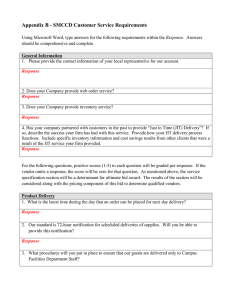

OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Procedure 03 Maintenance Management 02 Maintenance Planning, Scheduling & Execution PSM-MI-20433 BFJA JIT Management Document Ref. No.: MRCSB-06_03_02-L3-017746 Revision: 7 Published: 1 August, 2022 Next revision date: 1 August, 2025 Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 1 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management TABLE OF CONTENTS 1. PURPOSE .......................................................................................................... 3 2. SCOPE ............................................................................................................. 3 3. PERFORMANCE MEASUREMENTS ........................................................................... 4 4. PROCEDURE ...................................................................................................... 6 5. ROLES AND RESPONSIBILITIES .......................................................................... 14 6. DEFINITIONS .................................................................................................. 18 7. LINK WITH OTHER DOCUMENTS ......................................................................... 20 8. ATTACHMENTS ................................................................................................ 20 9. DOCUMENT HISTORY ........................................................................................ 22 Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 2 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 1. PURPOSE This document is a major revision of previously issued PSM-MI-20433 Joint Integrity (JIT) Management procedure. It consolidates and streamlines all previously issued MI procedures for Bolted Flange Joint Assembly (BFJA/JIT) works as listed below. These MI procedures are combined into this document and the below document will be removed. a. PSM-MI-20401 Bolt Tensioning b. PSM-MI-20405 Assembling Flanges (Flange Make-up) c. PSM-MI-20407 Blinding/De-blinding for Isolation/Normalizations including First Break d. PSM-MI-30401 Re-Torquing and Leakage Control e. PSM-MI-30414 Control Torquing This procedure provides requirement in managing the integrity of a bolted joint assembly works, from identification of joints to selection of bolt tightening method, detail execution and result documentation. 2. SCOPE This procedure shall apply to 2.1 2.2 All nominal pipe diameter of bolted flange joint assemblies. All equipment girth flanges and nozzle flanges as per clause 2.1 unbolted for maintenance activities or energy isolation purposes. 2.3 All INTERNAL JOINTS for C1 Criticality Equipment as per OEM requirements. OEM BFJA manual/specification shall be referred to. For e.g., Catalyst Transfer Pipe (CTP) for CCR UOP Reactors R-23201/2/3/4 which have specific OEM / Licensor requirement. The guideline provided shall be followed for joint making on piping flanges and process equipment during routine maintenance activity and plant modification project work in MRCSB including Major Turnaround work executed by TA Planning team. It is also applicable for battery limit blinding and process blinding activity Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 3 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 3. PERFORMANCE MEASUREMENTS SAFETY Prior to starting the work, Assigned Person shall ensure all necessary safety precautions have been carried out and it is safe to execute the BFJA/JIT works in accordance to all safety requirements specified in the this procedure, Permit To Work (PTW) and all relevant HSEMS procedures. Observe and identify hazards involved with the works. If necessary, Job Hazard Analysis (JHA) shall be conducted prior to execution. All hazards information shall be communicated and understood by all parties involved prior to work execution. Consider the requirements for special Personal Protective Equipment (PPE) such as heat resistance suit and gloves, SCBA, chemical suit, splash goggle, or others for blinding/deblinding work and Re-Torquing or Leakage Control Works. Caution The close proximity of the stud and self-reinforced nozzles shown below had cause SERIOUS hand injury during prior tightening activity. As such, GAPS SHALL BE made available to allow ring spanner application for any tightening works. Special considerations for Re-Torquing and Leakage Control Works As these works are performed while equipment or piping is in operating condition, High Pressure and/or High Temperature hazards should always be observed and identified prior to work execution. All Leakage Control Works performed on hydrocarbon/toxic services may require usage of breathing apparatus (SCBA) during work execution as specified in JHA. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 4 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management The gasket material of the joint shall be determined prior to execution. Compressed, nonasbestos gasket (NAF) shall never be Re-Torqued due to its rubber content which degrades and hardens. Re-Torquing can cause gasket failure due to fracture. Teflon based gasket will deformed after being re-torqued as these are soft at elevated temperature. Re-Torquing of these gaskets shall only be done after process cycle while the equipment or piping is cooled. PERSONNEL Only trained and competent Assigned Person’s JIT Inspector and Assigned Person MRCSB trained by TCU are allowed to perform the BFJA/JIT management works as specified in this document. JIT Inspector trained by TCU after undergoing JIT training are allowed to perform the BFJA/JIT management works and to lead joint making and bolt tightening works. He/She can be MRCSB staff or contractor staff. Only Competent Contractor Fitter confirmed by TCU after passing ECCA assessment are allowed to perform joint making and bolt tightening works. Only trained and competent HTW and HBT operators are allowed to perform joint making and bolt tightening activities using these machines. TOOLS AND EQUIPMENT All necessary hand tools shall be prepared, inspected and tested prior to the execution of BFJA/JIT works. Correct sizes of tools to be used must be correctly pre-determined to avoid any damages or injuries. Sufficient numbers of JIT Tags and JIT Record Forms shall be prepared and filled correctly. For equipment with frequent routine maintenance works, JIT Record Book shall be used in-lieu of the JIT Record Form. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 5 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management All JIT tools (MTW, HTW & HBT) need to be inspected and calibrated before starting of job. The power and control unit of the hydraulic torque wrench and bolt tensioning machine shall be inspected to ensure ability to provide required pressure during tightening. Calibration sticker for measuring gauge shall be valid and the hydraulic unit shall have inspection sticker validated by MRCSB. These requirements are necessary prior to work. All tools shall be non-sparking and of industrial standards. Modified or self-fabricated tools shall not be used. 4. PROCEDURE PREPARATION Prior to executing any BFJA/JIT works, a walkabout shall be carried out by Assigned Person with Area Operation Technician (OTF) to identify the correct joint(s) to be blinded/de-blinded, assembled and tightened. The blinding list (either EIS-Equipment Isolation Sheet or PIS-Process Isolation Sheet) shall be obtained from Area Operation and approved by Area Owner. These joint(s) shall be correctly marked in the blinding list and subsequently tagged with JIT tag with reference number to the blinding list upon site verification. Evaluate site condition for height and space restrictions to ensure safe execution of work. Identify requirement for scaffolding for working at heights, and clear working area for any obstructions. BFJA/JIT Management Workflow (Attachment A) provides guidance in the execution of BFJA/JIT Management works in accordance with this procedure and the correct utilization of JIT Tag, JIT Record Form and/or JIT Record Book. Assigned Person shall obtain the recommended bolt tightening method and required torque value for each joint from respective tables in Attachment E. For non-standard joints, torque value shall be obtained from respective Mechanical Static Engineer. Method Selection for Flange Tightening (Table 1) and Recommended Torque Tables (Attachment E) shall be used as reference. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 6 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Table 1 : Method Selection for Flange Tightening Note: 1) If HBT is not practical at site e.g., tool restriction due to clearance around nut and fillet geometry, switching to HTW will be under approval of Technical Authority and with proper documentation Note: Refer to Attachment U for HBT Exception List 2) Critical Joints are defined as per item 6.0 Definitions 3) For oxygen service piping/flanges shall follow as per stipulated in Attachment Q New bolts and nuts that will be used for JIT activity shall have marking. In case of missing marking or new bolts and nuts without any marking, contractor shall mark the bolts & nuts with permanent marking. For proper bolt and nuts arrangement, contractor shall provide container or storage after bolts cleaning activity. All incoming materials (gaskets, bolts, nuts etc.) shall be inspect and verify by competent personnel. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 7 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Any deviation from approved specification, shall notify MRCSB personal in charge and CAF shall be raised for documentation purposes. Personal’s Responsibility Responsibility Actions Assigned Person 4.1 and Area Identify the bolted flange joint from P&ID and EIS as reference. Production Technician (OTF) 4.2 Perform site verification of BFJA/JIT joints. Sign the White Section of JIT tag and attached it on the joint. Assigned Person’s 4.3 Inspector Verify correct tightening method and recommended torque value per Tables in Attachment E. Torque values for nonstandard joints shall be obtained from Mechanical Static Engineer. Assigned 4.4 Fill in Section I of JIT Record Form. 4.5 Perform the Flange Break activities in accordance with person/JIT inspector Attachment G: Blinding/De-blinding for Isolation/Normalization including First Break and HSEMS20050 (LOTO) Caution: First break of flange shall be done under SCBA / Air line for Hydrocarbon, Nitrogen environment, service contain H2S and with the presence of the Assigned Production Personnel (reference: PRD-OPP-CP-022 Equipment Isolation and Blinding /De-Blinding). Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 8 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management To review JIT list prepared by contractor during the Assigned Person 4.6 planning stage 4.7 Conduct Assessment on the joint faces, studs and nuts in and JIT Inspector accordance to Attachment H: Bolt Joint Assembling Flanges (Flange Make-up). Fill and sign section II of JIT Record Form. Assigned Person 4.8 Perform flange repairs (if any) in accordance to approved repair procedure. Assigned Person 4.9 and JIT Inspector Perform BFJA/JIT make-up work in accordance to Attachment H: Bolt Joint Assembling Flanges (Flange Makeup). Ensure correct tightening method is used. Refer to Attachment I: Control Torquing for tightening works using MTW and HTW. Refer to Attachment J: Bolt Tensioning for tightening works using HBT. Record the tightening details in Section III of JIT Record Form Assigned Person 4.10 Measure and record the flange gap and alignment and conduct joint inspection after tightening activity. Sign the Green Section of JIT tag. Assigned Person and JIT Inspector 4.11 Fill Section IV of JIT Record Form. 4.12 Perform pressure/leak test (if required). 4.13 Upon acceptance pressure/leak test and BFJA/JIT works, Sign Section V of JIT Record Form. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 9 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Assigned Person’s 4.14 MRCSB Assigned Person Verify completion and acceptance of BFJA/JIT works and Sign Section V of JIT Record Form 4.15 Remove JIT Tag from the joint and attach to its JIT Record Form. Attach copy of JIT Record Form (Attachment C) to completed MWO before TECO for Routine Maintenance Work. Include JIT Record Form (Attachment C) for final project document for plant modification work. Tasks 4.17 to 4.22 are only applicable for BFJA/JIT that requires Re-Torquing or Leakage Control Works. Assigned Person 4.16 Obtain the initial JIT Record Form (Attachment C) of the joint. Assigned Person 4.17 Perform the BFJA/JIT Re-Torquing and/or Leakage Control Works in accordance with Attachment K: Re-Torquing and Leakage Control Works. Record tightening details and process parameters in Section VI of JIT Record Form (Attachment C) 4.18 Measure and record the flange gap, alignment and conduct joint inspection after tightening activity. Fill Section VII of JIT Record Form. 4.19 Upon acceptance of works, sign Section VIII of JIT Record Form. Attach JIT Record Form (Attachment C) to completed MWO before TECO for Routine Maintenance Work. Include JIT Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 10 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Record Form (Attachment C) for final project document for plant modification work. Assigned Person’s 4.20 Verify completion and acceptance of BFJA/JIT Re-Torquing/ Leakage Control Works and Sign Section VIII of JIT Record MRCSB Form. Area Production 4.21 Supervisor OTF/PE Verify acceptance of BFJA/JIT Re-Torquing/ Leakage Control Works and Sign Section VIII of JIT Record Form SUSD Tasks from 4.23 is only applicable for BFJA/JIT for Frequent Routine Maintenance Work [Frequency of once (1) a month or more]. AMT Manager & 4.23 Operation Engineer To develop Area Specific Routine Maintenance Task List (Attachment W) To develop Equipment Isolation Sheet (EIS) with running number & fixed Joint Number Area Static 4.24 Engineer (MTS) Area Manager & Maintenance Task List 4.25 Principal Static Assigned Person & To review and endorse Area Specific Frequent Routine To review and approve Area Specific Frequent Routine Maintenance Task list 4.26 Identify bolted flange joints for all equipment in the Area Area Operator Specific Frequent Routine Maintenance Task List using P&ID (OTF) and EIS as reference. Assigned Person 4.27 Perform site verification of BFJA/JIT joints. 