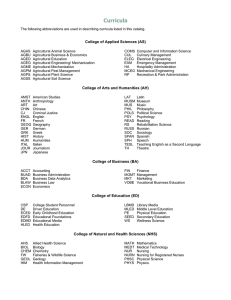

Current Perspective of Mechanization Level and Its Supporting Policies in Asia Rashad Hegazy and Mahmoud Okasha Summary Agricultural mechanization has been playing a significant role in enhancing agricultural production and improvement of farmer’s livelihood in Asia in last decades, both agricultural mechanization and its policies have been evolving and they are not entirely independent issues. Out of many exist issues related to mechanization; current study is focusing on the status and policies in each country. 14 countries were chosen for case studies, namely Philippine, Cambodia, Indonesia, Bangladesh, Laos, Malaysia, Myanmar, Thailand, Vietnam, Sri Lanka, China, India, Nepal and Pakistan and they are representing most of south and Southeast Asian countries. Each country has different level of agricultural mechanization and has different policies too, the huge diversities between and within countries is clear, the dissimilarities in country profiles and the level of development ensure that making comparison among them is difficult. The study has been divided into two major parts; first is to present the current updated status of mechanization in each country and its supporting policies, second part is comparison between countries as a result and analysis depending on available mechanization levels and number of machines involved in rice production. It was clear that there were different mechanization levels in different years for most countries in South and Southeast Asia; some of these levels have been existed long time now and the other recently cited, beside the mechanization level for Cambodia, Laos, Malaysia and Myanmar are not available yet. For the number of machines related to rice production system, data are available with better situation than the mechanization index, but still some numbers are missing and other number estimated without accurate data collection process. In the comparison between countries according to the mechanization index, there were two options to use it, first option was according to the maximum value we got and second option according to the average value obtained in different years, in both options India and China ranked as first two countries with highest mechanisation level 3.88 and 2.55 hp/ha and Indonesia ranked last with lowest machination level 0.47 hp/ha. The total number of equipment available per 1000 hectare of rice cultivated area was other country comparison factor and gave us new order according to the availability of machines. For the different policies in South and Southeast Asia, each country has its own policies and supporting institutions which can push these policies to achieve favorable level of mechanization, some countries were able to do and reached a good level in mechanization by dint of these policies. 1. Introduction Some of South Asia countries like China and India have significant development in adopting farm mechanization. Southeast Asian countries like Bangladesh, Cambodia, Thailand and Vietnam are adopting limited advanced machinery in farm and post-harvest operations. In the other countries, agricultural mechanization is still in the developing stage. In these countries farmers still use inefficient manual tools which resulted in low production. For instance, in Nepal, the land size is small, which has prevented farmers to adopt large machinery. Lack of appropriate machineries to conduct various farming operations has left farmers with no choice but to continue with traditional farming techniques (Soni and Ou, 2012). Countries under study have different demographics and land use trends as clear from data provided by the Economic and Social Commission for Asia and the Pacific (ESCAP), Food and Agricultural Organization (FAO) and The World Bank (Table 1) 1 Table 1 Demographics and land use trends in South and Southeast Asia countries Country Population (millions), 2011 (ESCAP, 2012) Population growth (annual average, %), 2005−10 (ESCAP, 2012) Agricultural land (% of land area), 2011 (world Bank)● Philippines 94.9 1.7 40.6 Cambodia 14.3 1.1 32.0 Indonesia 242.3 1.1 30.1 Bangladesh 150.5 1.1 70.1 Laos 6.3 1.5 10.3 Malaysia 28.9 1.7 24.0 Myanmar 48.3 0.7 19.2 Thailand 69.5 0.7 41.2 Vietnam 88.8 1.1 35.0 Sri Lanka 21.0 1.0 41.8 China 1347.6 0.5 55.7 India 1241.5 1.4 60.5 Nepal 30.5 1.9 29.7 Pakistan 176.7 1.8 34.4 * World Bank data from http://data.worldbank.org/indicator/AG.LND.AGRI.ZS/countries. FAOSTAT data from www.fao.org as of May 2013. Rice area harvested (2011), ha FAO* 4,354,160 2,776,510 13,244,200 11,800,000 870,000 673,745 8,051,700 10,990,100 7,513,700 1,060,360 30,116,900 36,950,000 1,481,290 2,365,000 The mechanization level/degree is used as one of the quantitative indices by which the mechanization degree of different operations within a limit can be assessed. Generally, there are three specific indices for the study and evaluation of mechanization in different regions. These indices include degree, level, and capacity of mechanization. Level of mechanization is total percentage of mechanized field operations and the power of machines employed in unit of field operation ( hp /ha) (Soni and Ou, 2012). As calculated by Almasi et al. (2000) , Mechanization level is, hp ha-1 = Total power / cultivated area, The Total power of existing tractors (hp) = Average nominal power of one tractor x Number of working tractors, Total real power of tractors = Total power of existing tractors x Conversion coefficient, According to the recommendations given by Almasi et al. (2000) the conversion coefficient is 0.75 (The amount of this coefficient is variable according to the ASABE (2006) Standards from 0.45 in soft soils to 0.8 in hard soil which the coefficient 0.75 is recommended. the term mechanization degree is used to show and measure the percentage of using mechanization in specific operation. Also helpful are indices of energy inputs per ha and the value of power utilized per working hour. But, the level is appropriate choice and subsequent proper use of mechanized inputs into agriculture as long as it contain various field performance parameters of the farm machineries and implements and has also a direct and significant effect on achievable levels of land productivity, labour productivity, the profitability of farming, the sustainability, the environmental and, on the quality of life of people engaged in agriculture (Khambalkar et al., 2012; Olaoye and Rotimi 2010). Advanced models also are available to estimate mechanization indicators e.g. Mechanization Index (MI) and Machinery Energy Ratio (MER), to develop such models, data from different farming system to be obtained from farmers, agricultural machinery suppliers, researchers and government officials (Ramírez et al., 2007) . Gyanendra Singh (2007) has been suggested a mechanisation index based on the ratio of cost of use of machinery to the total cost of use of human labour, draught animals and machinery for estimation. For the assessment of this mechanisation index, and to study its impact on yield, cost of cultivation and 2 deployment of human and animal power, crop-wise secondary data have to be adopted from the cost of cultivation of principal crops. As the mechanization related data coming from south and Southeast Asian countries still not have a sufficient information regarding to the actual cultivation systems, trend in use of farm-power, the matrix of energy sources and time dimension etc., even the simplified mechanization level (farm power intensity (hp/ha)) is not available for certain number of countries, we have to use the limited available data which mainly reflect the number of different machines being used in these countries beside the demographics and land use trends as comparison keys between the countries. 2. Methodology Data available and related to mechanization status and its supporting polices in different South and Southeast Asian countries has to be collected from different reliable sources. These sources may include and not limited to governments, international organizations, projects and scientific journals. This data has to reconstructed in tables and figure and up to date to be in easy and in suitable way to represent the actual situation of the mechanization and its policies in the countries. Within these data both number of farm machinery which being used in rice production and the farm power intensity (mechanization level) for each country, are to be comparison keys among countries. According to the availability of mechanization levels, the comparison will include all of them and excluding the countries which don have current or past available number regarding to the mechanization level. Both maximum value of mechanization level and the average will be considered in comparison. The data which represent number of different pre/post-harvest machines in each country will be used to generate some other indicator of mechanization level, e.g number of tractors/100 ha, equipment/ 1000 ha, equipment / 10000 people involved in agriculture etc.., in this study we will have one indicator which express the total number of available machines for 1000 hectare (No. equipment/1000 ha) as an example. 