I. Theory introduction

A. Fresnel Equations

Since we have decided to build up an plasmonics sensor in which the amplitude of the reflected beam

(reflected intensity or reflectance) from gold-dielectric interface is detected, and also a more precise way to

detect surface plasmon resonance is to detect phase changing. Where both the theory of reflected amplitude

and phase changing are based on Fresnel equations. Hence we would like to introduce the theory for our

master project starting from Fresnel equations.

Let us first consider an incident beam at the boundary between two materials with different index of

refraction (for example, air: n1 and glass: n2). We will discuss two different conditions for both TM (transverse

magnetic) and TE (transverse electric) mode waves.

Figure 1[1] shows the picture of the incident, reflected and transmitted waves at an planar interface for TE

(left) and TM (right) mode respectively.

Figure 1. Left: incident wave of TE mode (electric field is perpendicular to the plane of incidence) at the

interface; Right: incident wave of TM mode (magnetic field is perpendicular to the plane of incidence). We can

see that “E” represents electric field, “B” represents magnetic field, “Xr” represents the reflected components,

“Xt” represents the transmitted components.

On the basis of law of reflection and law of refraction (Snell’s law):

r

nr sin r nt sin t

We first introduce the definition of the required boundary condition: the components (both electric field

and magnetic field) parallel to the interface should be continuous when crossing the boundary.

The boundary conditions for TE waves:

E Er Et

B cos Br cos Bt cos t

The boundary conditions for TM waves:

B Br Bt

E cos Er cos Et cos t

Taking account of the relation between electric field and magnetic field:

c

E B B

n

Then the above boundary conditions for both wave modes can be presented as following:

E Er Et

TE :

n1 E cos n1 Er cos n2 Et cos t

n1 E n1 Er n2 Et

TM :

E cos Er cos Et cos t

If we further employ Snell’s law to eliminate the angle of refraction θt while introducing the relative

refractive index n=n2/n1 as shown below:

n cos t n 1 sin 2 t n 2 sin 2

In this way we can finally get the reflection coefficient r=Er/E and transmission coefficient t=Et/E for two

modes as following:

r

TE :

t

Er cos n 2 sin 2

E cos n 2 sin 2

Et

2 cos

E cos n 2 sin 2

E

n 2 cos n 2 sin 2

r r 2

E

n cos n 2 sin 2

TM :

2n cos

t Et

E n 2 cos n 2 sin 2

The above equations (9) and (10) are known as Fresnel equations. For non-planar interface, the scattering

losses should be also taken into consideration when calculating both reflection and transmission coefficients.

B. Total internal reflection and evanescent wave

1). Total internal reflection (TIR)

After having got the coefficients for both reflection and transmission, we now turn to discuss the energy

issue at the planar interface between two materials, that is, the power of incident beam Pi will be separated

into reflected part Pr and transmitted part Pt, and the proportion for each part compared with the total energy

of the incident wave is called reflectance (represented by R) and transmittance (represented by T) respectively.

Here we give their mathematical expression without proof:

P

E

R r r2 r

Pi

E

T

2

Pt

cos t 2

r2 n

t

Pi

cos i

As we plot the incident angle θ versus R, and take the boundary between air (n=1) and glass(n=1.5) for

instance, the reflectance R for both external and internal can be shown as below:

Figure 2.[1] The reflectance of TM and TE modes for both external and internal reflection, nair=1, nglass=1.5.

From Figure 2 we can see the external and internal Brewster angle, or so called polarizing angle, which is

expressed by θp=tan-1(nt/ni), in which nt and ni represent the index of refraction for the material of incident

space and transmitted space separately. Additionally, we could also find that under the condition of internal

reflection, the reflection coefficient rTM and rTE reaching to unity value not occurs at normal incidence. This

phenomenon is known as total internal reflection, in which the corresponding incident angle is θc=sin-1(nt/ni),

the subscript ‘c’ indicates the specific name of this angle: critical angle.

2). Phase change of TIR mode

Let us continue the topic of internal reflection. However, when the incident angle θ>θc, it means sinθ>n,

with n=nt/ni, then the expression of reflection coefficient should be rewritten as followings:

Er cos i sin 2 n 2

E cos i sin 2 n 2

Er

n 2 cos i sin 2 n 2

E

n 2 cos i sin 2 n 2

rTE

rTM

For (13) and (14) either equation, r could be taken the form of r=±(a-ib)/(a+ib), then the phase of can be

expressed by polar form:

e i

r i e i 2

e

Where the expression for r (polar form) and β in each mode are presented as followings:

r e i 2

sin 2 n 2

TE :

tan 1

cos

r e i 2 e i 2

sin 2 n 2

TM :

tan 1

n 2 cos

Now we take the phase change of the E-field of the reflected wave into consideration with respect to the

original phase of the incident wave, and we represent it as φ, then using the reflection coefficient and the

wave equation of incident wave, the E-field of the reflected wave now is:

Er rE r e i E0 e i k.r t r E0 e i k.r t

Hence if we combine equations (16) - (18), we could get the phase change for each wave mode at interval

of total internal reflection (θc<θ<π/2):

2

2

1 sin n

TE 2 2 tan

cos

c :

2

2

2

1 sin n

2

2

tan

TM

2

n cos

3). Evanescent wave

However, when under TIR mode, the electromagnetic field should be still continuous at the boundary of

two mediums, akin to the transmitted wave, we call it as the “evanescent wave”. We will investigate the

properties of evanescent wave by first looking at its wave equation as shown below.

Et E0t e i k t .r t

We assume that the evanescent wave is propagating at x-z plane as shown in Figure 1, in which the E-field

could be presented by x-y coordinate, then we can get:

k t .r kt sin t , cos t , 0

. x,

y, 0 kt x sin t y cos t

For the case of TIR mode, the angle of refraction θt can be presented by:

cos t 1 sin 2 t 1

sin 2

sin 2

i

1

n2

n2

So now the exponential factor is shown as following:

k t .r kt x

sin

sin 2

ikt y

1

n

n2

For convenience, we could also define a real and positive value:

sin 2

1

n2

kt

Then the transmitted wave can be rewritten as:

Et E0t e

i t

e

ixk t

sin

n

e y

From equation (25) it is obvious that the evanescent wave has harmonic functions with invariable amplitude

along x direction, but also decreasing exponentially along y direction. There exists a range that the energy of

the evanescent wave will return to the first medium after having propagated at the second medium, this range

is called penetration depth, which can be represented by equation (26), in which the wave amplitude is

decreased to the 1/e of the original value.

y

1

sin 2

2

1

n2

An exception occurs that the energy of evanescent wave can continue forward propagation, which is

realized by placing an extra medium in contact with the medium of the evanescent wave, then the total

internal reflection can be frustrated. The most common way to have frustrated TIR is to put two right-angle

prism together with the diagonal surface facing to each other, as shown in Figure 3, in this way, the evidence

of the evanescent fields, in which the field that leaks through the TIR surface, is provided.

Figure 3. Comparison of TIR and frustrated TIR.

C. Optical properties of materials

1). Dielectric

a). Polarization of dielectric materials

When we apply electromagnetic field (EM field) to dielectric material, there will be tiny displacement for

electron regarding the position of nuclei, which will further produce an induced dipole. Then we introduce the

dipole moment p which is the product of the displaced charge and the separated distance of negative and

positive charge as below:

p qr

As we can see, the vector of the dipole moment is pointing from electrons to nuclei. Then we introduce

another important notion, the polarization P, which represents the total dipole moment per unit volume, its

expression is given by equation (28) as shown below, N is the number of dipole pairs per unit volume, e is the

charge amount of a single electron.

P Ner

As the magnitude of the nuclei mass is far higher than that of electron mass, we can consider that the

electrons are bind by nuclei via elastic force given by Hooke’s law. Furthermore, in an alternating EM field,

electrons also oscillate, and the oscillation is actually a damping process because the kinetic energy of electron

will decrease when colliding with other electrons. Therefore, we can use Newton’s classical mechanics to

interpret the motion of oscillating electron by adding the above conditions into consideration, hence we can

get the following equation to describe oscillation model of electron:

dr

d 2r

Kr m

eE m 2

dt

dt

In equation (29), K is the spring constant of the elastic model; m is the mass of electron; γ is a frictional

constant, of which reciprocal is the relaxation time (time period between two collisions) of the free electron.

