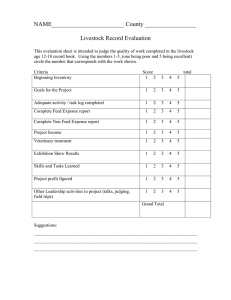

A TECHNICAL REPORT ON STUDENT INDUSTRIAL WORK EXPERIENCE SCHEME (S.I.W.E.S) Oracle farms limited BY ASEN STEPHE JOESEPH SAAWUAN TARKAA UNIVERSITY MAKURDI BENUE STATE NIGERIA. SUBMITTED IN PARTIAL FULFILMENT OF THE AWARD OF BACHELOR OF ENGINEERING (B.ENG) IN MECHANICAL ENGINEERING CHAPTER ONE 1.0 INTRODUCTION This report is a brief description of my six months internship carried out as compulsory component of the B.Eng. MECHANICAL Engineering under ITF’S SIWES Program the internship was carried out at ORACLE FEEDMILL INDUSTRAIL LAYOUT, NAKA ROAD BENUE STATE. I was posted to the maintenance and repairs department where I participated actively as an intern. I sought to get fieldwork experience in an environment unknown to me, which involved taking note of skills I would need to work in a professional environment. This report contains my activities that have contributed to achieving my desired goal. The following chapter contains an outline of the history, aims and objectives of SIWES and a description of ORACLE FEEDMILL INDUSTRAIL LAYOUT, NAKA ROAD BENUE STATE. and its activities. And after is a reflection of my functioning, the unexpected circumstances and the learning goals achieved in the course of my industrial training. Conclusively, my whole industrial training experience is viewed in relation to my learning goals 1.1 Brief history (SIWES) The Student Industrial Work Scheme (SIWES) was initiated by the industrial training fund (ITF) in 1973, to serve as a medium through which theoretical and practical experience could be combined to better the Nigerian educational system. It is a tripartite Program involving the students, the Universities and Industries. It is funded by the Federal Government of Nigeria and jointly coordinated by the ITF and the National Universities Commission (NUC). It is a skill training Programme designed to expose and prepare students of tertiary Institutions for the industrial work situation they are likely to meet after graduation. The scheme also affords the students the opportunity of familiarizing and exposing themselves to the needed experience in handling equipment and machinery. 1.2 Aims and objectives of SIWES The objectives of the programme are: 1.To expose students to actual working culture and industrial practice 2.To allow students to extend their theoretical knowledge into practice 3.To motivate students to practice the right working attitudes and professionalism to increase their employability potential. 4.To facilitate students to potential employers. The three vital experiences to be provided by any Industrial Training centre shall include but not limited to: 1.Basic skills of technical staff 2.Application skills of engineers 3.Management skills CHAPTER TWO. 2.0 TRAINIG ORGANISATION Oracle farms limited is a Nigeria owned company, incorporated under the laws of the Fedreal Republic of Nigeria in the year 2001. We redefined our standard and practices of work through our stock of sound equipment, state of the art machinery and pool of experience professionals. ORACLE FARMS LIMITED is a conglomerate of various companines which include: oracle agro feed mill, oracle star shea butter company, oracle rice mill, oracle corn mill, and oracle yam/cassava mills. 2.1 Organisational Chart For oracle farms limited Below is the organisational chart for oracle farms limited Fig 1 2.2 Feed mill safety and maintenace safety Feed mill operation precautions 1. First choose the installation location of the crusher and power machine. For longterm fixed operations, the unit should be fixed on the concrete base. The unit must be installed firmly and without looseness; the pulleys of the two machines should be in a straight line and should not be skewed. 2. After the base is fully solidified, repeat the system to statically check the unit thoroughly, and then carry out the dynamic empty load test run for 3 to 5 minutes. If there is no abnormality, it can be officially put into operation. 3. If you use electricity for power, you should find a reasonable layout of the line by a professional (electrician). The electrical lines and facilities should be neatly arranged and must not be installed and used in private. 4. When the pulverizer is put into operation for about 10 days, the cover should be opened, and the running parts such as the rotor and the hammer should be inspected. The bolts should be tightened to check whether the bearings are well lubricated. If there is stuck or rubbing, Eliminate in time. 5. Carefully check the processed materials during work, and remove hard objects such as nails, stones, and iron wires to avoid injury or damage. 