3. Status of mechanization and its supporting policies in South and Southeast Asian countries 3.1 Philippines 3.1.1 Mechanization status: In general, the transfer of agricultural mechanization technology has been a very slow process. The level of mechanization in the Philippines, in terms of available mechanical power in the farm was around 0.52 hp/ha in 1990 (RNAM, 1994), This level of agricultural mechanization is relatively low and such low level of mechanization was one of the primary reasons which prevented rice production from achieving maximum yield (Committee Affairs Department, 2009). However, different authors cited that level of agricultural mechanization in 1994 was 1.69 hp/ha (Rodulfo and Amongo, 1994). Recently, the latest survey by the Philippine Center for Postharvest Development and Mechanization (PhilMech) showed that the mechanization level of farms in the Philippines is from 1 to 1.23 hp/ha, rice had the highest level of available farm power at 1.6 to 2.31 hp/ha ( PhilMech, 2011). The production of rice is relatively more mechanized than other crops. The level of mechanization for land preparation and threshing operations are intermediate to high while milling is highly mechanized (Suministrado, 2003). Other operations like planting, harvesting and drying are in the low level of mechanization. Land preparation is mechanized mostly through the use of power tiller and may be due to 4WT little usage. Mariano et al., (2012) cited that 13 % of farmers use machines in land preparation and harvesting and 65 % of them thresh rice right after harvest as postharvest management. Pumps are widely used to facilitate irrigation. About 47 percent of rice produced is threshed with the power threshers while 98 percent of the rice farmers bring their crop to rice mills. Fig. 1 presents the level of 3 mechanization in selected rice production operations and the percentage of mechanization in each operation in 2005 as mentioned in Philippines’ Country Report (Elepaño et al. (2009). In addition to figure 1, data collected from different sources also showed that planting, weeding, fertilizers application, spraying and field drying don’t have any visible mechanization levels. For harvesting and drying, the availability of dryers is some places makes level of mechanization around 0.15 hp/ha for both harvesting and drying, Suministrado (2008) mentioned that using flatbed dryer with capacity from 1 to 6 ton/batch used to dry 14% of total rice produced in the country and the other 86 % have been sundried. Fig. 2 shows the number of different machines used in rice production within the Philippines from different available sources. Fig. 1 Level and % of mechanization in rice production system in Philippines Fig. 2 Number of available machines for rice production 4 3.1.2 Supporting policies: There are many government agencies and institutions involved in research and development of agricultural mechanization in the Philippines, e.g. PHilMech and the Philippine Rice Research Institute (PhilRice), and they co-operate for implementation the rice mechanization programs. Also, the Institute of Agricultural Engineering (IAE) in College of Engineering and Agro-Industrial Technology (CEAT) under University of the Philippines (UPLB) which established The Agricultural Mechanization Development Program (AMDP) in 1979 to implement the research, development and extension activities in agricultural mechanization. AMDP has tackled various activities that contribute to government efforts of increasing agricultural productivity and improving farmers’ income. AMDP had developed, designed, tested and promoted affordable farm machinery for farmers; conducted technology and information dissemination through, pilot testing, demonstration of machines, exhibits, publication; and conducted training for different target beneficiaries. Most of government agencies involved with international and regional institutes and organizations e.g. International Rice Research Institute (IRRI), The United Nations Economic and Social Commission for Asia and the Pacific (ESCAP) etc. At present, most of these programs continue to perform they role to improve the status of the Philippine agricultural mechanization sector (AMDP, 2002). Recently the Philippines approved the Republic Act No. 10601 otherwise known as the Agricultural and Fisheries Mechanization (AFMech) Law on January 2013. The law mandates the state to promote the development and adoption of modern, appropriate and cost-effective and environmentally-safe agricultural and fisheries machinery and equipment to enhance farm productivity and efficiency in order to achieve food security and safety and increase farmers’ income. Under the Act, the Department of Agriculture (DA) will craft a five-year National Agri-Fishery Program to promote a conduciveenvironment for the local assembling and manufacturing of equipment for agricultural and fisheries production, processing and marketing. also the use of renewable and nonconventional energy such as wind, solar, hydro, biomass and other farm-based energy sources shall be promoted as power sources for the operation and maintenance of agricultural and fisheries machinery. The law in his different articles focused on strengthening the agricultural engineering groups and institutions, enhancing local assembling and manufacturing system, standardization and accreditation and many other issues which improve the mechanization situation in the country (The Official Gazette, official journal of the Republic of the Philippines, 2013) 3.2 Cambodia 3.2.1 Mechanization status In Cambodia rice is standing as the major and main crop with the yield of slightly over 3 ton/ha, almost 70% of the total population is involved in agriculture; however, the productivity is still low due to the late adoption of proper mechanization solutions in some of rice production operations, even though the four-wheel tractors have been used in Cambodia since the late 1950s, irrigation Pumps, two wheel tractors and more than 250 engine-powered threshers also have been used in some places before 1995 (Rickman et al, 1997). Fig 3 shows data related to number of 4-wheel tractors, hand tractors, threshers & milling machines, water pumping engines and harvesting machines (MAFF, 2013, Chan Saruth, 2011 and vichet, 2013). There is fast increment in the use of combine harvesters, 2WT and water pumping engines, the number of these machines increased by 68, 30 and 23 % respectively within 2 years from 2010 to 2012 (Fig 4). Also, Plowing done by tractors and mechanical tiller reached 64% of the total cultivated area and in dry season, mechanical plowing reached 91%. (MAFF, 2013). 5 Fig 3 Number of 4-wheel tractors, and 2-wheel (hand) tractors, threshers & milling machines, pump engines and harvesting machines. Fig 4 Increase in selected rice production machines within two years (2010 to 2012). Post-harvest technology and activities in Cambodia reached a good level, Well founded rice milling technology has been established within the country, There are 27,407 rice millers registered by the 6 Ministry of Industry, Mines and Energy of Cambodia (MIME) (MIME, 2011), and the annual range in milled rice capacity varies widely from 1 to 48,000 ton, this level arose from the different post-harvest products and efforts which have been introduced by projects, government and private sector, in some project sites; 25% of farmers used improved postharvest technologies in 2012 and postharvest losses reduced by 5% in 2011(Gummert, 2013). 3.2.2 Supporting policies No clear or separate policies to boost the mechanization level in Cambodia, mechanization comes under the general agricultural strategic development plans, The Ministry of Agriculture, Forestry and Fisheries (MAFF) has formulated an Agricultural Sector Strategic Development Plan 2006-2010 outlining seven priority goals, and they constraints and actions to be taken to reach these goals. These include: 1) food security, productivity and diversification; 2) improving and strengthening agricultural research and extension systems; 3) market access for agricultural products; 4) institutional and legislative development framework; 5) land reform, land tenure and pro-poor land access; 6) fisheries reform; and 7) forestry reform. (Vuthy and Ra, 2010). Within Priority areas for action to promote the development of the agricultural sector, Chao Lay, (2009) mentioned the research on agricultural technology as long term development objective and also mechanism for making sustainable agricultural progress. New technology activities would focus on the establishment of sample agricultural mechanization center, training in agricultural machinery, import of new agricultural machinery/equipment; and agriculture land rehabilitation in some provinces bordering with Viet Nam and Thailand. MAFF with FAO has restructured its organization based on government reform policies. The restructured organization has a vertical management system. The important feature of the newly reformed organization is that some entities would become public enterprises, with autonomous management. Provincial Agricultural Departments and District Agricultural Offices would have to manage and strengthen their basic units to carry out effective and timely technology transfer as well as other tasks, however, still Cambodia Agricultural Research and Development Institute (CARDI) and the Department of Agricultural Engineering/Machinery is undertaking several activities including agricultural machinery management and production with contribution of education and extension of agricultural mechanization which made the using of mechanization of rice production is increasing from 16% to 63% of the total rice cultivation area (Pech, 2013, Chao Lay, 2009 and DAE, 2008). In addition, advanced rice production and post-harvest technology e.g. laser leveling, direct seeding, drum seeder, Chinese cultivator drill model, Indian limit plot drill, hermetic storage, dryers and rice mills have been introduced to the farmer through ADPIRRI project, CAVAC project, CARDI, Department of Agriculture Engineering and the private sector. 