Hydrometallurgy, 5 (1980) 9 7 - 1 0 7

97

© Elsevier Scientific Publishing Company, Amsterdam -- Printed in The Netherlands

CRUD IN SOLVENT EXTRACTION PROCESSING

CAUSES AND TREATMENT

-

A REVIEW OF

G.M. RITCEY

Extractive, Metallurgy Section, Ore Processing Laboratory, CANMET, Energy, Mines and

Resources Canada, Ottawa (Canada)

(Received May 3rd, 1979; accepted May 25th, 1979)

ABSTRACT

Ritcey, G.M., 1980. Crud in solvent extraction processing -- A review of causes and treatment. Hydrometallurgy, 5: 97--107.

An overview is presented on the various aspects affecting solvent loss through crud

formation, encountered in many hydrometallurgical plants that employ solvent extraction

processing. This crud, or stable emulsion mixed with solids, can be caused by properties

of the feed solution, the solvent and its composition, the type of contactor selected and

the method of operation. Cruds differ between plants and therefore treatment schemes

and preventative measures are impossible to define without actual testing and evaluation.

A summary of items for consideration in solving crud problems is given.

INTRODUCTION

Common to all or most solvent extraction operations in the mining industry is the problem of stable emulsions and the eventual formation of cruds.

The crud can constitute a major solvent loss to a circuit and therefore adversely affect the operating costs. Because there can be many causes of crud

formation, each plant may have a crud problem unique to that operation.

Factors such as ore type, solution composition, solvent composition, presence of other organic constituents, design and type of agitation, etc. can

adversely affect the chemical and physical operation of the solvent extraction

circuit, and result in crud formation.

Crud is defined as the material resulting from the agitation of an organic

phase, an aqueous phase, and fine solid particles, that form a stable mixture.

Crud usually collects at the interface between the organic and aqueous phases

Other names that have been used for the phenomena are grungies, mung,

gunk, sludge, etc.

This paper will cover, in an overview, the general aspects of solvent losses

by crud; its formation and characteristics, and its treatment and prevention.

Solvent losses in processing can be attributed to: (1) entrainment, (2)

solubility, (3) evaporation, (4) degradation, (5) adsorption on solids, (6)

98

formation of stable emulsions and cruds, (7) spillage and (8) sampling. These

solvent losses, and particularly those losses attributed to emulsion and crud

formation, can in part be related to: (1) nature of feed, (2) reagent choice,

(3) equipment selection and (4) m e t h o d of operation, such as the droplet

size, continuous phase, excessive turbulence, etc. Additional details on solvent

losses are noted in a text co-authored by the writer [1].

POSSIBLE CAUSES OF CRUD F O R M A T I O N

Nature of feed

The nature of the feed composition can be a major determining factor as

to whether crud will be formed in the subsequent extractive operations.

Solids must be absent from most solvent extraction circuits, and clarification

is usually aimed at achieving about 10 ppm solids. One of the major causes

of crud is the lack of good clarification, with the result that solids get through

to the solvent extraction circuit. The presence of colloids, such as silica [2],

can produce stable emulsions and crud during the mixing of the phases to

achieve mass transfer. Aged feeds can constitute a greater potential crud

problem than fresh leach solutions [3]. In plants where bacteria have been

prevalent, due to favourable environmental conditions, crud has resulted and

expensive circuit modifications were subsequently required. The elimination

of air to such circuits is often necessary to minimize bacteria and fugal growth

[4]. Certain systems may have hydrolysed compounds precipitating out of

solution, and thus a crud results. In certain extraction systems the anionic

strength of the aqueous feed solution may be insufficient, so that stable

emulsions occur when the two phases are mixed. If sufficient agitation is applied over a period of time, then crud can result. One other important cause

of cruds in solvent extraction plants is the dust from the air, if permitted to

be drawn into the agitation in a mixer-settler circuit. Thus, vessels should be

covered to prevent dust accumulation. Organic matter in the feed, such as

lignin or humic acids, may also promote crud formation.

Nature of solvent

The choice of the extractant and solvent composition is an important

aspect in the successful solvent extraction operation, but the possibility of

crud due to the solvent composition must not be overlooked. Many systems

require a modifier, to improve phase disengagement, to assist in solubilizing

the metal-organic species and to reduce third phase and emulsion tendency.

If a solvent has the tendency to produce emulsions on mixing with the aqueous feed solution, which could cause cruds if colloids or suspended solids

are present in the aqueous feed, then the cause may be due to several factors.

