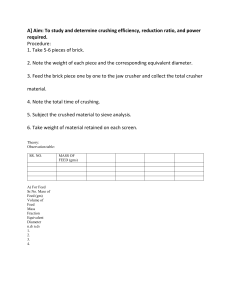

Available Available online online at at www.sciencedirect.com www.sciencedirect.com ScienceDirect Available online atonline www.sciencedirect.com Available at www.sciencedirect.com Procedia CIRP CIRP 00 00 (2020) (2020) 000–000 000–000 Procedia ScienceDirect ScienceDirect www.elsevier.com/locate/procedia www.elsevier.com/locate/procedia Procedia CIRP 00 (2017) 000–000 Procedia CIRP 91 (2020) 858–863 www.elsevier.com/locate/procedia 30th CIRP Design 2020 (CIRP Design 2020) Design ofDesign a small-scale stone crusher 28th CIRP Conference,granite May 2018, Nantes, France Tauyanashe Chikuku ,to Royanalyze N. Mushonga *, Tendai Sakala , Wilson R. Nyemba , Simon of A new methodology the functional and physical architecture a,c Chinguwaa,c existing products for an assembly oriented product family identification Department of of Mechanical Mechanical Engineering, Engineering, University University of of Zimbabwe, Zimbabwe, P PO O Box Box MP MP 167, 167, Mount Mount Pleasant, Pleasant, Harare, Harare, Zimbabwe Zimbabwe Department aa a, a, aa a,b a,b aa bb Department Department of of Quality Quality and and Operations Operations Management, Management, Faculty Faculty of of Engineering Engineering and and the the Built Built Environment, Environment, University University of of Johannesburg, Johannesburg, Auckland Auckland Park Park Bunting Bunting Road Road Campus, Campus, South South Africa. Africa. cc Department of of Mechanical Mechanical Engineering Engineering Science, Science, Faculty Faculty of of Engineering Engineering and and the the Built Built Environment, Environment, University University of of Johannesburg, Johannesburg, Auckland Auckland Park Park Kingsway Kingsway Department Campus, Campus, Auckand Auckand Park Park 2006, 2006, Johannesburg, Johannesburg, South South Africa. Africa. Paul Stief *, Jean-Yves Dantan, Alain Etienne, Ali Siadat École Nationale Supérieure d’Arts et Métiers, Arts et Métiers ParisTech, LCFC EA 4495, 4 Rue Augustin Fresnel, Metz 57078, France * Corresponding Corresponding author. author. Tel.: Tel.: +263713900710; +263713900710; fax: fax: +263-242-303280. +263-242-303280. E-mail E-mail address: address: nyasharoy@gmail.com nyasharoy@gmail.com * * Corresponding author. Tel.: +33 3 87 37 54 30; E-mail address: paul.stief@ensam.eu Abstract Abstract Abstract This paper paper describes describes the the design design of of aa manually manually operated operated granite granite stone stone crushing crushing machine. machine. This This machine machine is is targeted targeted for for people people who who are are currently currently in in This the the stone stone crushing crushing business business and and use use manual manual methods methods like like the the hammer hammer and and anvil. anvil. Due Due to to the the expensive expensive nature nature of of available available stone stone crushers crushers in in In today’s business environment, trend people towards moreafford product variety andand customization unbroken.ways Dueof this development, need of Zimbabwe small-scale crushingthe business people cannot afford these machines and hence resort resort is to primitive primitive ways oftocrushing crushing that are are both both the tedious Zimbabwe small-scale crushing business cannot these machines hence to that tedious harmful. After analysis of stone crushing and thorough aa solution was that safe, agile and andpotentially reconfigurable production systems emerged to cope with variousmethods products productstudy, families. To design and optimize production and potentially harmful. After careful careful analysis of current current stone crushing methods andand thorough study, solution was developed developed that is is safe, affordable solution addresses the of stone provides Research systems as welland as efficient. to chooseThe