3.3 Indonesia 3.3.1 Mechanization status Agricultural mechanization had been used by farmers intensively to speed up land preparation, pest control, harvesting and processing of rice product. However, in some areas, manual labor is still being used in rice production. The number of agricultural machinery is still relatively small compared to agricultural land area. This is mainly because of the low affordability of farmer to buy agricultural machinery and lack of knowledge to operate agricultural machinery. Currently, the level of mechanization in the country varies from low to high primarily in rice cultivation, ranging from 10% to 90% depends on the intensity of the farming system, common figure indicates its average level of 30% (Handaka, 2005), in addition, The total power available per hectare of rice cultivated area was 0.41 hp/ha (RNAM, 1994), and it increased from 0.37 hp in 1997 to 0.47 hp in 2006 with an average 7 growth of 4.97% per annum. During the same period, the stage of rice mechanization process has also been relatively low of about 4.7 hand tractors/1000 ha of cultivated area and still below the take-off stage in critical point of the mechanization process (Paman et al., 2012). Table 2 provide number of machinery in three different years for different authors, as the number of two hand tractors and rice mills increased, we found number of some other machines decreased like water pumps and dryers. Table 2 Changing in number of agricultural machinery in Indonesia from 2001 to 2010. Machinery 2001 (BPS, 2002) 2002 (BPS, 2003) Hand tractor 4WT Pesticide applicator Irrigation pump Thresher (pedal and power) Dryer Rice mills 86,644 NA 1,562,217 215,774 340,654 7,117 39,996 103,446 NA NA 216,643 347,658 5,045 46,123 2010 (Unadi, 2011) 126,453 2,969 NA 187801 201,241 (power only) 2,857 58,512 3.3.2 Supporting policies Various levels of policies and strategies have been established in promoting agricultural mechanization development to farmers, this development of agricultural mechanization have been done partially by involving government, agribusiness society, international organizations, consumers, farmers, agricultural machinery industry & producers and banking institutions, the government used to promote to foreign or domestic investors such “less technology but using as many as manpower instead”. This symbolic word is mainly to reduce unemployment and it is part of the government program, but now, Policy for agricultural mechanization development in Indonesia have been concentrated on increasing quality and added value of the agricultural products and its by products, promoting the opportunity of local agricultural machinery industry to produce better quality of the machines which are suitable to local conditions and to strengthen the collaboration among small, medium and large scale of agricultural machinery industry (Hendriadi and Alihamsyah, 2007; Unadi, 2011). Production of agricultural machine and equipment in Indonesia consists of units mainly engaged in assembling machinery for preparing and processing agricultural land for example, tractors and plough machines and machines for the first processing of agricultural crops (ICE, 2010). Most Efforts have been and still to be carried out to increase the number of machinery such as capital subsides for farmer group, revitalization of farmer group for leasing the machinery through Farm Machinery Service Unit, increasing the capacity of infrastructure and improving human resource capability on mechanization. 3.4 Bangladesh 3.4.1 Mechanization status Bangladesh is a proper mechanized country within South and Southeast Asia, and the history of Mechanisation in Bangladesh is in many ways a remarkable one, in which the government, international institutes and the private sector played important roles. (Justice & Biggs, 2010 ; Biggs et al., 2011). Early mechanization level was 0.40 hp/ha as mentioned by RNAM, (1994). Alam et al., (2005) cleared that the mechanization level reached 0.373 hp/ha only in 2005 but in 2008 it was 1.57 hp/ha (Islam, 2008). Table 3 presents current and past figure of some of farm machinery used in rice production system from different sources, in addition to that the projection numbers of 2 and 4 wheel tractors supposed to be 500,000 and 41,500 respectively by 2015 (iDE, 2012) Table 3 Farm machinery used in Bangladesh 8 4-wheel tractor 2006 + 12,500 2-wheel tractor 300,000 2008† 25000 350,000 NA About 30 NA 100● 175.000 185,000 NA 155,000 + About 40 NA NA NA 50 ● Deep tube well NA NA 33,670 □ Shallow tube well NA NA NA 1,549,149 □ Low lift pump NA NA NA 173,669 □ Sprayers NA 1,250,000 NA NA Item Combine Harvester Threshers (open and close drum) Reaper * iDE (International Development Enterprises), 2012 □ Hossain, 2011 + 2010 21,638 * 400,030 * 2011 26,369 * 420,027 * Roy and Singh, 2008 † Ahmed and Matin , 2008 ● Abdul-Wohab, 2011 In addition to above mentioned available numbers, there are 40,000 small and medium sized metal workshops producing different non precision machines (weeder, threshers etc.), also at present, the initial 2-WT based developments with zero tillage, single-pass shallow, full tillage, strip tillage and bed planting in Bangladesh were established (Haque et al., 2010) which maybe it is the reason that 80% of primary tillage operations are mechanized, performed mainly by 300,000 small 2WTs and a few 4WTs. But, it is anticipated that, in near future, a significant portion of 2-wheeled tractor use will be replaced by 4-wheeled tractor. In that case research and field work will be shifted to 4-wheeled tractor (Rashid et al 2007). As for part of post-harvest technology, rice milling is almost fully mechanized now. More than 30,000 small scale parboiling and milling establishments in addition to a few dozen larger automated mills are in operation. A large number of itinerant vendors are also taking rice-hulling services to the farmers’ homesteads. Also, there are around 500 dryers have been used including mills dryer in Bangladesh in 2008 (Ahmed and Matin , 2008) 3.4.2 Supporting policies Agricultural mechanization is a major section in Bangladesh National Agriculture Policy; the government has devoted special importance to agricultural mechanization since they released the National Agricultural Mechanization Policy 1999 to encourage the use of machines in agriculture. Testing and standardization restrictions have already been withdrawn in the free market distribution system, as a result, the use of agricultural machinery has increased significantly and immense potential is created for further increase. In order to accelerate the current trend of agricultural mechanization, various facilities including exemption of import duties on agricultural machinery have been provided and the same will continue, serious steps have been taken to promote and speed up the process of agricultural mechanization (SDNP, 2013). Many Priority research areas identified by the Bangladesh Rice Research Institute (BRRI) for 2009-2015 and Agricultural Engineering Division of Bangladesh Institute of Nuclear Agriculture (BINA) for 2000-2010, these priority research areas included; direct seeding technology; development, modification and adoption of rice transplanter and combine harvester; research on postharvest loss assessment; development of small scale dryer and many other areas (Ziauddin and Ahmmed, 2010). 3.5 Laos 3.5.1 Mechanization status 9 Farm mechanization in general is low, there was almost no mechanization of production until late 1995, and mechanization of any aspect of production or postharvest processing was exceptional. By 1996 mechanization increased of both land preparation and threshing in the main lowland rice-growing area of the Mekong River Valley (MRV) (Schiller et al., 2006). In 1996 the number of tractor was just over 1000 unit and the rate of tractor use has increased slowly with 0.28 % annually between 1996 and 2006 (MAF, 2010) (Fig 5). Even with the low number of tractors, 90% of non–tractor–owning farmers acquired the use of tractor for tillage operation by custom hire, and about 70% of them paid by paddy due to lack of cash (Latmany, et al., 2008). For postharvest mechanization Laos has an estimated 18,000 rice mills. Survey of rice-mill owners in the six central and southern provinces showed that there are averages of three-to-four rice mills per village. Daily milling capacity ranges from a few hundred kilograms for smaller mills to more than 6 tons for larger ones, and most mills continue to rely on single- and two-stage milling processes (Tuntivate, 2011). Fig 5 increase in tractor use with 0.28 % annually between 1996 and 2006 in Laos 3.5.2 Supporting policies Mechanization activities in Laos are running now under the Agricultural Master Plan 2011-2015 which is being implemented by the Ministry of Agriculture and Forestry (MAF). This plan is based on the Agricultural Development Strategy (ADS) 2011 to 2020. This strategy provides the framework, the vision and the long term development goals of the Government for the sustainable development of the sector aiming at food and income security (MAF, 2010), as intermediate and short term priorities (2011-2013) MAF aimed to reduce the production cost and improve competitiveness of export commodities throw the expanded mechanization of on-farm production and enhancing the agriculture infrastructure related to post harvest handling, also to develop agricultural mechanization action plan with fiscal policy incentives for smallholder mechanization. 3.6 Malaysia 3.6.1 Mechanization status Rice production is considering highly mechanized operations that have reached good level in Malaysia, as Malaysian Agricultural Research and Development Institute (MARDI) cited. MARDI also introduced the precision farming technology in the major growing regions in the north, making use of 10 sensors to optimize inputs. The adoption of these technologies depends on the local condition and the skill of the farmer or the contractor/operator. The selection and adoption of machine size and weight in particular the prime movers and self-propel machines depend on farm and lot size as well as soil bearing capacity while the sophistication of the technology depend on the skill of the farmers or the service providers or operators (Ismail and Daud, 2012). Mechanized activities are including; land preparation, repair and bund construction, disc ridger, rotary bund former, primary and rotary tiller (rotovator), land leveling & smoothing, direct seeding, spreader, row seeder, and combine harvester. 3.6.2 Supporting policies The long term agricultural development in Malaysia is guided, among others by the National Agricultural Policy (NAP). The current policy, the NAP III, laid the foundation and strategies for a sustainable development of Malaysian agricultural and agro-based industries to meet global competition. It was in this document that specific reference to mechanization technology as an enabler to modernize the local agriculture and agro-based industry to overcome the critical labor shortage and low productivity on a sustainable basis was highlighted. The policy also identifies the areas of focus and underlined major technological gaps for the industry to be bridged through domestic R&D undertakings, technology prospecting and acquisition, adoption and adaptation (Rukunudin, I. H. 2009). 