Perhaps the system requires the addition of a modifier, a change to a different

modifier, or a higher modifier concentration is demanded. Also, possibly the

diluent type and composition may not be compatible with the system. An

aromatic diluent or an aliphatic diluent with some aromatic content may be

99

more desirable than a completely aliphatic diluent for that particular process.

Frequently, in the solvent makeup, there are unreacted chemicals from the

manufacturing process or, possibly, impurities from the containers used to

transport the solvent components. The problems associated with such impurities become particularly evident if their effects are not considered during

bench scale investigations [1]. Their presence in a solvent system can produce

cruds, good or poor phase separation and enhanced or poor loading characteristics. Such effects could result in abandoning a particular solvent because of

its poor chemical and physical characteristics.

Degradation of the solvent, due to the presence of certain metals in the

feed solution, use of oxidizing agents during stripping, high temperature

processing, biodegradability, etc. may result in decomposition products

forming stable emulsions and cruds. Several uranium plants have reported the

degradation of the isodecanol modifier to isodecanoic acid in the amineisodecanol system. Naphthenic acid extraction of copper from leach liquors

also showed degradation to an insoluble crud composed of 23% of the extractant [4]. In the refining of uranium using tributyl phosphate in contact

with nitric acid, degradation products of mono- and dibutyl phosphates are

produced. Amines are susceptible to degradation in the presence of oxidizing

agents. Carboxylic acids and D2EHPA have been reported to withstand lowpressure reductions in a process to produce metal powders [ 5]. The LIX

reagents containing LIX 63 (e.g., LIX 64, LIX 64N, LIX 70 and LIX 73) are

stable up to temperatures of 40°C, while those not containing LIX 63 {e.g.,

LIX 65N, and LIX 71) can safely withstand higher temperatures.

Equipment selection

There is no universal contacting equipment suitable for all solvent extraction operations. Even within a plant, it may be completely wrong to

select the same type of contactor for all stages of the extraction process. Each

plant, therefore, has to make a choice; the final selection is governed by the

t y p e of aqueous feed and composition, the solvent type and composition,

and how the respective physical characteristics affect the mixing process, flow

patterns and coalescence [6]. Naturally the mass transfer efficiency must also

be considered. With an adequate understanding of all physical--chemical

variables present in the process that will thus have an effect on the extraction

as well as the minimizing of emulsion and crud, then the right equipment for

that plant can be selected [1, 6 ] . That is, the type of equipment and the

method of agitation used to achieve mass transfer is of concern, if emulsion

tendency is to be minimized. Degradation of the solvent may have to be

considered in the equipment choice, due to the chemical system. In one

plant, centrifugal contactors were chosen over mixer-settlers because of lower

solvent degradation [ 7 ].

Method of operating

In the solvent extraction process, one of the major concerns should be the

100

technique by which mass transfer is achieved. That is, the physical design and

operation can contribute n o t only to high solvent losses, such as by entrainment, b u t also to the formation of stable emulsions and cruds. The physical

aspects of the process are concerned with the dispersion of the two phases

on mixing, the t y p e of droplet formation and the rate and completeness of

coalescence. These are important aspects in the choice of suitable contacting

equipment and in the design and operation of the plant. Depending upon the

t y p e of contacting equipment selected and the energy input to the system,

different types of dispersion will be created for a particular system. Differences will be evidenced b y rates of mass transfer, drop size distribution,

wetting of surfaces, sedimentation and coalescence rates, and entrainment.

Depending upon the physical--chemical properties of the two phases being

dispersed, such as viscosity, surface tension, presence of solids, colloids, etc.,

then with increasing agitation and decrease in drop sizes, a region of instability will be reached followed by a stable emulsion. If solids or colloids are also

present, then a crud will result. This is demonstrated in Fig. 1 showing the

operating regions of pulsed columns [ 8]. The information is readily related

to excessive turbulence in mixer-settlers, particularly of the pump--mix

design, and in certain agitated columns where backmixing is severe. Flow

patterns during mixing can influence emulsion tendency, which can be further

influenced b y the continuous phase.Thus, if solids are present in mixer-settler

operations, and excessive turbulence exists, it would be advisable to use a

t y p e of contactor more suited to the physical--chemical characteristics of

the system. Centrifugal contactors would also be an unwise choice if solids

are present or crud formation is likely. Equipment such as the Graesser

Contactor, pulse sieve-plate column, ARD contactor and possibly in-line

mixers could be considered. Pulse columns have been described in the extraction of uranium from ore leach slurries and in the presence of crud [9, 10]

oJ

~0//

Flooding

(insufficient

pulse)

~%~/

Flooding

Region

~/

~/

Pulse Frequency x Amplitude

Fig. 1. Operating regions of a pulsed column.

