Drill Stem Testing Tools: Specs & Operations | Expro

advertisement

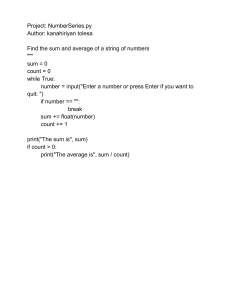

Drill Stem Testing Annulus Reference Trap System (ARTS) The ARTS is used to trap a pressure in the reference section of the Pressure Operated Tester Valve (POTV). Once this reference pressure has been trapped, the POTV can then be operated through the application and removal of applied annulus pressure. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ¾” Stub Acme, 6 TPI Lower Thread connection 3 ¾” Stub Acme, 6 TPI Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length (in/mm) 55.4in/1mm Tool Weight (lbs/kg) 250 lbs/ 133 kg Service condition H2S per Nace MR-01-75 Operation: The ARTS is run as part of the POTV/reference section. By isolating the I.D. from the O.D. (i.e. setting a packer or placing seals into a sea bore) and applying an annulus pressure, a reference is trapped in the POTV. The POTV can now be operated by annulus pressure. The ARTS also contains a check valve system which regulates the operating pressure. The check valve also relieves the trapped reference pressure at the end of the test as the tool is pulled to surface. This ensures that bottom hole pressure is not brought to surface in the tool. © Expro International Group LTD AnnulusReferenceTrapSystem 290410_v2 exprogroup.com Drill Stem Testing Self Fill Tubing Tester Valve (SFTTV) The SFTTV (Self Fill Tubing Tester Valve) provides a means of pressure testing tubulars while running in the hole. The flapper valve in the tool will only support pressure from above thereby allowing completion fluid to enter the test string via the bypass. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ¾” Stub Acme, 6 TPI Lower Thread connection 3 ¾” Stub Acme, 6 TPI Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length ( in/mm) 74in/1879mm Tool Weight (lbs/kg) 572 lbs/ 260 kg Service condition H2S per Nace MR-01-75 Operation: When used in conjunction with permanent packer systems, the SFTTV will allow fluid bypass when both stinging into and out of the packer. This is possible by the incorporation of a normally open bypass port which enables multiple entry to permanent packers without operating the tool. When required the SFTTV can be fired open by applied annulus pressure of circa 500psi. The basic functions of the SFTTV are: • To allow fluid fill of the tool string during entry • To provide a method of testing the tool string during entry. © Expro International Group LTD SelfFillTubingTesterValve 230311_v3 exprogroup.com Drill Stem Testing Slip Joint (SLPJ) The Slip Joint is a telescopic joint run in the tool string, allowing five feet of free travel. It allows for tubing movement caused by temperature changes. The tool is internally pressure and volume balanced. It is also splined so that torque can be transferred below the tool. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ½” IF Lower Thread connection 3 ½” IF Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length ( in/mm) 267.9in/6805mm Tool Weight (lbs/kg) 1,040 lbs/ 472 kg Service condition H2S per Nace MR-01-75 Operation: Slip Joints should be run together in the work string when testing with annulus pressure operated tools. At the time the packer is set the Slip Joints will be 1/2 closed allowing for a maximum of expansion or contraction due to changes in well conditions. © Expro International Group LTD SlipJoint 230311_v3 exprogroup.com Drill Stem Testing Safety Joint and Overshot (SFJT) The Safety Joint provides for an emergency release between the work string and the packer. In the event that the Safety Joint is released, the Overshot can be run to reconnect the work string with the packer assembly. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ½” IF Lower Thread connection 3 ½” IF Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length ( in/mm) 27.2in/690.88mm Tool Weight (lbs/kg) 140 lbs/ 63.6 kg Service condition H2S per Nace MR-01-75 Releasing operation: The Safety Joint is run on the test string directly above the packer. Release is effected by taking an upstrain on the test string and rotating to the right. Release is controlled by make-up torque, which can be varied. Eleven turns are required to back off the Safety Joint. Retrieving operation: The Safety Joint can be reconnected to the test string by slowly setting down and rotating the overshot to the right into the retrieving threads. © Expro International Group LTD SafetyJointandOvershot 230311_v3 exprogroup.com Drill Stem Testing Pressure Operated Tester Valve (POTV) The POTV is an annulus pressure-operated downhole ball valve. It is run with a nitrogen section which compensates for changes in annulus hydrostatic pressures. The POTV is designed to work in conjunction with either retrievable or permanent packers as no set-down weight is required when operating. An optional index lock-open system allows the ball to be retained open every second cycle. This lock open feature allows the POTV to act as a fluid by-pass when placing seals in a packer bore and aids in wireline and well kill procedures. