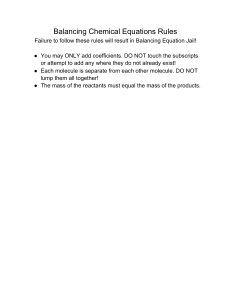

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2163 Issue 12, Volume 4 (December 2017) www.ijirae.com PRODUCTIVITY IMPROVEMENT IN STITCHING SECTION OF A GARMENT MANUFACTURING COMPANY Anand Jayakumar A* Department of Mechanical Engineering, SVS College of Engineering, Coimbatore, India jay4upeople@gmail.com Krishnaraj C Department of Mechanical Engineering, Karpagam College of Engineering, Coimbatore, India krishna.kce@gmail.com Aravinth Kumar A Department of Mechanical Engineering, KGiSL Institute of Technology, Coimbatore, India aravinthkumar004@gmail.com Manuscript History Number: IJIRAE/RS/Vol.04/Issue12/DCAE10082 DOI: 10.26562/IJIRAE.2017.DCAE10082 Received: 16, November 2017 Final Correction: 09, December 2017 Final Accepted: 17, December 2017 Published: December 2017 Citation: Anand Jayakumar, Krishnaraj, Aravinth Kumar (2017). PRODUCTIVITY IMPROVEMENT IN STITCHING SECTION OF A GARMENT MANUFACTURING COMPANY. International Journal of Innovative Research in Advanced Engineering, Volume IV, 08-11. doi: 10.26562/IJIRAE.2017.DCAE10082 Editor: Dr.A.Arul L.S, Chief Editor, IJIRAE, AM Publications, India Copyright: ©2017 This is an open access article distributed under the terms of the Creative Commons Attribution License, Which Permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited Abstract— In this study one heuristic assembly line balancing technique known as the “Ranked Positional weight Technique”, developed by Helgeson and Birnie was applied to solve the problem of assembly line balancing in a garment manufacturing company for one model. Information about solution methods related to assembly line balancing problems is given. Operator reduction is achieved by line balancing. Layout was modified using the template method. The aim of this article is the usage of these techniques to improve the productivity in a clothing company. Keywords— Assembly line balancing; garment manufacturing industry; layout modification; ranked positional weight technique; operator reduction; I. INTRODUCTION Over the past 170 years, apparel structures has changed from the custom fitting and assembly of individual hand sewn garments to mechanised, automated and sometimes robotised mass production and distribution of ready to wear products in the world market. Apparel manufacturing comprises a variety of product categories, materials and styling and such complexities of manipulating flexible materials and styling and such complexities of manipulating flexible materials and process. Therefore good balancing and small stocks of work in process during sewing are the basic concepts to increase the efficiency of production. An assembly line is described as a set of distinct tasks that is assigned to a set of workstations connected by a transport mechanism in detailed assembling sequences. _________________________________________________________________________________________________ IJIRAE: Impact Factor Value – SJIF: Innospace, Morocco (2016): 3.916 | PIF: 2.469 | Jour Info: 4.085 | ISRAJIF (2016): 3.715 | Indexcopernicus: (ICV 2016): 64.35 IJIRAE © 2014- 17, All Rights Reserved Page –8 International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2163 Issue 12, Volume 4 (December 2017) www.ijirae.com In garment sewing, the components are assembled through a sub assembly process in order to form the finished product. Therefore the production process includes a set of workstations, at each of which a specific task is carried out in a restricted sequences with hundreds of employees and thousands of bundles of sub assemblies producing different styles simultaneously. Generally apparel manufacturers are focussed on whether assembly work will be finished on time for delivery, finding ways to have more efficiency, how machines and employees are being utilized and how labour intensity can be minimised whether any station in the assembly line is lagging behind the schedule and how the assembly line is doing overall. Therefore in order to focus on this kind of labour intensive structure a pant sewing line was chosen for this study. The production line is analysed by considering the innovative use of industrial engineering concepts, time study and assembly line balancing. Firstly real data taken from the factory floor using time studies and precedence constraints are taken into consideration to model the allocation of operations. The project was carried out at a garment factory in Chennai. Q2D122 model of pant produced in Line A is taken for the study. In this study, one heuristic assembly line balancing technique known as “Ranked Positional Weight Technique” developed by Helgeson and Birnie was applied to solve the problem of assembly line balancing in a clothing company for one model. The aim of this article is to solve the problem of assembly line balancing in a clothing company. The layout of line A was modified using the template method. II. LITERATURE REVIEW The assembly line balancing problem has received considerable attention in the literature and many studies have been made on this subject since 1954. COMSOAL (Computer Method of Sequencing Operations for Assembly lines) was first used by Arcus [6] in 1966 as a solution approach to the assembly line balancing problem. Helgeson and Birnie [7] developed the “Ranked Positional Weight Technique”. In this method the ranked positional weight value is determined. It is the sum of a specified operation time and working times of the other operations that cannot be assembled without considering the operation finished. While taking into consideration the cycle time and technological precedence matrix, the operation having the largest ranged weight is assigned to the first workstation and other operations are assigned to workstations in accordance with their ranked positional weight value.For the multi-model assembly line, Kilbridge and Wester[8] developed a simple method to solve line balancing. In the first stage they formed an appointment table and then they made necessary workload balance among workstations time taking into consideration precedence relationships and cycle times. III. METHODOLOGY In this study the production of Q2D122 model was investigated to improve productivity. By using the “Ranked