thedeveloped optimal product methods are crushers needed. and Indeed, mostaa viable of the alternative. known methods aim to affordable and efficient. The developed solution matches, addresses product the needs needsanalysis of the the hammer hammer stone crushers and provides viable alternative. Research wasa performed performed through experiments, thethe usephysical of local local level. libraries and site siteproduct visits to to families, stone crushing crushing companies and various various quarry sites thatnumber use the the and analyze product orthrough one product family on Different however, may differ largely quarry in terms of the was experiments, the use of libraries and visits stone companies and sites that use and were conduct experiments and minimum crushing needed for hammer and anvil anvil approach. approach. University laboratories were used used to toand conduct experiments and determine determine minimum crushing forces forces needed for naturehammer of components. This fact University impedes anlaboratories efficient comparison choice of appropriate product family combinations for the production various granite stones. A portable stone crushing machine was then designed which meets the minimum crushing force of 225KN. An additional various granite stones. A portable stone crushing machine was then designed which meets the minimum crushing force of 225KN. An additional system. A new methodology is proposed to analyze existing products in view of their functional and physical architecture. The aim is to cluster of 10% to safety the and potential to stones range of granite stone. granite allowance of new 10% assembly to carter carter for for safety of of the machine machine andfor potential to crush crush other other stones within within rangelines of the theand granite stone. The The small scale granite theseallowance products in oriented product families the optimization of existing assembly the creation ofsmall futurescale reconfigurable stone crusher crusher was was designed designed to to crush crush stones stones of of approximately approximately 25-135mm 25-135mm to to about about 24-20.2mm 24-20.2mm in in size. size. SOLID SOLID WORKS WORKS was was used used as as aa stress stress stone assembly systems. Based on Datum Flow Chain, the physical structure of the products is analyzed. Functional subassemblies are identified, and analysis tool tool on on the the gear gear (main (main crushing crushing part) part) to to determine determine the the regions regions where where the the gear gear experiences experiences maximum maximum force force according according to to Von-Misses Von-Misses analysis a functional analysis is performed. Moreover, a hybrid functional and physical architecture graph (HyFPAG) is the output which depicts the failure criteria. was the inner diameter of assembly and gears are prone high stress results in failurebetween criteria. It Itproduct was observed observed theby inner diameterdesign of the the gear gear assembly and the the gears themselves themselves prone to to high stress which which resultsAn in tearing tearing similarity families providing support to both, production system are planners and product designers. illustrative off of of the the material material in in those those regions. regions. off example of a nail-clipper is used to explain the proposed methodology. An industrial case study on two product families of steering columns of thyssenkrupp Presta France is then carried out B.V. to B.V. give a first industrial evaluation of the proposed approach. © 2020 The The Authors. Published Elsevier 2020 The Authors. Published byby Elsevier © 2020 Authors. Published by Elsevier B.V. © 2017 The Authors. Published byunder Elsevier B.V. This is an open access article the CC BY-NC-ND (http://creativecommons.org/licenses/by-nc-nd/4.0/) Peer-review