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ¾” Stub Acme, 6 TPI Lower Thread connection 3 ¾” Stub Acme, 6 TPI Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length ( in/mm) 153in/3886mm Tool Weight (lbs/kg) 640 lbs/ 290 kg Service condition H2S per Nace MR-01-75 Operation: The POTV is run above the packer and recorder carriers in a cased hole test string. Thereafter it provides for downhole shut-in and flowing test procedures by selectively closing and opening the test string to flow. When the test assembly is run to depth and the packer set, applied annulus pressure causes the ball valve to rotate to the open position, allowing full bore passage through the tool. It remains open until the pressure is bled off, or when running the lock open feature, and closes when the tool is cycled again. The POTV will normally be run in the lock open position, testing the string against the Self Fill Tubing Tester Valve (SFTTV). If run in the closed position it may be tested against as many times as desired. (If used in conjunction with Expro’s circulating valves it provides an effective system for running TCP guns in a well and establishing an underbalance by running a portion of the tubing string dry). © Expro International Group LTD PressureOperatedTesterValve 230311_v3 exprogroup.com Drill Stem Testing Hydraulic Jar (JAR) The Hydraulic Jar is used for the purpose of freeing stuck pipe and tools in the wellbore. This device delivers heavy impact blows to the test string by storing energy within the tool. In well test applications the tool is run directly above the Safety Joint. The Hydraulic Jar is designed to transmit torque and withstand severe tensile and compressive loads. Specifications: Working Pressure (psi/Mpa 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ½” IF Lower Thread connection 3 ½” IF Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure. 30,000lbf/13,345daN Tool Length ( in/mm) 113.8in/2890mm Tool Weight (lbs/kg) 525 lbs/ 133 kg Service condition H2S per Nace MR-01-75 Maximum overpull before the Jar fires 80,000lbs/36 tons Operation: The Hydraulic Jar is activated by picking up on the test string and holding tension. The applied tension at the tool forces the oil in the oil chamber to pass through a flow regulator at a controlled rate. This controlled action continues until the piston reaches the grooved section of the cylinder bore; the oil is then rapidly discharged at an uncontrolled rate to the lower section of the oil chamber. This release of energy together with the energy stored in the stretched test string causes the mandrel to accelerate upwards until the mandrel hammer area strikes the anvil stop, delivering high impact force to the stuck object. The tool is multi-use and can be rapidly re-cocked by slacking off the work string. © Expro International Group LTD HydraulicJar 230311_v3 exprogroup.com Drill Stem Testing Multi Reverse Spot Tool (MRST) The Multi-Reverse Spot Tool provides a means of establishing communication between the annulus and the drill string. It has three functional positions: closed, reverse, and circulate, and may be run in the well in either the closed or reverse positions. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ¾” Stub Acme, 6 TPI Lower Thread connection 3 ¾” Stub Acme, 6 TPI Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length (in/mm) 138.2in/3510mm Tool Weight (lbs/kg) 575 lbs/ 261 kg Service condition H2S per Nace MR-01-75 Operation: The tool may be cycled as many times as required. It may be used to displace fluids before a test, to spot fluids (nitrogen or acid) and/or to reverse circulate recovered fluids from the drill string. © Expro International Group LTD MultiReverseSpotTool 230311_v3 exprogroup.com ExACT Tool 30/07/2013 08:04 Page 1 Drill Stem Testing Expro Annulus-Operated Circulating and Test (ExACT™) Tool