3.7 Myanmar 3.7.1 Mechanization status Farmers realized the huge benefit of using farm machinery since 1988; they began to use the agricultural machines like tractors, power tillers and power threshers for they own use and hiring to get extra income. They also used those tractors and power tillers with trailers as a means of transportation of farm products to other villages or to towns. That is the driving force to other farmers to buy and utilize those machines for multiple purposes as well. Later the private sector has started to be involved in the agricultural machinery by modifying and producing the machines for the cultivators . Fig. 6 Provide Current numbers of farm machinery in Myanmar during 2010/2011 (Maung, 2011). Fig. 6 Numbers of selected farm machinery in Myanmar 11 In addition to provided number of machines, Small-scale mechanical workshops and small industries producing the spare parts, Workshops also started to produce paddy threshers and spare parts themselves and water pumps but with limited quantity only. In addition, during 2011 about 20000 units of power tillers and 200 units of farm tractors, and its implements have been imported and distributed to farmers. 3.7.2 Supporting policies In Myanmar, there are three Ministries which are monitoring agricultural machinery industry in government sector, they are; Ministry of Agriculture and Irrigation (MOAI), Ministry of Industry (MI) and Ministry of Cooperative, Agricultural Mechanization Department (AMD) under the Ministry of Agriculture and Irrigation has started the production of agricultural machinery since 1993, AMD distributes the agricultural machines to farmers and provides tractor hire service to farmers through its 99 Tractor Stations and farm mechanization units which are located around the whole country. Three farm machinery factories were further established to produce power tillers and farm implements. Nowadays, these farm machinery factories manufacture various types of machines such as power tillers, mono wheel tractors, cultivating roller boats, threshers, paddy reapers, gasifiers etc. The most productive volume is that of power tillers and is annually about 4000 units (Maung, 2011). 3.8 Thailand 3.8.1 Mechanization status Mechanization consider an important input for Thailand’s agricultural production system, it is rapidly expanding with both increases in number and size of machinery in use. Mechanization has been moving from power intensive to control intensive machines. The population of power tillers, irrigation pumps and power threshers has become almost stable, but the number of rice combine harvesters has been increasing rapidly (Thepent, 2012). The mighty matter in Thailand is the most equipment used by the farmers is produced locally such as, tractor, power tiller, disc ploughs, disk harrow, water pump, sprayer, threshing machine, reaper, combine harvester, cleaning equipment, dryer, rice milling machine and processing equipment etc. also, the diversity in using such machine has been established e.g. for dry land soil preparation mainly large four-wheel tractors with disc tillers are used while locally made power tillers (8-12 hp) are popularly used for the wetland cultivation. The only available mechanization level was 0.40 hp/ha as mentioned by RNAM, (1994) and no official level released after that. NSO (National Statistical Office) published the 2008 Agriculture Intercensal Survey results including the following numbers of farm machines being used in rice production and number of produced machines every year (Table 4), in addition to 93,000 of small and large tillage implements have been produced also locally. Table 4 number of machines being used in Thailand and the yearly local production (NSO, 2010) Machine Number in use Locally manufactured per year Tractors a- 4WT 287,225 NA b- 2WT 2,644,982 80,000 Threshers 32,239 2000 Planters/seeders a- Manual 332471 b- Engine 58,176 NA c- Attached to 2WT 111,384 d- Attached to 4WT 77,825 Combine harvesters 41,143 600 Rice mills 56,536 NA 12 Water pump a- Engine b- Electric motors c- Natural energy Sprayers (total) NA: not available 1,615,692 406,666 13,158 3,087,035 55, 000 (Total) 60,000 (Sprayer with hand operated) In rice fields; disk plow, two-wheel tractor, four-wheel tractor, rotary tiller, moldboard plow, disk plow, disc harrow, spring-loaded cultivator, rotary tiller, combine harvesters are used widely. Transplanting, broadcasting and direct seeding are common practices in Thailand also. In post-harvest, Thailand has large modern technology for drying and highly competitive capacity mills, new technologies exist that might address some problems in the postharvest chain, hermetic storage for example could help improving seed quality leading to better milling outputs and reduced losses. Laser leveling of land would lead to better paddy quality and again to higher milling outputs (IRRI, 2010). 3.8.2 Supporting policies The general objective of developing the agricultural sector is to improve capacity to compete in agricultural production by promoting the replacement of human labour by agricultural machinery. The Government policies and strategies relate to agricultural engineering are focusing more on Promote agricultural development based on the “New Theory” as an important alternative for small farmers; at the same time, expand opportunities for product development and improve product quality through the use of technology, management and access to markets; That’s why Thailand keep promoting research and development in industry by better Joint Corporation with researchers in universities and National Science and Technology Development Agency which reflected into better mechanization situation in the country, Thai Government always give attention to the mechanization development plans; starting from eighth plane to currently running eleventh plane which mainly concentrate on improving the capacity to compete in agricultural production by promoting the replacement of human labour by agricultural machineries (Soni and Ou, 2010). 3.9 Vietnam 3.9.1 Mechanization status Since 2001, there was continuous increasing in mechanization and the number of machines used by the farmers, By 2009, there were nearly 500,000 tractors of all kinds with a total capacity of about 5 million horsepower (hp), an increase three times higher than in 2001, including two-wheeled tractors under 12 hp accounted for 65%, tractors over 12 to 35 hp 27%, a large tractors (over 35 hp) accounted for 8%, the number of combine harvester and threshers was 256, 422 as calculated by FAO in year 2000. National average of power equipped level is 1.2 hp/ha of cultivated land (another mechanization level was 1.56 hp/ha as cited by PhilMech, (2011)), table 5 presents average rate of mechanization in rice and agricultural production activities are as (Viet, 2012): Table 5 average rate of mechanization in Vietnam rice and agricultural production activities Rice production activities Mechanization Rate (%) Soil preparation for rice cultivation 72 Soil preparation upland crops 65 Active irrigation for rice 85 Transport in agriculture and rural 66 Rice drying in summer-autumn season in Mekong River Delta (MRD) 38.7 Rice harvester in MRD 15 Rice thresher 84 Rice milling 95 13 For post-harvest, the development and dissemination of flatbed dryer sin Vietnam recorded as successful story within the country, where it started in Long Nam University based on IRRI design and continued in the Mekong Delta from 1990 to 2011 (Nguyen, 2012). Recently, Hermetic Seed Storage (HSS) also known as the IRRI Super Bag, laser leveling and rice quality tool and other post-production technologies have been introduced to Vietnam by IRRI Scientists and achieved good economic impact (Gummert et al. 2006 ; Gummert 2012a ; and Gummert 2012b). 3.9.2 Supporting policies Since 2004, Vietnam government has issued policies to support farmers to buy machines for agricultural production using budget’s provinces. 30 provinces and cities implemented the supporting policy. Another financial policies like tax has many changes; For ASEAN countries: tax rate since 2010 for imported agricultural machines is 0%, or 5% in some cases: the government also gave priorities to investment under the Key Program of Mechanization to manufacture more tractors and agricultural machines (Viet, 2012) 3.10 Sri Lanka 3.10.1 Mechanization status A lot of the farmers still practice traditional/hand broadcasting, application of chemical herbicides and harvesting in some parts of Sri Lanka but in other parts specially lowland and highland in the country, Power tiller with rotovator is the commonly used as land preparation machine also four wheel tractors with disc plough or tine tiller are used. The population of four wheel tractor is considerably lower than the power tiller population. The riding type 12 hp tractor versions is the most popular power tiller because of its riding facility and comparatively high field capacity. For harvesting and threshing, In the Eastern province where the rice cultivation is done extensively in large size plots, the majority of the farmers use large scale combine harvesters imported mainly from India, number of threshers and harvesters recorded from 2001 to 2007 varied from 112 to 153 and the different number of other machines involved in rice production are presented in Fig. 7 as estimated by FAO. In some places within the country; reaper, windrower and backpack type modified brush cutter is used in paddy reaping followed by combine thresher for threshing. Though, the use of dryers is necessary after use of combine harvesters but appropriate dryers are not available yet. The Institute of post-harvest technology has introduced new dryers and effective storage systems for rice but there are no indicators about usage or efficiency of such dryers (Bandara, 2012). The national mechanization level was 0.58 hp/ha (RNAM, 1994). 