under responsibility of the scientific of Design Peer-review under responsibility of the scientific committee committeelicense of the the CIRP CIRP Design Conference Conference.. Peer-review underunder responsibility of theofscientific committee of theof28th CIRPBioManufacturing Design ConferenceConference 2018. Peer-review responsibility the scientific committee the CIRP 2019. Keywords: Granite Granite stone stone crusher; crusher; crushing crushing force; force; quarry quarry stones. stones. Keywords: Keywords: Assembly; Design method; Family identification 1. Introduction Introduction 1. As indicated indicated in in Fig. Fig. 1, 1, the the crushing crushing process process involves involves As transferring force which can be be amplified amplified by mechanical mechanical of the product rangewhich and characteristics manufactured and/or transferring aa force can by advantage aa material that has bonds with This advantage through through material that context, has stronger stronger bondschallenge with aa in This paper paper provides provides aa problem problem solver solver for for aa small-scale small-scale stone stone assembled in this system. In this the main higher to compared to being crushing in not crushing higher resist resistand to deformation deformation as compared to the the material being crushing industry in Zimbabwe, Zimbabwe, not only only making stone crushing Due to industry the fast development inmaking the stone domain of modelling analysis is as now not only to material cope with single crushed. Crushing devices hold material between two parallel easier and more productive but also making it more desirable crushed. Crushing hold material betweenproduct two parallel easier and more but also making it more desirable communication andproductive an ongoing trend of digitization and products, a limiteddevices product range or existing families, or tangent tangent solid surfaces, and and apply apply sufficient sufficient force force to to bring bring the career choice choice for those those who whoenterprises were limited limited by risk of ofimportant injury or or or surfaces, career for were risk injury digitalization, manufacturing areby facing but also tosolid be able to analyze and to compare products to the define surfaces together together to to generate generate enough enough energy energy within within the the material material low body body strength. strength. Stone Stone crushing crushing is is reducing reducing the the size size of of large large surfaces low challenges in today’s market environments: a continuing new product families. It can be observed that classical existing being so that its separate or change rocks into rocks or Quarry in this being crushed crushed so are thatregrouped its molecules molecules separateoffrom, from, or or change rocks towards into smaller smaller rocks or orofgravel gravel or dust. dust. Quarry stones stones this tendency reduction product development timesinand product families in function clients features. alignment in relation to, each other [2]. However, paper refer to granite ¾ inches (20mm) or less. These stones are alignment in relation to, each other [2]. However, the the paper refer to granite ¾ inches (20mm) or less. These stones are shortened product lifecycles. In addition, there is an increasing However, assembly oriented product families are hardly to find. vital convectional way way of of stone stone crushing crushing consists consists of of high high chances chances of of vital to to the the construction construction industry industry and and when when crushed crushed are are mainly mainly convectional demand of customization, being at the same time in a global On the product family level, products differ mainly in self-inflicted injuries injuries such such as as injuring injuring fingers fingers when when holding holding the the two used for for road road base base aggregate aggregate and and in in concrete concrete mix mix [1]. [1]. self-inflicted used competition with competitors all over the world. This trend, main characteristics: (i) the number of components and (ii) the which is inducing the development to micro type of components (e.g. mechanical, electrical, electronical). 