6. The operator is strictly forbidden to wear gloves. When feeding materials, they should stand on the side of the crusher to avoid rebounding debris and damage the face. Do not hold too tight when smashing long stalk crops to prevent accidents. 7. During the operation process, pay close attention to the working condition of the pulverizer. If vibration, abnormal noise, excessive temperature of the bearing and the machine parts or external spraying are found, stop the inspection immediately and continue working after troubleshooting. . 8. When the blockage occurs and the load is too heavy, stop it immediately. It is strictly forbidden to use a wooden stick or hand to force the feed to avoid injuring the arm and damaging the machine. After each shift is completed, the unit should be inspected and maintained to ensure that the unit is in good condition. 2.3 Introduction to Feed Mill Industry Feed manufacturing refers to the process of producing animal feed from raw agricultural products. Fodder produced by manufacturing is formulated to meet specific animal nutrition requirements for different species of animals at different life stages. According to the American Feed Industry Association (AFIA),[1] there are four basic steps: Receive raw ingredients: Feed mills receive raw ingredients from suppliers. Upon arrival, the ingredients are weighed, tested and analyzed for various nutrients and to ensure their quality and safety. Create a formula: Nutritionists work side by side with scientists to formulate nutritionally sound and balanced diets for livestock, poultry, aquaculture and pets. This is a complex process, as every species has different nutritional requirements. Mix ingredients: Once the formula is determined, the mill mixes the ingredients to create a finished product. Package and label: Manufacturers determine the best way to ship the product. If it is prepared for retail, it will be "bagged and tagged," or placed into a bag with a label that includes the product's purpose, ingredients and instructions. If the product is prepared for commercial use, it will be shipped in bulk. 2.4 Feed preparation and quality The quality of the prepared feed ultimately depends on the quality of the material such as the grain or grass used; the raw material should be of very good quality. Commercial feed manufacturing is an industrial process, and therefore should follow HACCP procedures. The Food and Drug Administration (FDA) defines HACCP as "a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product". The FDA regulates human food and animal feed for poultry, livestock, swine, and fish. Additionally, the FDA regulates pet food, which they estimate feeds over 177 million dogs, cats, and horses in America. Similar to human foods, animal feeds must be unadulterated and wholesome, prepared under good sanitary conditions, and truthfully be labeled to provide the required information to the consumer. 2.5Feed formulations For swine Feed makes up approximately 60% to 80% of the total cost of producing hogs. Manufactured feeds are not merely for satiety but also must provide animals the nutrients required for healthy growth. Formulating a swine ration considers the required nutrients at various growth stages in creating an appropriate feed. Three basic methods are used to formulate swine diets: Pearson square, algebraic equations and linear programs (computers). In recent times, microcomputer programs are available that will balance a diet for many nutrients and assist with economic decisions. The basic nutrients required are crude protein, metabolizable energy, minerals, vitamins and water. The formulation procedure has both fixed and variable portions. Swine rations are generally based on a ground cereal grain as a carbohydrate source, soybean meal as a protein source, minerals like calcium and phosphorus are added, and vitamins. The feed can be fortified with byproducts of milk, meat byproducts, cereal grains; and "specialty products." Antibiotics may also be added to fortify the feed and help the animal's health and growth. Distillers dried grains with solubles (DDGS), which are rich in energy and protein, have been used in place of corn and soybean meal in some livestock and poultry feeds and corn DDGS have become the most popular, economical, and widely available alternative feed ingredient for use in U.S. swine diets in all phases of production. The U.S. Grain Council reported that corn DDGS is used primarily as an energy source in swine diets because it contains approximately the same amount of digestible energy (DE) and metabolizable energy (ME) as corn, although the ME content may be slightly reduced when feeding reduced-oil DDGS. A 2007 study highlighted the recent trends in the use of DDGS, as many producers are