14 Fig. 7 Number of two wheel tractor, Plough and seeder available in Sri Lanka in different years according to FAO 3.10.2 Supporting policies There are many acts in effect in the field of agriculture like seed certification act, plant protection act, and land use act etc. A draft of farm machinery act has been prepared and submitted to the Ministry of Agriculture in order to get approved by the government. The purpose of The Farm Machinery Act is to regulate the sale and distribution of Farm Machinery or parts. The Act is applicable to leases as well as sales. The Act provides legal guidelines for warranties, sales contracts, emergency parts service and compensation claims. It will protect farmer, distributor, dealer and environment (Bandara, 2012). The National Testing & Evaluation centre, Farm Mechanization Research Centre of the Department of Agriculture is entrusted to conduct tests and certify the appropriate farm machinery. At present, the certificate issued by FMRC is not a compulsory requirement for import and distribute farm machinery. However most of the machinery suppliers are volunteered to get tested their products in order to verify the performance. Combination of the test codes and procedures formulated by RNAM, Indian Test codes and Japanese test codes are being used in testing of the machines. There is agro machinery/ equipment providing project as one of many projects were being implemented in Sri Lanka recently. These projects are funded by international Donor Agencies (IFAD, FAO, AUSAID, JICA, EU, and WFP) and Government of India, Australia, Korea and Japan. Such projects are implemented by the Ministry of Agriculture itself or by the Ministry of Agriculture and various PCs under the Ministry of Agriculture. In 2011, distribution program of Agro-machinery and equipment being received as Japanese Grant to ensure the food security of less privileged farmers (Ministry of Agriculture, 2012) 3.11 China 3.11.1 Mechanization status China is one of well mechanized countries in south and Southeast Asia, the earlier mechanization level by RNAM, (1994) was 3.88 hp/ha, China has Continuous optimization of agricultural equipment structure; large and medium tractors; transplanters and combine harvesters. Combine harvesters increased respectively each year. Now tillage planters reached beyond 0.6 million, the acreage of 15 conservation tillage has reached more than 4.3 million ha. Rice production mechanization got a large development where planting machines and harvesting level reached 16.7% and 56.7% respectively in 2010, which represented 2.4 percent and 5.8 percent improvement each year separately (Hongwen, 2012), now planting machines and harvesting level reached about 20.86 % and 64.49 % as for last mechanization survey in Agricultural year book 2012, table 6 provides the available number of some of rice production machines and also the produced number in year 2011 (Agricultural Year Book, 2012 and China Statistical Yearbook, 2011) beside the estimated numbers by FAO in 2001. Also, China has the supporting technology related to drying technique and equipment by combining mechanical drying and in-store drying, energy-saving dryers such as heat pump dryer are actively promoted to be applied in the rice drying process. In general, Lingyun (2011) cleared that in 2009 China’s rice processing capacity was 190 million tonnes, there were 2661 rice processing enterprises with a daily processing capacity of more than 100 tonnes of which 153 had more than 400 tonnes capacity. Table 6 available number of selected rice production machines in 2001 and available with produced number in year 2011 Number in 2001, million Available number in 2011, Produced units in 2011 Farm machine by FAO million Power tiller NA NA 50,495 Tractor (all sizes) 13,689 21,7796 18,233 rice transplanter NA 0.333 23,361 Power cultivated for paddy NA NA 29,485 Power sprayers Water pump Combine harvesters Rice drier NA NA 0.2321 NA NA NA 0.9921 NA 110,504 98,167 9,768 31,942 3.11.2 Supporting policies Agricultural mechanization is part of national economic development strategy in china, according to the study of Shen ad Wang (2008), in order to achieve modernization, the following targets must be achieved by 2020; agricultural mechanization level to be 70 per cent, farming scale per agricultural labor force to be 1.6 ha, total farm power should be <1 billion kW and extend areas of technology innovation to new machinery development for post-harvest processing. Now series of policy incentives to support the agricultural machinery sector and subsidies for the purchase of farm machinery (From 2006 to 2010, 9.6 billion RMB of subsidy investments from central government promote 70.0 billion RMB investments from local governments and businesses), the agricultural machinery industry in China witnessed one of rapidest development. Currently, more than 20 provinces in China have established research institutes of agricultural machinery, which have become the backbone of technology innovation and research and product development. In universities, there are research institutes specialized in technology research, agricultural machinery design and training (Soni and Ou, 2012). 3.12 India 3.12.1 Mechanization level: India has a long history in the development and promotion of tractors and a tractor industry. India is now the number one producer of 4WT in the world, (Radjou, 2009) and also number one in sales of tractors and power tiller with 607,000 and 60,000 unit respectively during year 2011/2012 (DCA, 2013). Today, there are over 20 factories producing nearly 300,000 tractors per year with an estimated total population of 4WT of 2.8 million (More than 50 per cent of tractors in < 60 hp category is 16 produced in India (Singh and Mani 2009). During 1981, the average farm power available was about 0.63 hp/ha which increased up to 1 hp/ha in 1990 (RNAM, 1994) and up to 1.96 hp/ha in 2005 comprising of about 84 per cent from mechanical and electrical sources and 16 per cent from animal power and human labour. Now it is estimated that average farm power available India will increase up to 1.9 kW/ha (2.55 hp/ha) by 2011-12 (Sidhu, 2011). Interestingly, India's agriculture is far less mechanized than its neighbors Bangladesh and Sri Lanka, where Chinese engines and equipment are used. While India has 22% of its area under mechanized tillage Bangladesh and Sri Lanka both have about 80% (Kulkarni 2009). While India's agricultural conditions are far more diverse than Bangladesh and Sri Lanka, some of this lower level of mechanisation can be explained by the small numbers of 2WTs in India. There are only 110,000, which is a third of the number in Bangladesh. Fig. 8 show variations in number of 4WT, 2WT and combine harvester & threshers in India from year 2001 to 2003 according to FAO. The development and utilization of laser leveling is most advanced in India where IRRI supported development and training, research, and on-farm trials in four states in 2001/2002 (Gummert et al. 2012b). Laser leveling has been adopted on approximately 200,000 ha (Jat et al. 2009) and the benefits of laser-assisted leveling for farmers in India are well documented. Fig 8 Number of two and four wheel tractors and combine harvester & threshers in India in different years according to FAO 3.12.2 Supporting policies No doubt that level in mechanization in India would be not able to reach that limit without the adequate and proper policies, The Government has laid emphasis to provide financial assistance to the farmers and other target groups for purchase of different kinds of farm equipment, demonstration of new equipment among farmers for spread of new technology, human resource development in operation, maintenance/ repairs and management of agricultural machinery, one of the latest important policies exist and in effect is the Twelfth Five Year Plan (2012–2017), it came with title; Faster, More Inclusive and Sustainable Growth and has new strategy for promoting farm Mechanisation. A dedicated Sub-Mission on Agricultural Mechanization has been proposed for the XIIth Plan which includes custom-hiring facilities for agricultural machinery as one of its major components. The SubMission aims at catalyzing an accelerated but inclusive growth of agricultural mechanization in India. Its focus is on increasing the reach of farm mechanization to small and marginal farmers and to the 17 regions where availability of farm power is low. Custom hiring of farm machinery envisages promoting establishment of farm machinery banks for custom hiring by way of providing financial assistance to individual self-help groups or farmers’ co-operatives since the prohibitive cost of hi-tech and high productive equipment renders it difficult for individual ownership. The other major components included in the Sub-Mission, apart from custom hiring facilities for agricultural machinery are promotion and strengthening of agricultural mechanisation through training, testing and demonstration; post-harvest technology and management (PHTM); financial assistance or procurement subsidy for agriculture machinery and equipments; establishment of farm machinery banks for custom hiring; enhancing hi-tech, high productive equipment hub for custom hiring; enhancing farm productivity at village level by introducing appropriate farm mechanisation in selected villages; and creating ownership of appropriate farm equipments among small/marginal farmers in eastern/north eastern region. And now many agricultural equipments being used in rice production are available on subsidy under Central Sector Plan Schemes (NIC, 2013). 