2212-8271 © 2020 2020 The The Authors. Published by by from Elsevier macro B.V. 2212-8271 © Authors. Published Elsevier B.V. markets, results in diminished lot sizes due to augmenting Classical Peer-review under responsibility of the scientific committee of the CIRP Design Conference 2020. Peer-review under responsibility of the scientific committee of the CIRP Design Conference 2020. methodologies considering mainly single products product varieties (high-volume to low-volume production) [1]. or solitary, already existing product families analyze the To cope with this augmenting variety as well as to be able to product structure on a physical level (components level) which identify possible optimization potentials in the existing causes difficulties regarding an efficient definition and production system, it is important to have a precise knowledge comparison of different product families. Addressing this 1. Introduction 2212-8271 © 2020 The Authors. Published by Elsevier B.V. This is an©open article Published under theby CC BY-NC-ND 2212-8271 2017access The Authors. Elsevier B.V. license (http://creativecommons.org/licenses/by-nc-nd/4.0/) Peer-review under responsibility of scientific the scientific committee theCIRP CIRP BioManufacturing Conference 2019 Peer-review under responsibility of the committee of the of 28th Design Conference 2018. 10.1016/j.procir.2020.03.119 Tauyanashe Chikuku et al. / Procedia CIRP 91 (2020) 858–863 2 Chikuku et al./ Procedia CIRP 00 (2020) 000–000 rocks and eyes due to flying stones during impact. Not only is this unsafe to the person at hand but also to the people around. As a result, there was a need to design a machine that is more efficient, secure and environmental friendly during operation. As part of the research, interviews were conducted so as to get a better understanding of the working environment. General questions asked such as: •What are the challenges faced in using the hammer and anvil method? •What is the rate of production? •What are the general needs/requirements on machine to be designed? Fig. 1. Basic Principles of rock crushing [2] Some of the responds given were: Safety is a prime concern as one has to be very careful otherwise one can lose a hand, there is also risk of inhalation of quarry dust. Some hammer and anvil crushers have also tried to find alternative methods but generally the cost of the machines is very high and also the cost of maintenance is not worth it. There is also the problem of getting a power source on site. Because the hammer and anvil method is slow, the crushers cannot meet high demand of crushed rock and they lose customers to bigger companies due to inadequate amount of rock available as the customer would have to wait for days for enough crushed stone to be gathered. Average time taken to fill one-wheel barrow with crushed granite is 1hr 30mins that is not including time taken to retrieve stone from the dwalas and breaking them into manageable sizes. The cost of one cubic metre of crushed stone is USD$24 and 1 cubic is equal to 12 wheelbarrows of stone. Sorting of stone to desired sizes is a major setback. The information obtained tallies with the main aims of the designing a machine that provides better working conditions and safer environment. special qualifications and hence many people have resorted to it for a living. There is also a high demand in construction materials like quarry stones due to the increase in the number of housing cooperatives