including 20% DDGS in diets of swine in all categories. Although 20% is the recommended level of inclusion, some producers are successfully using greater inclusion rates. Inclusion rate of up to 35% DDGS has been used in diets fed to nursery pigs and finishing pigs. For fish Farmed fish eat specially formulated pellet feeds containing the required nutrients for both fish health and the health of humans who eat fish. A fish feed should be nutritionally well-balanced and provide a good energy source for better growth. Commercially farmed fish are broadly classified into herbivorous fish, which eat mostly plant proteins like soy or corn, vegetable oils, minerals, and vitamins; and carnivorous fish, which are given fish oils and proteins. Carnivorous fish feed contains 30-50% fish meal and oil, but recent research suggests finding alternatives to fish meal in aquaculture diets. Among the various feeds investigated, soybean meal appears to be a better alternative to fishmeal. Soybean meal prepared for the fish industry is heavily dependent on the particle sizes contained in the feed pellets. Today technology to process these types of feed is based on fish feed extruder machines. Fish feed extruder is essential for vegetable protein processing. Particle size influences feed digestibility. The particle sizes of fish pellet feed are influenced by both grain properties and the milling process. Properties of the grain include hardness and moisture content. The milling process affects particle size based on the mill equipment type used, and some properties of the mill equipment (for example corrugations, gap, speed, and energy consumption) For poultry As reports have indicated, feeding makes up the major cost in raising poultry animals as birds in general require feeding more than any other animals, particularly due to their faster growth rate and high rate of productivity. Feeding efficiency is reflected on the birds' performance and their products. According to National Research Council (1994), poultry requires at least 38% components in their feed. The ration of each feed components, although differing for each different stage of birds, must include carbohydrates, fats, proteins, minerals and vitamins. Carbohydrates, which are usually supplied by grains including corn, wheat, barley, etc. serves as a major energy source in poultry feed. Fats, usually from tallow, lard or vegetable oil are essentially required to provide important fatty acid in poultry feed for membrane integrity and hormone synthesis. Proteins are important to supply the essential amino acids for the development of body tissues like muscles, nerves, cartilage, etc. Meals from soybean, canola, and corn gluten are the major source of plant protein in poultry diets. Supplementation of minerals are often required because grains, which are the main component of commercial feed contain very little amounts of these. Calcium, phosphorus, chlorine, magnesium, potassium and sodium are required in larger amounts by poultry. Vitamins, such as vitamin A, B, C, D, E, and K, on the other hand, are the components that are required in lower amounts by poultry animals Fanatico (2003) reported that the easiest and most popular way to feed birds is to use pelleted feeds. Aside from the convenience to the farmer, pelleted feeds enable the bird to eat more at a time. In addition, some researchers also found improvement of feed conversion, decreased feed wastage, improved palatability and destruction of pathogens when birds were fed with pellet feed as compared to birds fed with mash feed. Commercial manufacturing of pelleted feed usually involves a series of major processes including grinding, mixing and pelleting. The produced pellets are then tested as to pellet durability index (PDI) to determine quality. To enhance good health and growth, antibiotics are often added to the pelleted feed. Researchers have concluded that smaller particle-sized feed will improve digestion due to the increased surface area for acid and enzyme digestion in the gastrointestinal tract. However, some researchers have recently brought to our attention the necessity of coarse particles for poultry feed to complement the natural design and function of the gastrointestinal tract (GIT). Hetland et al (2002) and Svihus et al. (2004) discussed that the GIT retention time decreased due to lack of gizzard function that eventually gave a negative impact on live performance. Zanotto & Bellaver (1996) compared the performance of 21-day-old broilers fed with different feed particle size; 0.716 mm and 1.196 mm. They found that the subject fed with larger particle size feed showed better performance. Parsons et al. (2006), evaluating different corn particle