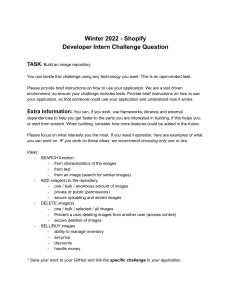

C.R. Woodcock · J.S. Mason Editors.

Bulk solids

handling :

an introduction to the practice and

technology

BULK SOLIDS HANDLING

An Introduction to the Practice and

Technology

Prepared by Thames Polytechnic Bulk Solids Handling Unit

and edited by

C.R.WOODCOCK, DipTech, MSc, PhD, CEng, MIMechE

Principal Lecturer, School of Engineering, Thames Polytechnic

and

J.S. MASON, BSc, PhD, CEng, FIMechE, FIMarE, MIMinE

Head of School of Engineering, Thames Polytechnic

Springer Science+Business Media, LLC

1987 Springer Science+Business Media New York

Originally published by Blackie & Son Ltd in 1987

~)

First published 1987

Al/ rights reserved.

No parc of chis puhlication may he reproduced.

stored in a retrieval system, or transmitted,

in anyform or hy any means,

electronic, mechanical, recording or otherwise,

without prior permission of the Puhlishers.

British Library Cataloguing in Publication Data

Bulk solids handling: an introduction to

the practice and technology.

1. Bulk solids handling

1. Woodcock, C.R. Il. Mason, J.S.

III. Thames Polytechnic. Bulk So/ids

Hand/ing Unit

621.8'6

TS180.8.B8

Library of Congress Cataloging-in-Publication Data

Woodcock, C.R.

Bulk solids handling.

Bibliography: p.

lncludes index.

1. Bulk solids handling. 1. Mason, J.S.

Il. Title.

TS180.8.B8W66 1987

629.04

85-29147

ISBN 978-1-4757-1360-2

DOI 10.1007/978-1-4757-1358-9

ISBN 978-1-4757-1358-9 (eBook)

Phototypesetting by Thomson Press (1) Ltd, New Delhi and

Preface

An understanding of the properties and the handling characteristics of liquids

and gases has long been regarded as an essential requirement for most

practising engineers. It is therefore not surprising that, over the years, there has

been a regular appearance of books dealing with the fundamentals of fluid

mechanics, fluid flow, hydraulics and related topics. What is surprising is that

there has been no parallel development of the related discipline of Bulk Solids

Handling, despite its increasing importance in modern industry across the

world. It is only very recently that a structured approach to the teaching, and

learning, of the subject has begun to evolve.

A reason for the slow emergence of Bulk Solids Handling as an accepted

topic of study in academic courses on mechanical, agricultural, chemical,

mining and civil engineering is perhaps that the practice is so often taken for

granted. Certainly the variety of materials being handled in bulk is almost

endless, ranging in size from fine dust to rocks, in value from refuse to gold, and

in temperature from deep-frozen peas to near-molten metal. Almost everyone

has seen a belt conveyor in operation-perhaps carrying grain on the local

farm, or stone and rock from a nearby quarry-but how many would know

that belt conveyors are now being developed to transport bulk solids at rates

in excess of 30 000 tonnes per hour? The domestic vacuum cleaner is a familiar

machine in which dust particles are conveyed through a pipe in a stream of air,

but few people would appreciate that large lumps of coal and rock, and even

fish, can be transported in a similar way. Examples of bulk solids handling can

be found in almost every kind of industry and the problems associated with the

design, installation and operation of plant for the storage and transport of

materials in bulk are many and varied. No book can be a substitute for the

technical skill acquired through long experience in the industry. Nevertheless,

we have attempted to present here a foundation of knowledge, generally with a

practical rather than an academic emphasis, upon which expertise in various

specialized aspects of bulk solids handling can be developed subsequently.

Governments of many nations are now recognizing that the education and

training of engineers in many fields should include some study of the

technology of bulk solids covering the properties, storage, flow and transport

of a wide range of materials in particulate or granular form. In the United

Kingdom, for example, recent initiatives emanating from the Department of

Industry have led to conferences, courses, and various publications aimed at

promoting a greater awareness of the unique features of bulk solids. The

School of Engineering at Thames Polytechnic, and in particular the staff of its

iv

PREFACE

Bulk Solids Handling Unit, have been deeply involved in these initiatives from

the outset and this book is the result of a clearly perceived need for an

introduction to the subject that would identify and set out a structure for the

area of study that is becoming known by the convenient, if not entirely

accurate, title 'Bulk Solids Handling'. Many specialist treatments are already

available: works on particle technology, hopper design, fluidization, dust

control, pneumatic conveying, and others, can be found on library shelves and

in most cases these are excellent and valuable works of reference for the

experienced engineer. However, for the student and for the engineer who

requires an overview of the emerging discipline of bulk solids handling,

supported by an adequate coverage of fundamentals, this book should

provide essential reading.

In common with most books of similar size and scope, this one should really

be regarded as the product of a team effort. We, as authors and editors, would

unhesitatingly acknowledge the contributions, both direct and indirect, of our

colleagues in the Bulk Solids Handling Unit at Thames Polytechnic, notably

Dr David Mills and Dr Alan Reed. In their various ways the academic and

technician staff of the School of Engineering, together with many of our

postgraduate and undergraduate students, have played some part in the

events leading up to the conception, preparation and, ultimately, the

production of this book. Although it is perhaps a little unfair to mention

individuals by name, we do gratefully acknowledge the patient and tolerant

efforts of Mrs Pam Colley in undertaking the massive task of typing the

manuscript. Finally, our sincere thanks and appreciation goes to our

respective families, especially to our wives Angela and Fran, for the patience,

understanding and considerable fortitude that they have shown during the

months that this book has been in preparation, and indeed during the many

years that we have both been so deeply involved in the multitude of activities

arising out of our interest in the fascinating subject of Bulk Solids Handling.