in recent years. These stone crushers obtain their granite rock from local dwalas by exposing the parent rock (dwala) to extreme fluctuating temperatures through the burning of tires over the dwalas (Fig. 2). After cooling, pieces of rock can be chipped off using a sledge hammers, the process is basically forced exfoliation. These chunks of rock are then crushed into the desired aggregates to be sold for their various application. Fig. 2. Setting up tyre to burn Dwala Rock crushers are used for breaking rock particles into smaller fragments. Rock materials of different sizes, normally called aggregates, are used as building materials in a vast number of products and applications in modern society. Infrastructure and building industries are heavily dependent on rock material with specified characteristics as the basis for foundations, concrete structures, roads and so on. Hence this gives a strong incentive to facilitate the production of aggregates at low cost, high quality and low environmental footprint [3]. 3. Previous designs Fig. 3. presents a manual stone crusher which was designed by New Dawn Engineering (Swaziland). The main disadvantage of this crusher is that it is not locally available and has poor safety mechanisms incase an uncrushable material enter the crusher. The new Dawn crusher is also operated by at least five individuals and it is said to be able to produce 10 cubic metres of stone per day. 2. Background The small-scale (hammer and anvil) stone crushing sector is an important part of the stone crushing industry, it is not necessarily new but it is growing by the day along with the slight boom in construction that can be attributed to the increase in the number of housing cooperatives and similar schemes. The closing of major companies in Zimbabwe has resulted in high unemployment rate and this has resulted in people relying on informal work like stone crushing. This work requires no Fig. 3. New Dawn Engineering manual stone crusher [4] 859 3 Chikuku et al./ Procedia CIRP 00 (2020)CIRP 000–000 Tauyanashe Chikuku et al. / Procedia 91 (2020) 858–863 860 Another type of manual stone crusher is the crazy crusher; it is mainly used in laboratories for crushing rock samples for testing. It uses a lever to create the necessary force needed to crush stone. Currently its design is still patent pending. The crazy crusher is very small and therefore would not work for big quantities of rock. it also crushes stone into fine powder which is not ideal as the desired level of crushing in this case is ¾ inches. Fig. 5. Open ended steel cylinder, plunger, base plate. Fig. 4. Crazy crusher 4. Methodology 4.1. Experimental results In order to come up with the design, experimental work was carried out to determine parameters such as the minimum force required to start crushing, size of the aggregate obtained at different loads. By considering the aggregate crushing value (ACV) which gives a relative measure of the resistance of an aggregate to crushing under a gradually applied compressive load. It was observed that they was a gradual decrease in ACV as the aggregates decreased in size. The standard aggregate crushing test shall be made an aggregate passing the 24mm BS test sieve and retained on the 20.2mm BS test sieve. 4.2. Apparatus The following apparatus is required for the standard test. •An open-ended steel cylinder of nominal 150mm internal diameter, with a plunger and a baseplate •A straight steel tamping rod, of circular cross-section 16mm diameter, and 450mm to 600mm long, rounded at the end •A balance 3000g accurate to 1 g •BS sieves, sizes 24mm; 20.2mm; •A compression testing machine, capable of applying force of 400kN at a uniform rate so that maximum load is reached in 10mins. •A rigid cylindrical metal measure, for measuring the sample, of internal diameter 115mm and an internal