3.13 Nepal 3.13.1 Mechanization status The available mechanical power in Nepal up to 2006 was only 23 % and Most of the mechanization activities are concentrated in Terai region where 92.28% operation is mechanized out of total available mechanical power of Nepal (FBC, 2006). Mechanization level increased from 0.3 hp/ha in 1990 (RNAM, 1994) to 0.84 hp/ha (Salokhe and Ramalingam, 1998), but it was 0.52 hp/ha as mentioned by Iqbal Hossain (2009). Number of 2 wheel tractors, 4 wheel tractors, threshers, pump-sets and biomass stoves in Nepal in 2001, 2008 and 2009 are presented in table 7 (Source Pariyar et al. 2001; Biggs and Justice, 2011; FAO). Table 7 Number of 2-wheel tractors, 4-wheel tractors, threshers, pump-sets and biomass stoves in Nepal. Item Number of each item in 2001 FAO, 2008 Number of each item in 2009 (Pariyar et al. 2001) (estimates by Biggs and Justice, 2011) Four Wheel tractor 17,500 28,971 34,000 Two-wheel tractor 1,000 8,901 11,000 (NAEF, 2009) Pump-set 50,000 NA 100.000 Rice Husk Stoves NA NA 50,000 Threshing machines NA 58,057 NA Since nineteenth Number of tractors being registered with the Department of Transport Management is increasing every year. Total number of four & two wheel tractors registered had reached 64164 in 2010/2011. Later, 2WT, reapers, diesel pump sets, combine harvester and thresher have been used but in specific places within country. (Shrestha, 2012). The rice sheller, polisher and mechanical grinding mills are found to be adopted in majority of villages of terai and hills. However in the mountains, still the milling is found to be performed in local devices such as mortar & pestle, quern and traditional water mills. Attempts have made to improve more than 2000 local water mills by changing the wooden runner in to metallic one to increase the grinding capacity and to derive power for multiple processing operations (viz. hulling, oil expelling etc.). 3.13.2 Supporting policies Government of Nepal didn’t support separate policies towards the mechanization; mostly with help of donors they have been promoting engines and pump sets from India. The long open boarder with India poses a particular agricultural engineering policy. The lack of policy analysis in this area, going back to the exclusion of agricultural mechanization from the Agricultural Perspective Plan of the late 1990s, has meant, in effect, a policy of facilitating an Indian agricultural mechanization policy in Nepal. As 18 we have seen commercial and engineering interests of India have been promoting their technology in Nepal for years. Whether, 4WTs, combined harvesters, large heavy pump sets are the best choices, from a national development perspective needs investigating (Biggs and Justice, 2011). The recent experiences of the spread of Chinese engines and equipment, and the spread of other technologies from other countries, almost by chance, rather than as a result of government and donor policies to investigate and promote a wide range of relevant engineering options suitable for Nepal, leads us to conclude that agricultural engineering and rural engineering more broadly, needs to come into the centre of Nepal's energy and development policy debates. Policies and regulations to promote decentralized hydroelectric generation and other alternative energy sources will be important for rural development. (NCVST, 2009). 3.14 Pakistan 3.14.1 Mechanization status Total power available in the country is estimated to be 1.2 hp/ha in 1990 (RNAM, 1994) and same level has been cited again by PhilMech (2011), Tractor contribute about 70.4 % of the farm power available, No. of working tractors reached 439,741 unit in 2006 as FAO estimated number. Most of harvesting activates are not mechanized, Harvesting 50% area of paddy by head-feeding track tube combine harvesters, Table 8 present the number of machinery have been used in Pakistan in 1994 and 2004 including combine harvesters (Amjad, 2006). And according to the same author, there were 228 rice mills in the year of 2000/2001, however, most of post-harvest operations are not mechanized; therefore the losses are high and in a significant level. Table 8 Number of machinery have been used in Pakistan in 1994 and 2004 Item Number of each item in 1994 Tractor° Combine Harvester Reaper Grain Drill/Planter Number of each item in 2004 252,861 401,663 859 6,000 7,972 NA 64,126 70,810 ° It was not clear from the report that the number represents four or two wheel tractors. 3.14.2 Supporting policies Mechanization policies mainly are covered by Pakistan's environmental policy and management framework which is based on the Pakistan environment protection act 1997 (PEPA), also government ten years perspective development plan 2001-2011/ 2012-2022 and the three years development program presents the strategies to be undertaken to develop post-harvest technologies. National Board for Agricultural Mechanization (NBAM) headed by the minister of food, agricultural and livestock was set up in 1981 with the mandate of advice the government in the formulation of agricultural mechanization policies and strategies. NBAM has established two committees namely, farm mechanization promotion and farm machinery standardization committee; these are responsible for introduction of suitable farm machines and development of machinery standards (Amjad and Anwar, 2003). 4. Analysis, conclusion and results a. Multi-country, cross-national comparison of mechanization level 19 It is clear that there are different mechanization levels in different years for most countries in South and Southeast Asia; some of these levels have been cited long time now and the other cited in recent years, beside the mechanization level for Cambodia, Laos, Malaysia and Myanmar are not available yet. The cumulative available mechanization levels for countries are presented in Fig. 9 with their cited year. To make a compression between them, both maximum available value of mechanization level and the average of different levels which linked to different cited years for each country have been calculated and presented in Fig. 10 The presented values showed two different country orders; first one is according to the maximum value we got and second order according to the average value obtained in different years. Fig. 9 Values of available mechanization levels for South and Southeast Asian countries Fig. 10 two different country orders according to mechanization index 20 In both orders and according to the mechanization level, China and India ranked first and second respectively, Indonesia ranked as last country with lowest mechanization index. To categorize South and Southeast countries according to mechanization level, and from the literature, three levels: low, fair, and high are common and used to present the mechanization degree. Also, we can consider them as mechanization levels categories if each category has certain range of mechanization level value i.e. first category will include countries with more than 2 hp/ha, second category for countries have from 1 to 2 hp/ha and last gadgetry (third one) will be for countries have less than 1 hp/ha as farm power intensity or mechanization level. According to this classification, countries in South and Southeast Asian will be in one of three categories as shown in table 8 and as the available mechanization level values. Table 8 south and South East Asian countries in categories according to the value of mechanization level Country category High (> 2hp/ha) Fair (1-2 hp/ha) Low (<1 hp/ha) With maximum available mechanization level China - India Philippines-Bangladesh Nepal -Thailand Vietnam-Pakistan Sri Lanka-Indonesia India-Vietnam Thailand Bangladesh- Sri Lanka-Nepal-Indonesia China With average of available mechanization levels Philippines-Pakistan And for sure, these categories are fixable with changing the value of mechanization level in each country or availability of these levels. b. Multi-country, cross-national comparison of rice production related machines The situation of available number of machines in each country is slightly better than the mechanization level, rice production related machines are partially available and cited in different years as shown in table 9. This table preset only available and latest number of selected machine exist in each country which may be related more to rice production system. Table 9 number of available different machines in South and Southeast Asia, rice harvested area and agricultural population Country Rice area harvested, ha (2011) Laos Malaysia Myanmar Thailand 2WT Threshers Combine harvesters Dryers Rice mills 100,955 (2011) - 51,287 (2011) 25,371 (2011) 31.24 14,390 (2010) 2,935 (2012) - 27,407 (2011) 9.42 - 88.24 9,306 (2012) 2,776,510 7491 (2012) > 1,000,000 (2001) 95,722 (2012) 13,244,200 2969 (2010) 126,453 (2010) 201,241 (2010) - 2857 (2010) 26,369 (2001) 9,222 (2006) 420,027 (2001) 155,000 (2001) 100 (2001) 500 (2008) - - - - - - - 3.24 - - - 32.35 41,143 - - 27.67 Indonesia Bangladesh 4WT Agricultural population, Millions in 2012 4,354,160 Philippines Cambodia Number of rice production related machines 11,800,000 870,000 673,745.00 8,051,700 10,990,100 - - - 11479 (2010) 287,225 199,668 (2010) 2,644,982 37,678 (2010) 32,239 21 30,000 (2008) 18,000 (2001) 66.24 4.75 (2008) (2008) 7,513,700 175,000 (2009) 325,000 (2009) 1,060,360 - 47,717 (2007) Vietnam Sri Lanka China 30,116,900 India 36,950,000 Nepal Pakistan 1,481,290 2,365,000 2,177,960 (2001) 2,532,900 279,300 (2003) (2008) 256, 422 (2001) - 130 (2007) - - 992,100 (2001) - - 55.90 9.05 - 2,661 (2011) 825.33 - - 596.69 - - 28.80 228 (2001) 75.15 423,700 (2003) 34,000 11,000 (2009) (2009) 439,741 (2006) (2008) (2003) 58,057 (2008) - - 859 (2001) The comparison based on above table also difficult because of the missing data in some countries regarding specific type of machines and also the different years when the machines have been cited. But in general, some indication values can be generated from the table and may express the situation in those countries e.g. available equipment/1000 ha of rice harvested land, and equipment /1000 capita of Agricultural population etc….. The missing data of machines in a country doesn’t mean that the machines not exist, but maybe because they haven’t been included in data collection processes yet. To see the trend of having rice production related machines and to arrange the countries in an order according to number of available machine being used, equipment/1000 ha of rice harvested land could be indicator. We assume that using machine is continues operation for many year and not even limited to the machine serviceable time in south and southeast countries. So, the total number of machine according to latest surveys and data will be related to the rice harvest area. After excluding