The ExACT™ tool is a combined annulus operated multi-cycle, shut-in ball-circulating valve. The unique ‘SmartCollet’ and interlocking system makes this tool highly operationally flexible and efficient, requiring a maximum of four annulus pressure cycles to place the ball and circulating ports in any required position, however the ball and ports are mechanically prevented from being open at same time. As the tool operates against a trapped reference pressure, there are no costly waiting times between cycles. The ExACT™ tool is placed above the packer assembly and gauge carriers and functions as a downhole shut-in valve and a circulating valve for spotting underbalancing fluid, reverse circulating produced fluids and circulating during the well kill process. As the valve is operated by annulus pressure, it is ideal for spotting nitrogen cushions and for cycling open in gas well applications. Its high rate circulating capability (10 bbl/min) makes it operationally efficient in high rig cost operations such as in deepwater. The high strength, debris tolerant ball sealing mechanism has superior sealing capability for downhole shut-ins and can be opened with up to 7,500 psi (51.7 Mpa) differential pressures, from above or below the ball. The ball can be locked open, which allows self-filling of the tubing string while running in hole and stabbing into production packers. It also optimises the well-kill process and allows the passage of through tubing tools below the valve, without fear of the ball closing. Specifications: Working Pressure and Temperature 15,000 psi / 103.42 Mpa at 350°F/177°C (Std dress) 15,000 psi / 103.42 Mpa at 450°F/232°C (HT dress) OD 5 in / 127 mm ID 2.25 in / 57.2 mm Upper Thread Connection 3 1/2” IF or 3 1/2” PH6 Box Lower Thread Connection 3 1/2” IF or 3 1/2” PH6 Pin Tensile Strength 350,000 lbf / 155,600 daN Approx. Tool Length 40 ft / 12.2 m Approx. Tool Weight 1,700 lbs / 771 kg Service Condition H2S per NACE MR-01-75, CO2 exprogroup.com ExACT Tool 30/07/2013 08:04 Page 2 Drill Stem Testing Expro Annulus-Operated Circulating and Test (ExACT™) Tool Operation: The ExACT™ tool, pre-charged with nitrogen, is run in the hole locked open (position 1) allowing the test string to fill from below. A self-fill tubing test valve (SF-TTV) is utilized to pressure test the string. When the DST tool string is at depth and the packer set, hydrostatic pressure is trapped in the nitrogen reference section of the tool on the first application of annulus pressure. The ball and circulating ports can now be operated as required by annulus pressure cycles as per the table below. The tool will respond immediately to pressure cycles, so there is no waiting time between cycles. Also, there is no limit to the number of tool operating cycles. On completion of the well test, trapped reference pressure is automatically relieved whilst pulling out of hole. Position Functionality 1 Run in hole/Through-tubing work/ Below packer circulating/ Pull out of hole Well flowing 2 Ball Status Ports Status Annulus Status (nom.) psi Apply/Bleed Annulus (nom.) psi Goto Position Open Closed 0 2000 2 Open Closed 2000 0 3 2000 4 1500/0 5 3 Well shut in Closed Closed 0 4 Transit position Open Closed 2000 0 1 5 Reverse / Circulate Closed Open 0 1500 6 6 Transit position Closed Open 1500 7 Circulate Closed Open 0 8 Transit position Closed Closed 2000 9 Transit position Closed Closed 0 0 7 2000 8 1000/0 5 0 9 2000 4 1500/0 5 © Expro International Group LTD ExproAnnulus-OperatedCombinedCirculating & Test(ExACT™)Tool 140213_v1 exprogroup.com Drill Stem Testing Annulus Operated Reversing Valve (AORV) The AORV is a single shot circulating valve giving unrestricted flow between tubing and annulus. Once open, the tool is retained in this position by a lock ring and cannot be reclosed. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ¾” Stub Acme, 6 TPI Lower Thread connection 3 ¾” Stub Acme, 6 TPI Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length ( in/mm) 41.4in/1052mm Tool Weight (lbs/kg) 250 lbs/ 133 kg Service condition H2S per Nace MR-01-75 Operation: The AORV is opened by applied annulus pressure, bursting a high-accuracy rupture disc (± 2% of the disc's rupture rating). The pressure acts on an unbalanced piston, forcing the mandrel to the open position. The mandrel is then locked in the open position by the locking mechanism. © Expro International Group LTD AnnulusOperatedReversingValve 230311_v3 exprogroup.com HTHP Retrieveable Packer 02/05/2013 09:50 Page 1 Drill Stem Testing BigCat™ HPHT Retrievable Packer The Expro BigCat™ HPHT packer is a premium high-strength, compression set, retrievable hook-wall packer, ideal for Drill Stem Testing (DST), perforating and stimulation operations. It is capable of withstanding 15,000 psi differential pressure when set, at temperatures up to 400°F. The hydraulic hold down sub1 ensures that the packer remains set when subjected to excessive pressure from below during stimulation operations, for example. An integral fluid bypass ensures efficient deployment. The packer requires only a small amount of right-hand rotation to set (one-eighth of a turn at the tool) and releases with straight pull. This packer is available with standard or premium element sealing systems, depending on the service requirements. Specifications: Packer with Hold Down Sub Working Pressure and Temperature 10,000 psi / 68.95 Mpa at 350°F/177°C (Standard dress) 15,000 psi / 103.42 Mpa at 400°F/204°C (Premium dress) Casing Weight Range 7 in, 26 lb/ft to 7 in, 38 lb/ft Casing ID Range 5.868 in / 149.0 mm to 6.492 in / 164.9 mm Max. OD (Gauge Ring) 5.968 in / 151.6 mm (for 26 – 29 lb/ft casing) 5.812 in / 147.6 mm (for 32 – 35 lb/ft casing) 5.656 in / 143.7 mm (for 38 lb/ft casing) Min. ID 2.25 in / 57.2 mm Upper Thread Connection2 3.750 in – 6 Stub Acme Box Lower Thread Connection3 3.750 in – 6 Stub Acme Pin Min. Required Setting Weight4 8,000 lbf / 3,560 daN (for standard dress – 10k) Max. Compressive Load 520,000 lbf / 231,300 Tensile Strength5 200,000 lbf / 89,000 daN Approx. Length 13.25 ft / 4.039 m Approx. Weight 635 lbs / 288 kg Service Condition H2S per NACE MR-01-75, CO2 2,500 lbf / 1,120 daN (for premium dress – 15k) (1) Hydraulic hold down sub, not shown in tool illustration, opposite. (2) Crossover to work string, as required. (3) Crossover to tail pipe assembly, as required. (4) Operationally, when run with Slip Joints, a min. net weight of 15,000 lbf should be included below the free-point. (5) Limited by design to allow controlled parting of the packer body mandrel. Operation: The packer is used in conjunction with Expro’s DST tools, and provides isolation of the formation for production or injection purposes. As it is a compression-set packer, drill collars are incorporated in the bottomhole assembly (BHA) to provide the necessary setting weight. The packer is deployed in the ‘safety’ position, and has an integral bypass allowing fluid to displace from below the packer whilst running in hole. When at setting depth, the packer is set by picking up on the string, then applying right-hand rotation to give one-eighth turn at the tool. The string is then lowered to set the packer, also closing the bypass. The bypass can be opened by limited pick up of the string without unsetting the packer, allowing pressure equalisation across the packer or to monitor for losses. Set down weight will reclose the bypass. To fully unset the packer, pick up on the string; the packer will automatically move to the ‘safety’ position, which allows movement down the hole, should this be required. The packer can be reset as many times as desired by repeating the setting process described above and ultimately retrieved from the well with the rest of BHA on completion of in-hole operations. exprogroup.com © Expro International Group LTD HP/HT Retrievable Packer 120213_v1 Drill Stem Testing Annulus Operated Reversing Valve (AORV) The AORV is a single shot circulating valve giving unrestricted flow between tubing and annulus. Once open, the tool is retained in this position by a lock ring and cannot be reclosed. Specifications: Working Pressure (psi/Mpa) 15,000psi/103.42 Mpa Working Temperature (°F, °C) 350°F / 175°C OD (in/mm) 5” / 127mm ID (in/mm) 2.25”/57.2mm Upper Thread connection 3 ¾” Stub Acme, 6 TPI Lower Thread connection 3 ¾” Stub Acme, 6 TPI Tensile Strength 350,000lbf/155,600daN Tensile strength at Max working Pressure 30,000lbf/13,345daN Tool Length ( in/mm) 41.4in/1052mm Tool Weight (lbs/kg) 250 lbs/ 133 kg Service condition H2S per Nace MR-01-75 Operation: The AORV is opened by applied annulus pressure, bursting a high-accuracy rupture disc (± 2% of the disc's rupture rating). The pressure acts on an unbalanced piston, forcing the mandrel to the open position. The mandrel is then locked in the open position by the locking mechanism. © Expro International Group LTD AnnulusOperatedReversingValve 230311_v3 exprogroup.com