depth of 180mm Fig. 6. Final sieved aggregate on scale. The granite was put under gradual load and it was observed that 225KN was the minimum load under which the granite was crushed to 20.2 mm. Impact force required is 400N Average force from a human arm is 150N Average force from pedalling used as 200N The relationship between the impact force required (400N) and the average force of a human (150-200N) shows that without mechanical advantage it would be near impossible to crush granite. Therefore, the aim for the success is for the machine to offer at least double the mechanical advantage that is to ensure crushing will occur. 5. Governing equations According to Chakrabarty [8] The constitutive equations of the elastic-plastic deformation of a material is based on combining the Hooke’s law and either the Incremental or Deformation theory which are stated as below. According to Hooke’s law: � 𝑑𝑑𝑑𝑑�� =� 1 + 𝑣𝑣 1 − 2𝑣𝑣 � 𝑠𝑠̇�� + � � 𝜎𝜎̇�� 𝛿𝛿�� 𝐸𝐸 3𝐸𝐸 Based on Prandtl-Reuss Incremental Theory (IT): (1) Tauyanashe Chikuku et al. / Procedia CIRP 91 (2020) 858–863 4 1 − 2𝑣𝑣 � 𝜎𝜎̇�� 𝛿𝛿�� 3 3𝜎𝜎�̇ 𝐸𝐸 + � − 1� 𝑠𝑠�� 2𝜎𝜎� 𝐸𝐸� 𝐸𝐸𝜀𝜀̇�� = (1 + 𝑣𝑣)𝑠𝑠̇�� + � 3 𝐸𝐸� 2𝑞𝑞 − 𝑝𝑝 𝑠𝑠 𝑐𝑐�� = �1 − � � � 𝐸𝐸� 𝜎𝜎� 𝜎𝜎� 2 (2) 𝑐𝑐�� = 3 According to the Deformation theory (DT): 𝐸𝐸𝜀𝜀̇�� = � 861 Chikuku et al./ Procedia CIRP 00 (2020) 000–000 3𝐸𝐸 1 − 2𝑣𝑣 1 − 2𝑣𝑣 + � 𝑠𝑠̇�� + � � 𝜎𝜎̇�� 𝛿𝛿�� 2𝐸𝐸� 2 3 3𝜎𝜎�̇ 𝐸𝐸 𝐸𝐸 + � − � 𝑠𝑠 2𝜎𝜎� 𝐸𝐸� 𝐸𝐸� �� (3) Where: 𝜀𝜀̇�� is the change in strain and 𝑖𝑖 𝑎𝑎𝑎𝑎𝑎𝑎 𝑗𝑗 = 1,2 or 3 𝜎𝜎̇�� is the change in stress 𝜎𝜎�̇ is the change in the effective stress 𝑣𝑣 poison ratio 𝐸𝐸� is tangent modulus 𝐸𝐸� = 𝜎𝜎� ⁄𝜀𝜀̅ 𝑠𝑠̇�� is the stress deviator tensor given by: 𝐼𝐼 𝑠𝑠�� = 𝜎𝜎�� − 𝛿𝛿�� 3 By further manipulating the above equation, the stress rate corresponding to the strain rate in the can be expressed as: 𝜎𝜎̇� 𝛼𝛼 𝛽𝛽 𝒳𝒳 𝜀𝜀̇� (4) � 𝜎𝜎̇� � = 𝐸𝐸 � 𝛽𝛽 𝛾𝛾 𝜇𝜇 � � 𝜀𝜀̇� � 𝜏𝜏̇ �� 𝒳𝒳 𝜇𝜇 𝛿𝛿 𝛾𝛾̇�� Where The corresponding parameters 𝛼𝛼, 𝛽𝛽, 𝛾𝛾, 𝛿𝛿, 𝜇𝜇, 𝒳𝒳 depend on the type of plasticity theory used i.e. IT or DT and 𝐸𝐸 is the Young modulus. 1 � ) (𝑐𝑐 𝑐𝑐 − 𝑐𝑐�� 𝜌𝜌 �� �� 1 𝛽𝛽 = (𝑐𝑐�� 𝑐𝑐�� − 𝑐𝑐�� 𝑐𝑐�� ) 𝜌𝜌 1 � ) 𝛾𝛾 = (𝑐𝑐�� 𝑐𝑐�� − 𝑐𝑐�� 𝜌𝜌 1 𝒳𝒳 = (𝑐𝑐�� 𝑐𝑐�� − 𝑐𝑐�� 𝑐𝑐�� ) 𝜌𝜌 1 𝜇𝜇 = (𝑐𝑐�� 𝑐𝑐�� − 𝑐𝑐�� 𝑐𝑐�� ) 𝜌𝜌 1 � ) 𝛿𝛿 = (𝑐𝑐�� 𝑐𝑐�� − 𝑐𝑐�� 𝜌𝜌 𝑐𝑐 𝑐𝑐 𝑐𝑐 𝐸𝐸 �� �� �� 𝜌𝜌 = �𝑐𝑐�� 𝑐𝑐�� 𝑐𝑐�� � 𝐸𝐸� 𝑐𝑐 �� 𝑐𝑐�� 𝑐𝑐�� 𝛼𝛼 = (5a) (5b) (5c) (5d) (5e) (5f) (5g) 𝐸𝐸� 𝑞𝑞� 𝑠𝑠 � � � � + �� 𝐸𝐸� 4𝜎𝜎� 𝜎𝜎� 1 𝐸𝐸� 𝑐𝑐�� = − �1 − (1 − 2𝑣𝑣) 2 𝐸𝐸 𝐸𝐸� 𝑝𝑝𝑝𝑝 𝑠𝑠 � − 3 �1 − � � � + � �� 𝐸𝐸� 2𝜎𝜎� 𝜎𝜎� 3 𝐸𝐸� 2𝑝𝑝 − 𝑞𝑞 𝑠𝑠 𝑐𝑐�� = �1 − � � � 𝐸𝐸� 𝜎𝜎� 𝜎𝜎� 2 𝐸𝐸� 𝑝𝑝� 𝑠𝑠 � 𝑐𝑐�� = 1 − 3 �1 − � � � + � � 𝐸𝐸� 4𝜎𝜎� 𝜎𝜎� (6f) Let 𝜎𝜎� = −𝑝𝑝, 𝜎𝜎� = −𝑞𝑞, 𝜏𝜏�� = −𝑠𝑠 at the point of bifurcation. Assuming that the material is in a state of plane stress i.e. 𝜎𝜎� = 𝜏𝜏�� = 𝜏𝜏�� =0, the effective stress 𝜎𝜎� can be expressed as: � (7) 𝜎𝜎� � = 𝜎𝜎�� − 𝜎𝜎� 𝜎𝜎� + 𝜎𝜎�� + 3𝜏𝜏�� G. H. Handelman and W. Prager [10] carried out serval experiments focusing on the plastic deformation analysis of a material (plate under compressive load) in order to assess the difference between the IT and DT. They observed that their results obtained by DT were in good agreement with the experimental results. Based on studies carried out by Handelman the present study only focused on using DT. The basic integral of uniqueness of a material under deformation is given by the strain energy function given by Chakrabarty [8] as: 1 (8) ��𝜎𝜎̇� 𝜀𝜀̇� + 𝜎𝜎̇� 𝜀𝜀̇� + 𝜏𝜏̇�� 𝛾𝛾̇�� �𝑑𝑑𝑑𝑑 2 The potential energy V for the material subjected to uniform in-plane compressive stresses is given as: 1 𝜕𝜕𝜕𝜕 � 𝜕𝜕𝜕𝜕 � − � �𝜎𝜎� ℎ � � + 𝜎𝜎� ℎ � � 2 𝜕𝜕𝜕𝜕 𝜕𝜕𝜕𝜕 (9) 𝜕𝜕𝜕𝜕 𝜕𝜕𝜕𝜕 + 2𝜏𝜏�� ℎ � � � �� 𝑑𝑑𝑑𝑑 𝜕𝜕𝜕𝜕 𝜕𝜕𝜕𝜕 𝑈𝑈 = By using calculus of variation, Solid Works is able to use the Euler-Lagrange differential equations associated with the minimization of the total potential energy functional with respect to the arbitrary variation of the displacement function w, which is given