CRW

JSM

Contents

PART 1 CHARACTERIZATION, FLOW AND STORAGE

1 The nature of bulk solids

Introduction

Sampling

1.2.1 Obtaining a gross sample

1.2.2 Preparing laboratory and test samples

1.3 Voidage and bulk density

1.4 Particle density

1.5 Particle size

1.5.1 Definition of 'size' and 'size distribution'

1.5.2 Measurement of particle size

1.6 Particle shape

1.7 Surface area

1.8 Particle hardness

1.9 Cohesion and adhesion

1.9.1 Angle of repose

1.9.2 Shear strength

1.9.3 The shear cell as a means of determining shear strength

1.9.4 Wall friction

1.9.5 Measurement of wall friction

1.9.6 Arching phenomena

1.10 Moisture content

1.11 Explosiveness

1.12 Notation

References and bibliography

1.1

1.2

2 Gravity flow of bulk solids

2.1

2.2

2.3

2.4

2.5

2.6

Introduction

Pressure distribution in a bulk solid

2.2.1 Bulk solid at rest

2.2.2 The effect of flow on the pressure distribution

Flow of bulk solids from hoppers

2.3.1 Introduction

2.3.2 Core flow

2.3.3 Mass flow

2.3.4 Obstructions to gravity flow

2.3.5 Predicting the solids discharge rate

Flow of bulk solids in chutes

2.4.1 Introduction

2.4.2 Flow patterns in straight inclined chutes

2.4.3 Flow patterns in curved chutes

2.4.4 Chute design

Flow of bulk solids in vertical pipes

2.5.1 Introduction

2.5.2 Mode of flow

2.5.3 Flow control-J-valves and L-valves

Notation

References and bibliography

1

1

3

3

4

7

9

10

10

15

25

26

28

29

31

33

35

39

40

41

43

44

45

46

47

47

49

49

52

54

54

54

55

55

56

64

64

65

68

69

74

74

76

79

81

82

VI

CONTENTS

3 Dynamics of fluid/solids systems

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

Introduction

Flow through beds of fixed particles

3.2.1 Characteristics of flow in porous media

3.2.2 The prediction of pressure-drop across a fixed particulate bed

Settling behaviour of particles

3.3.1 Motion of a spherical particle settling in a stationary fluid

3.3.2 The settling of non-spherical particles

3.3.3 The settling of concentrations of particles (hindered settling)

3.3.4 Classification and sorting of particles

Fluidization

3.4.1 The fluidization process

3.4.2 The prediction of minimum fluidizing velocity

3.4.3 Entrainment of particles from a fluidized bed

3.4.4 The porous membrane, or distributor

3.4.5 The influence of particle size and density

Spouted bed behaviour

Gas/solids flow in pipes

3.6.1 Introduction

3.6.2 The flow of gas/solids suspensions in horizontal pipes

3.6.3 The flow of gas/solids suspensions in vertical pipes

3.6.4 Flow around 90" bends

3.6.5 The prediction of pressure-drop in flowing gas/solids suspensions

Liquid/solids flow in pipes

3.7.1 Flow characteristics of liquid/solids mixtures (slurries)

3.7.2 Non-Newtonian flow models for homogeneous suspension

3.7.3 The modelling of heterogeneous suspensions

Notation

References and bibliography

4 The design of storage bins and hoppers

4.1

4.2

Introduction

Hopper geometry

4.2.1 Shape

4.2.2 Overall dimensions

4.3 Outlet size and cone angle

4.3.1 Jenike's 'flow-no flow' criterion

4.3.2 Flow Functions and flow factors

4.3.3 Outlet dimension and cone angle

4.4 Period of storage and time consolidation effects

4.4.1 Caking

4.4.2 Testing for time consolidation

4.4.3 Practical ways of minimizing time consolidation

4.5 The effect of moisture

4.6 Overcoming space limitations

4.6.1 The use of low-friction linings

4.6.2 Changing hopper shape

4.7 Structural design

4.8 Control and measurement of discharge rate

4.9 Feeders

4.9.1 Introduction

4.9.2 Belt feeders

4.9.3 Apron feeders and rotary feeders

4.9.4 Rotary table feeders

4.9.5 Screw feeders

4.9.6 Vibratory feeders

4.10 Discharge aids

4.10.1 Introduction

84

84

84

84

85

91

91

95

98

98

99

99

104

109

109

110

113

116

116

117

122

124

125

138

138

139

148

150

152

154

154

156

156

159

162

162

165

166

168

169

170

171

171

172

173

175

176

178

180

180

181

183

184

185

187

187

187

CONTENTS

4.10.2 Pneumatic methods

4.1 0.3 Vibrational methods

4.10.4 Mechanical methods

4.11 Notation

References and bibliography

5 Dust control

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

Introduction

Dust as a hazard to health

5.2.1 Dust particle size

5.2.2 Dust concentration limits

Dust suppression

5.3.1 Elimination of dust

5.3.2 Control of dust dispersion

Gravity and inertial separators

Air cleaners-cyclones

5.5.1 Principle of operation

5.5.2 Prediction of collecting efficiency

5.5.3 Prediction of pressure-drop

5.5.4 Cyclone selection

Air cleaners-wet washers or scrubbers

5.6.1 Principle of operation

5.6.2 Low pressure-drop wet washers

5.6.3 High pressure-drop wet washers

Air cleaners-filters

5.7.1 Mechanism of filtration

5.7.2 Filter media

5.7.3 Bag filters-design and selection

5.7.4 Filter cleaning

Air cleaners-electrostatic precipitators

Notation

References and bibliography

6 Explosion hazards

6.1

6.2

6.3

6.4

6.5

6.6

Introduction

Characteristics of dust explosions

6.2.1 Ignition

6.2.2 Explosibility limits

6.2.3 Expansion effects and explosion pressures

Measurement of explosion parameters

Explosion risks and system design

6.4.1 Minimizing sources of ignition and prevention of ignition

6.4.2 Containment

6.4.3 Explosion relief venting

6.4.4 Detection and suppression

Static electricity

Conclusion

References and bibliography

vu

188

192

198

200

201

203

203

204

204

208

208

208

209

211

213

213

215

218

218

218

218

220

222

224

224

226

227

230

232

233

233

235

235

238

238

239

240

241

246

248

249

250

253

256

258

258

PART 2 MECHANICAL HANDLING

7 Belt conveyors

7.1

7.2

Introduction

Features of belt conveyors

7.2.1 Belt construction

7.2.2 Idlers

7.2.3 Drive arrangements

260

260

261

261

265

268

CONTENTS

V111

7.2.4 The power unit

7.2.5 Loading and discharge arrangements

7.2.6 Belt cleaners

7.3 Belt conveyor design

7.3.1 The bulk solid to be transported

7.3.2 Belt speed

7.3.3 Belt width

7.3.4 Belt tension

7.3.5 Idler spacing

7.3.6 Power requirements

7.4 Belt conveyor variants

7.4.1 The cable belt conveyor

7.4.2 Belt conveyors without idlers

7.4.3 Closed-belt or pipe conveyors

7.4.4 Sandwich belts

7.5. Notation

References and bibliography

8 Bucket elevators

8.1

8.2

8.3

8.4

Introduction

Principal types of bucket elevator

8.2.1 Centrifugal discharge elevators

8.2.2 Continuous bucket elevators

8.2.3 Pivoted buckets

8.2.4 Profiled-belt elevators

Design and selection of bucket elevators

8.3.1 Design features

8.3.2 Loading

8.3.3 Discharge

8.3.4 Capacity

8.3.5 Driving power

Notation

References and bibliography

9 Chain and flight conveyors

9.1

9.2

9.3

9.4

9.5

9.6

9.7

Introduction

Drag conveyors

En-masse conveyors

9.3.1 Design features

9.3.2 Performance calculations

9.3.3 Applications of en-masse conveying

Tubular drag conveyors

Apron conveyors

Aerial ropeways

Notation

References and bibliography

10 Screw conveying

10.1

10.2

10.3

10.4

Introduction

Principle of operation of screw conveyors

The enclosed screw or 'auger' conveyor

I0.3.1 Constructional features

10.3.2 Prediction of the performance of an auger conveyor

The industrial screw conveyor or 'U-trough' conveyor

10.4.1 Constructional features

10.4.2 The conveyed product

271

272

273

274

274

275

277

281

284

284

289

289

290

291

293

295

296

298

298

300

300

301

303

304

305

305

308

309

312

315

316

317

318

318

318

321

321

323

325

327

328

331

333

334

335

335

337

338

338

340

342

342

344

CONTENTS

I 0.5

10.6

10.7

10.4.3 Conveyor selection

10.4.4 Conveyor power

10.4.5 Inclined screw conveyors

Vertical screw conveyors

Conclusion

Notation

References and bibliography

11 Vibratory conveyors

11.1

11.2

11.3

11.4

11.5

11.6

Introduction

Movement of a bulk solid in a vibrating trough

11.2.1 The motion of the trough

11.2.2 The motion of bulk material in the trough

11.2.3 Average conveying velocity

11.2.4 The influence of the design parameters

11.2.5 Two-phase trough motion

Design features

11.3.1 Drive mechanism