Additionally, the Lorenz force (ev×B) for the moving charge can be omitted due to the negligible magnitude

of magnetic field compared to E-field.

Considering E-field and the motion of oscillator as harmonic wave, which can be written as E=E0e-iωt and

r=r0e-iωt respectively, then equation (29) can be solved as following:

r

eE

m im K

2

Therefore the polarization can be expressed by:

Ne 2

E

P

2

m im K

However, the E-field in the above equation actually represents the local field Eloc of dipole, which is the

superposition of the applied field Eapp and the field that caused by the interaction with other dipoles, the latter

component is given by P/3ε0, therefore:

E loc

P

Eapp

3 0

Next we rewrite the expression of polarization as following:

Ne 2

P

P

E

2

m

im

K

3

0

Now we can see polarization appears at both side of equation (33), before solving the above equation to get

the expression of polarization, let us define the resonance frequency of the medium dipole:

02

K Ne 2

m 3m 0

Thus the equation for polarization can be written as:

P

Ne 2 / m

E

02 2 i

And the magnitude of P can be presented by:

P

Ne 2 / m

2

0

2 2

2

2

E

From equation (36) we can see that when ω«ω0, P has the same sign with E, hence the oscillations of

dipoles are in phase with E-field; On the contrary, when ω»ω0, P has the opposite sign against E, hence the

oscillations of dipoles have a phase difference of 180° compared with E-field. Furthermore, at resonance

frequency (ω=ω0), the polarization becomes maximum, here the damping term (iωγ) can not be negligible

now, meanwhile inducing a 90° phase shift between polarization and E-field.

b). Propagation of light waves in dielectric materials

Let us consider about the charge density ρ of dielectric material. Normally, the charge in a certain material

are made of free charge and bound charge. But the free charge is thought to be zero in dielectric, therefore

the charge density of dielectric is simply bound charge density, and it could be also associated with

polarization P as shown below:

b f b 0 b

b P

In the above equation, ρb and ρf are the bound and free charge density respectively. And the same condition

is also applicable for current density J as shown:

J J b J f J b 0 J b

P

Jb

t

Combined with equation (37) and (38), we can write Maxwell's equations for dielectric as followings:

P

E

0

B

E

t

B 0

2

E 1 P

c B

t 0 t

We assume the dielectric material is homogeneous, then there is a net surface charge density caused by

polarization, but the internal charge density is still zero, according to Gauss’s law for E-field, E 0 . So we

can get:

E E 2 E 2 E

E B B

t

t

Then Ampere’s law in Maxwell's equations can be rewritten as:

c 2 2 E

2E 1 2 P

t 2 0 t 2

And now we can apply the expression of polarization P using equation (35) into the above equation:

2E

Ne 2

c 2 2 E 1

2

2

2

m 0 0 i t

Considering E-field as harmonic wave: E=E0ei(kz-ωt), the solution for k2 becomes:

k2

2

Ne 2

1

1

2

2

2

c m 0 0 i

Obviously the propagation constant k is a complex number, so k can be further presented by its real and

imaginary part: k=kR+ikI. Hence now the E-field harmonic wave can be rewritten as:

E E 0 e i k R z ik I z t E 0 e k I z e i k R z t

Therefore kI determines the damping rate of the E-field harmonic wave. Moreover, since

2

AE I E , in

which A and I are amplitude and intensity of E-field separately, then we can get Beer-Lambert law:

I I 0 e z

In which α=2kI is the attenuation coefficient of the medium. Additionally, now the refractive index becomes

complex number as well, using the relation: n=(ck/ω), we can get the complex refractive index n=nR+inI (nI is

also called extinction coefficient) and also the corresponding relative permittivity εr:

c2

Ne 2

1

r nR inI 2 2 k 2 1

m 0 02 2 i

Ne 2

Ne 2

02 2

1

i

2

2

2

2

2 2

2

2

2 2

m 0 0 m 0 0

Let us further discuss the complex refractive index of dielectric, if we plot the complex n derived from

equation (46), as shown in Figure 4[1]:

Figure 4. Graph of angular frequency ω versus nR and nI. Parameters are chosen as followings: ω0=1×1016/s,

γ=1×1014/s, N=1×1028/m3.

From the above graph we can see that nR experiences a drastic rising up and dropping down and meanwhile

nI is changing from a negligible number to a significant value when the angular frequency ω is falling into the

neighborhood of resonance frequency ω0:

0

2

The region mentioned above is the region of anomalous dispersion, and nR becomes unit value when it

passes through this region to higher frequency. In addition, the physical meaning for resonance frequency ω0

of a dielectric according to the above graph is that, the material suddenly has a great chance to absorb

photons when the frequency of incident beam is located at ω0. Moreover, ω0 here for dielectric indicates a

related incident beam wavelength around the magnitude of 101 nm, in which the wavelength is rather short

compared to visible spectrum.

Normally, for ω«ω0, the damping term of equation (46) can be neglected (γ=0) so that we can get the

expression of the refractive index at low frequency:

n2 1

Ne 2

1

2

m 0 0 2

In which the refractive index at low frequency for dielectric is found to only have real part. Furthermore, if

we rewrite the component in the bracket of equation (48) to series as below:

1

1

1 2

1 2 4

1 2 4 ...

1

2

2

2

2

2

0

0 0

0 0 0

Then equation (48) can be rewritten as:

n2 1

Ne 2 2 4

1 2 4 ...

2

m 00 0 0

Next if we apply ω=2πc/λ and consider about taking square root for both sides of equation (50), the so

called Cauchy dispersion equation is got as below:

n A

B

2

C

4

...

By using Cauchy dispersion equation, it is quite convenient for us to determine the refractive index of

different wavelength at low frequency region.

2). metal

a). Conduction current in metal

On the contrary, in metals, only free electrons exist, no electron bounds to nuclei by elastic force - the force

constant K=0, hence electron motion equation of metal can be presented by:

dr

d 2r

m

eE m 2

dt

dt

Here we introduce the notion of conduction current density J, which can be defined by:

J Ne

dr

dt

Consider the conduction current density J also as harmonic wave, so J=J0e-iωt, as well as E=E0e-iωt, then we

can rewrite the electron motion equation of metal as following:

E

m

i J Ne

2

Here we define the static conductivity σ, in which “static” means frequency ω=0, then we get:

Ne 2

E E

J 0

m

The above equation is also the description of Ohm’s law for DC condition, finally we present conduction

current density in frequency domain:

J

1 i /

E

b). Propagation of light waves in metal

Let us first rewrite Ampere’s law for metal in Maxwell's equations by adding the form of conduction current

density J into it:

c 2 B

E J

t 0

Then we use the conclusion of equation (40) combined with equation (57) to get the following result:

2E

1 2E

1

2

2

c t 0 c 2 1 i /

E

t

Since E-field in the above equation is in the form of harmonic wave given by: E=E0ei(kz-ωt), next we would like

to get the expression of propagation constant k for metal:

k2

0

i

c

1 i /

2

2

In which μ0 is the permeability of vacuum. In addition, it is obvious that the propagation constant k for

metal is also a complex number, and especially its coefficients for real part and imaginary part are the same:

k k R ik I 1 i

0

2

With the complex propagation constant k, the harmonic wave equation for metal has the same form as that

of dielectric given by equation (44) before, hence there still exists the damping term e k I z . Then we often

define a penetrated depth corresponding to the remained 1/e amplitude of E-field, this depth is specially

called skin depth δ, where:

1

2

kI

0

Normally, we can use skin depth to identify the conductivity of a certain type of metal, in which smaller skin

depth indicates larger conductivity.

c). Plasma frequency

Before we start the derivation, we would like to introduce an important notion called “plasmon”: if we

compare the free electron gas in metal to the real gas of molecules, when the metal is expected to have

fluctuation of electron gas densities, electron gas density waves can be generated, then this phenomena is

called plasmon.

