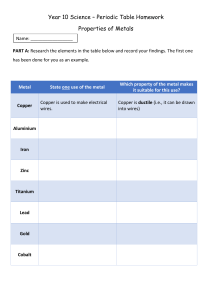

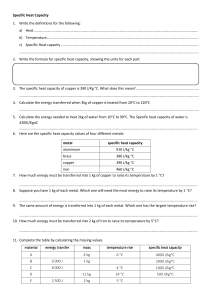

EASWARI ENGINEERING COLLEGE (AUTONOMOUS) BHARATHI SALAI, RAMAPURAM, CHENNAI – 89 DEPARTMENT OF MECHANICAL ENGINEERING BATCH NO: C11 IV YEAR C SECTION Date : 20-06-2022 ME8811 PROJECT WORK END SEMESTER UG PROJECT VIVA VOCE EXAMINATION JUNE 2022 SYNTHESIS AND ANALYSIS OF MECHANICAL PROPERTIES OF COPPER METAL MATRIX COMPOSITES REINFORCED WITH GRAPHITE AND SILICON CARBIDE Presented by SANDEEP J YOKESH S (310618114097) (310618114129) Supervisor Dr. V. ELANGO, M.E, Ph. D Professor & Vice Principal(academic) Department of Mechanical Engineering 1 EASWARI ENGINEERING COLLEGE ABSTRACT • • • • • Copper based metal matrix composite (CMMC) attracts the multiple applications due to their good electrical, thermal and mechanical properties. The present investigation is based on the fabrication of Coppergraphite with the addition of SiC by sintering followed by compacting. Four composites were prepared, One by considering full copper with no ceramics added and the rest by varying the percentages of Copper, Graphite, SiC respectively. The synthesis is followed by characterization of physical, mechanical and metallurgical properties such as Wear; Pin on disc, Hardness; Vickers hardness, Compression and Microstructure; Optical microscope. The results obtained from the above tests were reviewed and studied. DEPARTMENT OF MECHANICAL ENGINEERING 2 EASWARI ENGINEERING COLLEGE INTRODUCTION • Copper–graphite metal matrix composites possess the properties of copper, i.e. excellent thermal and electrical conductivities, and properties of graphite, i.e. solid lubricating and small thermal expansion coefficient. Addition of SiC which is high hardness material and holds a good wear resistance, enhances the properties of Cu-graphite matrix. • There were three composites prepared by varying the weight % of Cu, Graphite, SiC as follows Sample 1: 96:2:2; Sample 2: 94:2:4; Sample 3: 92:2:6. One was prepared as full copper (Sample X) with no addition of graphite or SiC to compare the results. • The techniques used for synthesis are Blending the materials accorrding to weight%, Compacting using UTM at 5 Tonne load, Sintering in a Argon Gas furnance at 850°C for three hours. • Three samples were prepared for each composition and the 3 DEPARTMENT testing was carried out. OF MECHANICAL ENGINEERING EASWARI ENGINEERING COLLEGE LITERATURE SURVEY AUTHORS TITLE SIGNIFICANCE Venkatesh R and Vaddi Seshagiri Rao Thermal, corrosion and wear analysis of copper based metal matrix composites reinforced with alumina and graphite The corrosion resistance of the composite with the maximum alumina reinforcement in nano scale exhibited better wear resistance. The presence of graphite certainly provides a lubricating effect. C.S. Ramesh, R. Noor Ahmed, M.Z. Abdullah Development and performance analysis of novel cast copper–SiO2– Gr hybrid composites The SEM images were taken and analysed for morphology and particle sizes. Microhardness, Ultimate tensile strength, Coefficient of friction of hybrid composites is higher than that copper. DEPARTMENT OF MECHANICAL ENGINEERING 4 EASWARI ENGINEERING COLLEGE AUTHORS T. Rajmohan, K. Palanikumar, S. Arumugam TITLE Synthesis and chara cterization of sintered hybrid aluminium matrix composites reinforced with nano-copper oxide particles and microsilicon carbide particles SIGNIFICANCE From the studies it has been concluded that the inclusion of CuO in the Metal Matrix composites improves the structure and property of the composite material. K. Rajkumar, S. Aravindan Tribological behavior of microwave processed copper–nanographite composites. Copper–NG composites exhibited higher physical and mechanical properties when compared to the copper–graphite composites for the same volume percentage. A. Fathy, F. Shehata, M. Abdelhameed, M. Elmahdy Compressive and wear resistance of nanometric alumina reinforced copper matrix composites The wear rates of the composites increased with increasing applied loads or sliding speed. The wear rate of the monolithic copper is more than that of the nanocomposites. DEPARTMENT