101

The Purex uranium reprocessing flowsheet was examined by investigators

to determine which of mixer settlers, centrifugal contactors or pulse columns

would be the most suitable where there existed the possibility of crud formation during the extraction stage [11]. Both the mixer settlers and centrifugal

contactors proved unsatisfactory in the presence of the crud, while the

pulsed columns were self-cleaning with respect to solids, and no accumulation

of solids or plugging occurred. From their evaluations, pulsed columns were

r e c o m m e n d e d as extractors in large reprocessing plants.

Choice of the continuous phase, coupled with the contactor and flow patterns produced during the operation, may reduce the tendency of emulsification and crud formation if solids ~¢e present.

Although it is usually desirable to operate at saturation loading of the

solvent, there are certain situations where it is necessary to maintain less-thansaturation. For example, in the extraction and separation of zirconium from

hafnium in a nitric acid system, using TBP, the system operates only if run

at a b o u t 10% less than saturation. As saturation of the solvent is approached,

a zirconium c o m p o u n d is precipitated. In the presence of the solvent and

agitation, the result is a stable emulsion and crud [12]. Similar crud problems

can occur in rare~arth circuits using D2EHPA, where below saturation loading has to be maintained to prevent crud formation [13, 14].

D E S C R I P T I O N O F SOME C R U D S

The chemical and physical aspects of crud can differ for each separate

operation, and will vary in inorganic composition, organic content, color,

density, etc. The composition of many cruds appear to have in c o m m o n

such constituents as Si, A1, Fe, P, SO4, together with solvent, particles of

gypsum, clay and other fine particles, Often there is a direct relationship

between the feed liquor and the crud compositions, indicating possible

aqueous carry-over as well as inefficient clarification prior to solvent extraction.

In some of the South African plants a tar-like substance is generated and

determined to be aliphatic carboxylic acids. There is evidence of the presence

of isodecanoic acid, resulting from the oxidation of the isodecanol modifier.

More than one plant in North America has experienced some crud problems

when greater than 3% isodecanol is present. Possibly the vortex created on

mixing is a contributing factor to the crud produced b y the break<lown of

the isodecanol. Ferric iron, as an oxidant, is also present. In one early plant,

the animal glue flocculent used for filtration of the leach pulp caused severe

fungal growth in the solvent extraction circuit. The addition of a solventsoluble fungicide (a derivative of benzo-thiozole) alleviated the crud due to

the fungus. Use of an aromatic diluent, instead of aliphatic, was also affective

in minimizing the crud problem due to bacteria.

In some scrub and strip circuits, the crud is mainly composed of silica, as

well as inorganic sulphates. Such crud may be treated with dilute sulphuric

102

acid, and recirculating through a pump results in the crud breaking down.

There is evidence in at least a few uranium circuits that the presence of

humic acids may be a possible cause of the crud problem. Lignin appears to

be another cause of crud formation.

Plants extracting uranium from phosphoric acid can also have excessive

crud formation, which is often a waxy material. This appears to be due to

the excessive agitation of the two phases in the presence of humic acids conrained in the phosphoric acid.

The presence of hydrolyzable compounds, which precipitate due to excessive agitation and high shear, can cause severe crud problems. Zirconium

presents a particular problem and is a major constituent of at least one crud

in a uranium processing circuit. Also, as stated earlier, zirconium will tend to

hydrolyze in a H N O 3 - T B P circuit given the right conditions of shear or energy

input (proximity to saturation of the solvent and the type and construction

of contactor, particularly in the coalescing zone). The use of Teflon plates

in columns for such an extraction process definitely increased coalescence and

decreased the tendency for hydrolysis and crud formation. [15].

