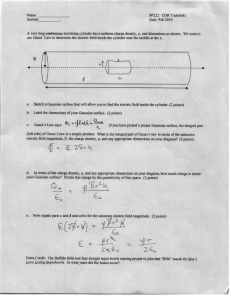

T.O. 33K1-4-1336-1 TECHNICAL MANUAL CALIBRATION PROCEDURE FOR GAUSSMETER 105645, 505056 (MAGNAFLUX CORP) 25 SERIES (RB ANNIS) This publication replaces T.O. 33K1-4-1336-1 dated 30 November 2009. Distribution Statement C - Distribution authorized to U. S. Government agencies and their contractors for official use or for administrative or operational purposes only, 30 August 1989. Requests for this document shall be referred to AFMETCAL, 813 Irving-Wick Dr W, Heath, OH 43056-1199. Destruction Notice - For unclassified, limited documents, destroy by any method that will prevent disclosure of the contents or reconstruction of the document. Published under Authority of the Secretary of the Air Force 30 JULY 2019 T.O. 33K1-4-1336-1 GAUSSMETER 105645, 505056 (MAGNAFLUX CORP) 25 SERIES (RB ANNIS) 1 CALIBRATION DESCRIPTION: Table 1. Test Instrument (TI) Characteristics Gauss Performance Specifications Test Method Range: P/N 105645, 20 to 0 to 20 Gauss; P/N 505056, 10 to 0 to 10 Gauss; P/N 25 Series: 5 to 0 to 5 Gauss, 10 to 0 to 10 Gauss, 20 to 0 to 20 Gauss, 50 to 0 to 50 Gauss Compare to a calculated Helmholtz Coil field Accuracy: P/N 105645 and P/N 505056, ±5% of FS; P/N 25 Series: 5, 10, 20 and 50 * Gauss, ±2% of FS * See step 3.4. 2 EQUIPMENT REQUIREMENTS: Noun 2.1 POWER SUPPLY Minimum Use Specifications Range: 0 to 30 A @ 10 VDC Calibration Equipment SubItem NJE Corp CS10SVC30 Accuracy: N/A 2.2 HELMHOLTZ COIL * Range: 0 to 10 Gauss Accuracy: ±1% of G/A Constant Worst case TAR: 2.2:1 for P/N 25 Series at 9 Gauss AFPSL Standard Helmholtz Coil (Local Manufacture) See footnote at end of Equipment Requirements. 1 T.O. 33K1-4-1336-1 Minimum Use Specifications Noun 2.3 HELMHOLTZ COIL * Calibration Equipment Range: 0 to 30 Gauss Accuracy: ±1% of G/A Constant Worst case TAR: 2.2:1 for P/N 25 Series at 18 Gauss 2.4 DIGITAL MULTIMETER Range: 0 to ±10 ADC SubItem AFPSL Standard Helmholtz Coil (Local Manufacture) Fluke 8508A/01AF Accuracy: ±0.1% of rdg * See step 3.5. 3 PRELIMINARY OPERATIONS: 3.1 Review and become familiar with the entire procedure before beginning the Calibration Process. WARNING Unless otherwise designated, and prior to beginning the Calibration Process, ensure that all test equipment voltage and/or current outputs are set to zero (0) or turned off, where applicable. Ensure that all equipment switches are set to the proper position before making connections or applying power. If not strictly observed, could result in injury to, or death of, personnel or long term health hazards. WARNING Voltages and current hazardous to personnel may be encountered during the sequence of this calibration procedure. All necessary precautions during the conduct of this calibration must be observed. If not strictly observed, could result in injury to, or death of, personnel or long term health hazards. 3.2 Connect test equipment to appropriate power source. Set all POWER switches to ON and allow warm-up as required by the manufacturer. 3.3 Use Table 2 or Table 3 as applicable for the TI being calibrated. 3.4 Due to lack of standards, the part number 25 Series, 50 to 50 Gauss TI will be limited to 18 Gauss. Annotate and attach a Limited Certification Label. Use Helmholtz Coil (2.3). 3.5 If using Helmholtz Coil (2.2), perform the calibration points listed in Table 2/3, as applicable, up through the nominal 10 Gauss value listed. This will sufficiently check the TI scale linearity and no Limited Certification Label is required. If using Helmholtz Coil (2.3), perform all applicable calibration points listed in Table 2/3, except the nominal 2 Gauss value listed. 3.6 Para 4.1 includes steps to aid in compensation for earths magnetic field. These include reversing the physical orientation by 180° and reversing the polarity of current through the circuit of Figure 1. 2 T.O. 33K1-4-1336-1 4 CALIBRATION PROCESS: NOTE Unless otherwise specified, verify the results of each test and take corrective action whenever the test requirement is not met, before proceeding. 