4.28 Fill in Attachment D for all the BFJA/JIT joints for every equipment’s declared Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 11 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Assigned Person 4.29 Verify and approve the filled Attachment D forms. Maintenance work 4.30 To maintain filing for the approved Area Specific Frequent Coordinator (MWC) Routine Maintenance Task List and Attachment D forms 4.31 Communicate & brief on BFJA/JIT requirements based on the filled in Attachment D form to the manpower performing the tasks at site. 4.32 Attach the respective Attachment D form to the PTW for the assigned task Assigned Person & 4.33 Supervisor Fill in Attachment D (JIT Completion Sheet) after work completion and approval by Supervisor ACCEPTANCE CRITERIA For all BFJA/JIT and Re-Torquing works, the following conditions shall be met after final torquing: a. No movement of nut at target torque value or 100% of tensioning. b. Flange gap shall be uniformed and any difference in gap shall be within 0.5 mm measured across any diameter c. Flange lateral misalignment shall not exceed the following values Table 2 – Maximum Lateral Misalignment for BFJA/JIT NPS (DN) Maximum Misalignment ≤4” (100) 2mm >4” (100) 3mm d. No leaks at joints during pre-commissioning and commissioning. For Leakage Control Works, all conditions below shall be met a. No leaks b. No movement of nut at final torque value Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 12 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management c. Flange gap shall be uniformed and any difference in gap shall be within 0.5 mm measured across any diameter. d. Flange misalignment shall not exceed values in Table 2 above. e. Gasket centering metal ring is not pressed or compressed. (Flanges using Spiral Wound Type Gaskets) Prohibition a. Metal jacketed gasket is not allowed to be used at any joints. b. Usage of torque multiplier is not recommended. If still require to be used, Contractor Shall get approval from MRCSB’s technical authority. APPROVED LUBRICANT For common / standard carbon steel flanges MOLYKOTE 1000™ ; µ= 0.13 (Coefficient Of friction), K=0.17 (Nut Factor) DRY ; µ= 0.16 (Coefficient Of friction), K=0.20 (Nut Factor) For stainless steel flanges in extremely high temperature (> 350 Deg C), P37 ; µ= 0.14 (Coefficient Of friction for thread), K=0.18 ; µ= 0.09 (Coefficient Of friction for head), K=0.13 Or equivalent and suitable which is chemically compatible with the bolt/nut/washer materials and the process fluid. Particular care should be taken to avoid lubricant chemistry that could contribute to stress corrosion cracking, galvanic corrosion, oxygen auto-ignition, etc. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 13 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 5. ROLES AND RESPONSIBILITIES BFJI Execution Personnel Work Matrix Roles Technical Capability Unit (TCU) Responsibilities Responsible to provide JIT training and assessment. Upon successful completion of relevant training courses and subsequent passing of mandatory tests, contractor candidates will be confirmed as JIT Competent Person by issuance of JIT Visa card. TCU also responsible to conduct assessment under Contractor Competency Assurance to confirm as Competent Contractor Fitter. TCU is responsible to train contractor experience fitter to become JIT supervisor. Maintenance Planner or Project Responsible in ensuring the preparedness of the team Engineer prior to work and provide the correct tools and specifications. He shall ensure the availability of flange Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 14 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management repair contractor to repair the flange gasket face(s) in the event of any damage or out of tolerance is found. He shall also ensure that MTW/HTW/HBT Torqueing Team presents or possess certificate. Area Production Technician (OTF) Responsible to identify correct bolted flange joint as per Equipment Identification Sheet (EIS), Equipment Drawings, ISO and P&ID. During tagging exercise, he shall sign the MRCSB (OPERATIONS) section of JIT Tag (WHITE Part). Area Production Supervisor (OTF/PE Responsible to ensure safe working conditions before any SUSD) BFJA/JIT works is executed. He shall acknowledge and sign Section VIII of JIT Record Form upon completion of Re-torquing or Leakage Control Works. Shall provide information on operating parameters Operation (Facility SUSD) (pressure