11.3.2 Mounting systems

Applications of vibratory conveying

Spiral elevators

Notation

References and bibliography

IX

345

349

351

354

356

356

357

358

358

361

361

365

367

369

370

370

370

374

375

376

378

379

PART 3 PNEUMATIC AND HYDRAULIC TRANSPORT

12 Basic pneumatic conveying systems

12.1

12.2

12.3

12.4

12.5

Introduction

Modes of conveying-dilute-phase and dense-phase

Low-pressure pneumatic conveying systems

12.3.1 Positive-pressure systems

12.3.2 Negative-pressure (vacuum) systems

12.3.3 Combined negative/positive pressure systems

High-pressure systems

12.4.1 General features

12.4.2 Single blow tank systems

12.4.3 Twin blow tanks and continuously operating systems

12.4.4 Long-distance conveying

Low-velocity conveying and the use of supplementary air feeds

12.5.1 General features

12.5.2 Plug-forming systems

12.5.3 Plug-limiting systems

12.5.4 Air-injection and booster systems

References and bibliography

13 Components of pneumatic conveying systems

13.1

13.2

Introduction

The air supply

13.2.1 General requirements

13.2.2 Fans and turbo-blowers

13.2.3 Roots-type blowers

13.2.4 Sliding-vane rotary compressors

13.2.5 Screw compressors

13.2.6 Reciprocating compressors

13.2.7 Vacuum pumps

380

380

386

386

386

390

392

392

392

393

396

398

399

399

401

403

405

407

408

408

408

408

409

411

411

412

414

416

CONTENTS

X

13.3

13.4

13.5

13.6

Feeding devices

13.3.1 Rotary valves

13.3.2 Screw feeders

13.3.3 Venturi feeders

13.3.4 Gate Jock valves

13.3.5 Blow tanks

13.3.6 Entrainment devices for vacuum systems

The pipeline

Disengaging and collecting devices

Notation

References and bibliography

14 Pneumatic conveyor design

14.1

14.2

14.3

14.4

14.5

Introduction

General design procedure

14.2.1 Conveying velocity and volumetric air flow rate

14.2.2 Solids mass flowrate and solids loading ratio

14.2.3 Pipeline diameter

14.2.4 Pressure-drop

14.2.5 Stepped pipelines

14.2.6 Selection of the air mover

Summary of preliminary design procedure for dilute-phase systems

Designing from available test data

14.4.1 Conveying characteristics

14.4.2 Scaling for pipe size and conveying distance

Notation

References and bibliography

15 Air-assisted gravity conveying

15.1

15.2

15.3

15.4

15.5

15.6

15.7

15.8

Introduction

The flow of fluidised solids

Practical air-assisted gravity conveying

Design parameters for air-gravity conveyors

15.4.1 Slope of channel

15.4.2 Conveying distance

15.4.3 Width of conveying channel

15.4.4 Air requirement

Properties of bulk solids for air-gravity conveying

Air-float conveyors for horizontal and upward transport

Energy consumption of air-gravity conveyors

Notation

References and bibliography

16 Hydraulic conveying

16.1

16.2

16.3

16.4

Introduction

Components of a hydraulic conveying system

16.2.1 Pumps

16.2.2 Slurry preparation plant

16.2.3 The pipeline

16.2.4 De-watering equipment

System design

16.3.1 General design approach

16.3.2 Flow characreristics and pressure-drop

Recent development

References and bibliography

17 Capsule transport

17.1

Introduction

417

417

425

426

427

428

431

433

436

436

436

438

438

439

439

441

442

443

446

446

447

448

448

449

454

454

456

456

458

461

465

465

466

466

468

470

472

475

476

476

478

478

481

481

485

486

487

489

489

490

491

492

494

494

CONTENTS

17.2

17.3

17.4

17.5

Index

Capsule transport in a pneumatic pipeline

17.2.1 General features of a pneumo-capsule system

17.2.2 The capsules

17.2.3 The pipeline

17.2.4 The air supply

17.2.5 Loading and unloading stations

Capsule transport in a hydraulic pipeline

17.3.1 General features of a hydro-capsule system

17.3.2 The capsules

17.3.3 The pipeline

17.3.4 The water supply and pump system

17.3.5 Injection and ejection of capsules

Size of capsule fleet

Notation

References

xi

498

498

499

501

502

503

504

504

504

505

505

508

508

510

510

513

... when you can measure what you are speaking about, and express it in numbers, you know

something about it; but when you cannot measure it, when you cannot express it in numbers, your

knowledge is of a meagre and unsatisfactory kind: it may be the beginning of knowledge, but you

have scarcely, in your thoughts, advanced to the state of SCIENCE, whatever the matter may be.

(Lord Kelvin, as Sir William Thomson, speaking on 'Electrical Units of Measurement' at the

Institution of Civil Engineers, London, 3 May 1883.)

(Arab proverb, freely translated as: 'Experience without learning is better than learning without

experience'.)

1

The nature of bulk solids

1.1 Introduction

A bulk solid consists essentially of many particles or granules of different sizes

(and possibly different chemical compositions and densities) randomly

grouped together to form of a bulk. The 'nature' of such a material-that is, its

appearance, its 'feel', the way it behaves in various circumstances, and so onis thus dependent upon many factors, but principally upon the size, shape and

density of the constituent particles.

The nature of a bulk solid, described in terms of appropriate characteristics,

is an essential consideration when designing or selecting equipment for its

handling or storage. There are innumerable examples in industry of problems

that have been attributable to insufficient attention being paid to the

properties of the bulk solid involved. Failure of a material to discharge from a

storage hopper, blockage of a pneumatic conveying line and uncontrollable

flushing of material through a weigh-feeder are typical of such problems. In

this chapter some of the principal parameters that are used to describe bulk

solids and their behaviour will be introduced.

When attempting to describe a bulk solid it is important to understand that

the characterization can be on two levels:

(i) By means of features descriptive of the behaviour of the material in its

normal bulk form; for example, the way in which it compacts, its flow

properties, the influence of moisture and electrostatic charging

(ii) By means of features of the constituent particles such as their size, density,

hardness, shape and surface texture.

At the present time our level of knowledge is not sufficient to enable a

reliable prediction to be made of the behaviour of a bulk solid solely from the

characteristics of its constituent particles. Nevertheless, research in this field is

progressing, and by continually seeking correlations between the observed

behaviour of various materials in the bulk form and measured particle

characteristics, a valuable database is being compiled for the benefit of

designers and users of bulk handling equipment.

There are many descriptive terms and numerical parameters that can be

used in the characterization of particulate and granular bulk solids, and these

may refer both to the appearance of the material and to its behaviour in

various circumstances. A first step in determining the characteristics of an

unfamiliar material is to consider its behaviour in very general terms; for

2

BULK SOLIDS HANDLING

Table 1.1 A 'materials personality test' helps to establish the behavioural features of a bulk solid

'Neurotic' materials

}

have poor flowability

have too much flowability

are sticky or tacky

tend to pack or bridge

'Sadistic' materials are

}

abrasive

corrosive

toxic

explosive

hot

'Masochistic' materials are

friable

degradable

contaminable

'Schizophrenic' materials are

hygroscopic

susceptible to electrostatic

charge

}

}

they move awkwardly

they attack their

surroundings

they suffer from

their surroundings

they change their

behaviour pattern

example, does it 'flow' easily or is it 'sticky'? Is it fragile? Is it abrasive?

Corrosive? Explosive? And so on. The 'Materials Personality Test' (Table 1.1 ),

which is believed to have appeared originally in an Australian publication,

conveniently summarizes these features of bulk solids behaviour.

Although purely descriptive terms are essential when communicating

information on bulk solids, they are unlikely to be sufficient on their own.

