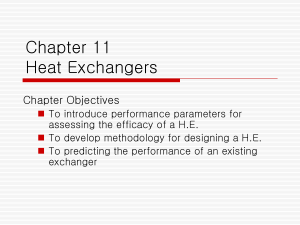

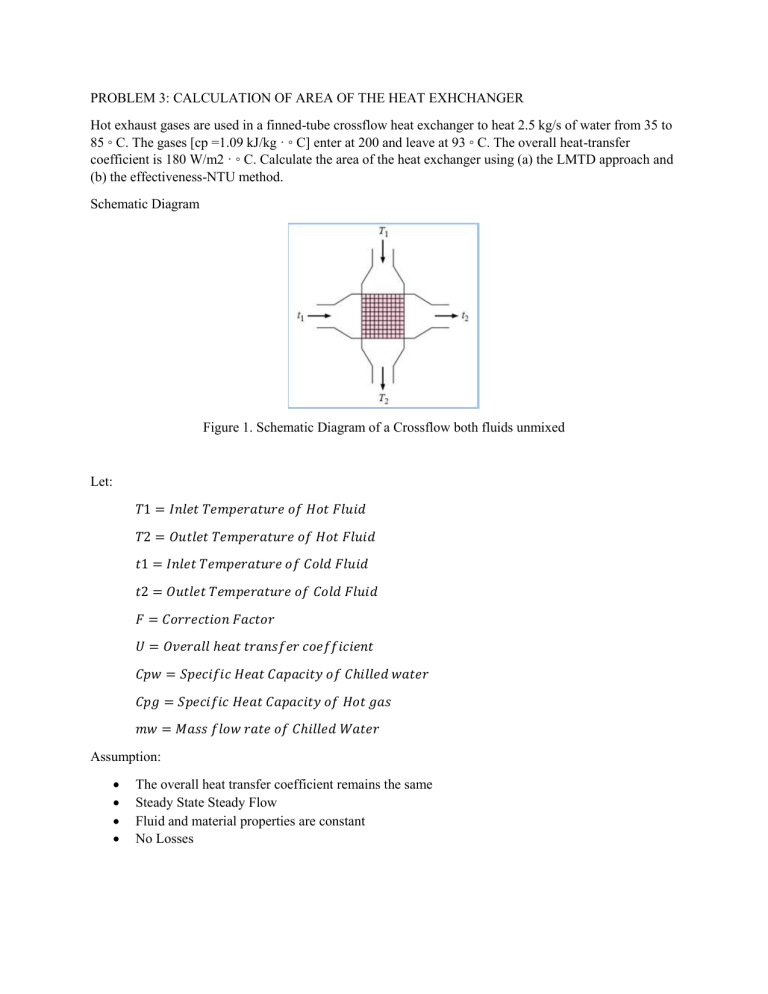

PROBLEM 3: CALCULATION OF AREA OF THE HEAT EXHCHANGER Hot exhaust gases are used in a finned-tube crossflow heat exchanger to heat 2.5 kg/s of water from 35 to 85 ◦ C. The gases [cp =1.09 kJ/kg · ◦ C] enter at 200 and leave at 93 ◦ C. The overall heat-transfer coefficient is 180 W/m2 · ◦ C. Calculate the area of the heat exchanger using (a) the LMTD approach and (b) the effectiveness-NTU method. Schematic Diagram Figure 1. Schematic Diagram of a Crossflow both fluids unmixed Let: 𝑇1 = 𝐼𝑛𝑙𝑒𝑡 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝑜𝑓 𝐻𝑜𝑡 𝐹𝑙𝑢𝑖𝑑 𝑇2 = 𝑂𝑢𝑡𝑙𝑒𝑡 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝑜𝑓 𝐻𝑜𝑡 𝐹𝑙𝑢𝑖𝑑 𝑡1 = 𝐼𝑛𝑙𝑒𝑡 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝑜𝑓 𝐶𝑜𝑙𝑑 𝐹𝑙𝑢𝑖𝑑 𝑡2 = 𝑂𝑢𝑡𝑙𝑒𝑡 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒 𝑜𝑓 𝐶𝑜𝑙𝑑 𝐹𝑙𝑢𝑖𝑑 𝐹 = 𝐶𝑜𝑟𝑟𝑒𝑐𝑡𝑖𝑜𝑛 𝐹𝑎𝑐𝑡𝑜𝑟 𝑈 = 𝑂𝑣𝑒𝑟𝑎𝑙𝑙 ℎ𝑒𝑎𝑡 𝑡𝑟𝑎𝑛𝑠𝑓𝑒𝑟 𝑐𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝐶𝑝𝑤 = 𝑆𝑝𝑒𝑐𝑖𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝑜𝑓 𝐶ℎ𝑖𝑙𝑙𝑒𝑑 𝑤𝑎𝑡𝑒𝑟 𝐶𝑝𝑔 = 𝑆𝑝𝑒𝑐𝑖𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝑜𝑓 𝐻𝑜𝑡 𝑔𝑎𝑠 𝑚𝑤 = 𝑀𝑎𝑠𝑠 𝑓𝑙𝑜𝑤 𝑟𝑎𝑡𝑒 𝑜𝑓 𝐶ℎ𝑖𝑙𝑙𝑒𝑑 𝑊𝑎𝑡𝑒𝑟 Assumption: The overall heat transfer coefficient remains the same Steady State Steady Flow Fluid and material properties are constant No Losses Given: 𝑇1 = 200 𝐶 𝑇2 = 93 𝐶 𝑡1 = 35 𝐶 𝑡2 = 85 𝐶 𝑈 = 180 𝑊/𝑚2 𝐾 𝑚𝑤 = 2.5 𝑘𝑔/𝑠 𝐶𝑝𝑤 = 4180 𝐽/𝑘𝑔 𝐾 Required: Calculate the Area of Heat Exchanger using a. LMTD Method Calculate the log mean temperature difference 𝛥𝑇𝐿𝑀𝑇𝐷 = 𝛥𝑇1 − 𝛥𝑇2 𝛥𝑇1 ln(𝛥𝑇2) when, 𝛥𝑇1 = 𝑇1 − 𝑡2 𝛥𝑇2 = 𝑇2 − 𝑡1 Substitute the given values 𝛥𝑇1 = 200 𝐶 − 85 𝐶 = 115 𝐶 