and temperature) of the equipment and piping flanges. Mechanical Static Engineer (MTS) Shall review technical information of the joint making Note: Engineer scope only for non-standard flange. Torque works with advice from Technical Professionals. He shall values for standard flanges shall be retrieved from Tables in Attachment E. specify the correct bolt tightening method in accordance with Method Selection for Flange Tightening (Table 1) and verify correct torque value for each joint per Manufacturer’s Data Book, Supplier Data Book, P-Bolt Calculation and/or Recommended Torque Table supplied as Attachment E of this document. Fitter Responsible to execute, disassembly and assembly of the joint as well as control torquing using Manual Torque Wrench (MTW). He/she must have undergone Engineering Contractor Competency Assurance (ECCA) assessment by TCU and be confirmed with ECCA green sticker on safety visa by TCU. He/she responsible to fill Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 15 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management up Section II & III of JIT form and, at least 1 pax shall be available in each fitter team. Control Bolting Technician Level 1 For HTW Activities Responsible to execute, disassembly and assembly of the joint as well as control torquing using Hydraulic Torque Wrench (HTW). He/she must have undergone Control Bolting Technician Assessment (CBTA). For control bolting technician level 1, at least 1 pax shall be available in the team for HTW activities. He/she responsible to fill up Section IV, VI and VIII of JIT form. Control Bolting Technician Level 2 For HBT Activities Responsible to execute, disassembly and assembly of the joint as well as control torquing using Hydraulic Torque Wrench (HTW) and Hydraulic Bolt Tensioning (HBT). He/she must have undergone Control Bolting Technician Assessment (CBTA). For control bolting technician level 2, at least 1 pax shall be available in the team for HBT activities. He/she responsible to fill up Section IV, VI and VIII of JIT form. JIT Inspector (Staff/Contractor) Responsible to supervise the joint execution/final torquing works and certify joint completion as Contractor’s representative. Upon joint completion, he shall sign the JIT Supervisor section (Joint Completion, Joint Set-up and Tightening) of the JIT Tag (GREEN Tag). In JIT form, He/she shall fill up and sign Section I until IV and also Section VIII. During Turnaround / Shutdown, He/she is from Contractor side while during normal routine whereby Contractor is not involved, JIT Supervisor shall be Mechanical Technician. Assigned Person / JIT Verifier A person that will verify the work done by JIT (Staff) Supervisor. Assigned Person is also a JIT Supervisor if it is done internally by MRCSB staff. He/she must be trained as JIT Competent Supervisor thru JIT Supervisor Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 16 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management assessment. He/she shall sign Section V and VIII. He/she is competent to provide inspection report and recommendation in accordance with ASME PCC I acceptance criteria and competent to provide Nonstandard joint calculation. He/she shall be able to verify the JIT work vs requirement in PSM-MI-20433 Bolted Flange Joint Assembly (BFJA/JIT) Management Procedure. During outside office hour (On-call) job, Assigned Person will be also act as Assigned Person’s Supervisor. JIT Verifier Leader (Staff) Shall be competent to lead and coordinate JIT verifier team, review inspection report and recommendation in accordance with ASME PCC I acceptance criteria. He/she shall be competent to lead Non-standard joint calculation and lead the JIT work vs requirement in PSM-MI-20433 Bolted Flange Joint Assembly (BFJA/JIT) Management Procedure. JIT Manager/ Assigned Person’s Responsible to ensure that the Assigned Person is Inspector (Staff) competent and trained to perform the work and certify the completion of the joints. He shall ensure the correct materials and tools are available and used throughout the execution of BFJA/JIT works. He shall sign Section V of JIT Record Form upon acceptance of BFJA/JIT works and Section VIII upon acceptance of Re-Torquing or Leakage Control Works. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 17 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 6. DEFINITIONS The following definitions apply for the purpose of this procedure. Terms Definitions Bolted Flanged Joint Pressure-boundary flanged joints with ring-type gaskets that are Assembly (BFJA/JIT) entirely within the circle enclosed by the bolt holes and with no contact outside this circle Manual Torque Wrench Wrench with positive (Click) indication when required torque is (MTW) achieved. Hydraulic Torque Wrench Two of the most common means of tightening large bolts, where (HTW) and Hydraulic Bolt high bolt loads are required. Tensioning (HBT) machine provide the tension by the amount of rotational force Hydraulic fluid pressure in HTW applied on the bolt while Bolt tensioning machine applies preload to a bolt by stretching it axially. Re-Torquing Proactive mean by retightening of bolts to maintain tightening force of the bolts during the process of temperature increase or after a certain relaxation period has passed. Re-Torquing shall be performed on all flanges in high temperature service (operating temperature above 200oC) having Leak History. ReTorquing work shall be carried out twice, at 50% and 75% of the operating temperature. Leakage Control Works Reactive mean by tightening joints when leaks occur during operation due to thermal expansion, inherent vibration, reduced gasket properties, damaged sealing surface or other situations where unit shutdown is not planned, or items not taken out of service. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 18 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Routine Maintenance Work A set of mechanically regular activities that is carry out at minimum Bolt frequency of once (1) in a month. Term refers to all type of threaded fastener that may be used in a pressure-boundary BFJA such as a machine bolt, stud bolt, etc. Working Surfaces The term “working surfaces” refer to those interfaces between fastener components and/or fasteners and flanges that slide past one another during tightening or loosening Critical Joints (Touched or Untouched) Critical Joints are defined by the following criteria: i. Flanged Joints with leak history as per Critical Flange Management Procedure ref: PRD-OPP-CP-052 First Break ii. Joints with RTJ flange & gasket iii. Operating temperature above 350 deg iv. Joints with special gasket or OEM proprietary design Opening of piping flange or equipment flange. See PRD-OPP-CP022 Equipment Isolation and Blinding /De-Blinding for definition of First Break flange for Normal Operation or Partial Shutdown, OR during Turnaround. WARNING: Not allowed to break joint without JIT tagging in place. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 19 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 7. LINK WITH OTHER DOCUMENTS The JIT Record Form shall be duly completed for each BFJA/JIT works. Reference ASME PCC-1-2013 Document Name Guidelines for Pressure Boundary Bolted Flange Joint Assembly PTS 12.00.03 Workshop Equipment and Mechanical Tools Petronas Technical Paper Joint Integrity Technical Sharing Presentation by PGTS (to define…) M-46-BP-7 Revision 4 Phillips 66 Recommended Best Practice for Joint Make-up Technical Paper by Gary Sears from Guidelines for the Management of Integrity Hydratight Sweeney Pipe Joints PTS 12.00.60 PTG – 12.00.06 Bolted Flange Joint Assembly (Amendments/Supplements to ASME PCC-1) Guideline for Bolted Flange Joint Integrity (BFJI) Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 20 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 8. ATTACHMENTS A BFJA/JIT Management Workflow A1 BFJA/JIT Joint List Registration Flow A2 BFJA/JIT Workflow for Turnaround (TA) B Joint Integrity (JIT) Tag - 4 colors C Joint Integrity (JIT) Record Form D Joint Integrity (JIT) Record Form for Routine Maintenance Work E Recommended Torque Tables F RACI Chart G Blinding/De-blinding for Isolation/Normalization including First Break H Bolt Joint Assembling Flanges (Flange Make-up). I Control Torquing J Bolt Tensioning K Re-Torquing and Leakage Control Works L Sample of JIT/BFJA Execution Team Organization Chart M Best Practice for Stud Bolt and Lubricant Application N Sample of Blinding List O Original Equipment Manufacturer (OEM) Specific Torque Value P JIT Component Strategy Q JIT Inspection report R Oxygen Service Piping S JIT Personnel Competency Development Plan Guideline T Scope Demarcation U HBT Exception List V PSR-1 P-Bolt Summary W X Area Specific Routine Maintenance List DIGITAL FLANGE INTEGRITY TOOLS (DIGI-FIT) Y Audit check list form for (BFJA) Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 21 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 9. DOCUMENT HISTORY Attachment : Revision History Revision No. Revised By Approved By Approval Date Description 0 MZAR AE 30/1/2015 These MI procedures are combined into this document and the below document will be removed. a. PSM-MI-20401 Bolt Tensioning b. PSM-MI-20405Assembling Flanges (Flange Make-up) c. PSM-MI-20407 Blinding for Isolation including First Break d. PSM-MI-30401 Re-Torquing and Leak Control e. PSM-MI-30414 Control Torquing Improvement on responsibility person. Scope includes