sizes in the broiler feed found that the largest particle size (2.242 mm) gave better feed intake than the other particle sizes tested (0.781, 0.950, 1.042 and 1.109 mm). Nir et al. (1994), however, argued that the development of broilers was influenced by changing particle sizes. However, variation in particle size between 0.5–1 mm usually did not have any effect on the broilers. Very fine particles (<0.5 mm) may impair the broilers performance due to the presence of dust that cause respiratory problems, increased water intake, feed presence in the drinkers and increased litter moisture. Chewning et al. (2012), in their recent study, concluded that although fine particle sizes (0.27 mm) enhanced broilers live performance, the pelleted feed did not. All of this data shows that both fine and coarse particle sizes do have different functions in poultry feed. Appropriate proportions of these two ingredients must be used with respect to the live performance of the broilers. Xu et al. (2013) compared the performance of nonpelleted feed to pellets with fine particles and found that the addition of coarse particles improved feed conversion and body weight. Similar results were also obtained by other researchers like Auttawong et al. (2013) and Lin et al. (2013). For livestock Livestock includes beef cattle, dairy cattle, horses, goats, sheep and llamas. There is no specific requirement of feed intake for each livestock because their feed continuously varies based on the animals' age, sex, breed, environment, etc. However, basic nutrient requirements of a livestock's feed must consist of protein, carbohydrates, vitamins and minerals. Dairy cattle need more energy in their feed than other types of cattle. Studies have shown that energy supplied by feed is provided by various carbohydrate sources, including non-fiber carbohydrates (NFC) such as fermentable feeds or neutral detergent fiber (NDF) such as forage. Feeds with high NDF are good for rumen health, however, they provide less energy and vice versa. Fats are added in the livestock feed to increase energy concentration, especially when the NFC content is already too high since excessive NFC lessens the NDF fraction, affecting the rumen digestion. In ruminants, most proteins consumed are broken down by microorganisms and the microorganisms later get digested by the small intestine. The National Research Council suggested that the crude protein required in livestock feed should be less than 7%. Lactating ruminants, especially dairy cattle require the highest amount of protein, especially for milk synthesis. Minerals including calcium, phosphorus and selenium are required by livestock for maintaining growth, reproduction and bone health. Like other animals, livestock also require appropriate proportions of fine and coarse particles in their feed. Theoretically, finer particles will be easier to digest in the rumen, however the presence of coarse particles might increase the amount of starch entering the small intestine, thus increasing energetic efficiency. Livestock could be fed by grazing on grasslands, integrated or non-integrated with crop production. Livestock produced in stalls or feedlots are landless and are typically fed by processed feed containing veterinary drugs, growth hormones, feed additives, or nutraceuticals to improve production. Similarly, livestock consume grains as the main feed or as a supplement to the forage based feed. Processing grains for feed is aimed at getting the easiest digestible grains to maximize starch availability, thus increasing the energy supply. Hutjens (1999) reported that milk performance was significantly better when the cattle were fed with ground corn. A study compared the digestibility of various corn particle sizes and distribution and concluded that to have 80% digestibility, a particle size of 0.5 mm should be used (for 16 hr incubation). A research team from the University of Maryland and the USDA studied the development, fermentation in rumen and starch digestion sites in dairy cow feeding on corn grain from different harvests and differently processing, and concluded that digestion, metabolism and heat energy were higher for high moisture corn compared to dry corn. Grinding increased DMI and resulted in increased yields of milk, protein, lactose and non-fat solids. 