𝛥𝑇2 = 93 𝐶 − 35 𝐶 = 58 𝐶 Solve for 𝛥𝑇𝐿𝑀𝑇𝐷 𝛥𝑇𝐿𝑀𝑇𝐷 = 115 𝐶 − 58 𝐶 = 83.27 𝐶 115 𝐶 ln( ) 58 𝐶 To identify the Correction Factor F, calculate the P and R value 𝑃= 𝑡2 − 𝑡1 85 𝐶 − 35 𝐶 = = 0.30 𝑇1 − 𝑡1 200 𝐶 − 35 𝐶 𝑅= 𝑇1 − 𝑇2 200 𝐶 − 93 𝐶 = = 2.14 𝑡2 − 𝑡1 85 𝐶 − 35 𝐶 Figure 2. Plot of Correction Factor for Heat Exchanger Through estimation based on the graph, we able to get the correction factor, 𝐹 = 0.92 Since, 𝑄ℎ𝑜𝑡 𝑔𝑎𝑠 = 𝑄𝑐𝑜𝑙𝑑 𝑤𝑎𝑡𝑒𝑟 𝑄 = 𝑚𝑤𝐶𝑝𝑤(𝑡2 − 𝑡1) 𝑄 = 𝑈𝐴𝐹𝛥𝑇𝐿𝑀𝑇𝐷 Then, 𝑚𝑤𝐶𝑝𝑤(𝑡2 − 𝑡1) = 𝑈𝐴𝐹𝛥𝑇𝐿𝑀𝑇𝐷 Substitute the values to the equation 2.5 𝑘𝑔 𝐽 𝑊 × 4180 − 𝐾 × (85 𝐶 − 35 𝐶) = 180 2 − 𝐾 × 𝐴 × 0.9191 × 83.27𝐶 𝑠 𝑘𝑔 𝑚 Solve for Surface Area 𝑨 = 𝟑𝟕. 𝟗𝟑 𝒎𝟐 b. Effectiveness-NTU Method Since, we need to solve the problem of a counterflow exhanger using Effectiveness-NTU Method, use equation 10-15 𝑄ℎ𝑜𝑡 𝑔𝑎𝑠 = 𝑄𝑐𝑜𝑙𝑑 𝑤𝑎𝑡𝑒𝑟 𝐶𝑚𝑖𝑛 = 𝑚𝑔 × 𝐶𝑝𝑔 (𝑔𝑎𝑠) 𝐶𝑚𝑎𝑥 = 𝑚𝑤 × 𝐶𝑝𝑤 (𝑤𝑎𝑡𝑒𝑟) 𝐶𝑚𝑖𝑛 Determine the value of C, when 𝐶 = 𝐶𝑚𝑎𝑥 For 𝐶𝑚𝑖𝑛 𝑚𝑔 × 𝐶𝑝, 𝑔 × (𝑇1 − 𝑇2) = 𝑚𝑤 × 𝐶𝑝𝑤 × (𝑡2 − 𝑡1) 𝑚𝑔 × 𝐶𝑝𝑔 × (200 𝐶 − 93 𝐶) = 2.5 𝑘𝑔/𝑠 × 4180𝐽/𝑘𝑔 − 𝐾 × (85 𝐶 − 35 𝐶) 𝐶𝑚𝑖𝑛 = 𝑚𝑔 𝐶𝑝𝑔 = 4883.18 𝑊/ °𝐶 For 𝐶𝑚𝑎𝑥 𝐶𝑚𝑎𝑥 = 𝑚𝑤 × 𝐶𝑝𝑤 = 2.5𝑘𝑔/𝑠 × 4180𝐽/𝑘𝑔 − 𝐾 𝐶𝑚𝑎𝑥 = 𝑚𝑔 𝐶𝑝𝑔 = 104500 𝑊/ °𝐶 Therefore, 𝐶= 𝐶𝑚𝑖𝑛 4883.18 𝑊/ °𝐶 = = 0.4673 𝐶𝑚𝑎𝑥 104500 𝑊/ °𝐶 From Equation 10-17, we can able to solve for 𝐸𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒𝑛𝑒𝑠𝑠, 𝜀 𝜀= 𝑇1 − 𝑇2 200 𝐶 − 93 𝐶 = = 0.648 𝑇1 − 𝑡2 200 𝐶 − 35 𝐶 Using the Effectiveness-NTU Chart where C=0.4673 and 𝜀 = 0.93 𝑜𝑟 93% Figure3.0 Plot for NTU Through estimation based on the chart above, we able to get 𝑁𝑇𝑈 = 1.4 and finally, solve for the surface area of heat exchanger when 𝑁𝑇𝑈 = 𝑈𝐴 𝐶𝑚𝑖𝑛 𝑊 𝑁𝑇𝑈 × 𝐶𝑚𝑖𝑛 1.4 × 4883.18 °𝐶 𝐴= = 𝑊 𝑈 180 2 − 𝐾 𝑚 𝑨 = 𝟑𝟕. 𝟗𝟖 𝒎𝟐