by: δ(U+V)=0 (10) The aggregate crushing value is calculated by the following equation: Aggregate crushing value % = B/A×100 (11) According to the deformation theory: 𝑐𝑐�� = 1 − 3 �1 − 𝐸𝐸� 𝐸𝐸� 𝐸𝐸� 𝑠𝑠 � − (1 − 2𝑣𝑣) + 9 �1 − � � 𝐸𝐸� 𝐸𝐸 𝐸𝐸� 𝜎𝜎� (6e) (6a) (6b) (6c) (6d) Where: A= mass of surface dry sample B=the mass of the fraction passing the 2,36mm BS sieve load is determined by: L=(14L_1)/(P+4) (12) Where: L = load to give percentage fines within the range 7.5 to 12.5% L1 = first test load P = percentage fines obtained with the first load Tauyanashe Chikuku et al. / Procedia CIRP 91 (2020) 858–863 862 Chikuku et al./ Procedia CIRP 00 (2020) 000–000 In the case of this design, the flywheel is directly attached to the crank therefore the input torque is a product of the crank force and the radius of the flywheel. An average human person can easily rotate a crank of radius 0.35m with radius of flywheel 0.4m to give allowance to screw on the handle. The energy stored in a flywheel is calculated by [5]: ∆𝐸𝐸 = 𝑚𝑚𝑅𝑅 � 𝜔𝜔 � 𝐾𝐾� (13) Where: m=mass of flywheel R=radius of flywheel=0.4m 𝜔𝜔=angular speed of rotation of flywheel 5 bottom of the jaws. The ores are fed to the machine from the top where the jaws are at the maximum distance apart. As the jaws come closer the ores are crushed into smaller sizes and slip down the cavity in the return stroke. In following cycle, further reduction of size is experienced and the ore moves down further. The process is continued till particles size is reduced to less than the bottom opening. The toggle is used to guide the moving jaw. The retrieving motion of the jaw from its furthest end of travel is by springs for small crushers or by a pitman for larger crushers. For a smooth movement of the moving jaws, heavy flywheels are used. The gear diameter was designed considering available space (0.5m) and the velocity ratio 2:1[5] 𝐷𝐷� + 𝐷𝐷� ≤ 0.5 (14) Where 𝐷𝐷� =pitch diameter of pinion 𝐷𝐷� =pitch diameter of gear The jaw of the crusher is responsible for transferring the rotary motion of the eccentric shaft and applying the reciprocating motion to the wear plate, therefore it provides the crushing force of the jaw crusher and hence it is a critical component. The thickness of the jaw was calculated from equation 5 [5]. 𝑀𝑀𝑀𝑀 2𝐼𝐼� Where: 𝑀𝑀 is the bending moment 𝑡𝑡 is the thickness of the jaw 𝐼𝐼� second moment of inertia 𝜎𝜎� = Fig. 7 Sketch plan view showing mechanism for the crusher (15) 6. Design 6.1. Operating and principle in detail The mechanism of jaw crusher is to crush using impact on the upper parts of the jaw, with a little shear towards the bottom. Jaw crushers consist of two jaws. One fixed and the other reciprocating. The opening between them is largest at the top (gape) and decreases towards the bottom (set). The jaw moves on an eccentric shaft and the lower part is hinged on the toggles. The rock is thrown between two jaws and crushed by mechanical pressure. Rotational motion drives the eccentric shaft to rotate. This makes the attached jaw to approach and leave the other jaw repeatedly, to crush, rub and grind the feed. Hence the material moves gradually towards the bottom and finally discharges from the discharge end. The fixed jaw mounted in a “V” alignment is the stationary breaking surface. The swinging jaw exerts impact force on the material by forcing it against the stationary plate. The space at the bottom of the “V” aligned jaw plates is the crusher product size gaper size of the crushed product from the jaw crusher. The rocks are crushed until they are small enough to pass through the gap at the Fig. 8. Exposed (a)Side view (b) Plan (c) Isometric view The flywheels have crank handles as was with the original design however the flywheel shaft is connected to spur gears that transfer power to the eccentric shaft thus there are now two shafts instead of one. The ratio of the gears simply 1:2 so as to double the torque provided by the human operator. These gears also further improve the smoothness of operating the crusher, reducing shock to the operator cranking the mechanism. This is because the gears have their own mass and hence inertia such that once they start moving they will tend to resist motion in the backward direction. 