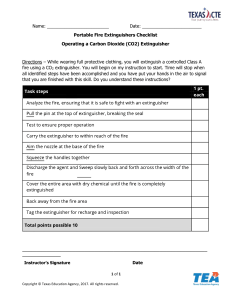

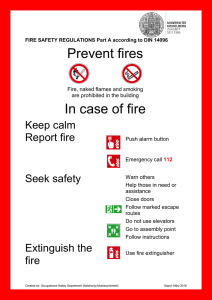

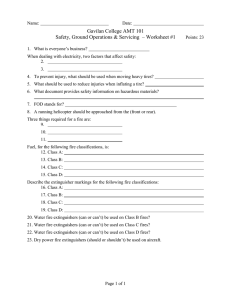

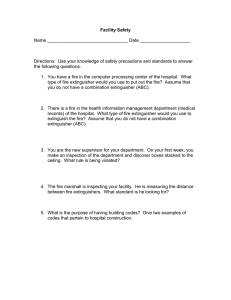

CSEC TECHNICAL DRAWING OCCUPATIONAL HEALTH, SAFETY AND THE ENVIRONMENT ASSIGNMENT # 1 GROUP PROJECT NAMES: Jada Melville Alecia Chan Aryanna Mohamed TOPICS: FIRST AID FIRES & FIREFIGHTING EQUIPMENT USING A FIRE EXTINGUISHER SAFETY HEALTH AND WELFARE STANDARDS 1 Contents USING A FIRE EXTINGUISHER ............................................................................................. 3 Guidelines ...................................................................................................................................... 3 Procedures for different types and range of fires ...................................................................... 4 Preparation/maintenance of an extinguisher ............................................................................. 5 Storage of fire extinguishers ........................................................................................................ 6 Additional methods of extinguishing fires .................................................................................. 6 SAFETY HEALTH AND WELFARE STANDARDS .............................................................. 7 Occupational Health and safety................................................................................................... 7 Local regulation for OSHA .......................................................................................................... 7 Standards for Workshops/laboratories, Equipment, Material and Workers ......................... 8 Guidelines for Working safely Preventing injury and accident Ensuring wellness ............... 8 2 USING A FIRE EXTINGUISHER Guidelines 1. 2. 3. 4. 5. 6. 7. 8. Make sure the fire does not involve electrics and is not near live electrical equipment unless using a water mist (deionized water) fire extinguisher and the voltage is less than 1,000 volts. If the fire is small and you are fully trained to extinguish a fire, stand at least 3 meters away with the appropriate extinguisher in hand. Break the tamperproof seal and pull the pin. Hold the operating lever in one hand and with the other, remove the discharge hose nozzle from its storage point. Hold the discharge hose 5cm from the nozzle. While holding the fire extinguisher, ensure it remains in the upright position. Face the fire extinguisher away from the fire, and gently squeeze the handle for a short sharp burst – this is to ensure it works. Aim the nozzle at the base of the fire (or back of the fire), gently squeeze the lever and then in a slow sweeping motion begin to sweep the nozzle from side to side across the fire. With the nozzle of the extinguisher aimed at the base of the fire, discharge the extinguisher fully to ensure the fire has been extinguished 3 Procedures for different types and range of fires There are 5 different classes of fire, depending on the type of "fuel" that is on fire. o o o o o Class A (Solids) Class B (Liquids) Class C (Gases) Class D (Metals) Class K (Cooking Fats & Oils) i. Class A Fires – Extinguish with Water Extinguish a Class A fire with water or mono ammonium phosphate. Stream a continuous supply of water from the hose to put out the fire. Do not enter the dumpster, as the contents within are unknown. Combustible and hazardous materials may explode at any given time. If you detect or suspect the presence of hazardous materials within the trash, contact your local environmental specialist right away. Water can be sprayed onto the burning fuel to cool it. By spraying a large volume of water onto the fuel, heat will be conducted away from the flame, reducing its temperature and thereby preventing combustion. ii. Class B Fires – Extinguish by Depleting Oxygen When a Class B fire sparks, extinguish it by smothering the flames. Oppressing the fire eliminates the oxygen feeding the flames, and, thereby, deadens the fire. Dry chemicals, like ammonium phosphate or pressurized carbon dioxide are effective means to extinguish a Class B fire. Never attempt to extinguish a Class B fire with water. Splashing water on a fire fueled by flammable liquids only splatters and spreads the flames, increasing the fire’s latitude. A better way to combust and extinguish a Class B fire is by removing oxygen from the environment, thus 4 suffocating it. Preventing fresh air from reaching the seat of the fire is one method used to extinguish a fire. By shutting off fresh air and allowing the combustion to reduce the oxygen content in the confined atmosphere until it extinguishes itself, or by reducing oxygen flow over time until the fire extinguishes itself. iii. Class C Fires – Extinguish by Cutting Power Extinguish a Class C fire by shutting off the electrical power, which serves as the fuel source for the electrical fire. Non-conductive chemicals like carbon dioxide should also be used to suppress the flames. Fire extinguishers are typically not the first line of defense against a fire. Fire extinguishers should be used to control fires only when other means of control, such as firefighting