Numerical parameters are required to characterize a bulk solid in a

quantitative manner and so to enable the designer of a handling system, in the

light of his past experience, to match the system to the product and to assess

the likelihood of problems occurring. Some of the more important of these

parameters will be considered in more detail in this chapter. Attention will

then be turned to some of the measurable characteristics of the constituent

particles. Useful particle properties include size, shape, surface area, density

and hardness, whilst more esoteric features such as surface texture may also

have some value when attempting to predict the behaviour of a bulk material

from a study of its particles.

In this book an attempt is made to define the common usage of various

properties of particles and bulk solids and to describe briefly examples of

currently available equipment and techniques for their measurement. A very

large amount of literature has been published on this aspect of particle

technology and for further information the reader would be well advised to

begin with one of the recent specialist guides or textbooks such as references

[1] or [2]. Much useful information on the sampling, testing and description

of very coarse materials such as mineral aggregates, which are generally

beyond the scope of this book, can be found in the series of British Standards

under the overall classification of BS 812 [3].

THE NATURE OF BULK SOLIDS

3

Before proceeding, some discussion will be undertaken on the essential need

for reliable methods of obtaining representative samples of material for

testing.

1.2 Sampling

The majority oflaboratory techniques for determining the properties of a bulk

solid and of its constituent particles naturally require only a very small sample,

usually to be taken from a large amount of material. Even a minute sample

may contain many thousands of individual particles and in order to appreciate

the difficulties of guaranteeing a representative sample, one needs only to

imagine trying to collect from, say, a one-tonne load of material, a few hundred

particles for analysis by microscope! There is little point in going to a great

deal of trouble to determine accurately the size distribution or the flow

properties, for example, of a bulk solid, if the sample used is not truly

representative of the larger mass of material from which it was taken.

In many processes involving the movement of a bulk solid, such as flow into

a hopper or on to a heap on a flat surface, significant segregation by size and/or

density can occur (Figure 1.1). Thus, there must be immediate doubt cast on

any sample taken by scoop or similar device from a large quantity of stationary

material. Where possible the sample should always be taken from a moving

stream of the material in question by diverting the whole stream for a series of

short intervals of time spaced over the period of flow of the complete batch.

Once a 'gross sample' (perhaps a few kg) has been obtained in this way it will be

necessary in the laboratory to further reduce it to a size suitable for whatever

measurement technique is to be used.

1.2.1 Obtaining a gross sample

Typical situations where it is necessary to take a sample from a large quantity

of a bulk material include:

(i) A moving stream of material; e.g. quality control of a product during a

continuous process

(ii) A static batch of material; e.g. in bags, in a bin or in a lorry or rail-wagon.

Figure 1.1

Segregation in a poured heap.

4

BULK SOLIDS HANDLING

It is almost always better to sample from a moving stream of material than

from a static batch, where this is possible, in order to minimize the influence of

segregation of particles during previous handling. In general, a careful

consideration of where segregation (and other spurious influences on the

homogeneity of the material, such as moisture) would be most likely to occur

can be of great help when deciding on the most appropriate sampling

technique. Thus, for example, when obtaining a sample from a moving

conveyor belt, care must be taken to avoid the effects of segregation of the

material as it was fed on to the belt. Sampling only part of the cross-section of

the moving stream could well be misleading, although taking a vertical 'slice'

out of the conveyed material would probably be better than 'skimming off' a

sample from the top. The best approach, however, is to sample the whole

stream for a short period of time. Even then, the possibility of variation of the

stream with time should not be overlooked, so that the sampling technique

finally adopted may be to divert the whole stream for a series of short intervals

during the conveying of a complete batch of material. Usually the easiest place

to carry out such sampling is at the discharge end of the conveyor.

Sampling from a static batch of bulk solid should always be regarded as a

poor alternative to sampling from a moving stream. Procedures can be

developed so that the worst potential errors are avoided. Thus, for instance, no

material should be taken from anywhere near a free surface. Various designs of

sampling probe are available commercially and, where one of these is used, a

number of samples should be taken from different regions within the batch of

material and mixed to form the gross sample.

Once the gross sample has been obtained, preferably from a moving stream

of the bulk solid, it will have to be 'divided' by one of the following methods to

yield a smaller sample suitable for laboratory use.

1.2.2 Preparing laboratory and test samples

As mentioned previously, a gross sample would typically be several kilograms.

For laboratory use it must be reduced in such a way that the final sample has

the same size distribution as the gross sample and is in all respects

Figure 1.2 'Cone-and-quartering'.

THE NATURE OF BULK SOLIDS

5

representative of the bulk material originally sampled. When reducing the

gross sample the main difficulty is again to avoid the effects of segregation.

A widely adopted method of preparing a laboratory sample is by 'cone-andquartering' (Figure 1.2) in which a conical heap of material is carefully divided

into four equal parts, two of these being re-mixed and formed into a smaller

conical heap which is again divided into four, and so on. Although this method

does reduce the effects of segregation it is still very sensitive to operator skill

and, where possible, some form of mechanical sample divider is preferable.

Many types of sample divider are available, such as chute splitters (Figure 1.3)

and table samplers (Figure 1.4), but perhaps the most reliable is the rotary

sample divider or 'spinning riffier' (Figure 1.5) which is capable of reducing a

gross sample of material down to several (typically eight or sixteen) 'equal'

samples for laboratory use, with minimum dependence on operator skill.

In many laboratory techniques for characterizing a bulk solid, the test

sample required is extremely small and further reduction of the laboratory

sample is necessary. For a free-flowing powder the spinning riffier should give

an acceptable sample down to one gram, but for cohesive materials, obtaining

a final test sample even of this size is not easy. One approach is to make up

paste of the laboratory sample in a suitable liquid and then to use a modified

cone-and-quartering technique. An alternative method, especially with very

fine powders, is to carefully mix the laboratory sample into a liquid dispersant

to form a suspension, a small quantity of which can then be extracted with a

pipette. Commercial models of suspension sampler are available which are

claimed to give more consistent samples than simple pipetting.

Figure 1.3

Sample divider (riffier).

6

BULK SOLIDS HANDLING

Figure 1.4 Table sampler.

mass flow hopper_

16-way dividing

head

Figure 1.5

Rotary sample divider (or 'spinning riffier').

7

THE NATURE OF BULK SOLIDS

1.3 Voidage and bulk density

The shape of particles constituting a bulk solid obviously depends upon the

manner of their production but, irrespective of whether they are of regular or

irregular shape, when they are packed together in random orientation there

will be a certain amount of free space between them. Thus a bulk solid is really

a combination of particles and space, the percentage of the total volume not

occupied by the particles usually being referred to as the 'voidage' or 'void

fraction'.

Thus

volume of voids

voidage, s = ----,--c-------=-----=-:----:---:--:total volume of particles and voids

or

vvoids

(1.1)

s=-----'-'-''--Vsolids

+ Vvoids

and, in a bed of material having unit volume, the actual volume of solid

particles, or 'fractional solids content', is (1 - s).

Sometimes the term 'porosity' is applied to bulk solids to mean the same as

'voidage'. However, it is probably advisable to reserve this term as a

description of the structure of individual constituent particles. Thus we can

define the particle porosity as the ratio of the volume of pores within a particle

to the volume of the particle (inclusive of pores). When quantifying either the

voidage of a bulk solid or the porosity of its constituent particles, it might be

necessary to avoid ambiguity by stating whether the values quoted are

inclusive or exclusive of closed pores.

Typical values of the voidage in static bulk materials consisting of

monosized spheres would range from 0.26 (that is, 26%) for regular hexagonal

packing, to 0.48 for regular cubic packing (Figure 1.6). For closely graded

irregular particles in random packing arrangements the voidage would

normally lie between these extremes, a high voidage corresponding to a loose

packing. A reasonable average figure would be around 0.4 for spheroidal•

(a} regular hexagonal:

Figure 1.6

E

~ 0.26

(b} regular cubic:

f ~

Packing arrangements for monosized spheres.