OF MECHANICAL ENGINEERING 5 EASWARI ENGINEERING COLLEGE METHODOLOGY PROBLEM STATEMENT LITERATURE SURVEY RAW MATERIAL PURCHASING RESULTS AND REVIEW TESTING, SPECIMEN PREPARATION MICROSTRUCTR E MATERIALS USED GREEN COMPACT DEPARTMENT OF MECHANICAL ENGINEERING 6 EASWARI ENGINEERING COLLEGE SPECIMEN PREPARATION COMPACTING & SINTERING • The size of the specimen was estimated as 15mm in Diameter and 25mm in Length. Considering the density of powdered copper the weight of 100% copper with the above dimensions is 39.6 grams. • From the above whole weight the percentage weights of the ceramics to be added were found and weighed accordingly. The mixtures of materials of each samples were blended thoroughly. • The mixtures were then subjected to compacting in the UTM subjecting to a load of 5 Tonne. • The green compacts were gently collected from the UTM and nummbered according to their compositions. Three samples of each compositon were prepared, Making a total of 12 samples. COMPACTING SINTERING AFTER SINTERING DEPARTMENT OF MECHANICAL ENGINEERING 7 EASWARI ENGINEERING COLLEGE TESTING WEAR ANALYSIS Initial Finalw Wearl Applie Sliding Slidin Slidin Sam Time weight eightg ossing d Velocit gDista g Timei pleN inMin g Load( y (m nce(m Diain rpm n Sec o /Sec N) /Sec) ) mm X 20 1 500 40 478 500 8.332 35.655 35.624 0.031 1 20 1 500 40 478 500 8.332 17.64 17.574 0.066 2 20 1 500 40 478 500 8.332 10.845 10.3664 0.181 3 20 1 500 40 478 500 8.332 34.072 34.042 HARDNESS SampleI.D SampleX SampleNo:1 SampleNo:2 SampleNo:3 0.03 Hardness Vickers : 0.2 Kgf; Dwell : 10Sec Reading-1 60.2 137.7 83.2 119 Reading-2 59.7 135.7 93.3 120.2 Reading-3 62.5 108.1 83 114.3 Pin-on-disc Vickers hardness tester DEPARTMENT OF MECHANICAL ENGINEERING 8 EASWARI ENGINEERING COLLEGE COMPRESSION SampleI.D ULTIMATE LOADN SampleX SampleNo:1 SampleNo:2 SampleNo:3 11020 9815 6785 13875 MAX. DISPLACEMENTm m 13.300 4.700 6.900 5.000 COMPRESSIVE STRENGTHN/MM2 140.02 124.91 86.35 176.591 COMPRESSION TESTING MACHINE MICROSTRUCTURE SAMPLE X SAMPLE 2 SAMPLE 1 SAMPLE 3 DEPARTMENT OF MECHANICAL ENGINEERING 9 EASWARI ENGINEERING COLLEGE CONCLUSION HARDNESS •The sample 1 containing equal amounts of graphite and SiC was observed to have the highest hardness compared to other compositions. •All compositions were seen to have a good hardness levels compared to pure copper. COMPRESSION •It is seen that the sample 3 that contains the highest percentage of SiC among other compositions has a greater compression strength. WEAR TEST •It is seen that the sample 3 that contains the highest percentage of SiC among other compositions has a greater wear resistance. Thus SiC makes the matrix more resistant to wear. MICROSTRUCTURE •The microstructure of the 4 samples is observed and studied. • Copper is visible as bright golden colour, SiC are the dark irregular shapes visible. Graphite is less visible in shades contrast to SiC. 10 DEPARTMENT OF MECHANICAL ENGINEERING EASWARI ENGINEERING COLLEGE REFERENCES 1.Onur Guler, Temel Varol application of the central composite design in optimization of machining parameters in drilling hybrid metal matrix composites. 2.T. Rajmohan, K. Palanikumar, S. Arumugam Synthesis and characterization of sintered hybrid aluminium matrix composites reinforced with nanocopper oxide particles and microsilicon carbide particles. 3.Baoyin jin, Ding-Bnag Xiong. Enhanced corrosion resistance in metal matrixcomposites assembled from graphene encapsulated copper nanoflakes 4.Ashraf Bakkar, Sabbah ataya. Corrosion behavior of stainless-steel fiberreinforced copper metal matrix composite with reference to electrochemical response of its constituents. 5.C.Ayyapadas, A. Muthuchamy. An investigation on the effect of sintering mode on various properties of copper-graphene metal matrix composites. 6.T. Kock, A. Brendel. Interface reactions between silicon carbide and inter layers in silicon carbide–copper metal–matrix composites. 7.Venkatesh R and Vaddi Seshagiri Rao Thermal corrosion and wear analysis of copper based metal matrix reinforced with alumina and graphite. 11 DEPARTMENT OF MECHANICAL ENGINEERING THANK YOU 12