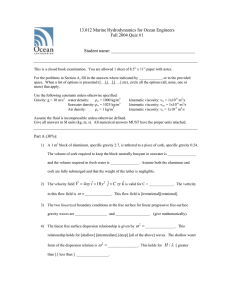

Airlocks Presented by Gordon Farquharson August 2015 Agenda Regulatory expectation Different functional configurations Good design practice What often goes wrong Qualification of airlock performance Slide 2 © PharmOut 2015 Regulatory expectation/guidance Slide 3 © PharmOut 2015 PIC/S Annex 1 guidance Slide 4 © PharmOut 2015 PIC/S Annex 3 guidance PIC/S Annex 5 guidance PIC/S Annex 10 guidance Slide 5 © PharmOut 2015 PIC/S Glossary Slide 6 © PharmOut 2015 WHO HVAC OSD supplementary Guidance Airlocks The Dp values are indicative – they aren’t a requirement Slide 7 © PharmOut 2015 Biosafety Regulations • For the containment of human & animal pathogens. • There are different regulations in each nation, but the principles are all similar. • Facility design impact: – Conflict – Containing Hazards vs Protecting Processes -ve pressure vs +ve pressure Let’s look at the essential features of the biosafety regulations. Slide 8 © PharmOut 2015 Biosafety levels: BL-1 Laboratory Practices Special Practices Containment Equipment Laboratory Facility Access limited Leak-proof container for off-site decontamination None Easily cleaned Daily and after-spill decontamination Pest control Waste decontaminated Screens in windows No mouth pipette Personal Wash Minimise aerosols Uniform Slide 9 Hand wash sink © PharmOut 2015 Biosafety levels: BL-2 Laboratory Practices Special Practices Same as BL-1 Same as BL-1 except Principal investigator limits Can also perform BL-1 if access Policies and procedures for isolated access Hazard warning sign if special procedures Special gowning for laboratory No spare animals in laboratory Avoid skin cross contamination Waste decontamination Limited use of syringes Report spills to NIH Worker blood samples Biosafety manual Slide 10 © PharmOut 2015 Containment Equipment Laboratory Facility Biosafety cabinets (Class I, II) if aerosols or high number of organisms Same as BL-1 Autoclave for waste decontaminatio n Biosafety levels: BL-3 Laboratory Practices Special Practices Containment Equipment Laboratory Facility Same as BL-2 Same as BL-2 and: Same as BL-2 No entry under age 16 Doors closed Lesser organisms in same laboratory must follow BL-3 Hazard sign required Biosafety cabinets (Class I, II, III) or physical containment devices More limits on access No open work Clean-up when finished Gowning decontamination Airlock or gown room access Sink near door has nocontact faucet Closed/sealed windows Self-closing doors Mask/respirator Special animal cages HEPA on vacuum Slide 11 Separated from building flow © PharmOut 2015 Ducted exhaust BSC exhaust outdoors Biosafety levels: BL-4 Laboratroy Practices Special Practices Containment Equipment Laboratory Facility Same as BL-3 Double container for waste Class III BSC Separate building or isolated zone Sealed internal shell, can be decontaminated Flooded floor drain traps connected to waste decontamination HEPA on vents and drains Minimize dust surfaces Seamless bench tops Dedicated central vacuum with HEPA at point of use Backflow prevention for process fluids Doors self closing and locking Break resistant windows Class I or II Decontaminate everything but BSC using one product leaving the piece suit with laboratory ventilation Access tightly controlled, locked doors, logbook Emergency protocols Access in/out through shower rooms Slide 12 © PharmOut 2015 Biosafety levels: BL-4 cont… Laboratory Practices Special Practices Containment Laboratory Facility Equipment Same as BL-3 No street clothing, special uniform Class III BSC Double door autoclave or dunk tank for Class I or II decontamination out Hazard signs Decontaminate incoming materials, airlock access No spare materials, clothing, animal BSC using one piece suit with ventilation Heat decontamination for liquid wastes Shower drain and toilet drain disinfection Dedicated HVAC with DP monitoring Worker health monitoring HEPA exhaust Class III BSC exhaust to outdoors through HEPA One-piece suit, suit-up area Chemical shower for suit decontamination, redundant HEPA exhaust Slide 13 © PharmOut 2015 Slide 14 © PharmOut 2015 Slide 15 © PharmOut 2015 Slide 16 © PharmOut 2015 Slide 17 © PharmOut 2015 Airlock functional configurations Slide 18 © PharmOut 2015 Objective of airlocks Before we look at different conceptual options, we need to understand some basics: • To maintain room differential pressure as personnel and/or materials enter or leave. • To maintain cleanliness differentials. • To provide an intermediate zone between rooms to implement a status change: – Gowning / Un-gowning of personal. Personnel changing rooms are special kinds of airlock. – Cleaning / Decontamination of materiel surfaces. Slide 19 © PharmOut 2015 Cleanroom application for the control of Dp and cleanliness Doors closed Corridor Grade D + A/L C ++ Room Grade C +++ Slide 20 © PharmOut 2015 When all doors closed: • Door closed pressures maintained. • Corridor is Grade D. • A/L must be at cleaner Grade C. • Room is Grade C. Cleanroom application for the control of Dp and cleanliness Grade D Door open Corridor Grade D + A/L D + Room Grade C +++ Slide 21 © PharmOut 2015 When Grade D side door is open: • A/L and Corridor pressures equalise. • Grade C room