Przewodnik wyboru O-ringów: Materiały, Temperatura, Kompatybilność

advertisement

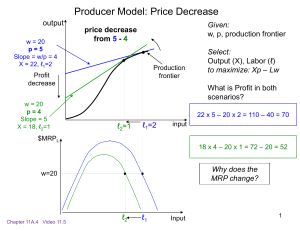

O-RING SELECTION GUIDE April 2015 Material Type/ Hardness Temp. °F 70 NBR Nitrile 80 H20 BPS B101, H30 Viton® FEPM Aflas® FFKM Chemraz3 FFKM 250 300 75 BPS B201, V35 275 90 BPS B201, V40 400 95 BPS B201, V45 90 BPS B201, A40 90 90 BPS B301, K20 90 BPS 402, B40 PSI Oil Chloride Base Brine Completion Completion Bromide pH> 10 Amine Completion Completion Inhibitor Decomp. Resistant Solvents 15 K w/PE10 10 K w/ T20 15 K w/PE10 100 ppm < 175°F OK OK NO NO OK < 175°F OK 6 hours OK OK NO NO OK < 225°F OK 4 hours < 250°F OK OK OK NO OK < 200 °F OK 24 hours < 300°F OK OK OK to 400F OK OK OK 4 hours < 300°F OK OK OK OK OK NO OK OK OK OK OK OK OK OK OK NO OK OK OK OK 10 K w/ T20 10 K w/ T20 325 BPS B301, C40 H2S 15 K w/PE10 H40 BPS B701, HNBR40 Kalrez3 EPDM 225 90 FKM Press.2 10 K w/ T20 BPS B101, BPS B101, 90 HNBR Hydrog. Nitrile Environmental Compatability Temp. & Pressure w/ B.U.1 1% < 200°F 15 K w/PE10 10 K w/ T20 15 K w/PE10 450 10 K w/ T20 to 450 15 K w/PE10 15 % <300°F 5% > 300°F 20% <300°F 7% >300°F 20% <350°F 15 K w/PE10 7% to 500 to 500°F 20% 350 15 K w/PE10 <350°F 7% to 500 15 K w/PE10 to 500°F 350 to 550 15 K w/PE10 100 ppm NO NOTE # 1 These recommendations are for long term static applications. Exposure of a few days allow higher temperatures or pressures. Dynamic use will lower temperature /pressure capability. For any material used near its upper temperature rating, temperature cycling capability will be reduced. NOTE #2 Pressure ratings for o-rings with back ups are dependent on type of back up material used and gaps sealed. T20 is Glass Filled Teflon® and PE10 is Glass Filled PEEK. Ratings for O-Rings w/o back-up are related directly to Equipment tested pressure and temperature ratings. NOTE #3 Some grades of Perfluoroelastomers, Chemraz, Kalrez and other brands, can seal better at low temperatures. High temp. versions will not seal as well at low temperatures. © 2015 Baker Hughes Incorporated. All rights reserved.