Next we introduce the complex refractive index of metal which is derived from equation (59), then we get:

0c 2

n 2 k 1 2

c

i

2

2

2

Here we also would like to introduce the notion of plasma frequency, which is given by:

Ne 2

1 Ne 2 Ne 2

0

0c 0 c

0 0 m m 0

m

2

p

2

2

Hence now equation (62) can be rewritten as:

n 2 nR inI 1

2

p2

2 i

If we plot the refractive index n of metal using equation (64), the resulted graph is shown in Figure 5[1]:

Figure 5. Graph of angular frequency ω versus nR and nI of metal. Here value of parameters are given:

ωp=1.63×1016/s, γ=4.1×1014/s.

Theoretically, the crossover of the above graph occurs at p2 2 . However, because ωp»γ, so the

crossover can be regarded as occurring at ω=ωp. The physical meaning for this crossover is that it forms the

boundary between optically transparent region and opaque (with high reflection coefficient) region. For ω<ωp,

complex refractive index is kept and the light wave is damping in metals; on the other hand, for ω>ωp, the

refractive index becomes a pure real number and the radiation can be transparent in metal. Therefore, it can

be conclude that above plasma frequency, metals allow EM wave propagation and become transparent, this

phenomenon can be also classified as a type of plasmon, the so called bulk plasmon or volume plasmon.

D. Surface plasmon polaritons

1). The wave equation of surface plasmon polaritons

Let us first rewrite Maxwell's equations for macroscopic EM field (also known as Maxwell’s equations in

matter) as followings:

D ext

B 0

B

E

t

H J D

ext

t

In which the equations elaborate the relation among four macroscopic fields as listed below:

E: electric field;

B: magnetic induction (or magnetic flux density);

D: dielectric displacement (D=ε0εrE);

H: magnetic field (B=μ0μrH, μr is relative permeability).

Additionally, ρext and Jext represent the external charge density and external current density respectively.

Here we would like to investigate the wave equations for the medium which is nonmagnetic (hence the

relative permeability μr=1) and no external charge (ρext=0) / external current (Jext=0) existed either. Next let us

assume that the wave here is a harmonic time-dependence wave, and we also assume the propagation

geometry that should be one-dimensional with propagation along x-axis and no spatial variation in x-y plane,

the assumed propagation geometry is shown in Figure 6:

Figure 6. Propagation geometry of a planar waveguide under a Cartesian coordinate system.

Then the harmonic time-dependent, one-dimensional wave gives:

t i : indicates harmonic time-dependence;

x i : indicates wave propagating along x axis, and β=kx is the corresponding propagation constant;

y 0 : indicates homogeneity along y axis.

Next, by using the above definitions and assumptions, we further expand the two curl equations from

Maxwell’s equations in matter, then we got (for convenience, we would like to replace symbol of relative

permittivity εr to ε in the following deductions, and we also define k0=ω/c as the wave vector in vacuum):

E y

i 0 H x

z

E 0 H E x i E z i 0 H y

t

z

i E y i 0 H z

H y

i 0E x

z

E H x

H

i H z i 0E y

0

t

z

i H y i 0E z

For TM mode wave, the nonzero components are: Ex, Ez and Hy, hence we can get the wave equation for TM

mode:

2H y

z

2

k02 2 H y 0

For TE mode wave, the nonzero components are: Hx, Hz and Ey, hence we can get the wave equation for TE

mode:

2Ey

z

2

k02 2 E y 0

2). Surface plasmon polariton at single interface

Let us first define a most simple geometry that could maintain surface plasmon polaritons (for convenience,

we use “SPPs” as the abbreviation of surface plasmon polaritons in the following text), which is a smooth

planar interface between a dielectric with positive real dielectric constant ε2 at half space z>0, and a metal

with dielectric function ε1(ω) at half space z<0.

In addition, the propagation of waves is along x-direction with evanescent decay in z-direction. Here we

would like to give the component of wave vector parallel to z axis for two media separately: ki=kz,i (i=1,2), so

now it is possible to know the confined vertical distance for wave propagation in two media which is the

reciprocal of kz: z=1/|kz|. Hence the defined geometry is shown in Figure 7:

Figure 7. A simple geometry for supporting SPPs.

Firstly we give the solution for the wave equation of TE mode wave:

E y z Aeix e k 2 z

dielectric( z 0) : H z iA 1 k e ix e k 2 z

x

0 2

i x k 2 z

H z z A

e e

0

E y z Aeix e k1z

1

metal ( z 0) : H x z iA

k1e ix e k1z

0

ix k1z

H z z A e e

0

Two components Ey and Hx need to be continuous at the interface, which requires:

Ak1 k 2 0

Since Re[kz]>0, so the above condition is only valid when A=0, hence no amplitudes for waves leading to no

SPPs excitation at all. Therefore SPPs can not be excited for TE polarization.

Secondly we give the solution for the wave equation for TM mode wave:

H y z Aeix e k 2 z

dielectric( z 0) : E z iA 1 k e ix e k 2 z

x

0 2 2

Ez z A

e i x e k 2 z

0 2

H y z Aeix e k1z

1

metal ( z 0) : E x z iA

k1e ix e k1z

0 1

ix k1z

E

z

A

e e

z

0

1

Two components Hy and Ez need to be continuous at the interface, which requires:

k2

2

k1

1

Since we have known that Re[kz]>0, so positive ε2 of dielectric needs Re[ε1]<0, which indicates the metallic

character of the related medium. Then here comes an important conclusion: the surface waves could only

propagate at the interface between two media with opposite signs of Re[ε][2].

Next, by further combining the expression of Hy in the solution with the original wave equation of TM mode

wave, we ultimately reach to the key result in this section:

k0

1 2

1 2

The above equation interprets the dispersion relation of SPPs in TM mode at smooth planar interface which

is between two media.

3). Dispersion relation of surface plasmon polaritons

Now we can get the dispersion relation of SPPs for different modes at the interface between a conductor

and an insulator, here we assume that the collision frequency of the conductor(metal) is negligible so that γ=0,

which comes out the Drude model for ideal conductor:

1 1

p2

2

The plot for whole dispersion relation is plotted in Figure 8[3].

Figure 8. Dispersion relation of SPPs.

From the above plot we can find three modes for dispersion relation:

Bound mode: the mode which corresponds to SPPs excitation, it is further presented in Figure 9[4]. Under

this mode, the propagation constant β is expressed by combining equation (73) - (74), then we can get:

kx

c

2 2 p2

1 2 2 p2

Figure 9. SPPs in bound modes.

Quasi-bound mode: theoretically, if we assume the ideal conductor with Im[ε1]=0, then this mode is just

corresponding to a frequency gap and the propagation constant β is a pure imaginary number, thus the

wave propagation is prohibited. For real metal, this mode is related to the leaky part between radiation

modes and bound modes, thus it is called “quasi-bound”. We will discuss about SPPs under the real metal

case in next section.

Radiation mode: as we have mentioned before, this modes indicate the transparency regime, and volume

plasmons is excited. In addition, the two components of wave vector kz and kx are both becoming pure

real number now.

4). Surface plasmon

If we introduce the Laplace equation for electrical potential φ at the interface of SPPs excitation, as shown

below:

z 0 : z A2 e ix e k 2 z

i x k z

z 0 : z A1e e 1

2 0

The former two formulas are the solutions of the third formula, we can see that the solution of φ is a kind of

wave which is propagating along x axis and exponentially damping along z axis. The reason that we introduce

the electrical potential here is that in order to sustain the continuity of φ and its 1st derivative, it needs:

1 2 0

If we apply equation (77) to equation (73), it can be found that now the surface wave propagation constant

β becomes infinity, which leads to the group velocity νg of electron gas to zero:

g

d

0

d

Therefore, the mode of this electrostatic phenomenon is called surface plasmon, and it can be fulfilled at

the surface plasmon frequency ωsp:

sp

p

1 2

However, for real conductor, we should concern about the interaction between electrons in electron gas,

therefore the collision frequency γ can not be zero, thus the relative permittivity ε1(ω) is actually a complex

number with both real and imaginary parts being nonzero. Figure 10[5] gives one example for the dispersion

relation of real metal.