T R E A T M E N T AND SOLVENT RECOVERY

Because crud originating in one plant is usually different from that obtained in another, or in another circuit in the same plant, the treatment

scheme adapted for solvent recovery will, of necessity, be different. That is,

there is no universal treatment scheme that would be amenable to all cruds

because of the difference in the causes of crud formation. Some cruds are

broken down by settling and skimming [16], others by filtering [17], some

by acidification [16] or neutralization to an alkaline condition [9, 16], some

are broken by extreme agitation such as cycling through a centrifugal pump

[ 16], etc. After such treatment procedures, if successful, the solvent that is

released can be readily decanted for recovery. In some plants, a separate

solvent treatment stage is necessary, with a wash such as Na2COa being used

[16].

As an example of how different plant cruds react to treatment, CANMET

treated three by acid and alkali adjustment of a slurry-water mixture. None

of the three, one of which was from a stripping circuit, responded to alkali

treatment. In fact the stable emulsion and crud problem became greater.

With the first extraction crud containing a large a m o u n t of slimes from the

CCD circuit, 50% of the crud was dissolved at pH 1, and about 70% at pH

1. The second extraction crud, containing no slime solids from clarification, when mixed with water, 50% of the organic was released. Acidification

to pH 0 released no further organic, and in strong H2SO4, 95% of the organic

was released but as a fine emulsion. A sample of crud from a stripping circuit

was determined to be composed of 60% organic, 30% solids (as a precipitate)

and 10% aqueous. Acidification to pH 1.2 dissolved 20%, while at pH 0.5,

85% of the solvent was released. Further acidification resulted in reforming

103

the crud. However, if the crud was slurried in the strip raffinate from that

circuit (initial pH 4.17), instead of water, only 50% of the crud dissolved at

pH 0.5, and only in strong acid was 90% of the solvent released.

Thus, with cruds differing in their chemical and physical-chemical history

of formation, treatment to break down the crud and recover the solvent is

only accomplished by the testing and evaluation of many possibilities. At

this time, only "trial and error" tests can be suggested to determine the best

treatment techniques.

CRUDPREVENTION

Because crud is a difficult phenomenon to completely characterize, is

often site specific, and indeed can vary within an extraction, scrub and stripcircuit operation, preventative measures are therefore difficult to cite. The

following are some of the methods that can be suggested as to the prevention

of crud. Again, it must be emphasized that because cruds have a different

history of formation one or more preventive measures may be necessary.

(a) Solids in the feed were mentioned as one of the major causes of subsequent crud formation in the solvent extraction circuit. Good clarification

is therefore necessary to minimize crud and therefore operating costs. Table

1 itemizes some benefits of good clarification [18].

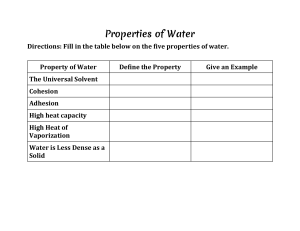

TABLE 1

Benefits of good clarification

Better mixing efficiency

Less crud and therefore less solvent loss

Lower organic entrainment

Less difficulty with maintaining continuous phase

Decreased iron transfer to electrolyte (in copper processing) via suspended solids

Increased efficiency in the tank house

Decreased maintenance

In North America and South Africa, the objective is to obtain approximately 10 ppm suspended solids in the feed to extraction. This is usually obtained

by the use of sand filters after a CCD circuit. At least one plant has reported

that crud quickly developed when the sand filters were not in operation [19].

New plants are attempting to achieve this objective by the use of Enviroclear

thickners, leaf clarifiers and sand filters. Although sand filters are used successfully in some plants, other plants have not been able to achieve their

objective. Insufficient frequency of back-washing the sand filters is a probable cause of poor clarification.

Because dust can cause crud if permitted in a mixer-settler circuit, particularly if the settlers are located in the open, adequate covers over the settlers should be provided.

104

(b) Colloidal silica in some circuits such as TBP--HNO3 in reprocessing of

uranium, can be reduced b y the addition of gelatine and heating to 80°C to

coagulate, followed b y centrifuge separation [2]. The addition of certain

surfactants, to lower the surface tension, may also reduce cruds due to colloidal silica [ 1 7 ] , as well as break emulsions [16]. Addition of sequestering

agents was successful in eliminating the deposition of calcium and the subsequent plugging of a centrifugal contactor with a calcium--rare earth precipitate, in a rare e a r t h - D 2 E H P A circuit [ 1 3 ] . However, the addition of

such reagents could also cause solvent degradation with continual cycling, so

the approach must be carefully investigated prior to adaption. Surfactants,

and other c o m p o u n d s used to enhance the liquid-solid separation after

leaching, could also enhance emulsion and crud tendency.