0.48

8

BULK SOLIDS HANDLING

particles, but where a material consists of particles of extremely irregular

shape, especially if they are also of very small size (i.e. fine cohesive products),

the voidage could be much higher.

A quantity ofparticulate or granular material will have an apparent density,

usually termed 'bulk density', which can be defined as the mass of the material

divided by its total volume (particles and voids).

Thus

b ulk d ensI.ty,

Ph =

+

+

msolids

mvoids

--"'='----___;_=

vsolids

vvoids

(1.2)

Writing pP as the 'true' density of the solid particles and Pr as the density of

the fluid in the void spaces, it can be shown that an expression for the bulk

density is

Pb =(pp- PrHl- t:) + Pr

(1.3)

For dry bulk solids the void spaces would, of course, usually contain air, and

thus the density Pr would be negligible compared with pP so that the

relationship between bulk density and particle density becomes

(1.4)

Clearly a knowledge of the bulk density of a product is essential in order to

design storage vessels, conveying systems and the like. Determination of this

parameter from a sample of the material concerned involves measurement of

the mass of the sample and its total volume. The measurements are essentially

straightforward, the problems arising more from the need to decide the

conditions under which the volume should be measured than from the actual

measuring techniques. It has been mentioned that the voidage (and therefore

the bulk density) of a particulate material depends upon the packing

arrangement. Therefore it is necessary to qualify any stated value of bulk

density with an indication of the condition of the material concerned. For

example, 'loose' or 'poured' bulk density might refer to a measurement for

which the sample of product was carefully poured into a measuring cylinder to

determine its volume. Alternatively, adopting a technique in which the sample

was packed by dropping the cylinder vertically a number of times from a

height of one or two centimetres on to a table could yield a value of'packed' or

'tapped' bulk density.

Note that the bulk density of a mixture of particles of different sizes will

depend upon the extent to which the smaller particles are able to fit into the

spaces amongst the larger ones.

Determination of voidage involves the separate measurements of the total

volume of the sample and the volume of the solid particles alone. The most

direct method of measuring the total volume is by pouring the sample into a

calibrated measuring cylinder and reading the volume from the scale, but note

the need to specify the condition of the product, as explained previously. The

THE NATURE OF BULK SOLIDS

9

determination of the volume of the particles will be discussed more fully in the

next section, but usually involves some form of fluid displacement technique

using a standard density bottle or a more sophisticated instrument such as an

air-comparison pycnometer. Difficulties arise with particles that are porous or

have internal voids (such as coke), since the definition of particle volume

becomes uncertain.

1.4 Particle density

It is important that the distinction between the bulk density of a particulate

solid and the 'true' particle density is clearly understood. For a single particle

the density is defined as the mass of the particle divided by its volume, so that

for a bulk material the average particle density can be determined by dividing

the mass of material by the true volume occupied by the particles (not including

the voids).

The determination of particle density thus involves the measurement of the

mass of a quantity of bulk solid and of the volume occupied by its constituent

particles, the latter measurement usually presenting the greatest difficulty. For

products oflarge particle size the density can be determined simply by noting

the volume ofliquid displaced by a known mass of particles in a partially filled

measuring cylinder. Fine powders require the use of a specific-gravity bottle or

air-comparison pycnometer.

The specific-gravity bottle (or density bottle) is a small flask fitted with a

ground-glass stopper which has a capillary hole running axially through it to

permit excess fluid to escape as the stopper is inserted into the bottle. The

normal procedure for use of the bottle begins with the determination of its

volume by carefully measuring the mass of distilled water to just fill it. A

sample of particulate material of known mass is then placed in the bottle and,

by weighing, the volume of distilled water required to just fill the bottle is

determined. Subtraction of this volume from the previously found volume of

the empty bottle thus allows the volume of the particle sample to be calculated.

Precautions should of course be taken against errors resulting from incomplete dispersion of the sample, moisture on the outside of the bottle,

temperature variations and dissolving of the particles! A more detailed

description of this method can be found in [4], Part 2.

For products that are soluble, fragile or very light, the air-comparison

pycnometer is almost essential. This commercially available instrument

consists basically of two identical cylinders connected through a valve and

each containing a piston, a differential pressure indicator and an output scale

reading volume in cm 3 (Figure 1.7). With the connecting valve closed, any

movement of the reference piston must be duplicated by an identical

movement of the measuring piston in order to maintain a null reading on the

differential pressure indicator. After setting the zero (tare) on the instrument,

the volume of any material placed in the measuring cylinder will be shown by

10

BULK SOLIDS HANDLING

top

reference

piston

measuring

piston

zero V

(tare)

Figure 1.7

scale

The principle of the Beckman air-comparison pycnometer.

the position of the measuring piston for a null reading of the differential

pressure indicator.

It should be noted that all these methods yield the average particle density of

the bulk solid. The densities of different constituent particles in a blended

product can only be determined with any certainty by measuring them before

blending.

it also should be noted that values of particle density obtained by an air

displacement method (such as the air-comparison pycnometer) may differ

slightly from those obtained by liquid displacement when the particles

involved have open pores, formed, for example, by air occlusion during crystal

growth. In general, the density determined for a porous material would be an

'apparent density' which could be defined as the mass of a particle divided by

its volume including closed pores but excluding open pores. If the particles are

immersed in a viscous fluid their average effective density would be the mass of

the particles divided by their volume including both open and closed pores

(that is, considering the boundary of the particle to be its external surface). The

'true density' of a porous particle should thus be defined as its mass divided by

its volume excluding both open and closed pores.

1.5 Particle size

1.5.1 Definition of'size' and 'size distribution'

Various terms are used to give a qualitative indication of the size of particles

constituting a bulk solid, the word 'size' here being used loosely to mean some

sort of average dimension across the particle. Naturally such terms are not

precise and tend to vary in usage from one industry to another. Nevertheless, it

helps to introduce the subject of particle characterization if the typical ranges

THE NATURE OF BULK SOLIDS

11

Table 1.2 Qualitative terms used to describe the size of bulk solids

Descriptive term

Typical

size range

Coarse (or broken) solid

Granular solid

5-IOOmm

0.3-5mm

Particulate solid:

coarse powder

fine powder

superfine powder

ultrafine powder

Coal, aggregates, etc.

Granulated sugar (0.3-0.Smm);

rice (2-3 mm).

100-300/lm

10-100/lm

1-10/lm

< lJlm

Table salt (200- 300 /lm)

Icing sugar ( ~ 45 Jlm)

Face powder

Paint pigments

Examples

of size covered by terms such as 'granular material', 'fine powder', and so on,

are appreciated. Table 1.2 sets out approximate ranges and, in order to assist

the reader to visualize these, some familiar bulk solid materials are quoted as

examples.

A mass of monosized, spherical particles can be described by a single

dimension-the particle diameter-and a mass of spherical particles of

varying size can be described by an 'average' particle diameter together with

some information on the distribution of sizes about that average value.

However, where the particles are non-spherical it becomes necessary to define

more carefully the parameters used for size and shape. (It may be remarked

that 'size distribution' is more a property of the bulk solid than of its

constituent particles. However, it is obviously convenient and relevant to

discuss the term at this stage along with characteristics of individual particles

such as size, shape, hardness, etc.)

In order to represent the size of an irregularly shaped particle by a single

quantity it is customary to use an 'equivalent diameter', corresponding to the

diameter of a sphere that exhibits the same behaviour as the particle under

certain conditions or that has the same value of some other descriptive

characteristics.