Figure 10. An example of dispersion curve with damping term γ.

From the above graph the leaky part between radiation mode and bound mode can be seen as we have

mentioned before. Now the wave vector at surface plasmon frequency becomes a finite value, and some

parameters of surface plasmon can be obtained as below:

Wavelength of surface plasmon λsp:

sp

2

Re[ ]

Propagation length Lsp along x direction (or so called energy attenuation length):

Lsp 2 Im[ ]

1

Penetration depth dsp,m in conductor medium:

d sp ,m

1

k1

1

2 k02 1

1

k0

1 2

12

5). Excitation of surface plasmon polaritons by prism coupling

However, there is no direct excitation of surface plasmon polaritons at planar conductor/insulator interface

by incident beam, since for a certain type of dielectric: β>k, in which k is the wave vector of the light at

dielectric medium. As a result, when the incident light a dielectric with an angle θ to the vertical axis of the

interface, the components of k which is along the interface: kx=ksinθ, is even smaller than β, hence

phase-matching is unachievable in this way.

Fortunately, there is one way to realize phase-matching, that is a tri-layer system with the thin metal film at

the middle and two insulators of different relative permittivity at two sides. For simplicity, we will set the

insulator with lower relative permittivity to be air (εair=1), when the light beam is reflecting between the

insulator with higher relative permittivity ε and metallic thin film (with incident angle θ), it will generate the

wave vector which is along the interface:

k x k sin

Now the in-plane wave vector is bigger than the propagation constant of surface wave: kx>β, the light line of

the in-plane wave is located between the light lines of two insulators, as shown in Figure 11[6][7][8]. Therefore, in

this way the excitation of SPPs at metal/air interface is achievable.

Figure 11. Excitation of SPPs using phase-matching method. εd is the lower relative permittivity (in our case:

air), and εp is the higher relative permittivity (prism).

The most common configuration to achieve the tri-layer structure is the Kretschmann method, in which a

metallic thin film is evaporated on the hypotenuse side of a right-angle prism, as shown in Figure 12. The

purpose of using prism is to create a rather bigger incident angle than total internal reflection angle on the

interface of metal/prism, which is further aimed to have evanescent wave propagation along metal/air

interface, thus SPPs propagation can be generated.

Figure 12. Kretschmann configuration

II. Simulations for surface plasmon polaritons

A. MATLAB simulation

1). Simulations for pure gold layer

a). Outline for simulation

Since we have two types of laser source used for SPPs excitation:

Diode laser: wavelength 795nm, maximum power 40mW;

Helium-Neon laser: wavelength 633nm, maximum power 5mW.

We have also decided to use Kretschmann configuration with a BK7 glass prism, and the Titanium adhesion

layer between gold thin film and prism is applied, we set the thickness of this adhesion layer to be constant

(3nm). All in all, the thickness of gold layer and the wavelength of laser source are two main parameters which

we would like to investigate, the aim for the investigation is to find the most suitable thickness of gold layer

with the better laser wavelength so that we can eventually get the best observation result of SPPs.

The criteria for the good observation for SPPs is that the groove of the reflectance graph (x axis: incident

angle on gold layer, y axis: reflectance) should be deep enough and not too wide. Firstly, deeper the groove

the better contrast between the reflectance at angle of surface plasmon and that of the other incident angles,

which means the difference between the reflectances at two vertices of the groove and the reflectance at the

bottom of the groove (the minimum value at the angle of surface plasmon) is big enough, then better contrast

helps the better observation. Secondly, too wide groove indicates a more wide range of incident angle could

have possibility to excite SPPs, therefore it will lead to a worse sensitivity for our sensor.

In addition, we also want to simulate the condition that the prism is surrounded by water instead of air just

for comparison, which means we would like to change the subphase to water as well. Hence we finally

summarized the parameters to change during simulations:

Laser source: Diode (795nm) / Helium-Neon (633nm);

Subphase: air (n=1) / water (n=1.33);

Gold layer thickness: 10 - 100;

Note that for different wavelength of incident beam, the refractive index is also changed. Therefore we have

searched the refractive index for BK7 prism, Titanium and Gold under the wavelength of 795nm and 633nm

respectively (the refractive index of water and air also changes with wavelength, but the difference is so little

that could be negligible), which is shown in Table 1. It should be mentioned that these refractive index are

from the specific literature, which we have collected them in “Bibliography” section.[9][10][11][12][13]

Refractive index

Diode

795nm

Helium-Neon

633nm

Gold

N

K

N

K

Titanium

0.18693

4.666

0.19591

3.2578

3.126

4.01

2.7043

3.7657

BK7 glass

1.5109

9.2489e-9

1.5151

1.2126e-8

Table 1. Refractive index of gold, Titanium and BK7 glass for two different wavelengths.

b). Process for simulation

The simulation is realized by MATLAB GUI (graphical user interface) programming with “uicontrol” module.

In this way, we can build up an user interface under MATLAB to real-time choose and input the parameters

(subphase, wavelength of laser source, gold layer thickness) which can further change the reflectance. In

addition, “uicontrol” module is applied in different way for each parameter:

Subphase: the pull-down menu with two options (air | aqua);

Laser source: the pull-down menu with two options (Diode-795nm | Helium-Neon-633nm);

Gold layer thickness: the slide bar, the input value is ranging from 10nm to 100nm with a step of 0.05nm;

End calculation: the press-button for termination of iteration, then the parameters which are set at last

and the related calculated values (reflectance etc.) will be stored in MATLAB Workspace, which can be

further extracted to a .txt or .xls file if needed.

Additionally, we also present the current refractive index of these three materials in real-time on the graph

of the interface. So finally the user interface for calculation of SPPs is designed as below:

Figure 13. User interface for SPPs calculation realized by MATLAB GUI programming.

The corresponding MATLAB source code is given in “Appendix” section, which is used to generate surface

plasmon resonance. The algorithm is inspired by Masahiro Yamamoto’s online self-study note: “Surface

Plasmon Resonance (SPR) Theory”.[14]

c). Results of simulation

Figure 14. Simulation result for Helium-Neon laser (633nm) with air subphase.

Figure 15. Simulation result for Diode laser (795nm) with air subphase.

Figure 16. Simulation result for Helium-Neon laser (633nm) with water subphase.

Figure 17. Simulation result for Diode laser (795nm) with water subphase.

Figure 14 to 17 have shown all the simulation results for SPPs generation on pure gold layer. The simulations

are divided to four parts which investigate the combination of the conditions of two different laser source and

two different subphase separately, and the thickness of gold layer is ranged from 10nm to 100nm within each

part.

Note that the calculated data from simulation are first extracted to .txt files and then implemented into

SciDAVis - the free scientific data analysis and visualization software to plot the reflectance graph (x axis:

incident angle on gold layer, y axis: reflectance).

For two different laser sources, we can see that the incident angle of surface plasmon resonance for each

wavelengths are totally different. Furthermore, it is also obvious that the dark spot in the reflectance curve of

Helium-Neon laser is generally wider than that of Diode laser’s.

For two different subphases, it is shown that there is no obvious SPPs excitation with water subphase. We

can only conclude that the gold thin film and the Diode laser with wavelength of 795nm is not suitable for

SPPs excitation when water plays the role of subphase.

From the two graph of air subphase, we further choose 35nm to 55nm thickness of gold layer to explore the

best thickness for SPPs excitation. We will quantify the criteria we mentioned before by first looking at one

graph of reflectance:

Figure 18. Demonstration of the evaluation of SPPs quality.

The parameters marked on the above graph are:

ΔRx (x=1,2): the reflectance difference between the maximum and minimum value, the incident angle of

ΔR1 is smaller than SPPs angle, the incident angle of ΔR2 is bigger than SPPs angle;

Δθ: the difference between two incident angles, in which the two angles correspond to ΔRx/2.