foam, have been tried and failed. In some cases, a fire can be extinguished simply by removing the fuel source. Firefighters may do this by stopping the flow of liquid or gaseous fuel; removing solid fuel in the path of the fire; or allowing it to burn until all of the fuel is consumed. iv. Class K Fires – Extinguish with Chemical Fire Extinguishers Chemical fire extinguishers are the only recommended way to extinguish a chemical fire. Fire extinguishers contain chemical agents that absorb the flames’ heat, cut oxygen to the fire, and effectively smother the fire. Homes and restaurants should be equipped with fire extinguishers; and, all those working in the kitchen should learn how to use the fire extinguisher. There are several different types of chemical fire extinguishers, but they all fall into two main categories: water-based and powder-based. Water-based or UCO 2 fire extinguishers use carbon dioxide instead of water, which is harder to keep in liquid form. CO 2 will also remove oxygen from the area where the fire is burning which is helpful for putting out a fire with oxidizing agents (like flammable gases). Preparation/maintenance of an extinguisher Carrying out a visual inspection. Taking a pressure gauge reading. Removing the discharge hose to check for blockages or corrosion. Weigh and clean the extinguisher. Ensure wall mountings are secure. Check the visibility and location of the fire extinguisher, making sure that they’re in a convenient, easy to reach place that doesn’t obstruct an exit and can be seen clearly. Make sure it is full, this can be done by just lifting the extinguisher or you can weigh it. For wheeled extinguishers, make sure the condition of tires, wheels, carriage, hose, and nozzle are acceptable. Examine the extinguisher for any signs of tampering, ensuring the tamper seal isn’t broken. Make sure the operating instructions are facing outwards and can be easily read. 5 Check the date of the last basic service to check for the next annual maintenance and then record your monthly visual check. Storage of fire extinguishers Fire extinguishers should be stored in the upright position, as this keeps the fire suppressant chemicals at the bottom of the tank where they belong. Fire extinguishers stored in a horizontal position may not function as effectively as those which are stored vertically. The best places to store fire extinguishers are in areas within your building that are highly susceptible to fires. Some examples include the kitchen, laundry rooms, garage spaces, and workshops. Anyone near or within those areas can find the fire extinguishers and put out fires at a moment’s notice, saving you from costly building repairs and expenses. Additional methods of extinguishing fires Cooling One of the most effective approaches in fire extinction is removing the heat. Thus, cooling with water is one of the most popular methods. The heat generated by the fire is absorbed by the water. This remains effective as long as the water can still absorb the heat. However, it is important to know that water should never be used in fires involving electricity, cooking oils/fat, grease and other flammable liquids. Starving Starving the fire from its fuel source is a different approach. When fire runs out of flammable materials, it will eventually burn out itself. For example, a bonfire in the open when it is not in contact with any other wood or dry grass will ultimately lose its blaze. In a gas fire, it will immediately extinguish if the gas supply is cut off. The same method is applied to your gas stove or Bunsen burner. Smothering The third approach involves the last element in the triangle, oxygen. Smothering is a technique where oxygen is removed from the equation. An example of this is using a fire blanket in a frying pan blaze to reduce the oxygen level below 16%. Covering a candle with a glass is also an example. The fire burns out all the oxygen inside the glass creating a vacuum. This approach is commonly applied to solid fuel fires. However, some materials may contain enough oxygen within their own chemical makeup to continue burning. 6 SAFETY HEALTH AND WELFARE STANDARDS Occupational Health and safety Occupational health and safety is the area of public health that focuses on illness and injury trends in the workplace. Experts in the field use this knowledge to develop and implement strategies and regulations aimed at limiting hazards that could lead to physical or mental harm now or in the future. Local regulation for OSHA Employers must provide the appropriate personal protective equipment (PPE) to each employee where necessary. This includes respirators, safety glasses, face shields, earplugs, protective gloves, flame resistant clothing, etc. Failure to provide the appropriate PPEs may place the employer in violation of OSHA standards for each employee. Employers must provide the appropriate safety training to employees either in-house or through third-party means, to adequately prepare them for hazards they may encounter at work. Failure to provide adequate safety training may place employers in violation of OSHA standards for each employee. Employers must ensure that all areas used for