Thus, for example, a 'volume diameter', d., can be defined as the diameter of

a sphere having the same volume as the particle.

That is to say,

(1.5)

where vp is the volume of the particle.

(It may be noted that for a cube of unit side, the 'volume diameter' is 1.241,

compared with the maximum dimension of the cube, which is 1.732.)

In general, the manner of describing the particle size depends upon the

method of measurement, and it follows that the type of particle 'diameter' used

should depend upon the reason for specifying it! For instance, if a particulate

solid is to be used as a catalyst, the surface area of the particles is the significant

12

BULK SOLIDS HANDLING

quantity and therefore it is the 'surface diameter' that should be used for

particle size:

A

ds = ( ~

n

)112 = 0 564A

.

(1.6)

1 2

sp1

where Asp is the surface area of the particle.

(Again, note that for the cube of unit side, the 'surface diameter' is 1.382, so

that the ratio djd. is 0.898.)

In general industrial practice it is of course likely that the equivalent

diameter used would correspond to the diameter of a sphere that exhibits the

same behaviour when subjected to a specified sizing technique. For instance,

the diameter used could be that of a sphere which just passes through the same

square sieve aperture, or which falls at the same velocity in a fluid

(sedimentation-the 'Stokes diameter'), or which has the same projected area

(microscopy). Indeed, the definition of particle diameter may be so specific to a

method of size analysis that it has little meaning when applied to a single

particle; for example, Feret's diameter, used in microscopy, is the distance

between parallel tangents on opposite sides of the particle. Many other

'equivalent diameters' may be defined and further examples are listed in [2].

The ratio of any pair of the listed 'diameters' (often known as a 'shape

factor') is found to be fairly constant over quite wide size ranges for any one

material which has been produced in the same way or derived from the same

source. Thus it is possible, for instance, to correlate analyses in which the

coarser fraction of a material has been subjected to a sieve analysis and the

sub-sieve fraction has been sized in some other way. Typical values of these

ratios, quoted in [5], are given in Table 1.3, but it should be emphasized that

caution is required in the use of these figures, especially where the particles of

the material are of extreme shapes.

In an industrial situation it is probable that bulk solids comprising a large

number of particles of non-uniform size would be encountered. In order to

describe such materials completely, it is necessary to determine the particle size

distribution. This information may be presented in tabular form, but it is

generally more convenient to present it graphically as a histogram or as a

fractional percentage plot.

Table 1.3 Particle diameter conversion factors [5, Parts 3, 4]

To convert

Multiply by

Sieve diameter to projected area diameter

Sieve diameter to Stokes diameter

Projected area diameter to sieve diameter

Projected area diameter to Stokes diameter

Stokes diameter to sieve diameter

Stokes diameter to projected area diameter

1.40

0.94

0.71

0.67

1.07

1.50

13

THE NATURE OF BULK SOLIDS

(f)

(f)

"'u-<=

c

Ql

g

"0

"ji:

~

c~ 0"'

Q;

Q.

particle size

100

Ql

Ol

"'c

~ .....

80

··~

I\

·- .

Ql

u

Q;

Q.

60

(f)

(f)

"'

