + = 112.7 106 Pa −3 A I 2.4 10 1.84 10−6 A = 112.7 MPa (b) B = P Mc 20 103 (4.8 103 )(0.040) − = − = −96.0 106 Pa A I 2.4 10−3 1.84 10−6 B = −96.0 MPa 40