pressure is maintained. • A/L assumed to be Grade D = Corridor. • Room maintains Grade C. Cleanroom application for the control of Dp and cleanliness Grade C Door open Corridor Grade D + A/L C +++ Room Grade C +++ Slide 22 © PharmOut 2015 When Grade C side door is open: • A/L and Room pressures equalise. • Grade C room pressure is maintained. • A/L assumed to be Grade C = Room. • Room maintains Grade D. What are the different types of Airlock used in the Pharma world? • • • • Cascading Pressure Airlock Pressure Bubble Airlock Pressure Sink Airlock Potent Compound Airlock del Valle, Manuel A. PE “Design and Operation of Biotechnology: Design and Operation of Biopharmaceutical Airlocks” CleanRooms February 2000 Slide 23 © PharmOut 2015 Cascading pressure airlock + Clean Area + 30 P aTypically, an equal amount of air is supplied to and returned from the airlock ³ 15 Pa Less Clean Corridor +15 0.05 in H2O = 12.5 Pascals Pressurized air cascades from a clean to a less clean adjacent area del Valle, Manuel A. PE “Design and Operation of Biotechnology: Design and Operation of Biopharmaceutical Airlocks” CleanRooms February 2000 Slide 24 © PharmOut 2015 Pressure Bubble Airlock Contained - Clean Area ³.15 Pa + + ³.15 -15 Clean conditioned air is used to pressurize the airlock. +15 Pa Less Clean Corridor 0 0.05 in H2O = 12.5 Pascals Cleaned conditioned air is used to pressurize the airlock. This air dissipates through the airlock doors to adjacent areas. del Valle, Manuel A. PE “Design and Operation of Biotechnology: Design and Operation of Biopharmaceutical Airlocks” CleanRooms February 2000 Slide 25 © PharmOut 2015 Pressure sink airlock Contained + Clean Area ³15 +15 Pa - 0 ³ 15 Pa + Less Clean Corridor All of the air that infiltrates into the airlock and all of the supply air is exhausted +15 0.05 in H2O = 12.5 Pascals Negative pressure is maintained relative to the adjacent areas and all of the air entering the room is exhausted. del Valle, Manuel A. PE “Design and Operation of Biotechnology: Design and Operation of Biopharmaceutical Airlocks” CleanRooms February 2000 Slide 26 © PharmOut 2015 Potent Compound Airlock + ³15 Pa 0 Potent Compound Clean Area + ³.30 Pa - - - + +15 Clean conditioned air is used to pressurize the airlock off of the corridor. There is no return. All of the air that infiltrates into the airlock off the Potent Compound Clean Area and all of the ³.15Pa supply air is exhausted -15 - .00 Less Clean Corridor 0.05 in H2O = 12.5 Pascals A two-cell combination of the pressure bubble and pressure sink airlocks del Valle, Manuel A. PE “Design and Operation of Biotechnology: Design and Operation of Biopharmaceutical Airlocks” CleanRooms February 2000 Slide 27 © PharmOut 2015 Estimation of leakage Important for any HVAC pressurisation design • • • • Slide 28 Designer must estimate the known leakage rate Designer must allow for any unknown leakage rates Doors should be the main leakage path Leakage rate through small gaps can be determined from: – Q = 0.827 x A x (DP)0.5 – Where: › Q = leakage rate m3/sec › A = leakage area m2 › and, DP = differential pressure between spaces Pa © PharmOut 2015 Estimation of leakage around door cracks Door Size Slide 29 Leakage (Iitre/s) at Differential Pressure (Pa) 5 10 15 20 25 30 35 40 45 Single 24 35 42 49 55 60 65 69 73 Double 53 74 91 105 118 129 140 149 158 © PharmOut 2015 Airlock Good Design Practice Slide 30 © PharmOut 2015 Good airlock practice – Check list Describe the function: Cleanliness levels: Define levels. Ventilation & air filtration requirement. ••Internal furniture & equipment. Recovery time. • • • Cleaning / decontamination ; gowning; etc. Adequate space: • Internal furniture & equipment. Interlocks: Choose types: • Electromechanical. • Traffic lights. Pressurisation & pressure control objectives. Time delays. Leak tightness. Slide 31 © PharmOut 2015 Things that go wrong with airlocks Slide 32 © PharmOut 2015 Common airlock problems • • • • Slide 33 Door leakage prevents adequate room pressure maintenance. Internal space too small. Recovery time not adequately characterised. Changing / Gowning rooms: – Inadequate space. – Process not well defined. – Inadequate segregation of different phases of change process. › Separation of entry & exit (Spatial or Temporal) − Failure to comply with Annex 1 “final part of change room should be the same grade as the space accessed”. © PharmOut 2015 Qualification of airlock performance Slide 34 © PharmOut 2015 Airlock performance qualification (PQ) To prove the function: • Confirm supply & return airflow volume. • Test pressure stability: 1. Open each door in turn, and confirm that the overall critical room/zone pressure regime remains within specification (some small changes should be anticipated because the leakage path resistance for the higher pressure room is reduced when individual doors are open. 2. Open individual doors to different airlocks to mimic normal simultaneous use worst-case situations. • Cleanliness classification A. At rest B. Operational • Recovery time to qualify interlock time delays. Slide 35 © PharmOut 2015 Thank you for your time. Questions? Gordon Farquharson Executive Consultant gordon.farquharson@pharmout.net www.pharmout.net Slide 36 © PharmOut 2015