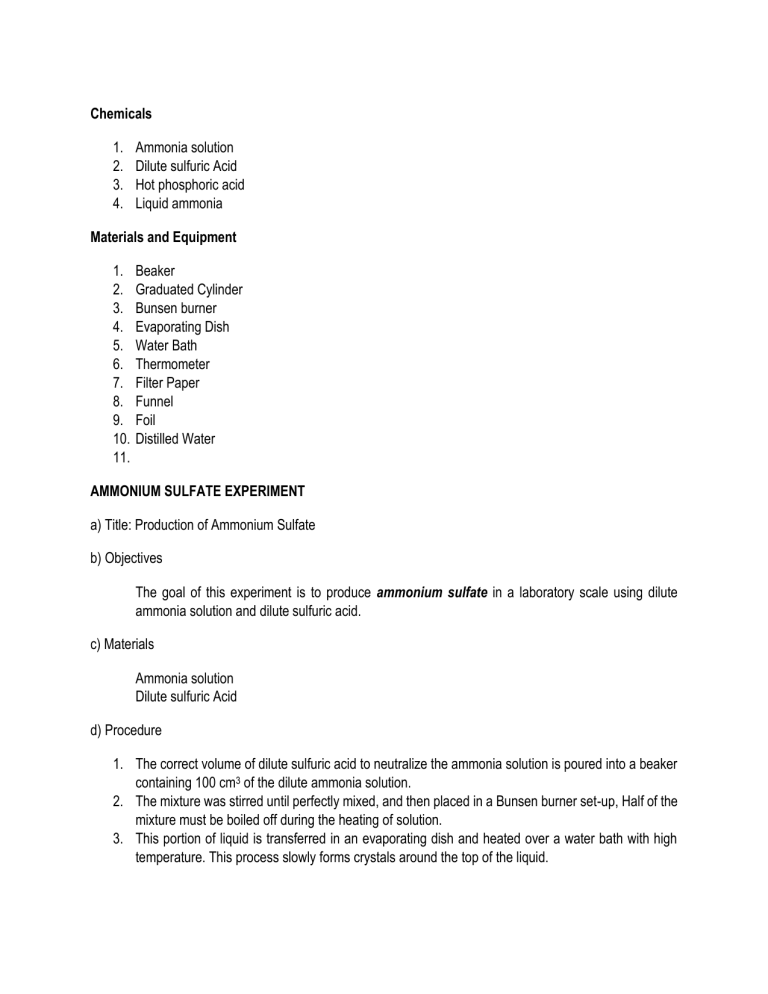

Chemicals 1. 2. 3. 4. Ammonia solution Dilute sulfuric Acid Hot phosphoric acid Liquid ammonia Materials and Equipment 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Beaker Graduated Cylinder Bunsen burner Evaporating Dish Water Bath Thermometer Filter Paper Funnel Foil Distilled Water AMMONIUM SULFATE EXPERIMENT a) Title: Production of Ammonium Sulfate b) Objectives The goal of this experiment is to produce ammonium sulfate in a laboratory scale using dilute ammonia solution and dilute sulfuric acid. c) Materials Ammonia solution Dilute sulfuric Acid d) Procedure 1. The correct volume of dilute sulfuric acid to neutralize the ammonia solution is poured into a beaker containing 100 cm3 of the dilute ammonia solution. 2. The mixture was stirred until perfectly mixed, and then placed in a Bunsen burner set-up, Half of the mixture must be boiled off during the heating of solution. 3. This portion of liquid is transferred in an evaporating dish and heated over a water bath with high temperature. This process slowly forms crystals around the top of the liquid. 4. The liquid is cooled at room temperature, then when cooled, the liquid is filtered using a funnel and a paper in order to separate the crystals, which is the ammonium sulfate. 5. The ammonium sulfate crystals is then dried in a warm place. DIAMMONIUM PHOSPHATE EXPERIMENT a) Title: Production of Diammonium Phosphate b) Objectives The goal of this experiment is to produce diammonium phosphate in a laboratory scale reacting hot phosphoric acid and liquid ammonia. c) Materials Hot phosphoric acid Liquid ammonia d) Procedure 1. Achieve a diluted phosphoric acid by neutralizing phosphoric acid with water (Ratio; 1.3:1) 2. Diluted solution is added in an enamel reaction tank. 3. Ammonia gas is passed through the ammonium distributor’s round tube for neutralization reaction and should have pH level of solution between 8 and 9. 4. The hot solution is filtered, and then sent to the cooling crystallizer. 5. The mother liquor is sent to a centrifuge and then dried to have diammonium phosphate products. The chemical reaction equation in the process: 6. H3PO4 + 2NH3 → (NH4) 2HPO4 7. The mother liquor which was centrifuged is sent to the separator together with ammonium sulfide to remove the iron content of the solution. 8. The concentrated filtrate is sent into the fine-tuning tank to adjust pH level of solution between 8 and 9 (again) then sent to the cooling crystallizer. 9. The process repeats. e) Results The reaction of hot phosphoric acid and liquid ammonia process garners a high purity diammonium phosphate.