2.6Feed manufacturing process Depending on the type of feed, the manufacturing process usually start with the grinding process. Figure 1 illustrates the workflow for general feed manufacturing process. Grinding of selected raw material is to produce particle sizes to be optimally and easily accepted by the animals. Depending on the formulation, feed could contain up to 10 different components including carbohydrate, protein, vitamins, minerals and additives. The feed ration can be pelleted by proportionally homogenizing the specific compositions. Pelleting is achieved by various methods, but the most common means is by extrusion. Formula and feed making machine are very important during the entire process of the feed production to ensure quality feed. 2.7 Grain milling for feed preparations Corn, sorghum, wheat and barley are the most used cereals in the preparation of feed for the livestock, poultry, swine, and fish industry. Roller and hammer mills are the two types of processing equipment generally used to grind grains into smaller particle sizes. Milling cereal grains by mechanical action involves several forces like compression, shearing, crushing, cutting, friction and collision. The particle size of the ground cereal is very important in the animal feed production; smaller particle sizes increase the number of particles and the surface area per unit volume which increase access to digestive enzymes. Other benefits are increased ease of handling and easier mixing of ingredients. The average particle size is given as geometric mean diameter (GMD), expressed in mm or microns (µm) and the range of variation is described by geometric standard deviation (GSD), with a larger GSD representing lower uniformity. According to Lucas (2004), GMD and GSD are accurate descriptors of particle size distribution when the particle size distribution is expressed as log data, and are distributed log normally. Studies have shown that grinding different grains with the same mill under similar conditions results in products with different particle sizes. The hardness of a grain sample is related to the percentage of fine particles obtained after grinding, with a higher percentage of fine particles from lower hardness grains. Rose et al. (2001) discussed that hard endosperm produces irregularlyshaped larger particles, while soft endosperm produces smaller size particles. The correlation between particle size and energy consumed is although not positive but, to obtain very fine particle sizes require higher energy which reduces the rate of production. Moreover, a very fine grind of grain has no impact on the efficiency of pelleting, nor on the power consumed during pelleting. Amerah et al. (2007) discussed the availability of more data suggesting grain particle sizes are very important in mashed diets than in pelleted diets 2.8 Introduction of feed mill machines and equipment. 1.0 FEED PALLET MACHINE. feed pellet machine is a feed processing machine that directly compresses powdery grains such as corn, soybean meal, straw, hay, rice husk into pellets. It is widely used in large, medium and small aquaculture, grain and feed processing plants, livestock farms, poultry farms, individual farmers and small farms. Working Principle The feed pellet machine is to extrude the mixed powder feed once. It doesn’t need to add water or drying during the granulation process. When the temperature rises to about 70 degrees naturally, the starch can be gelatinized and the inside of the granule is deeply matured. The surface of granules is smooth and high hardness, which can be stored for a long time. It is an ideal equipment for small or medium feed processing plants and farmers who raise rabbits, fish, chickens, pigs, sheep, cattle etc. Working steps: Step 1: Prepare raw material and mix Step 2: Adjust machine Step 3: Pour in the material and start granulation Step 4: Screen the granules FIG2: feed pallet machine. 2.0 WOOD HAMMER MILL MACHINE wood hammer mill machine is a special equipment for producing wood powder (sawdust), which is used for cutting wood, logs, branches, leftovers, etc. The machine adopts double feeding ports. It has the characteristics of reasonable design, compact structure, safety and durability. It is widely used in papermaking, edible fungi, machine-made charcoal, particle board, sawdust board, high density board, MDF and other industrial production material preparation section and single wood powder (sawdust) production base. It is also an ideal equipment for biomass burning pellets making. Working Principle It adopts blade cutting and high-speed airflow impact and collision, that is double crushing functions. And it can complete the micromaterial sorting process at the same time. In the process of blade cutting and pulverization, the rotor generates high-speed airflow, which rotates with the cutting direction of the blade. The material is accelerated in the airflow and repeatedly hit. The raw materials are doublepulverized at the same time, which accelerates the pulverization rate of the material. Product Details 1. Moving blade The cutting blade is made of high-quality alloy, which has the characters of tough, wearresistant, sharp in cutting, not easy to rust, corrosion-resistant and long service life. And it can improve the capacity. 