(c) Certain organic constituents, such as lignins and humic acids, may be

solubilized in the aqueous feed and may cause problems in the solvent extraction circuit. At this time, very little is known about this particular area of

crud formation. In phosphoric acid circuits, it has been found useful to

remove humates b y coagulation with surfactants followed by filtration [20].

Lignin can be removed by passing the leach solution through a bed of activated carbon [ 1 6 ] . Pressure treatment, under oxygen, at 200--250°C will

destroy the lignin components [16].

(d) Crud due to bacterial and fungal growth may be minimized by elimination of as much air as possible to the system [21]. These growths, in association with any solids present in the feed liquor, lead to the formation of crud.

Fungus growth in some circuits, due to the isodecanol modifier in an amine-uranium system, was eliminated by using 35% Solvesso 150 aromatic diluent

[ 2 2 ] . The aromatic diluent acts as a bactericide and fungicide. Commercial

bactericides have also been used successfully.

(e) Proper selection of the extractant as well as the other solvent components can minimize emulsions and crud formation. Freshly prepared solvents

can often contain impurities which could subsequently cause operational

problems. Therefore, all solvents should be conditioned prior to their use.

Having selected a suitable solvent system, cyclic tests should be performed to

determine whether degradation of any of the solvents components is taking

place. Any degradation products could cause crud formation m the circuit.

(f) There are a number of items for consideration in the operation of the

circuit to minimize crud formation. In certain systems, solvent saturation

can result in the formation of gelatinous solids, as in the rare earth--D2EHPA

system [13, 14] and in the z i r c o n i u m - T B P circuit [ 1 2 ] . The p h e n o m e n o n

is partially due to the increase in viscosity as loading is reached. An increase

in the O / A ratio thus results in a decrease in crud formation. As the viscosity

increases, excessive agitation can produce stable emulsions.

Flow patterns can be altered b y change of the continuous phase, and therefore the tendency for the formation of emulsions or cruds is altered. At one

uranium refinery, the solvent is maintained in the continuous phase in order

to produce flow patterns to reduce emulsion tendency [23].

105

Occasionally, the water used for solution makeup to scrub or strip circuits, because of impurities, can cause subsequent emulsions and cruds. At

one uranium plant in South Africa, deionized water was used to l~epare the

ammoniacal strip solution, rather than normal plant water which tended to

cause crud formation [ 2 2 ] .

Equipment selection is important, as is also the proper operation of the

contacting devices. It is generally recognized that high shear is the primary

cause of the droplet haze, and subsequent emulsion and crud formation.

TABLE 2

Possible items of information required for consideration in solving plant crud problems

(1) Ore

-- mineralogy and analysis

(2) Leach

Possible effects on degradation as well as

-- oxidant and quantity added

emulsion-production or crud-stabilization.

-- any other chemicals added

(3) Liquid--solids separation

-- type of separation (e.g., CCD)

-- type and quantity of surfactant added

use of sand filters or other types of clarifiers (e.g., anthracite and frequency of

regeneration.

(4) Feed solution to solvent extraction

suspended solids

dissolved solids

solution composition (e.g., silica, aluminum, molybdenum, zirconium, etc.)

presence of humic acids

presence of lignin

(5) Solvent ex trac rio n

(a) extraction

modifier and concentration

diluent

extractant

vortex in mixer

mixer design (e.g., baffling)

agitation (rpm and design, energy)

degradation of modifier and extractant (and surfactant from L/S separation)

settler design (entry to dispersion band, flow-rate design, baffling)

velocity across settler

continuous phase

any fungus or bacteria present

viscosity, surface tension or interracial tension

presence of precipitates

(b) stripping

mixer and settler operations as in " e x t r a c t i o n " above

degradation of modifiers and extractant

continuous phase

any fungus or bacteria present

stripping agent

viscosity, surface tension or interracial tension

presence of precipitates

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

106

T h u s , t h e t y p e a n d a m o u n t o f agitation (shear) m u s t be o p t i m i z e d f o r mass

t r a n s f e r while m i n i m i z i n g e m u l s i o n and c r u d f o r m a t i o n . Table 2 indicates

items o f i n f o r m a t i o n w h i c h m a y be r e q u i r e d in analysis o f c r u d f o r m a t i o n

problems in a plant.