E

~~~-

~~

~r--·

20

E

::J

u

'

-~ ~

1/

>

::J

'undersize

0

V

V

I

I

I

--

-~-~

40

Ql

ro

/

I\

~

·-1~

oversize

/

I

' .......

~mern

particle size

---~

Figure 1.8 Graphical methods of presenting particle size distribution.

(Top) Relative percentage frequency distribution by mass.

(Bottom) Plots of cumulative percentage under- and over-size.

Once the size distribution has been measured (for example, using one of the

methods described in the next section), it is relatively simple to develop a

suitable histogram by constructing rectangles over each class interval, the

widths of which would usually be chosen in geometric progression. The area

under each rectangle is proportional to the percentage of particles in that class

so that a smooth curve through the histogram would yield a frequency

distribution (Figure 1.8). An alternative, and often more useful approach is to

present the data as a cumulative graph in which particle size is plotted along

the horizontal axis and the ordinate represents cumulative percentage

undersize or oversize (Figure 1.8). The principal advantage of this latter type of

graph is that values not determined experimentally are reliably predicted.

14

BULK SOLIDS HANDLING

surface - mean

diameter

volume - surface

mean diameter

......

0

........

0

\

I

r

same volume

same

surface area

-0

volume - mean

diameter

same volume

~~

/_

/

~

CJO

=oonoooooooo~aOO O

average surface area

for the mixture

average volume

for the mixture

Figure 1.9 Three examples of definitions of 'mean particle size' for a mixture of non-uniform

non-spherical particles.

Also, the 'median size' (that is, the 50% size, or mid-point of the distribution)

can be read off directly.

The mass median mentioned above is probably the most commonly used

method of indicating the 'average size' of particles constituting a bulk solid,

since for the majority of materials it is the easiest to determine. However, it

may happen that the median is not the most appropriate parameter and a

number of alternative definitions of average particle size could be used. The

one chosen would normally be dictated by its relevance to the situation

concerned. Three examples will be considered; definitions are illustrated in

Figure 1.9.

(i) Surface mean diameter is defined as the diameter of a particle having a

surface area equal to the average for all the particles in the mixture. This

parameter is clearly relevant to processes in which the surface area of the bulk

solid is a critical factor. The average surface area of a number of particles can

be expressed as

1

2

Asm = N "L(nds)

(1. 7)

where d. is the diameter of a sphere having the same surface area as the

corresponding particle. Thus the diameter of this particle of average surface

area (the 'surface mean diameter') is given by

A

dsm = ( ~

1t

)112 = (-"Ld

1

)112

N

2

s

(1.8)

(ii) Volume-mean diameter is defined as the diameter of a particle having the

THE NATURE OF BULK SOLIDS

15

average volume for the mixture. By similar argument to the above, the

'volume-mean diameter' is given by

6V

dvm = ( ____lllll

1!

)1/3 = (-1 "Ld 3)1/3

N

v

(1.9)

where dv is the diameter of a sphere having the same volume as the

corresponding particle.

(iii) Volume-surface mean diameter is defined as the diameter of a particle

having a ratio of volume to surface equal to the average for the mixture (that is,

the diameter of a sphere having the same volume as the particle of average

surface area for the mixture). Although the definition is somewhat unwieldy,

this parameter tends to be biased towards the lower end of the size range and

therefore offers a useful advantage over the more commonly used median size

in situations where the finer fraction of particles has disproportionate

influence on the behaviour of the bulk solid (e.g. fluidization, gravity flow from

hoppers and in chutes, etc.). From the above definition it can be seen that the

volume-surface mean diameter is given by

dvsm =

"Ld3

"Ld:

d:m

d;m

(1.10)

A very convenient approximation that allows the volume-surface mean

diameter to be determined easily from a sieve analysis on a bulk solid is

dv•m

~

(

r.

:.r

1

(1.11)

where x is the mass fraction of particles passing through sieve aperture of size

d•.

1.5.2 Measurement of particle size

There are many methods of determining the particle size distribution of bulk

solids. British Standards exist for a number of these [5], [6] and the underlying

principles of a wide variety of sizing methods are discussed in depth in [2]. A

summary of the approximate range of application of the more familiar

techniques and equipment is given in Table 1.4.

Sieve analysis. The most popular (and cheapest) method of particle size

analysis, especially with relatively coarse materials, is sieving. A test sieve

generally consists of a woven wire screen (with square apertures) rigidly

mounted in a shallow frame (Figure l.lOa), but for coarse materials the sieve

screen is more usually a perforated plate with either round or square holes.

Traditionally the sieve size is specified by the number of apertures per unit

length (the 'mesh'), but current practice is to quote the actual dimension of the

16

BULK SOLIDS HANDLING

Table 1.4 Some familiar methods of size analysis and their approximate

range of application

Approximate useful range

Method

Sieving:

dry

wet

Electrical sensing zone

(Coulter counter)

Laser diffraction

spectrometry

Sedimentation and

elutriation

Optical microscopy

Electron microscopy

50 Jlm-100 mm

10 jlm-100 mm

I Jlm-800 Jlm

2 Jlm-75 Jlm

I Jlm-150 Jlm

O.QI Jlm-1 Jlm

aperture in J.lm (Table 1.5). The sieve sizes used in an analysis should be

selected to conform to a

series, or for more accurate work, a ~ series.

A wide variety of types of sieve is available commercially. Apart from the

standard woven mesh sieves and the perforated plate sieves for coarser

materials, a range of electro-formed sieves is manufactured for the size analysis

of very fine products (less than about 45 J.lm). Specially designed sieves have

been produced for specific applications, such as the measurement of flakiness

index [7] and grain size of cereals (Figure 1.1 Ob).

The lower size limit for material on a wire mesh sieve is around 50 J.lm,

although with special techniques sieving down to about 10 J.lm is possible. The

recommended mass of sample to be used on standard 200 mm (8-inch)

diameter sieves is 50 g for materials of particle density between 1200 and

3000 kg/m 3 , and 100 g for materials of density greater than 3000 kg/m 3 .

The test procedure involves introducing the sample to the top of a stack,

typically consisting of up to eight sieves which are graduated from the coarsest

at the top to the finest at the bottom. The stack is then shaken or vibrated

(manually or mechanically) for a set period of time in order to distribute the

material through the sieves. Finally, the mass of material retained on each

sieve is determined by careful weighing. A detailed procedure for manual

sieving is set out in a British Standard [6], but it is now far more usual to make

use of automatic sieve shakers (Figure 1.1 Oc). For materials that are cohesive

or susceptible to electrostatic charging, or that prove for any other reason to

be difficult to distribute through the sieve stack, 'wet sieving' is possible. In this

system water or other liquid is introduced via a spray header into the top sieve,

and washes the product downwards before being extracted from a drain in the

pan at the bottom of the stack.

The overall size range of the sample can be specified by stating two sieve

sizes; one through which the whole sample passed and the other on which the

whole sample would be retained. Information could also be quoted on the

proportion of the sample between any two sieve sizes, or the full size

J2

THE NATURE OF BULK SOLIDS

17

b

Figure 1.10 Bulk solids characterization by sieving. (a) A selection of standard woven mesh

sieves. (b) Grain sieves for agricultural use. (Sieves for flakiness measurement are similar). (c) A

variable-speed electromagnetic sieve shaker in use. (Photos by courtesy of Endecotts Ltd.)

distribution could be plotted as illustrated in Figure 1.8. Further guidance on

sieve analysis techniques may be found in [1], (2], [6] and [8].

Sedimentation and e/utriation. Various methods of size analysis have been

developed which rely on observation of the sedimentation rate of a suspension

of particulate material in a suitable liquid. Elutriation methods are somewhat

18

BULK SOLIDS HANDLING

Table 1.5 Relationship between standard sieve numbers and Jlm

Size of

sperture

(Jlm)

44

45

53

60

62

63

74

75

88

90

100

105

120

125

140

149

150

170

177

180

200

210

250

297

300

350

355

360

385

BS Fine Mesh

(BS 410;

Table I)

350

300

240

200

170

US Bureau

of Standards

270

200

120

60

52

44

200

170

120

72

(DIN 4188)

100

230

140

85

German

Standard

325

150

100

American Society

for Testing of

Materials

100

80

80

70

60

50

100

80

40

30

70

60

50

24

20

45

40

16

similar but are based on the measurement of the proportion of the product

which is carried off by an upward flow of gas (usually air) in a vertical column

at a known velocity. For small particles having the same density, the rate of

settling is approximately proportional to the square of the particle diameter,

and consequently the concentration at a fixed depth in a sedimenting

suspension will vary with time in a manner that depends upon the size

distribution of the particulate material (Figure 1.11). For a discussion relevant

to sedimentation analysis of the theory of particles settling in a gravitational

field, the reader is referred to Chapter 3.

One of the most convenient and reliable commercially available instruments using this principle of size measurement is the photosedimentometer.

For this instrument a suspension of the material to be sized is prepared in a

suitable liquid dispersant. This suspension, contained in a tall tank of opticalquality glass, is placed into the photosedimentometer and a narrow beam of

light of pre-set intensity passed through it on to a photocell. The attenuation of

19

THE NATURE OF BULK SOLIDS

Table 1.5 (Contd.)

Size of

sperture

(Jlm)

420

430

490

500

540

590

600

700

710

750

835

840

850

1000

1005

1020

1190

1200

1400

1405

1500

1680

2000

2380

2400

2800

2820

3350

3355

4760

BS Fine Mesh

(BS 410;

Table I)

36

US Bureau

of Standards

American Society

for Testing of

Materials

German

Standard

(DIN 4188)

40

14

12

30

35

11

30

25

10

25

22

8

20

20

18

16

18

6

16

14

12

5

14

4

10

8

12

10

10

8

7

6

7

5

6

4

this beam of light is continuously recorded and will initially indicate a high

concentration for the homogeneous suspension. The intensity of the light

falling on the photocell will begin to increase from the moment that the largest