Hence we define the quality index of SPPs Qspp, where:

Qspp

R1 R2

2

2

The evaluation results of 35nm to 55nm gold layer of both laser sources are given in Table 2.

Laser source

Diode laser

795nm

Helium-Neon

laser

633nm

Au thickness

35nm

40nm

45nm

50nm

55nm

ΔR1

0,91214745

0,88757353

0,86787727

0,84672059

0,82902754

ΔR2

0,63540803

0,66845591

0,68985055

0,70968995

0,72456091

Δθ

1,7

1,15

0,9

0,7

0,6

Qspp

0,444257657

0,67542699

0,852984698

1,032606227

1,063143108

35nm

40nm

45nm

50nm

55nm

0,84877662

0,81155226

0,78264978

0,75215024

0,72687003

0,43690948

0,48060078

0,51021099

0,53811189

0,5590118

4,8

3,6

2,9

2,3

1,95

0,127570289

0,178278703

0,222451806

0,269223873

0,288376806

Table 2. Evaluation of SPPs quality.

From the above results we can find that SPPs quality of diode laser is far better than that of Helium-Neon

laser’s. Moreover, since the inputs of gold layer thickness in simulation are a series of discrete values with

interval of 0.05°, thus the evaluation results just roughly indicate the best thickness range, not a precise

thickness. Therefore we conclude that in our project, it is better to adopt diode laser and choose gold layer

thickness from 45nm to 55nm to excite good quality surface plasmon resonance.

2). Trial of functionalised gold layer surface plasmon resonance simulation

Here we just try to simulate SPPs at functionalised gold layer, we would like to say that the simulation is

based on several assumptions. Hence we can not use this simulation to guide our experimental part, but can

help us to predict some possible phenomenon of experimental results. Some key points of this simulation are

highlighted as shown below:

Since we can not find the exact refractive index of the material for functionalization - Cyclam

(1,4,8,11-tetraazacyclotetradecane). Fortunately, we have found a predicted value of Cyclam[15], where:

n=1.43, and we also assume that Cyclam simply adheres on gold layer.

The thickness range of Cyclam on gold layer is unknown, and is probably depending on the concentration

of Cyclam solution. Therefore we choose four different order of magnitude of Cyclam layer thickness:

d=5nm, 50nm, 500nm, 5μm.

We will still use the MATLAB source code for pure gold layer SPPs generation to do functionalised gold

layer simulation, in which we just need to add 5th layer to the configuration, and the assumed refractive

index and thickness of Cyclam should be defined as well.

The gold layer here is chosen to be 50nm, and diode laser is applied. We also plot surface plasmon

resonance for pure gold layer just for comparison.

The simulation results are presented in Figure 19.

Figure 19. Simulation results for pure and functionalised gold layer with different Cyclam thickness.

From the above results, we can see that as Cyclam thickness increases from 5nm to 500nm, there exists

only one resonance frequency for each thickness. However, when the thickness of Cyclam reaches 5μm, multi

resonance frequencies occurs. Unfortunately, we can not give a reasonable interpretation for this result due to

the lack of theoretical knowledge. It is worthy to making investigation further on this phenomenon after this

project.

B. MEEP simulation

1). Brief introduction and installation of MEEP

In addition to MATLAB simulations, we also try to use MEEP to do surface plasmon resonance simulations.

MEEP (MIT Electromagnetism Equation Propagation) is a free software under GNU/Linux system specially used

for finite-difference time-domain (FDTD) simulation. It contains the packages for photonic calculation

algorithm, and the user has to call the specific algorithm by coding in certain programming languages to get

the raw data of simulations. It supports the libraries of C++, python and Scheme. Here we decide to use

Scheme programming language, which is a type of functional programming, to write the code for photonic

simulation, then the source code will be saved in .ctl file.

However, in order to run simulation programs in MEEP, we have to firstly install a type of Linux distributions,

here we choose to install VMware player first, which is a free platform (this is different from VMware

workstation, which is more powerful and requires payment) for virtual machines. Then we choose to install

one of the most common Linux distributions called Debian, which the newest stable release (Debian 7.8

“wheezy”) is installed. The reason we choose to use Debian Linux is because there is already prepared a

precompiled packages of MEEP software under Debian Linux, we just need to input: apt-get install meep

h5utils[16] under Root Terminal window in the system, and all the needed packages can be installed. Note that

except for MEEP package, other packages are also needed to assist the simulations, for example, we need

packages to form .gif dynamic map or plot the photonic graph.

After the .ctl file is written. We can run the .ctl file under Root Terminal window of Debian linux. After the

source code is finished running, one can further extract the data, plot the graph and draw pictures by input

the specific commands under the terminal. Some common-used commands for MEEP is summarized as

following:

meep filename.ctl |tee filename.out; Execute .ctl file and save the compile results in .out file.

grep parameters: filename.out > filename.dat; extracte the specific parameters from the compile results

and export them into data file.

h5topng filename.h5; Convert .h5 file to .png format picture. Normally, when compiling .ctl source code,

MEEP will generate an HDF5 output file (.h5).

The coding interface of .ctl file under Debian Linux is shown below:

Figure 20. Coding interface under Debian Linux.

2). Code structure of MEEP

Normally, the parameters (refractive index, polarization, permittivity, etc) of materials used for MEEP

simulation have to be defined by users, except for air, since we can just use the predefined optical parameters

of air in MEEP. Here we have to define the parameter of gold layer, the adhesion layer using Titanium and BK7

glass. For two metals (Au & Ti), we would like to apply a more complicated Lorenz-Drude model[17][18], in which

the dielectric function ε(ω) is the superposition of inter-band εinter(ω) and free-electron εfree(ω) with several

resonance frequencies, the corresponding equations is presented below:

int er free

2p

1

free

i0

k

f j p2

int er 2

2

i j

j 1 j

The parameters in above equations are:

Γ: the damping coefficient;

Ωp: plasma frequency specially for the condition of inter-band transitions;

ωp: plasma frequency for free electrons;

f: strength of oscillators.

The values of the above parameters are summarized as below:

j

Omega ωp,j

Gamma Γj

Sigma σj

1

1e-20

0.042747

4.0314e+41

2

0.33472

0.19438

11.363

3

0.66944

0.27826

1.1836

4

2.3947

0.7017

0.65677

5

3.4714

2.0115

2.6455

6

10.743

1.7857

2.0148

Table 3. Parameters for a complex Lorenz-Drude model of gold.

j

Omega ωp,j

Gamma Γj

Sigma σj

1

1e-20

0.066137

5.1166e+40

2

0.62669

1.8357

79.136

3

1.2461

2.0309

8.7496

4

2.0236

1.3413

1.5787

5

1.5671

1.4211

0.014077

Table 4. Parameters for a complex Lorenz-Drude model of Titanium.

For the definition of the optical parameters of BK7 glass, the Sellmeier Equation is applied[19], which is

specially used for computing the refractive index of transparent media, the equation is presented as below:

B120

B2 20

B320

n 0 1 2

0 C1 20 C2 20 C3

2

The coefficients Bi and Ci for BK7 glass is presented as below:

Coefficient

Value

B1

B2

B3

C1

C2

1.03961212

0.231792344

1.01046945

6.00069867e-3

2.00179144e-2

Table 5. Parameters for Sellmeier equation of BK7 glass.

C3

1.03560653e2

Here we also summarize some key components that we should define when coding the simulations:

lattice: the dimensions of the frame for the simulation, for example, if we want to define the lattice of a

cylinder waveguide, we should define the length and diameter of the cylinder;

geometry-list: determine where we should place the certain type of the material, for example, we have to

define the size and center for each material in 3-dimensions;

Resolution: the resolution for the simulation, which determines the precision of the simulation results,

normally we set it from 10 to 50;

Source: normally we have three different sources to use, continuous source, user-defined source and

Gaussian beam source. In our simulation, we adopt Gaussian beam source, in which we have to further

define the center frequency, bandwidth and the position of the Gaussian beam.