CONCLUSIONS

The f o r e g o i n g has been an a t t e m p t t o provide an overview o f the various

aspects o f c r u d , its f o r m a t i o n , r e c o v e r y o f solvent and possible m e t h o d s o f

p r e v e n t i o n . O b v i o u s l y there are m a n y items for c o n s i d e r a t i o n with respect t o

the c h e m i c a l and physical parameters, the engineering, design and o p e r a t i o n

o f solvent e x t r a c t i o n circuits if we are to fully u n d e r s t a n d and solve the

p r o b l e m o f c r u d f o r m a t i o n . Thus, m u c h research and basic studies are necessary in the f u t u r e if the p r o b l e m s , and expense, caused b y crud f o r m a t i o n

are t o be eliminated.

REFERENCES

1 Ritcey, C.M. and Ashbrook, A.W. Solvent Extraction--Principles and Applications to

Process Metallurgy. 2 volumes, Elsevier, Amsterdam. 1979.

2 Cao, S., Dworschak, H. and Hall, A. In: Proceedings of the International Solvent Extraction Conference, ISEC '74, Lyon. Soc. Chem. Industry, London, pp. 1453--1480.

3 Ritcey, G.M., Slater, M.J. and Lucas, B.H. Proceedings of International Hydrometallurgy Symposium, AIME, Chicago, Feb., 1973. AIME, New York, 1973, pp. 419--474.

4 Fletcher, A.W. and Hester, K.W. A new approach to copper-nickel ore processing,

paper presented at the Annual AIME Meeting, New York, Feb., 1964.

5 Burkin, A.R. In: Proceedings of First Hydrometallurgy Meeting, CIM, Ottawa, Oct.,

1971.

6 Ritcey, G.M. Solvent extraction contactors. In: Proceedings of AIChE Symposium

on Solvent Ion Exchange, Tucson, Arizona, 1973.

7 Orth, D.A., McKibben, J.M. and Scotten, W.C. Proceedings of International Solvent

Extraction Conference, ISEC '74, Lyon, Soc. Chem. Industry, London, 1971, pp.

514--433.

8 Sege, G. and Woodfield, F.W. Chem. Eng. Prog., Aug., 1954, p. 396.

9 Ritcey, G.M., Joe, E.G. and Ashbrook, A.W. Trans. A.I.M.E., 238 (1967), 330--334.

10 Ritcey, G.M., Slater, M.J. and Lucas, B.H. Proceedings of International Hydrometallurgy Symposium, AIME, Chicago, Feb., 1973. AIME, New York, 1973, pp. 419--474.

11 Huppert, K.L., Issel, W. and Knoch, W. Proceedings of International Solvent Extraction Conference, ISEC '71, The Hague. Soc. Chem. Industry, London, 1971, pp.

2063--2074.

12 Ritcey, G.M. and Conn, K. Liquid--liquid separation of zirconium and hafnium; Eldorado Nuclear, R&D Division, Ottawa, Report T67-7; 1967.

13 Lucas, B.H. and Ritcey, G.M. CIM Bulletin, January, 1975.

14 Gaudernack, B. and Braaten, O. Occurrence and extraction of rare earths in Norway.

Presented at the 9th Rare Earth Research Conference, Oct., 10--14, 1971, Virginia.

15 Ritcey, G.M. In: Solvent Extraction --Principles and Application to Process Metallurgy, Part II. Elsevier, Amsterdam, 1979, p. 544.

16 Personal communication.

17 Lucas, B.H. and Ritcey, G.M. CIM Bulletin, June 1975; Canadian Patent No. 101759,

Sept. 1977, U.S. Patent 3,969,476, 1976.

107

18

19

20

21

22

23

Rossiter, G. Anamax Twin Buttes Oxide Plant Operating Experience -- First Year.

Presented at the Arizona Section, AIME, Hydrometallurgical Division, spring, 1976.

Abramo, J.A. and Lowings, S.W.H. Uranium processing at Exxon's Highland Operation. Presented at Symposium on Solvent Ion Exchange, AIChE, Tucson, Arizona, May,

1973.

Hurst, F.J. Recovery of uranium from wet-process phosphoric acid by solvent extraction. Presented at Annual AIME meeting, Las Vegas, February, 1976.

Reference 15, Davy-Power Gas, p. 59.

Meyburgh, R.G.J. South African Inst. Min. and Metall., Oct., 1970, pp. 54--66, and

April 1971, pp. 190--197.

Ryle, B.G. USAEC Report TID 5295, 1956.