work, including production floors, storage rooms, and walking surfaces, are kept clean, orderly, and sanitary. Employers must ensure that all walking-working surfaces are strong enough to support the combined weight of workers, equipment, and machinery situated in the abovementioned area. Employers must ensure that walking-working surfaces are free of hazards including sharp/protruding objects, loose floorboards, chemical leaks, spills, snow, and ice. Employers must ensure that employees have access to safe entry and exit points to and from walking-working areas. Employers must ensure that walking-working surfaces are inspected and maintained regularly and as necessary to preserve safe conditions. Employers must ensure that hazardous walking-working areas are corrected or repaired before employees are allowed access to said areas again. If correction or repair cannot be done immediately, access must be closed-off until necessary corrective measures have been taken. Employers must provide portable fire extinguishers and ensure they are readily accessible to employees. Employers are responsible for the inspection, maintenance, and testing of portable fire extinguishers. 7 Standards for Workshops/laboratories, Equipment, Material and Workers Workshops/laboratories and Workers Employers have responsibilities for the occupational safety of their employees. The Occupational Safety and Health Administration (OSHA) is the U.S. governmental agency that has the mission to assure the safety and health of America's workers. OSHA sets and enforces standards that address potential workplace hazards; provides training, outreach, and education; establishes partnerships; and encourages continual improvement in workplace safety and health. For dentistry, infectious disease and hazardous chemicals are examples of potential workplace hazards of concern; the following sections will address certain OSHA standards specific to dental offices. When there is no standard, OSHA’s “General Duty Clause” may be used to provide regulatory guidance and enforcement for occupational exposures. Equipment and Materials Laboratory Equipment Standards cover the procedures, applicability, settings, data analysis, and other considerations revolving around laboratory equipment. Meta analysis such as comparing different equipment and procedures, quality management is also included. A focus on biological testing covers a range of medical testing and research. Guidelines for Working safely Preventing injury and accident Ensuring wellness 1. Follow the dress code It is important to dress according to the workplace dress code. This may prohibit jewelry or open-toe shoes, for example. Often a workplace may require employees to wear specific footwear and long sleeves and pants in order to protect against common workplace accidents. Dress codes can promote professionalism and also help keep employees safe. 2. Wear safety gear Safety gear is necessary in labs, around machinery and on construction sites, for example. Companies include safety gear in the dress code when it is necessary for your job. Safety gear is a precaution against hazardous materials and potentially dangerous working conditions. 3. Maintain personal hygiene 8 Maintain your personal hygiene, such as cleanliness, to help prevent illness at work. Good hygiene can also help promote health and self-esteem, which reduces risks. 4. Take responsibility for your personal safety To take responsibility for your personal safety means ensuring that you follow safety procedures. If employees rely on themselves to keep the workplace safe, this can create a safe environment for all. Responsibility also prevents negligence, which can limit on-the-job accidents. 5. Maintain a clean workspace It is important to keep your desk or other personal workspaces clean. Be sure to put away supplies when they are not in use. Gathering necessary materials before starting a task can help keep a clean workspace. Maintaining your work area promotes organization and attentiveness, both aspects of promoting safety in the workplace. 6. Follow work procedures A company creates work procedures to help comply with safety protocols and best practices, so if you follow work procedures, safety standards are likely met. It is important to follow procedures even if you think performing a task differently might save time. Often there'll be an employee handbook or safety station where the company provides their work procedures. 7. Learn how to act in an emergency Learn emergency protocols including where to go in case of a fire or during a natural disaster such as a tornado. Much like work procedures, companies design emergency protocols with strong consideration for safety regulations. Knowing where to go or how to behave during an emergency protects you as well as your coworkers. 