PML thickness: PML is the abbreviation of “perfect-match-layer”, this layer is defined to 100% absorb the

incident wave in order to pretend reflection. Normally we will place this type of layer along the

boundary(lattice) in the simulated condition to make sure the beam will not reflected to the configuration

again so that the precision of the simulation can be guaranteed.

3). MEEP simulation results

a). Dispersion relation

We have tried to do simulations to get the dispersion relation at Au-Bk7 glass interface (in this simulation,

Titanium adhesion layer is not included). For comparison, we also plot the corresponding theoretical solutions

of this dispersion relation, in which a simple MATLAB code is applied, then we extract the results to a .dat file.

On the other hand, for MEEP simulation, first we execute the .ctl file and extract the complied results to .out

file, then we further extract the data of frequencies to a .dat file, finally we plot the values of two .dat file in on

graph using gnuplot under Debian Linux. The Scheme source code (.ctl file) for MEEP simulation and the

corresponding theoretical solutions using MATLAB code are presented in “Appendix” section. The The graph of

both theoretical and simulation values of dispersion relation is shown as below:

Figure 21. Theoretical solution and Simulation result of dispersion relation at gold-BK7 glass interface.

Unfortunately, it seems like the simulated dispersion curves for different resonance frequencies are not

confined to the stable value (ωspp), it is worthy to do more research on how to use MEEP to demonstrate more

precise simulations.

b). Plane wave interactions with metal-dielectric interface

We also try to simulate the condition that the plane wave is interacting with the gold-BK7 glass interface,

this time Titanium adhesion layer is applied. We set the incident angle of of plane wave to be π/4 to see the

resulting E-field strength distribution. A Scheme code (.ctl file) is firstly compiled under the Root Terminal

window of Debian Linux, and then the compiled results will be extracted to a HDF5 file (.h5 file), then the

program will automatically export the data of .h5 file to draw the .png picture showing E-field strength

distribution. The Scheme source code has been added to “Appendix” section.

For comparison, we first give a picture which show the pure plane wave propagating in air with an incident

angle π/4 to the boundary. Note that more red color means the E-field strength is reaching closer to the

positive maximum value, while more blue color means the E-field strength is reaching closer to the negative

maximum value. Then we make the picture which shows the E-field strength when the plane wave is

interacting with the gold-BK7 glass interface with an incident angle of π/4. In Figure 23, we can see the

horizontal white line boundary in the middle of the picture, which refers to the Au + Titanium layer, the upper

space from the boundary is BK7 glass, while the space below the boundary is air. Unfortunately the simulation

result fails to demonstrate a well-organized confined E-field distribution along two sides of the interface. We

assume that the reflected and transmitted waves may have more complex interaction or maybe some

nonlinear photonic phenomenons occur. In addition, the code aimed for this simulation should be further

modified as well.

Figure 22. Plane wave propagating in air.

Figure 23. Plane wave interacting with gold-BK7 glass interface.

III. Experimental preparation

A. Optical setup

1). Overview

At first Helium-Neon laser source (λ=633nm, 5mW) is used, the optical setup is shared by two projects, the

laser beam is divided by a beam splitter used for two projects separately. The configuration of the optical

components is rather compact. Soon after the Helium-Neon laser is approved to be not suitable for SPPs

excitation for 50nm thickness gold metal layer, we build up the new optical setup using Diode laser source

(λ=795nm, 40mW), which is the optical setup we have used until the master project is finished, this time

optical components are placed within wider intervals, which facilitates to have more free space to add extra

optical components in order to try more assumptions and experiment. For the last part of the project, the

optical sensor is used to detect Cadaverine molecule, since Cadaverine is irritant and toxic, the whole optical

configurations are moved to the lab with fumehood installed in.

2). Configuration overview

Here we would like to show our ultimately adopted optical configuration used for SPPs excitation, in which

the two key components are chosen: 795nm-wavelength Diode laser and BK7 prism with 50nm gold layer

deposited on. Figure 24 and Figure 25 present the sketch diagram and the real picture of the whole optical

setup respectively. Note that the serial numbers in the below two figures should be corresponded.

Figure 24. Sketch diagram of the optical setup

Figure 25. Real picture of the optical configuration

3). Components description

a). Diode laser source

The picture of the highly sophisticated Diode laser source generator is shown below. The procedures for

starting the laser generator should be noticed:

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Unlock the laser generator by clockwise turn the key at the backside;

Press the yellow button at the left bottom of the front;

Press the black button beside the temperature display panel to switch it to “T set” mode, check

the set temperature (in our case Tset=23.3°C);

Wait until the real-time-display temperature to be stable at Tset, now the green indicator light

under the label “Temp ok” is on, which indicates now we can open the laser beam;

Press the red button under the label “LD on”, laser beam is turned on, switch the knob which is

above the “LD on” label to set the current of the laser beam (in our experiments, the current is

set to 100mA).

Figure 26. Control panel of the Diode laser source beam generator

b). Half wave plate

Let us first talk about the principle of half wave plate. For some crystal structures, where the atoms are

arranged in a certain order, different included angle between E-field vector and the crystal axes may cause

different refractive index of the incident beam, therefore now the multiple resonance frequencies of the

material are determined by different crystal polarization.

When the medium material with right asymmetric crystal structure is chosen, one crystal axis (fast axis)

which supports the fastest wave propagation speed, and the other axis (slow axis) which supports the slowest

wave propagation speed will have a π/2 included angle. Therefore, when an unpolarized light beam is

propagating through such an asymmetric crystal structure medium, double refraction will occur, which is

known as “birefringence”, as shown in the left picture of Figure 27, indicating the range of the refractive index.

This physical phenomenon can be used to design the wave plate. The wave plate is made of the above

mentioned material which can induce birefringence effect. If two waves with the same angular frequency and

the same phase but different in polarization, in which one is parallel to the fast axis and another is parallel to

the slow axis, are propagating perpendicularly through the wave plate. The phase difference between the

faster wave (along fast axis) and slower wave (along slow axis) can be expressed as:

nslow n fast L

c

The equation should be Where Γ is the phase difference between the fastest wave and the slowest wave, L

is the thickness of the wave plate. When Γ equals to π, the wave propagating along slow axis will have a half

wave retardation compared with the wave propagating along the fast axis, therefore now the wave plate is a

half wave plate. Note that wave plate is designed specifically for a certain wavelength, here we choose the λ/2

plate for λ=800nm.

If we further let a plane-polarized wave beam propagating perpendicularly through the half wave plate, the

polarization of the wave can be divided into two components which are parallel to the fast axis and slow axis

respectively. Let us track a fixed point on the wave, before penetrating through the half wave plate, the vector

of this point might be the vector sum of the positive maximum of the wave components along both fast axis

and slow axis. Since the wave component which is propagating along the slow axis will have a half wave

retardation (180° phase difference) compared with the other one propagating along the fast axis, now the

vector on the same point is the vector sum of the positive maximum of the wave component along fast axis

and the negative maximum of wave components along slow axis as shown in the right picture of Figure 27.

Figure 27. Schematic diagrams of birefringence effect (left)[20] and half wave plate (right)[21].

In Figure 27, θ refers to the included angle between the polarization of the incident wave and the fast axis,

we can see that after passing through the half wave plate, the polarization of the incident wave has a variation

of 2θ, thus the polarization of the incident wave beam has changed. As a consequence, we can change θ by

rotating the half wave plate in order to set our desired polarization of the wave beam.

c). Beam splitting polarizer

The polarizer is used to divide the unpolarized light wave into TM mode and TE mode components. In our

optical configuration, the polarizer is actually a beam splitting polarizer cube glued into the center of an

optical rotation mount. Normally, a beam splitting polarizer consists of two prisms adhering together, the gap

between the prisms is usually filled with one type of transparent glue or just air gap, the refractive index of the

gap material should be smaller than that of prisms’ anyway. The prisms are made from birefringent material.