6.2. Stress analysis on the main gear Fig. 9 indicates a simulation done by Solid Works of the mild steel gear, stressing out the regions expressing high and low amounts of stress during crushing. By assuming the gear will undergo elastic-plastic deformation (deformation theory) Tauyanashe Chikuku et al. / Procedia CIRP 91 (2020) 858–863 6 Chikuku et al./ Procedia CIRP 00 (2020) 000–000 and according to the Von-Mises failure criteria the gear will experience maximum stress at the root of the gear with stresses ranging from 6.767 to 9.473MPa. It was also observed that the regions surrounding the key way will also experience high stresses as a results of the high torque and resistance experienced during crushing. 863 [3] Quist, J, Cone crusher modelling and simulation. Development of a virtual rock crushing environment based on the discrete element method with industrial scale experiment validation. Goteborg, Chalmers University of Technology. 2012. [4] New Dawn Engineering. (2017). Rock crushing assembly instruction manual. Swaziland: New Dawn Engineering. [5] Khurmi R.S, G. J., 2005. A textbook of machine design. 14th ed. New Delhi: Eurasia Publishing House. [6] Hurst, K., Concept selection in engineering design Principles. 1999, New York: John Wiley and Sons, pp. 53-63. [7] Jones, J., Stone crushing. Complexities of construction, 2012, 1(1), p. 123. 14th ed. 2004, New Delhi: Eurasia Publishing House. [8]. Chakrabarty. Applied Plasticity,. 2010 [9] Oduori, M., Mutuli, S. and Munyasi, D. , Analysis of the single toggle jaw crusher kinematics, Journal of Engineering, Design and Technology, 2015, Vol. 13 No. 2, pp. 213-239. [10] G. H. Handelman and W. Prager, “Plastic buckling of a rectangular plate under edge thrusts,” 1949 Fig. 9 Stresses on main gear 7. Conclusions The purpose of this paper was to design a manually operated stone crusher that is efficient and affordable so as to suit the needs of the target market which is small scale stone crushers that depend on the hammer and anvil method of rock crushing. From the static and dynamic analysis of the jaw crusher mechanism it was noted that the jaw crusher can provide up to 60 times the mechanical advantage relating input and output torque, the use of gears also makes work easier for the operator of the machine. The combined weight of the machine is up to 200kg, due to heavy components like the flywheels which weigh 60kgs a piece, the ribbed casing combined with the jaws and wear plates provide the additional weight in order to balance the machine. It is thus recommended that the machine be disassembled in transit and assembled at the crush site, all components are modular hence assembling the machine is very simple. Acknowledgements The authors wish to acknowledge the assistance from the construction company, Design Team as well as other small sale contractors from where the data was collected and eventual testing of the mortar spraying machine. The researchers would also want to appreciate the residents of Budiriro in Harare whose homesteads and construction sites were visited. In addition, the authors are also grateful for the financial support provided by the Royal Academy of Engineering to promote such innovations through conferences and publications. References [1] Moavenzadeh, F, Concise encyclopedia of building and Construction Materials. Masettuses : MIT Press, 1990. [2] Satyendra, 2015. Ispat Guru. [Online] Available at: http://ispatguru.com/crushers-and-their-types