Malaysia due to non-availability of machine numbers and also, avoiding not exact numbers e.g. 2WT in the Philippines, Fig 11 shows the court order as for number of available rice production machines. Fig. 11 Country order according to available number of equipment per 1000 hectare of rice harvested area It was clear that from fig that the country order according the number of equipment per hectare differed from the order related to the mechanisation level, that maybe because of the large number of 2WT 22 which is exist in some countries, while some other country depends more on 4 well tractors. Also, the big harvested area in both India and china may reduce the number of equipment assigned to this area compared to smaller areas in other countries. Many other indicators can be run from table, and every time, different order will come for south and Southeast Asian countries due to the huge variations we discussed. c. Number of tractor per 1000 ha of rice harvested land Country Tractor per 1000 ha of rice harvested land (Different sources) Tractor per 1000 ha of arable land (World Bank, 2009) 4WT 2WT Thailand 28.05 26.13489 240.6695 Vietnam 26.25 23.29079 43.25432 Pakistan 15.34 India 12.85 68.54939 7.558863 Philippines 11.68 2.137266 229.6654 Nepal 11.17 22.95297 7.42596 China 8.18 Myanmar 1.07 1.425662 24.79824 Cambodia 0.59 2.697991 34.47565 Indonesia 0.2 0.224174 9.547802 Bangladesh 0.12 2.234661 35.59551 Laos Not available 10.6 Not available Sri Lanka Not available Not available 45.00075 185.937* 72.31687* Numbers include both two wheel tractor and four wheel tractor Any comments? 23 References Ahmed, N. U. and Matin M. A., 2008. Farm Mechanization for Smallholder Agriculture in Bangladesh. Proceed Ings of the Regional Workshop on Farm Mechanization for Small Holder Agriculture in SAARC Countries. Organized by SAARC Agriculture Centre and CIAE, 22-24 September 2008, SAARC, Dhaka. Alam, M. S., Alam M. R. and Islam K. K., 2005. Energy Flow in Agriculture: Bangladesh. American Journal of Environmental Sciences 1 (3): 213-220. Almasi, M., Kiani S. and Louimi N., 2000. Principles of Agricultural Mechanization. Ma'soumeh (PBUH) Publication, Ghom, Iran. p: 19-40. AMDP (Agricultural Mechanization Development Program), 2002. AMDP brochure. Institute of Agricultural Engineering, College of Engineering and Agro-Industrial Technology, University of the Philippines Los Banos. Amjad, N., 2006. Agricultural Mechanization and Processing in Pakistan. Report 01, 2nd APCAEM GC/TC Meeting, 2006, Republic of Korea. Available at: http://uncsam.org/Activities%20Files/A23/Pakistan-RoK.pdf. Amjad, N. and Anwar, M. T., 2003. Country Report: Pakistani. Presented at 2nd Session of Technical Advisory Committee (TAC) of the Asia and Pacific Center of Agricultural Engineering and Machinery. Beijing, China. AMMDA (Agricultural Machinery Manufacturers and Distributors Association), 2012. Inc. established in the 1970s, it is the recognized spokesperson of the agricultural machinery industry. ASABE Standard, 2006. Agricultural Machinery Management Data. ASAE D497. 5FEB2006. Bandara, M. H. M. A., 2012. Mechanization status in Sri Lanka. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 - 9 December 2011. Bangkok, Thailand, P: 81-87. Biggs, S. and Justice S., 2011. Rural Development & Energy Policy Lessons from Agricultural Mechanisation in South Asia. ORF occasional paper #19. Observer Research Foundation, New Delhi, India. Biggs, S., Justice S. & Lewis D., 2011. Patterns of Rural Mechanisation, Energy and Employment in South Asia: Reopening the Debate. Economic and Political Weekly, Vol. XLVI, No. 9, pp. 7882. BPS (Badan Pusat Statistics Indonesia), 2002. Statistics of Indonesia. Central Bureau of Statistics. BPS (Badan Pusat Statistics Indonesia), 2003. Statistics of Indonesia. Central Bureau of Statistics. Chan Saruth, 2011. Cambodia Perspective on Rice Production and Mechanization in Cambodia. The Regional Seminar on Rice Production & Mechanization, 12- 13 December, 2011 Sanya, China. Chao Lay, 2009. Country Report Cambodia. Agricultural Mechanization and Agricultural Development Strategies in Cambodia. Fifth Session of the Technical Committee of UNAPCAEM 14-15 October 2009, Los Banos, the Philippines. Pp 16-21. 24 China Agricultural Year Book, 2012. General Surveys: Agricultural Mechanization, Information Center, Center for International Cooperation Services, Ministry of Agriculture, PRC. China Statistical Yearbook, 2011. China Statistics Press, National Bureau of Statistics, Jia 6, Xisanhuan Nanlu, Fengtai, Beijing 100073, People’s Republic of China. Committee Affairs Department, 2009. Low level of mechanization sets back agri-fishery production. HOUSE OF REPRESENTATIVES, 15th Congress of the Philippines. Volume 16, No. 35:18 February, 2009. DAC (Department of Agriculture and Cooperation), 2013. Farm Mechanization in India: Presentation. Mechanization and Technology Division, Dept. of Agriculture and Cooperation, Ministry of Agriculture. 2013 Farm Mechanization in India. Available at: http://agricoop.nic.in/presentation.html. DAE (Department of Agricultural Engineering), 2008. Agricultural Engineering in Cambodia. The report of Department of Agricultural Engineering, Ministry of Agriculture, Forestry and Fishery, Phnom Penh. Delfin C. Suministrado, 2008, History and status of Agricultural Mechanization in the Philippines, Paper presented at the 2008 Annual conference of the Philippine Association of the Japanese Government Scholars (PHILAJAMES). PHILAJAMES Leadership in Development. September 26-27, 2008, College of Social Work and Community Development, University of the Philippines Diliman, Quezon City, Philippines. Elepaño, A. R., Resurreccion A. N., Suministrado, D. C., Rodulfo Jr., V. A. and Larona, M. V. L., 2009. Country Report: Agricultural Mechanization Development in the Philippines. UNAPCAEM 5TH Technical Committee Session and Expert Group Meeting on Application of Agricultural Machinery for Sustainable Agriculture in the Asia-Pacific Region, Los Baños, Laguna, Philippines. ESCAP (and Social Commission for Asia and the Pacific), 2012. Statistical Yearbook for Asia and the Pacific 2012, Country Profiles, ESCAP Reference No.: ST/ESCAP/2647 Published Date: 6 November 2012. Available on http://www.unescap.org/stat/data/syb2012/countryprofiles/index.asp. FAOSTAT, data from www.fao.org as of May 2013. Gummert, M., 2012a. Postproduction Work Group. Presented at the Meta-Impact Assessment Gummert, M., 2012b. Lessons learned from postharvest and mechanization projects and ways forward. Workshop report, ADB Postharvest Projects, Postproduction Work Group, IRRC, IRRI. (unpubl.) Gummert, M., 2013. IRRI-ADP Postharvest Project Overview, Presentation. International seminar on postharvest losses, kemeara Battanmbang Hotel, Cambodia, 19 June 2013. Gummert, M., Rickman J., Kyaw M. A., Ben D. C., and Rachmat, R., 2006. Hermetically sealed storage systems for farmers and rice millers. In: Science, technology, trade and peace for prosperity. Proceedings of the 26th International Rice Conference, 9-12 Oct2006, New Delhi, India. 25 Gyanendra Singh, 2006. Estimation of a Mechanisation Index and Its Impact on Production and Economic Factors—a Case Study in India .Biosystems Engineering (2006) 93 (1), p: 99–106. Handaka, S., 2005. Agricultural engineering research and development in indonesia: challenge and prospect toward sustainable agriculture and APCAEM programme. Paper for APCAEM TC/GC Meeting in New Delhi, 21 – 24 November 2005, India. Haque, M. E., Esdaile R. J., Enamul K. R., Wendy V., Richard B. W., Musa A. M., Shahidullah A. K. M., Maruffuzama M. and Chris J., 2010. Minimum-tillage: mechanized sowing of pulses with two-wheel tractors. Proc. 19th World Congress of Soil Science: soil solutions for a changing world. Brisbane, Australia. 1-6 August 2010, published in CD, pp.156-159. Hendriadi, A. and Alihamsyah T., 2007. Sustainable and Development in Indonesia: Problem and Policies. Third session of TC and GC meeting of UNAPCAEM, Beijing, 20-23 November 2007, p: 1-10. Hongwen, L., (2012). Agricultural Mechanization Status and Context in China. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 - 9 December 2011. Bangkok, Thailand, P: 44-45. ICE (the Italian Institute for Foreign Trade), 2010. Indonesia Brief on Agriculture Industry and Agriculture Machinery & Equipment, Report. Italian Trade Commission – Jakarta. P: 5-7. Available at: http://www.ice.gov.it/paesi/asia/indonesia/upload/169/AGRICULTURE%20EQUIPMENT_BR IEF%20REPORT.pdf iDE (International Development Enterprises), 2012. Study into the Commercialization of Selected Agricultural Machines in Bangladesh. The report was commissioned for the Cereal Systems Initiative for South Asia (CSISA) and was made possible with the generous support of USAID. Report Submitted to International Maize and Wheat Improvement Center (CIMMYT), p: 3033. Iqbal Hossain, S. M., 2009. Agricultural Mechanization. University/college report Dept. of Agricultural Engineering, Bangabandhu Sheikh Mujibur Rahman Agricultural University (BSMRAU), Gazipur, Bangladesh Available at http://smiqbalhossain.faculty.bsmrau.edu.bd/files/2009/07/Chapter-1.-FarmMechanization.1.pdf IRRI (International Rice Research Institute), 2010. Establishing sustainable, resource efficient agrifood supply chains (IRRI Ref. No.: DPPC201022) Final Report: Resource efficiency and ecosystems services in rice production in Thailand’s central plain: Baseline research. Ismail, M. Z. and Daud A., 2012. Agricultural Mechanization Status & Issues – Malaysia. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 - 9 December 2011. Bangkok, Thailand, P: 53-55. Islam, Md. S., (2008). Farm mechanization for sustainable agriculture in Bangladesh: problems and prospects. BARI, Joydebpur, Gazipur, Bangladesh. Jat, M., Gupta R., Ramasundaram P., Gathala M., Sidhu H., Singh S., Singh R. G., Saharawat Y., Kumar V, Chandna P., 2009. Laser-assisted precision land leveling: a potential technology for resource conservation in irrigated intensive production systems of the Indo-Gangetic Plains. In: 26 Ladha JK, Yadvinder-Singh, Erenstein O, Hardy B, eds. Integrated crop and resource management in the rice-wheat system of South Asia. Los Baños (Philippines): International Rice Research Institute. 