When unpolarized light wave propagating through the beam splitting cube, as shown in Figure 28[22]. The

p-polarized wave will propagate along slow axis and s-polarized wave will propagate along fast axis, since

nslow>nfast, p-polarized wave has a bigger total internal reflection angle than that of s-polarized wave’s, where

θc=sin-1(ngap/nslow,fast), therefore at the interface between the gap and the prism, the incident angle θi of both

wave modes is specifically designed, so that s-polarized wave will have total internal reflection and the

direction of propagation is changed, on the other hand, the incident angle θi is still smaller than the TIR angle

of p-polarized wave, therefore the p mode wave will still propagate along the original direction.

Figure 28. Beam splitting polarizer.

For our optical configuration, the wave beam coming out from the polarizer will be pure TM mode wave

beam (p-polarization). In addition, by rotating the λ/2 plate we can change the polarization of the incident

laser beam to be totally parallel with the slow axis on beam splitting polarizer, in this way the maximum

fraction of TM wave will be generated, and now the coming out TM wave beam will certainly get the

maximum power as well.

d). Convex lens

Since the angle range of surface plasmon resonance excitation is quite narrow, the black line in the reflected

light spot on a screen is sometimes too narrow to recognize. Therefore a convex lens can be applied before the

prism, the distance between the convex lens and the prism glass surface should be around the focal length of

the lens, then the laser beam will be first focused on the gold-prism interface and then diffusing to the CCD

camera, in this way, the black line of SPPs can be distinguished on the screen. The principle of using convex

lens in our optical configuration is shown below:

Figure 29. Comparison of SPPs excitation with and without convex lens.

e). Absorptive filter

In order to get the clear image of the light spot with SPPs black line in the middle, a Thorlabs neutral density

filter (NE10A Ø25 mm Absorptive ND Filter with Optical Density=1.0) is applied. The neutral density (ND) filter

can reduce the intensity of incident light within a long range of wavelength, especially the intensities for

different wave lengths will be reduced equally. Therefore we can utilize this property of the neutral density

filter to reduce the reflected light intensities, in which the corresponding incident angles are closely in either

sides of SPPs angle. In this way the light intensities between the SPPs black line on the screen will be

weakened, causing the SPPs black line easier to be recognized. The optical property of this ND filter is

presented in Figure 30[23] which is obtained from Thorlabs official website. From the following transmission

graph we can see that the transmission coefficient at λ=800nm is around 13.5%, which means around 86.5%

intensity of the reflected beam has been filtered using this neutral filter.

Figure 30. Transmission coefficient graph of NE10A Ø25 mm Absorptive ND Filter.

4). Optical setup for Helium-Neon laser source

Here we also give the original version of the optical configuration using Helium-Neon laser source, note that

this setup is originally shared by two master projects. The real picture of the optical setup based on

Helium-Neon laser is shown in Figure 31, in which the marked components and the green light path are

applied by our project.

Figure 31. Optical setup based on Helium-Neon laser source

The components marked in the above picture are listed : 1. Helium-Neon laser source (λ=633nm); 2. Mirror;

3. Polarizer; 4. Beam splitting cube; 5. Mirror; 6. Half wave plate; 7. Rotation mount with prism; 8. Ruler used

for beam height calibration; 9. CCD camera. Note that before assembling the polarizer (component No.3), the

laser gun of Helium-Neon laser source should be rotated in order to have two same power beams after the

incident wave propagating through the beam splitting cube. Figure 32 shows the Helium-Neon laser source

used in the original optical setup.

Figure 32. Helium-Neon laser source generator.

B. Gold thin film deposition on prism

1). Prism cleaning

The cleaning procedures for BK7 glass prism is summarized below, each steps is shown in Figure 33 as well.

Step 1:

Step 2:

Step 3:

Put the prism into a beaker of Acetone at least 15 minutes;

Put the prism in a second beaker filled with Isopropanol, use ultrasound to clean the prism

surface at least 10 minutes;

Rinse the prism with distilled water, then use nitrogen to dry the prism.

Figure 33. Procedures for prism cleaning.

2). Metal thin film deposition on prism

a). Prism mounting

The E-beam system (Cryofox Explorer 600) is used to deposit metallic thin film on the hypotenuse surface of

BK7 prism. Before the deposition starts, the prism should be mounted and stabilized with a holder. Since prism

can not be mounted with a planar holder, here we choose to use a bracket which has the vertical wall to stick

the prism, then we use tapes to fix the prism on the wall of the bracket, as shown in Figure 34.

Figure 34. Mounting the prism.

b). Titanium and gold layer deposition

First, a 3nm thickness Titanium layer will be deposited on prism surface as an adhesion layer, following by a

50nm gold layer deposition. The recipe on the Cryofox system is shown below:

Figure 35. E-beam Ti+Au deposition recipe on Cryofox system screen.

The procedures for operating the Cryofox Explorer 600 is summarized as below:

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Step 6:

Step 7:

Step 8:

Step 9:

Step 10:

Step 11:

Set the needed recipe, always remember to “Append Recipe” when altering it, press “Use

Recipe” until the check-mark appears.

When Cryofox is in standby mode, the pressures in two chambers are: Load-lock chamber: ~10-3

mbar; Main chamber: ~10-7 mbar.

”Coating Process”; when the load-lock chamber pressure goes to ~103 mbar, open the load-lock

chamber, put the sample in.

“Start / Stop Process”, use hands to push the load-lock chamber.

When the pressure of load-lock chamber goes down to ~10-3 mbar, it will be detected by a

sensor in main chamber.

The system itself will choose the certain mode (E-beam / DC Sputter / RF Sputter) regarding the

recipe.

Load-lock chamber will connect to main chamber regarding the certain mode (E-beam / DC

Sputter / RF Sputter).

When pressures of both load-lock chamber and main chamber together go down to 5×10-5 mbar,

press “Start Layer”.

Two chambers’ pressure will go up to ignition pressure.

When deposition finished, system will automatically vent, then take out the sample, close the

load-lock chamber.

Press “Coating Process” (light off), and “Standby Vacuum” (light on).

One thing should be highlighted is that when mounting the prism to the vertical wall of the bracket, the

upper end of the vertical wall should be aligned with the edge of the hypotenuse surface of the prism. If the

edge of the prism is lower than the upper end of the wall, it will cause anisotropic scattering of gold atoms

during E-beam deposition, as shown in the left picture of Figure 36, hence the nonuniform thickness gold layer

and even the contamination of gold layer might happen. An unsuccessful gold deposited prism is shown in the

right picture of Figure 36, we can see some contamination occur on the part of the gold layer marked by blue

frame.

Figure 36. Investigation of nonuniform gold layer thickness and contamination.

C. Determination of SPPs angle on pure gold layer

1). Preparation

The position for placing the BK7 glass prism on the rotation mount should be chosen carefully, in which to

make sure the rotating angle of the rotation mount is exactly the rotating angle of the incident beam on the

prism. The position for the prism on the rotation mount is shown in Figure 37. Note that the purple-line

triangle refers to the position for placing the prism.

Figure 37. The position for placing the prism on the rotation mount.

The calculation for the incident angle on the gold-prism interface according to the incident angle read from

the rotation mount is applied. Note that we would like to build up an .xls table file to record the raw data and

do computations, the recorded angle from the rotation mount is deg form and .xls file supports rad form,

therefore the transform between two forms should be noticed. Figure 38 shows the principle of incident angle

calculation and the corresponding equations is shown below:

1

sin

180

180

1

3 sin

4

n prism

The parameters in the above equation are:

θ⊥: The perpendicular incident angle on prism, indicating a 45° incident angle on gold layer;

θ1: The incident angle on prism;

θ3: The incident angle on gold-BK7 glass interface.

Figure 38. Geometry for calculating the incident angle on gold layer.