8. Report accidents if they occur Report accidents to the managers or other personnel when they occur. If you injure yourself or cause an accident, be sure to report it and follow procedure immediately to help reduce the risks of further harm or endangering coworkers. This helps to get proper treatment for your injury and addresses the possible causes of the incident to prevent it from happening again. It is important to follow company policy and report even minor incidents. Your employer may require a written report of the incident as well. 9. Report unsafe conditions If you observe an unsafe practice or condition such as faulty equipment, it is helpful to report this so that personnel can address the situation and make corrections to prevent an incident. Unsafe conditions pose a threat to your coworkers and to you, so reporting a potentially dangerous situation is in the best interest of all employees. Consider marking any unsafe condition to protect others who may encounter it while you go to report it. 9 10. Lift objects carefully Professionals advise lifting by squatting and using your knees when picking items up instead of bending at your waist because this can cause strain on your back and may result in injury. Use equipment if necessary or ask for help in lifting heavy items. Back pain is a common workplace injury that you can avoid with proper posture and using caution in actions that you often repeat at work, such as carrying materials. 11. Operate machinery that you are familiar with Only operate machinery that employers authorize you to use. Some types of workplace equipment, such as forklifts, require training. Training can prevent misuse and provide proper safety knowledge and skill for machines. It is important to become familiar with all equipment that is in regular use at work. 12. Use break times Taking breaks can maximize employee attentiveness because they are well-rested. Breaks provide other benefits, such as time to relax and reduce stress. During breaks, you may need to sit or stretch to maintain personal safety and prevent muscle injury. 13. Stay in your work zone While working, try to stay in your designated work area. This allows you to be familiar with your surroundings and increases the likelihood that you understand the rules of conduct in the area. If you visit another working area, try to find a professional who can help you navigate the area so you are confident in your surroundings. 14. Stay alert and attentive Being alert and attentive to your surroundings in a work environment helps identify risks. It is important to limit distractions as well and ensure you focus on tasks at work. Taking care to be mentally present while working helps you actively follow procedures and practice caution. 15. Keep exits clear Try to keep walkways clear and take care not to block exits. This prevents falls and helps people leave the room or building safely and quickly in the event of an emergency. In small spaces keeping walkways clear can be difficult but it may be useful to practice a walk-through to ensure that employees can maneuver safely around equipment. 16. Ask for help 10 If you require assistance, ask for help. This greatly reduces the risk of having an accident and helps foster a safe work environment by setting an example. Refer to company protocol when performing tasks or operating equipment, and if protocol suggests doing a task with another employee, do not attempt the task alone. 17. Use caution signs Use caution signs when applicable. For example, wet floor signs prevent slips on a floor after you mop or after a spill. Areas at work may require barriers or signs when equipment such as forklifts are in use. Another example is road signs to notify drivers of workers or highway cleanup crews. It is important to place caution signs while working and read and obey caution signs placed by others. 18. Use proper equipment Use the equipment a procedure recommends to help prevent an accident. Companies usually provide equipment to limit strain on employees and to comply with safety regulations. It is also important to learn how to operate any equipment that is available before using it for work. 19. Eat in designated areas Employers sometimes restrict food and drink to specific areas at work to prevent spills, contamination and unsafe conditions. Having liquids around machines risks spills that can cause malfunctions, and eating where you work can cause contamination and possibly result in illness. If your workplace requests employees eat in a certain place or restrict food and drinks in a work environment, it is important to observe this rule. 20. Follow safety guides Follow all safety guides put in place to protect you and your coworkers. Companies design safety rules to prevent incidents. Sometimes rules result from a previous accident which is why it is important to report your injuries as well as unsafe conditions. If you do not understand why a safety rule exists, you can ask your employer for clarification. 11 References https://www.thefpa.co.uk/advice-and-guidance/advice-and-guidance-articles/how-to-use-a-fireextinguisherhttps://www.haspod.com/blog/fire/classes-of-fire https://www.servicemastersanfrancisco.com/types-of-fires-how-to-extinguish www.nfpa.org https://dorsetfireprotection.co.uk/fire-extinguisher-maintenance/ https://fire-extinguisher-guide.com/how-to-store-and-maintain-a-fire-extinguisher/ https://webstore.ansi.org/industry/laboratory-safety https://www.indeed.com/career-advice/career-development/safety-rules-workplace 12