Positional Weight Technique” the assembly line balancing problem was solved. The layout was modified using the template method. This Heuristic method was developed by Helgeson and Birnie of the General Electric Company in 1961. In this method, the ranked positional weight value of each operation is determined. The procedures below are applied in order to assign operations to workstations. The ranked weight value of an operation is obtained by summing the operation time considered with the time of other operations that come after that in series. After all of the ranked positional weights of the operations are determined, they are arranged in decreasing order. Then tasks are assigned to each workstation starting from the task with the highest ranked positional weight. Before this the operation having the second highest ranked value should be selected from the remaining working operations in order to assign to the workstation the precedence constraints the operation time the unused workstation time should be controlled. The assignment procedure is continued until any one condition below is obtained. 1. If all the operations are assigned to the stations. 2. If there are no operations having either precedence or unassigned time constraints. This model has 75 operations and an operation list. Its standard times, precedence relations and machine types are listed below. After the determination of the precedence relationships between operations a technological precedence diagram was shown in figure. Then the cycle time is calculated as shown below. C = T/PA. C = Cycle time. T = Total working time in a day. PA = Total production amount in a day. C = T/PA = 57600/1120 = 51.42 seconds / piece Then ranked positional weights of operations are calculated by using the method explained above and listed in a descending order as shown in figure. As a result of balancing, it is found that n = 100 workstations are needed to balance the line. Balancing results of the ranked positional weight technique as given in table. Balancing loss is calculated BL = (nxC - ∑ti ) / ( n x C) x 100% = (100 x 51.42 – 3674.79) / (100 x 51.42) x 100% = 28.53% For this assembly line efficiency values are calculated. LE = [N∑i=1 ti /(nxC)] x 100% = 75.43% _________________________________________________________________________________________________ IJIRAE: Impact Factor Value – SJIF: Innospace, Morocco (2016): 3.916 | PIF: 2.469 | Jour Info: 4.085 | ISRAJIF (2016): 3.715 | Indexcopernicus: (ICV 2016): 64.35 IJIRAE © 2014- 17, All Rights Reserved Page –9 International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2163 Issue 12, Volume 4 (December 2017) www.ijirae.com TABLE I - SAMPLE DATA Work Work Ranked Precedence Operation Name Total Machine Type Station Task Positional Relations Cycle Number Number Weight Time Value 1 1 142 0 Make fly box at bottom 20 SNUBT 2 2 123 1 Turn fly box 19 Helper table 3 3 93 2 Press fly box 30 Ironing table 4 4 69 3 Top stitch fly box 24 SNUBT 5 5 30 4 Serge fly and fly box 39 3TO/L 6 6 18 5 Tack fly box overlap threads 12 SNUBT 7 7 0 6 Inspection 18 Inspection Table Section Fly Section Fly Section Fly Section Fly Section Fly Section Fly Section Fly Section Fig. 1 Layout before modification Fig. 2 Layout after modification _________________________________________________________________________________________________ IJIRAE: Impact Factor Value – SJIF: Innospace, Morocco (2016): 3.916 | PIF: 2.469 | Jour Info: 4.085 | ISRAJIF (2016): 3.715 | Indexcopernicus: (ICV 2016): 64.35 IJIRAE © 2014- 17, All Rights Reserved Page –10 International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2163 Issue 12, Volume 4 (December 2017) www.ijirae.com IV. CONCLUSIONS The Ranked Positional Weight Technique is easier to apply and has higher line efficiencies. For this reason, when work elements are assigned to workstations, standard deviation values of standard times are taken into consideration. This situation enables work elements to be assigned to workstations more sensitively and thus more reliable assembly line balancing results are obtained. As a result of operator reduction, line efficiency was improved by 7.11%. By modification of layout travel distance was reduced by 13m and work in process between two sections was reduced. REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. Eryuruk S. H, Kalaoglu F, Baskak M, “Assembly Line Balancing in a Clothing Company”, Fibers and Textiles in Eastern Europe, Vol 16, No 1(66) pp 93-98. Rezul Hasan Shumon Md, Kazi Arif-Uz-Zaman and Azizur Rahman, “Productivity Improvement through Line Balancing in Apparel Industries”, Proceedings of the 2010 International Conference on Industrial Engineering and Operations Management Dhaka, Bangladesh, January 9 – 10, 2010. Mucella G Guner, Can Unal, “Line Balancing in the Apparel Industry Using Simulation Techniques”, Fibers and Textiles in Eastern Europe, Vol 16, No 2(67), pp 68-71. Fatma Kalaoglu, Canan Saricam, “Analysis of Modular Manufacturing System in Clothing Industry by Using Simulation”, Fibers and Textiles in Eastern Europe, Vol 15, No. 3(62), pp 93-96. Senem Kursun, Fatma Kalaoglu, “Simulation of Production Line Balancing in Apparel Manufacturing”, Fibers and Textiles in Eastern Europe Vol 17, No 4(77) pp 68- 71. Arcus A.L, “COMSOAL: A Computer Method of Sequencing for Assembly Lines”, International Journal of Production Research, 4(4) pp. 259-277, 1966. Helgeson W.P, Birnie D.P, “Assembly Line Balancing Using the Ranked Positional Weight Technique”, Journal of Industrial Engineering, Vol. 12(6), pp384-398, 1961. Kilbridge M.D, Wester L ,”A Heuristic Method for Assembly Line Balancing”, Journal of Industrial Engineering, Vol. 12(4), pp292-298, 1961. El-Sayed E. A, Boucher T.O, “Analysis and Control of Production Systems”, Prentice Hall, New Jersy, 1985. Hadi Gokcen, Kursad Agpak, Recep Benzer “Balancing of parallel assembly lines”, International Journal of Production Economics, pp 600-609. _________________________________________________________________________________________________ IJIRAE: Impact Factor Value – SJIF: Innospace, Morocco (2016): 3.916 | PIF: 2.469 | Jour Info: 4.085 | ISRAJIF (2016): 3.715 | Indexcopernicus: (ICV 2016): 64.35 IJIRAE © 2014- 17, All Rights Reserved Page –11