2). Finding the SPPs angle by power meter

First we should determine the rotation angles of the λ/2 plate and the polarizer. Normally, the rotation angle

for the polarizer is around 90° (also 180° is suitable). Then the power meter can be placed after the polarizer,

by rotating the angle of the λ/2 plate to find the maximum power measured by the power meter, we can

roughly determine the rotation angle of the λ/2 plate. Note that after introducing the convex lens and

absorptive filter into the light path, in order to get the clearest real-time video of the black line at SPPs angle,

the polarizer and the λ/2 plate will be further adjusted precisely. Hence finally the rotation angle for polarizer

is determined to be 89°, and 239° for λ/2 plate.

Next we can roughly find the angle at SPPs by checking whether there is a red light spot appearing on the

gold layer when rotating the rotation mount, as shown in Figure 39, in which the red light spot indicates the

confinement and propagation of surface wave at SPPs incident angle.

Figure 39. Red spot light on gold layer indicating the surface plasmon resonance.

Then rotating the rotation mount to a smaller angle until the red spot light disappears. Now we can place

the power meter on the other side of the prism surface with respect to the prism plane of the incident wave,

and increase the angle of the rotation mount slowly for each step, the accuracy of the rotating angle can be

both 0.2 degree (12’) or 0.04 degree (2’24’’), the reflected light intensity is recorded by power meter, as

shown in Figure 40. Note that we do not apply the absorptive filter and the convex lens when during the

section of determination the SPPs angle, since convex lens will change the light distribution on the

cross-section profile of the Gaussian beam (the laser beam is actually one type of Gaussian beam), hence

causing the measurement results to be inaccurate. Besides, the light intensity measured behind the absorptive

filter is quite sensitive to the included angle between the reflected beam and the planar of the filter, thus it is

quite inconvenient to make measurements when applying the absorptive filter.

Figure 40. Measurements of the reflected light intensity by power meter.

Note that the mainframe and the detector has been marked in the above picture, the reading on the screen

of the mainframe is always fluctuating since it is quite sensitive to the surrounding natural light. Hence one

should move the detector slightly to find the maximum reflected intensity and wait until the reading is stable

value then record the date for each time measurement.

One thing should be also mentioned is that we choose to measure and calculate the normalized reflected

intensities instead of measured reflectance, since part of the laser beam energy will be transformed to

thermal energy during propagation, therefore the measured reflectance does not have so much reference

value.

We have done two measurements in order to find SPPs angle for Diode laser source, the related graphs are

shown in Figure 41.

Figure 41. The 1st and 2nd SPPs measurement on pure gold layer using Diode laser source (795nm).

It can be seen that the SPPs angle found in two measurement are slightly different, and we also compared

the two measured values with the simulation value (Diode laser - subphase: air - gold layer thickness: 50nm):

Simulation value: θspp=41.6°;

The 1st measurement value: θspp=42.43°, with polarizer angle (97°) and λ/2 plate angle (220°);

The 2nd measurement value: θspp=42.5°, with polarizer angle (89°) and λ/2 plate angle (239°).

Note that the rotation angles of polarizer and λ/2 plate are different between the 1st and 2nd measurement,

we assume that these differences of polarizer and λ/2 might be the reason to explain why the SPPs angle got

from two measurements are not critically equal. Furthermore, the simulated value of SPPs angle has slightly

less than 1 degree difference compared with two measured values, in which the corresponding explanation

can be diverse, for example: the deposited gold layer might not ensured to be 100% pure; the way we

determine the 45° incident angle on gold layer is not absolutely right; the refractive index of air should be

altered with the changing laser source wavelength in the simulation, etc.

In addition, the surface plasmon polariton excited by Helium-Neon laser source is also measured, as shown

in Figure 42.

Figure 42. SPPs excitation on pure gold layer using Helium-Neon laser (633nm).

This time the measured angle of SPPs (43.97°) is quite close to related simulation value (43.7° for 50nm gold

layer thickness). What’s more, the measurement and simulation of SPPs excited by Helium-Neon laser both

demonstrate that the reflected intensity contrast at SPPs angle and other angles is smaller than that of the

excitation by Diode laser, in other words, the gaps in the graph of both simulation and measurement are still

wider than that of Diode laser. Therefore it can be totally confirmed that the quality of SPPs excitation using

Helium-Neon laser is worse than that of Diode laser.

3). Video collection of the SPPs spot light using CCD camera

The CCD camera is used as an image sensor to record the real-time video of the light spot shooting at its

photo-sensitive array, then the binary data collected by the camera will be transported to the PC via a special

data cable, the video is recorded in the PC using UC480 Viewer software, the process is shown in Figure 43.

Note that the light intensity will be quantified as the pixel intensity in the software.

The light spots generated in different situations are recorded. Firstly the video of light spot without convex

lens or absorptive filter is recorded. Then two videos are recorded where convex lens and absorptive filter are

singly added into the light path. And three types of convex lenses with different focal length (50mm, 75mm

and 100mm) are chosen to find the best solution.

Figure 43. Video collection for SPPs light spot by CCD camera and UC480 Viewer user interface on PC.

Firstly the comparisons are made for four different conditions, note that the focal length of the used convex

lens here is 50mm, the focal point is roughly adjusted on the surface of prism.

Figure 44. Collected images of light spot reflected at SPPs angle in 4 different conditions

The optical configuration for each picture in Figure 44 are given as following:

SPPs excitation reflected light spot 1: without convex lens and absorptive filter;

SPPs excitation reflected light spot 2: only with absorptive filter;

SPPs excitation reflected light spot 3: only with convex lens;

SPPs excitation reflected light spot 4: with both convex lens and absorptive filter.

We can see that when simply adding the absorptive filter to the light path, the contrast ratio of the light

spot is strengthened, in other words, the black-colored part in the image now becomes darker compared with

picture 1. If we simply add the convex lens, the size of the light spot will be enlarged as shown in picture 3, but

the gray level of the dark part is still too low. Then by adding both absorptive filter and convex lens, we can

eventually get the high contrast SPPs light spot with black line (indicating the surface plasmon) in the middle.

Also, images of light spots with convex lenses of different focal lengths are captured and investigated, as

shown in Figure 45, in which picture 1 to 3 are using 50mm 75mm and 100mm focal length convex lenses

respectively.

Figure 45. SPPs excitation light spots of 50mm 75mm and 100mm focal length convex lenses.

Note that the distance between each convex lens and the prism is roughly controlled around corresponding

focal length. We can see that the convex lens with 50mm focal length result in the best SPP light spot image

since it has the biggest amplification factor among these three lenses when the light path is limited.

Moreover, when using isopropanol to distill at the red spot on the gold layer during SPPs excitation, now the

current 2nd medium is isopropanol instead of air, following by the change of refractive index of the 2nd medium,

then the surface plasmon frequency ωspp and the wave vector β=kx propagating along gold-air interface have

also changed, hence eventually there will be a different SPPs angle for this area, namely the black line in the

light spot will disappear since this angle is currently not the SPPs angle. However, after isopropanol has been

evaporated at all, the refractive index at gold-air interface has been recovered, and SPPs excitation occurs

again, so the black line will appear again in the light spot as well, as shown in Figure 46.

Figure 46. SPPs light spot distilled with isopropanol (left) and then isopropanol is evaporated (right).

Particularly worth mentioning is that we can use the light spot of SPPs excitation to examine the purity of

gold layer. Figure 47 gives the comparison between two SPPs light spots excited at different areas on the gold

layer, in which gold layer on these two areas have obvious difference in purity. We can see that purer gold

layer can result in better contrast of SPPs spot light with black line in the middle.

Figure 47. Comparison of two SPPs light spots related to difference gold layer purity.

In the end, we also would like to give two graphs of reflected intensities at SPPs angle, as shown in Figure 48,

the 1st graph simply applies convex lens (with 50mm focal length), and SPPs are excited by using both convex

lens and absorptive filter in the 2nd graph.

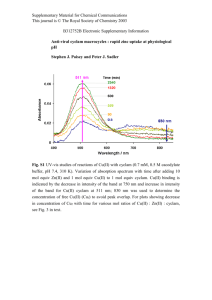

From the 1st graph, we can see that the power intensity in the cross-section profile of the Gaussian beam