plant modification. Add requirement to attach JIT Form to SAP prior to TECO or in Final project document for plant modification project work. Additional requirement to check flange flatness prior to flange make-up Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 22 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 1 MZAR AE 10/8/2015 Additional responsibility for Maintenance Planner/Project Engineer Additional responsibility for Technical Capability Unit (OEX), Assigned Person, Additional requirement in Sect II of Sample of Joint Integrity (JIT) Record Form Additional information in Attachment H : Bolt Joint Assembling Flanges (Flange Make-up) [Guideline] Added up Attachment L : JIT/BFJA Execution Team Organization Chart Scope includes Major Turnaround Scope includes battery limit blinding and process blinding activity. Area Production Supervisor; replace accepted with acknowledge Scope of assigned person during On-call Improvement on JIT tag look Improvement on Attachment C: Joint Integrity Record Form Improvement on Attachment D: Joint Integrity Record Form for Routine Maintenance Work Improvement on Attachment E: Recommended Torque Tables New attachment: - - - Attachment L: JIT/BFJA Execution Team Organization Chart Attachment M: Best Practice for stud bolt and lubricant application Attachment N: Sample of Blinding List Attachment O: Original Equipment Manufacturer (OEM) Specific Torque Value Overall, replace certified with trained or confirmed Additional requirement Attachment A: Joint Integrity (JIT) Workflow Additional requirement in Sect 9 PREPARATION Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 23 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Removal of AIM from procedure Attachment J: Bolt Tensioning [Guideline] 1.0 Procedures Include in 2.4 and 2.9 Assemble the bolts to the flange with extra thread length (1D) protruding above the hexagon nuts on the side of the flange on which the tools are to be used. Addition and Update; Attachment E: Recommended Torque Tables 2 MFFMF ARAR 21/6/2016 Additional responsibility for Assigned Person Additional requirement added in workflow Attachment A: Joint Integrity (JIT) Workflow Updated JIT Tag to include flange size and rating Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 24 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 3 MFS EAA 5/1/2017 Revised responsibility for Area Production Supervisor, Assigned Person and Assigned Person Supervisor Included new definitions for Bolt, Working Surfaces and Critical Joints Amended torqueing method selection for H2S service, more than 1.5 inch, class rating should be above 600# for HBT application Included disclaimer for downgrading HBT to HTW Amended final flange gap acceptance criteria Section 11 Improved flow chart for TA to include instructions to remove sections of JIT tag upon activity completion Amended JIT Tag to include Gasket Specifications Included new JIT tag with distinct color and required signature for Critical and Normal Joints for TA New improvised JIT form New JIT sheet Included new torque table for Gr. 660 bolt Amended Att. H, 3.1 to use soft brass wire brushes Included new para. for graphite residual acceptance Att. H, 3.1 Added paragraph for guide on inspection after breaking flange Att. H, 3.2 Added notes for flange gap alignment prior tightening Att. H, 3.4 Added statement on approved lubricant for stainless steel flanges in extremely high temperature Section 12 Added para. and Caution notes for bolt reuse Att. H, 3.2 Added clause for lubricant Att. H, 3.3 Added clause and sample picture of prohibited use of masking tape for gasket adhesive Added caution for application of graphite tape Att. H,3.7 Added statement for method to gauge misalignment in flanges Att. H, 3.11 Revised and removed old appendix on Attachment H Added note for minimum HTW tool on critical joints Att. I, 2.6 Added note and sample numbering sequence for split ring type joint tightening sequence Improved clause for final pass of tightening Att. I, 2.14 Added clause for leakage control Att. I, 2.16 Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 25 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Added new note for torque value for low yield strength bolts Att. I ,2.5 New revised figure for bolt numbering sequence and table for legacy tightening Att. I, 4.0 Added clause for information required for HBT Att. J, 1.0 Revised clause for percentage of bolt tightening Att. J, 2.1 Updated PTS numbering and name reference Aligned final acceptance criteria per Section 11 for Att. K, 4.14 Added reference for torque table for re-tightening Att. K, 4.15 Added recommended manpower loading Att. I, Org Chart Revised bolt replacement criteria Att. M Amended unit for minimum torque value to ft.lb Att. O 4 EAA MNIK 23/5/2017 Added First Break definition and Flange Break activity for blinding/de-blinding for Normal operation and Partial shutdown taking excerpt from PRD-OPP-CP-022 Equipment Isolation and Blinding/De-Blinding Procedure requirement to have mandatory presence of Production Personnel during activity. Recommended Action from Incident Investigation First Aid Case due to contact with Flushing Diesel at E-21256B/C on 10 Feb 2017. Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 26 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 5 HA MAR 17/11/2017 Replaced PP(M)SB with MRCSB. Revised responsibility of Mechanical Static Engineer, JIT Supervisor, Assigned Person/JIT Verifier and introduced responsibility of Competent Fitter Level 1&2, Control Bolting Technician Level 1&2 and JIT Verifier Leader. Added requirement for first break. Added Oxygen Service and Critical/Thermal Shock in 'Method Selection for Flange Tightening'. Added Procedure of Handling Oxygen Piping/Flanges included in 'Attachment Q' Removed JIT Tag – 2 colours. Added approved lubricant that can be used for stainless steel flanges in extremely high temperature. Additional info and some amendment in JIT Inspection form. Amended recommended torque value for Table E5, E8 and E9. Added Recommended Value Table E16, E17, E18 & E19. Included JIT Inspection Report as per 'Attachment P'. Added workflow for Attachment A1: BFJA/JIT Joint List Registration Flow. Added pre-check requirement for critical joint added in JIT Form. Added Non-Standard Joint in 'Attachment E: Recommended Torque Table Summary'. Amended value for 1" Stud size for 'Table E1Recommended Torque Values at 60% Bolt Yield' Amended RACI Chart in 'Attachment F'. Added clear statement for bolt size and its requirement for round 5 of bolt tightening. Added Attachment P: JIT Components Strategy Added Attachment S: JIT Personnel Competency Development Plan Added Attachment T: Scope Demarcation 6 MB MNIK 13/11/2018 Added HBT Exception List & PSR-1 P-Bolt Summary Attachments 7 MB MNL 3 Apr 2020 1. 2. 3. 4. Added Tasks 4.23 – 4.34 for Routine Maintenance BFJA/JIT Tasks Amended Attachment D Form for Routine Maintenance Added Attachment W for Area Specific Equipment List with Routine Maintenance Amended Table E1 – E11 to follow latest PTG BFJA JIT Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 27 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management 8 MB/ HA / ARAR Revision No. 9 Revised By MB/HA MNL 28 May 2020 Approved By Approval Date MNIK 19.3.2022 1. SCOPE: ADD scope of Internal joints as per INC/2019/RA/0151-09-01 CCR Action item. 2. ITEM 4 PREPARATION: REPLACE Table 1 : Method Selection for Flange Tightening with MRCSB MI table because more comprehensive as it based on MRCSB experiences in actual site application and Lesson Learnt. 3. ATTACHMENT E: REMOVE "Table Summary" in Attachment E. To follow PTG new recommendation. 4. ATTACHMENT E: ADD Table E19 Recommended Torque Values for Bolts used at SPM CALM Buoy (Spiral Wound Gasket and Hoses as per PTG new recommendation Description 1. 2. 3. 4. 5. 6. Amended Attachment C on JIT Form section 1 add item (AFC Plug material) Improvement on responsibility person suit to OER2 Amended Table E4 with latest correct bolt load calculation based on bolt coefficient for lubricant P37 with approved lubricant that can be used for stainless steel flanges in extremely high temperature. Add new revised recommended torque value for from Table E1, till 11 for bolt size 13/8’’ nut size 55mm Add new deployment strategies for digital flange management (Digi Fit) Add new attachment Y Audit check list form for (BFJA) Document Authorisation Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 28 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering Administrative Procedure 06 Physical Asset Management 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Author: Mukhriz B Badarudin (ENG/MRCSB) Date: 14 July, 2022 Reviewer: Eddy Azrai B Ariffin (ENG/MRCSB); Date: 22 July, 2022 Approver: M Nasrul Islam B Kupordin (ENG/MRCSB) Date: 1 August, 2022 Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 29 of 30 OPERATIONAL EXCELLENCE MANAGEMENT SYSTEM (OEMS) Refining & Trading MRCSB Engineering 06 Physical Asset Management Administrative Procedure 06_03_02-L3 PSM-MI-20433 BFJA JIT Management Supporting Document Link No. 1 2 3 4 Supporting Documents PSM-MI-20433 BFJA JIT-MB-signed PSM-MI-20433 MRCSB Joint Analysis Summary List_2019.7.31 (002) PSM-MI-20433 P Bolt Summary TA 2018 PSM-MI-20433 BFJA JIT Management Open Useful This hard copy document is valid for 48 hours only unless clearly identified as controlled copy. Date & time printed 19 September 2022, 11:55 AM Page 30 of 30