particles, falling from the free surface, pass through the beam, and will tend

towards a maximum as the finest particles reach the level of the light beam. The

variation of the photocell output with time thus allows the size distribution to

be determined, provided that the particle density and the viscosity and density

of the liquid dispersant are known.

A refinement of this instrument is a scanning device which speeds up the

analysis by allowing the light beam to scan the suspension vertically at a rate of

10 mm/min. The wide-angle scanning photosedimentometer (WASP), which

gives a readout in the form of a pen-recorder trace showing the variation of the

optical density of the suspension with time, is illustrated in Figure 1.12.

Sedimentation techniques generally are appropriate for bulk solids that are

too fine to be analysed by sieving but not so fine that they take an inordinately

20

BULK SOLIDS HANDLING

-1

H

. •. ··:· .·:

. ·.·.:·.· .·

.. · .....

--Xl· ;_;:.:;;: :,

(c)

Figure 1.11

sensitivity controls

•

•

•

0

•

::

••

0

•••

:

-x-

Concentration at

XX begins to

decrease: largest

particles have

settled distance

H in time since

sedimentation

started.

Sedimenting

suspension:

largest particles

settling at fastest

rate.

Concentration at

XX still

unchanged.

Homogeneous

suspension.

Sedimentation

begins.

\1$~,~~

::: ~- ....... :

-X

(d)

Concentration at

level XX continuing

to decrease. Time

period since start

allows determination

of smallest particle

size to fall to XX

from the free

surface.

Differential sedimentation of a polydisperse material.

-"'--m~-~-----i~~o

~-----=--~--

~f----

pen recorder

-

stirring rod --------1f----.l4.1L-~

sedimentation tank --;--..oo 11

zero adjustment

~

Lk~W===~JI~Hl:i~lt:~-::::ilfrUI~

F--r---photocell

i t - - - l(.iil

photocell ----------"1-----11 1 \

_1

-i:i

1....___ _ _ _ _ _

time clock

1

I

1

I

I

1

:: 0'

' :~+--\l,----------......------11

J.l -: / :-

;=~1\

:

1

I II

11

\light source

'

I

~~:

lr----1

scanning motor

'

I I

Ill

---H+-- 1: :

l,-<~

lA .-,

~ I

1

n

""

'

I

1

I

I

I

I

1

I

IL---:;tw-=------111

11

\bench

neutral density filters

(for setting sensitivity)

r------

manual scan/return

L.J-+------+

L---~,---j

Figure 1.12 The wide-angle scanning photosedimentometer ('WASP').

21

THE NATURE OF BULK SOLIDS

Table 1.6 Approximate upper size limits for particles in sedimentation analysis

Critical diameter (Jlm)

Material

Sand (pP = 2700 kg/m 3)

PVC (pp= 1400kg/m 3)

Settling in

air

Settling in

water

Settling in

ethylene glycol

31.6

39.4

60

97.2

560

1000

long time to settle under gravity in the selected dispersant. The exact size range

that can be determined by photosedimentation depends principally upon the

dispersant used and the density of the particles but, as an example, for sand

settling in water, measurement over the range 2-60 .urn should be possible. The

upper end of this range could be extended considerably if a more viscous

dispersant such as ethylene glycol were to be used (Table 1.6).

Optical microscopy. As a technique for size analysis of particulate solids,

optical microscopy has become well established for particles ranging in size

from about 0.8 .urn up to 150 .urn. It has the advantage of allowing examination

and measurement of individual particles of the material in question, and the

method can often be used where other techniques fail.

Disadvantages may be summarized as:

(i) Difficulty of obtaining a very small representative sample for study

(ii) Small depth of focus

(iii) Time-consuming procedure for counting particles.

The basic procedure for size analysis uses a microscope fitted with a

micrometer stage, and an eyepiece in which a glass disc engraved with a

suitable scale is positioned against the field stop. This ocular scale is calibrated

against a linear scale engraved on a microscope slide by bringing the two

images into sharp coincidence, and the engraved slide is then replaced by a

slide carrying the prepared powder sample. The sample is scanned in strips,

each particle being sized and counted as its image passes over the scale.

A linear scale in the eyepiece gives Feret's diameters of the particles

examined, but a number of alternative forms of graticule have been developed

which enable the particle images to be compared with engraved circles, thus

giving projected area diameters. One of these, shown with its relative

dimensions in Figure 1.13, has been adopted as the British Standard graticule

([5], Part 4).

The full procedure to be followed when carrying out a size analysis can be

found in various publications, for example, [5] Part 4; [9], but a summary is

given below.

(i) With the graticule in place in the microscope eyepiece, adjust the

B

22

BULK SOLIDS HANDLING

Relative dimensions of British Standard Graticule

Numerical value

(units)

~

0 os 0

7

1

T

~

Grid length

Grid breadth

Distance between

calibration marks

Diameter of circle I

2

5

0 4 o3 o2

grid length (mm)

o'

3

4

5

6

7

Figure 1.13

(ii)

(iii)

(iv)

(v)

64

45.3

60.4

1.00

1.41

2.00

2.83

4.00

5.66

8.00

British Standard graticule (BS 3625: 1963) (Ref. 2, Part 4).

magnification so that the diameters of the reference circles correspond to

the size range of the particles to be examined

Select a suitable regular pattern of sample fields in order to cover the

whole sample of powder on the slide (this step is simplified by using a

suitably engraved slide or counting cell)

Adjust the micrometer stage to position the graticule in the centre of the

first sample field

For particles within the graticule area (and on the boundary lines on two

adjacent sides) count the number within each size class by visual

comparison with the graticule circles

Repeat the counting of particles in this way with the graticule positioned

at the centre of each field area in turn until the whole sample of powder on

the slide has been scanned.

The Coulter counter. The Coulter counter, the best known commercially

available instrument for size analysis of particulate materials by the electrical

sensing zone technique, was originally developed by W.H. Coulter for

counting blood cells. A recent British Standard ([5], Part 5) describes the

method in detail and gives useful information on suitable electrolytes.

The Coulter technique enables the number and size of particles suspended in

an electrically conductive liquid to be determined by making the suspension

flow through a small orifice on either side of which is immersed an electrode.

As any particle passes through the orifice it increases the resistance between

the electrodes momentarily and thus generates a voltage pulse, the magnitude

of which is a function of the volume of the particle. These pulses are

electronically scaled and counted and from the resulting data the size

distribution of the suspended particulate material can be determined. For

23

THE NATURE OF BULK SOLIDS

particles of diameter within the range 2-40% of the orifice diameter it is found

that the magnitude of the voltage pulse is directly proportional to the particle

volume and it is on this principle that the reliability of the Coulter counter

depends.

A range of orifice sizes is available, so that the Coulter counter is well suited

to the measurement of particle sizes in the sub-sieve range (less than 75 ,urn)

down to about 1 ,urn. With special techniques this range can be extended up to

800 ,urn and down to 0.6 ,urn or even less. Almost any kind of material may be

analysed using the Coulter technique (except for some organic compounds

that are too soluble in any electrolyte), although the use of dispersants is often

required.

Figure 1.14 shows diagrammatically the basic components of a Coulter

counter. In operation the stopcock A is opened so that the action of the

vacuum pump causes the electrolyte to flow from the beaker through the

orifice and also draws mercury up into the siphon. The stopcock is then closed,

but the effect of the mercury siphon restoring its balance causes the flow of

electrolyte through the orifice to continue. Electrical contact of the advancing

mercury column with probes mounted in the glass tubing causes counting of

the voltage pulses to begin automatically and to stop after a pre-determined

volume of electrolyte (typically 0.5 ml) has passed through the orifice.

The voltage pulses are amplified and fed to a threshold circuit having an

Orifice

to vacuum pump

+

Voltage pulse generated

as particle passes

through IS directly

proportional to the

volume ol the part1cle

for particles having

diameters in the

range 2-40% of

the orifice diameter

counter 'start'

counter 'stop'

Figure 1.14 Diagrammatic representation of a basic Coulter counter.

24

BULK SOLIDS HANDLING

adjustable threshold level. If this level is reached or exceeded by a pulse, the

pulse is counted. By taking a series of counts at selected threshold levels, data

are directly obtained for plotting cumulative frequency (larger than stated size)

against particle size.

Laser diffraction spectrometry. During the early 1970s methods were described

for determining the size distribution of a sample of fine particulate material by

measuring the diffraction that occurs as a beam of light passes through a

suspension of the sample. Since that time the technique has been improved to

the point where the laser diffraction spectrometer (LDS) is commercially

available from several manufacturers in a form that allows a reliable size

analysis to be made by a semi-skilled operative in just a few minutes. Although

very costly, these instruments offer significant advantages in that special

electrolytes are not required and calibration is unnecessary. However, there

have been doubts expressed about discrepancies between analyses carried out

on the LDS and results from other size-measurement techniques.

The principle of laser diffraction spectroscopy is quite complex and only a

simplified explanation can be given here. The angle of diffraction of a beam of

light passing through a suspension of particles depends essentially upon the

wavelength of the light and the size of the particles. Thus a beam of

monochromatic light (from a laser source) passing through a suspension of

monosized particles would be diffracted through a specific angle (Figure 1.15a)

which is not dependent on the position or movement of the particles. If this

light then passes through a lens it will be drawn to a focus in the form of an

annular ring on the focal plane (Figure 1.15b ). For a mixture of particles the

0

(a) Laser light diffracted by

uniform-sized particles

focal plane

laser light _ . ,_ _i-"-2'

~

so' lid

particles

(b) Light patterns formed at

focal plane of lens

Figure I. IS

The principle of laser diffraction spectrometry.

25

THE NATURE OF BULK SOLIDS

measuring cell

laser

suspension (ultrasonically

and/or mechanically

stirred)

-

photodetector