223 p. Justice, S. and Biggs S., 2010. Diverse Patterns of Rural and Agricultural Mechanisation in Bangladesh and Nepal: Status and Emerging themes; Section for a FAO book on Agricultural Mechanisation. Khambalkar, V. P., Ritesh Suman, Rathod C. V. and Gangde C.N., 2012. Assessment and Requirement of Farm Mechanization: A Case Study. Indian Res. J. Ext. Edu., 12 (3), p: 84-91. Kulakarni, S. D., (2009). Mechanisation of Agriculture - Indian Scenario: Presentation made to the 5th UN APCAEM Technical Committee and Expert Group Meeting on Application of Agricultural Machinery for Sustainable Agriculture. The Philippines, 14 - 16 October 2009. http://unapcaem.org/ppt/in200910-01-p1.htm. Lingyun, I., (2011). Rice Post-harvest Handling in China. Presentation: Workshop on Modernizing the Asian Rice Industry, FAO, Agricultural and Food Marketing Association for Asia and the Pacific. Bangkok, Thailand, 16-17 Feb 2011. MAF (Ministry of Agriculture and Forestry), 2010. Agricultural Master Plan 2011- 2015 for Laos. Final Draft, the Government's Strategic Vision for the Agricultural Sector, Vientiane, 15 September 2010. MAFF (Ministry of Agriculture, Forestry and Fisheries), 2013. The Mechanization of Cambodian Agriculture. Notes in meeting. provided by Agricultural Minister. Mariano , M. J., Villano R., Fleming E., 2012. Factors influencing farmers’ adoption of modern rice technologies and good management practices in the Philippines. Agricultural Systems 110 (2012) 41–53. Maung, K. K., 2011. Agricultural Mechanization Status and Context in Myanmar. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 – 9, December 2011. Bangkok, Thailand. P 56:59. Ministry of Agriculture, 2012. Performance Report in 2011. Ministry of Agricultural, Sri Lanka. MIME (Ministry of Industry, Mines and Energy), 2011. Statistic of Small Industries and Handicrafts 2009-2010, Cambodia. NAEF (National Agricultural Engineering Forum), 2009. National Agricultural Engineering Forum and the International Development Enterprises (IDE), Nepal. NCVST (Nepal Climate Vulnerability Study Team), 2009. Vulnerability Through the Eyes of Vulnerable: Climate Change Induced Uncertainties and Nepal's Development Predicaments, Institute for Social and Environmental Transition-Nepal (ISET-N, Kathmandu) and Institute for Social and Environmental Transition (ISET, Boulder, Colorado) for Nepal Climate Vulnerability Study Team (NCVST) Kathmandu. Nguyen L. H., 2012. On some factors promoting key stages of the progress of rice postharvest mechanization in the Mekong Delta, Vietnam. Paper presented at the workshop titled Lessons learned from postharvest and mechanization projects and ways forward, International Rice Research Institute, Los Baños, Philippines. 27 NIC (National Informatics Centre), 2013. New Strategy for Promoting Farm Mechanisation during 12th Five Year Plan Dedicated Sub-Mission on Agricultural Mechanisation Proposed. MP: DS:CP: mission (4.2.2013), Release ID :91981. Available at: http://planningcommission.gov.in/plans/planrel/12appdrft/appraoch_12plan.pdf. NSO (National Statistical Office), 2010. The 2008 Agriculture Intercensal Survey: Whole Kingdom, national statistical office. Ministry of Information and Communication Technology, Thailand. Paman, U., Inaba S. and Uchida S., 2012. Power Availability and Requirements for Small-Scale Rice Farm Operations: A Case in Riau Province, Indonesia. American Journal of Agricultural Science Engineering and Technology. Vol. 1 Issue 2, 27- 36. Pariyar, M. P., Shrestha, K. B. and Nara Hari Dhakal, 2001, Rice-Wheat Consortium Paper Series 13, Rice-Wheat Consortium for the Indo – Gangetic Plains, New Delhi 110 012, India. PhilMech (Philippine Center for Postharvest Development and Mechanization), 2011., Annual Report and newsletters, Central Office, Central Luzon State University (CLSU) Compound, Science City of Munoz, Nueva Ecija. Platmany, P., Shinkai S., Hotta, K. and Nanseki T., 2008. Agricultural Mechanization in Rural Area of Lao PDR: A Case Study of Farm Tractorization. J. Fac. Agr., Kyushu Univ., 53 (2), 593–599. Radjou, N., 2009. Polycentric Innovation: A New Mandate for Multinationals. The Wall Street Journal, November 9, 2009 Ramírez, A. O., Nakashima, H., Miyasaka J. and Ohdoi K., 2007. Mechanization Index and Machinery Energy Ratio Assessment by means of an Artificial Neural Network: a Mexican Case Study. Agricultural Engineering International: the CIGR EJournal, Manuscript PM 07002. Vol. IX. May, 2007. Rashid, M. H., Roy K. C. and Hossain M. M., 2007. Research and Development of Agricultural Machinery and Institutional Arrangement. In Proceedings of the National Workshop on Agricultural Mechanization. Bangladesh Agricultural Research Council, Dhaka. Rickman, J. F., Meas Pyseth, and Om Sothy, 1997. Rice production in Cambodia: Farm mechanization, Cambodia-IRRI-Australia Project, International Rice Research Institute Publication, BISBN 971-22-0100-7, CHAPETER SEVEN, P: 93-98. RNAM (The Regional Network for Agricultural Machinery), 1994. Report of the Regional Network for Agricultural Machinery. Economic and Social Commission for Asia and the Pacific, UN. Rodulfo, V. A. Jr. and. Amongo R. C., 1994. Farm Mechanization Study and Machinery Ownership Analysis in Region IV. Paper presented during the 44th PSAE Annual National Convention. Cagayan de oro City, Philippines. Rodulfo, V. A.; Amongo, RM, C.; Larona, MV. L., 1998 Status of Philippine agricultural mechanization and its implication to global competitiveness. Philippine Agricultural Mechanization Bulletin, 5(1):3-13. Romnea Pech, 2013. Overview; Rice Production in Cambodia. Agri benchmark Cash Crop Conference 2013 Benefit Plaza Hotel, Voronezh, Russia, June 30 - July 5th, 2013. 28 Roy, K. C. and Singh G., 2008. Agricultural Mechanization in Bangladesh. Agricultural. Mechanization in Asia, Africa and Latin America. Vol. 39, No. 2 , p:83:93. Rukunudin, I. H., 2009. Mechanization and Automation Research Center, Malaysian Agriculture Research and Development Institute (MARDI), Malaysia. Paper presented at the Asian and Pacific Center for Agricultural Engineering and Machinery (APCAEM), Los Banos, Philippines, 14th – 16th October 2009. Schiller, J. M., Chanphengxay M.B., Linquist B. and Appa Rao S., 2006. Rice in Laos. International Rice Research Institute publication, ISBN 978-971-22-0211-7. p: 65, 325-326. SDNP )Sustainable Development Networking Programme(, 2013. Agricultural Database. National Agriculture Policy, Bangladesh. Acced, June, 2013, available at http://www.sdnbd.org/sdi/issues/agriculture. Shrestha, S., 2012. Status of Agricultural Mechanization In Nepal. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 - 9 December 2011. Bangkok, Thailand, P: 60-63. Sidhu, H. S., 2011. Conservation Agriculture and Sustainable Agricultural Mechanization Strategies. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 - 9 December 2011. Bangkok, Thailand, P: 46-47. Singh, G. and Mani, I., (2009). Agricultural Mechanization in India: Status and Future Challenges. Proceedings of the 10th International Agricultural Engineering Conference, Bangkok, Thailand, 7-10 December, 2009. Role of agricultural engineering in advent of changing global landscape 2009 pp. unpaginated Soni, P. and Ou Y., 2010. Agricultural Mechanization at a Glance Selected Country Studies in Asia on Agricultural Machinery Development. United Nations Asian and Pacific Centre for Agricultural Engineering and Machinery (UNAPCAEM). The Official Gazette, Republic Act No. 10601, 2013. An Act Promoting Agricultural and Fisheries Mechanization Development in the Country. Npo, Official Gazette Section Edsa Cor. National Printing Office Road Diliman, Quezon City. Philippines. (http://www.gov.ph/2013/06/05/republic-act-no-10601/. Theng Vuthy and Koy Ra, 2010. Review of Agricultural Policy and Policy Research; A Policy Discussion Paper. Cambodia Food Security and Agricultural Policy Stocktaking Roundtable, Phnom Penh Hotel, 4 November 2010. Phnom Penh, Cambodia. Thepent, V. 2012. Research Report from Thailand. “ANTAM” ,Technical working Group & Steering Committee Meeting on advancing progress with establishing an Asia-Pacific network for testing agricultural machinery, 15-16 May 2012, Bangkok, Thailand. Available at: http://www.unapcaem.org/Activities%20Files/A1205_AS/PPT/th.pdf Tuntivate, Voravate Tig. 2011. Powering Up Productivity in Rural Lao PDR : Stimulating Small and Medium Enterprises to Use Electricity for Income Generation. World Bank, Washington DC. https://openknowledge.worldbank.org/handle/10986/12773 License: CC BY 3.0 Unported 29 Unadi, A., 2011. The Status Of Agricultural Mechanization In Indonesia .Sustainable Agricultural Mechanization Strategies , Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region, 8 - 9 December 2011. Bangkok, Thailand, P:48-52. UPLB-BAR, 2001. National farm mechanization needs survey and analysis project, Terminal Report. Los Banos, Laguna: Institute of Agricultural Engineering, CEAT, UPLB, 2001. Vichet, S., 2013. Highlights on milling activities and outcomes in Cambodia, Presentation. International seminar on postharvest losses, kemeara Battanmbang Hotel, Cambodia, 19 June, 2013. Viet, N. Q., (2012). Current Status of Agricultural Mechanisation in Vietnam. Roundtable on Developing Environmentally Sustainable Agricultural Mechanization Strategies (SAMS) for Countries in the Asia-Pacific Region 8 - 9 December 2011. Bangkok, Thailand, P: 95-97. Abdul-Wohab, 2011. Current Status of Agricultural Mechanization in Bangladesh. Sustainable Agricultural Mechanization Roundtable: Moving Forward on the Sustainable Intensification of Agriculture, 8-9 December 2011. http://www.unapcaem.org/PPT/bd-index.htm. World Bank, data, from http://data.worldbank.org/indicator/AG.LND.AGRI.ZS/countries. Accessed May 2013. Ziauddin, A. T. M. and Ahmmed S., 2010. Agricultural Research Priority : Vision- 2030 and beyond : A final report on Research Priorities in Farm Machinery, Irrigation & Water Management and Post-harvest Technology (engineering aspects), Submitted to: Bangladesh Agricultural Research Council, Dhaka.p:10-14. 30