2. Main partof the machine The main part of the machine is processed by dynamic balancing equipment, and the weight error in all directions of the machine is not more than 15g, which has the benefits of running smoothly, low noise, improving efficiency, prolonging the service life. It’s low cost and high capacity, which is a mature wood processing machinery. 3. Cutterhead The cutter head is made of thickened steel, which changes the original characteristics of fragile and increases the service life of the machine. The fan blade design not only improves the running speed of the wood, but also accelerates screening of the wood from the machine. The cutter head operates stably and plays the role of secondary crushing. 4. Hammer The hammer is made of carbon steel, which can crush the wood chips for many times, thereby improving the crushing rate. And the hammer can be used on both sides. After one side is damaged, the user can replace the hammer, but the hammer can only be replaced in the same position. It can not be exchanged with each other, so as not to affect the dynamic balance of the machine. The double-sided use reduce the cost. FIG 3 wood hammer mill machine. 3.O Grass Crushing and Cutting Machine The grass cutting and crushing machine can turn corn stalks, wheat stalks, rice stalks, peanut stalks and other agricultural crops and pastures into softer filamentous feeds through the principles of cutting, shattering, kneading, and crushing, which improves the utilization rate and palatability of feed and grass. Product Usage The new cutting and crushing machine is a new type of multi-functional feed machine developed by our company according to market demand and feedback. It can guillotine and knead grass at the same time. Compared with the ordinary guillotine machine, this machine adds a triangular blade, cutterhead and triangular dead knife. After the forage is cut, it is smashed by the triangular blade again to make the material finer. It is mainly used for cutting various dry and wet crop straw and pasture, such as corn stalks, rice stalks, which are used to raise cattle, sheep, horses, deer and other animals. This machine is suitable for pastures and farmers, and is the preferred bestselling model for farmers. Work principles This machine is a kind of an agricultural and pasturage machinery which is used for cutting green (dry) corn stalks, straws and other crop stalks and pastures. The working principle of the cutting machine: the motor is used as the supporting power. The power is transmitted to the main shaft, and the gear at the other end of the main shaft transmits the speed-adjusted power to the grass press through the gearbox, universal joint, etc. When the material to be processed enters between the upper and lower grass presses, it is clamped by the grass presses and sent to the cutting mechanism at a certain speed. After the material is chopped by the high-speed rotating cutter, it is smashed again by the high-speed rotating upper and lower triangular blades (hammers) of the grass crushing system, and finally thrown out of the machine through the grass outlet. This crushing machine has a beautiful appearance, adopts an all-steel body, thickened steel, and the coating adopts a baking paint process, with bright colors, good durability, corrosion resistance and durability. FIG 4.0 Grass Crushing and Cutting Machine 4.0 TCXT Series Permanent Magnet Sleeve TCXT Series Permanent Magnetic Drum is mainly used for separating magnetic metal impurities, such as screws, bolts, nuts, washers and iron chippings and shavings, etc. from the raw materials. Product features: ◆High magnetic intensity, powerful iron removal performance; ◆No power consumption, made with stainless steel. MECHINE FEATURES 1. High magnetic intensity, powerful iron removal performance; 2. No power consumption, made with stainless steel. APPLICTIONS TCXT SERIES PERMANENT MAGNETIC DRUM is mainly used for separating magnetic metal impurities such as screw, blot , nuts, washers and iron chippings and shavings, etc. from the raw materials. FIG5.0 Permanent Magnet Sleeve . KDVM SERIES VACUUM COATING SYSTEM. MACHINE FEATURES: 1. Horizontal structural with horizontal area brings the larger the materials into contact with the spraying liquid. 2. Three rows of nozzles uniformly distributed on the rotor axial make spraying more uniform high accuracy and uniformity of liquid spraying. APPLICATIONS 1. It is used for spraying liquid additives, such as oil,liquid fat, etc. to extruded pellets directly after drying section.