4.1 GAUSS CALIBRATION: 4.1.1 Set up the Helmholtz Coil on a plastic stand in an area where the effects of external magnetic fields can be minimized (i.e., maximize distance from electronic equipment, transformers and etc.). 4.1.2 Connect equipment as shown in Figure 1. HELMHOLTZ COIL Magnetic fields about each POWER SUPPLY - + Resistant magnetic field DIGITAL MULTIMETER LO A Figure 1. 4.1.3 Set Digital Multimeter to measure ADC. 4.1.4 Place the TI inside the Helmholtz Coil orienting the TI sensing element as close as possible to the Helmholtz Coil three-dimensional geometric center. 4.1.5 Set the Power Supply for a TI cardinal point indication at the first applicable value listed in the Nominal Value column of Table 2/3. 4.1.6 Record the Digital Multimeter indication as DMM +0° for the corresponding Nominal Value. 4.1.7 Repeat steps 4.1.5 and 4.1.6 for each applicable remaining Nominal Value listed in Table 2/3. 4.1.8 Set Power Supply to minimum. 3 T.O. 33K1-4-1336-1 4.1.9 Reverse leads on Power Supply output to reverse the current direction through the Helmholtz Coil. 4.1.10 Set the Power Supply for a TI cardinal point indication at the first applicable value listed in the Nominal Value column of Table 2/3. 4.1.11 Record the Digital Multimeter indication as DMM -0° for the corresponding Nominal Value. 4.1.12 Repeat steps 4.1.10 and 4.1.11 for each applicable remaining Nominal Value listed in Table 2/3. 4.1.13 Set Power Supply to minimum. 4.1.14 Rotate TI 180° and reposition the sensing element as close to the original position in the Helmholtz Coil as possible. 4.1.15 Set the Power Supply for a TI cardinal point indication at the first applicable value listed in the Nominal Value column of Table 2/3. 4.1.16 Record the Digital Multimeter indication as DMM -180° for the corresponding Nominal Value. 4.1.17 Repeat steps 4.1.15 and 4.1.16 for each applicable remaining Nominal Value listed in Table 2/3. 4.1.18 Set Power Supply to minimum. 4.1.19 Reverse leads on Power Supply output to reverse the current direction through the Helmholtz Coil (original setup). 4.1.20 Set the Power Supply for a TI cardinal point indication at the first applicable value listed in the Nominal Value column of Table 2/3. 4.1.21 Record the Digital Multimeter indication as DMM +180° for the corresponding Nominal Value. 4.1.22 Repeat steps 4.1.20 and 4.1.21 for each applicable remaining Nominal Value listed in Table 2/3. 4.1.23 Set Power Supply to minimum. 4.1.24 Using corresponding values recorded in steps 4.1.6, 4.1.11, 4.1.16 and 4.1.21, calculate and record the average of the absolute values for each TI nominal value using the following formula: 𝐷𝐷𝐷𝐷𝐷𝐷𝐴𝐴𝐴𝐴𝐴𝐴 = |𝐷𝐷𝐷𝐷𝐷𝐷 +0°| + |𝐷𝐷𝐷𝐷𝐷𝐷 -0°| + |𝐷𝐷𝐷𝐷𝐷𝐷 -180°| + |𝐷𝐷𝐷𝐷𝐷𝐷 +180°| 4 4.1.25 Calculate the TI Gauss using the following formula: Where: 𝐺𝐺𝐺𝐺𝐺𝐺𝐺𝐺𝐺𝐺 = 𝐾𝐾 ∗ 𝐷𝐷𝐷𝐷𝐷𝐷𝐴𝐴𝐴𝐴𝐴𝐴 K = Helmholtz Coil Gauss/Ampere Constant. DMMAvg = value recorded in step 4.1.24. 4.1.26 Verify the calculated TI Gauss value in step 4.1.25 is within the corresponding values listed in the applicable Limits column of Table 2/3. 4 T.O. 33K1-4-1336-1 Table 2. Nominal Value (Gauss) P/N 105645 Limits (Gauss) P/N 505056 Limits (Gauss) 2 1.0 to 3.0 1.5 to 2.5 4 3.0 to 5.0 3.5 to 4.5 6 5.0 to 7.0 5.5 to 6.5 8 7.0 to 9.0 7.5 to 8.5 9 8.5 to 9.5 10 9.0 to 11.0 14 13.0 to 15.0 18 17.0 to 19.0 Table 3. Nominal Value 5 to 0 to 5 P/N 25 Series Limits (Gauss) 10 to 0 to 10 20 to 0 to 20 2 1.9 to 2.1 1.8 to 2.2 1.6 to 2.4 4 3.9 to 4.1 3.8 to 4.2 3.6 to 4.4 3.0 to 5.0 6 5.8 to 6.2 5.6 to 6.4 5.0 to 7.0 8 7.8 to 8.2 7.6 to 8.4 7.0 to 9.0 9 8.8 to 9.2 10 9.6 to 10.4 9.0 to 11.0 14 13.6 to 14.4 13.0 to 15.0 18 17.6 to 18.4 17.0 to 19.0 50 to 0 to 50 4.1.27 Calibration complete. Set all POWER switches to OFF, disconnect and secure all equipment. 4.1.28 For part number 25 Series, 50 to 0 to 50 Gauss, annotate and attach a Limited Certification Label IAW step 3.4. CALIBRATION PERFORMANCE TABLE Not Required 5/(6 Blank)