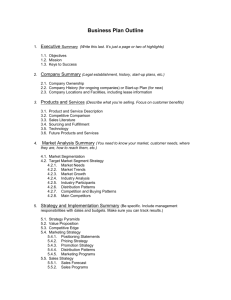

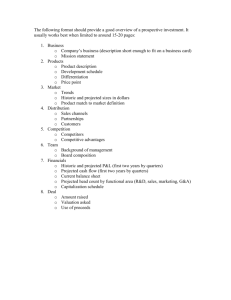

Detailed Project Report (DPR) of M/s RAJDEEP STEEL Prepared by : CA Yogesh Shah & Co. Tax Consultants Surat 88090 ##### Sample DPR from LoanDPR CONTENTS 1. EXECUTIVE SUMMARY 1.1 Project Snapshot – Introduction and Overview 1.2 Profile of Promoters, Business Owners 1.3 Employment Details 1.4 Cost of Project 1.5 Means of Finance 1.6 Existing Obligations 1.7 Subsidy 2. PROJECT VIABILITY & MARKET STUDIES 2.1 Feasibility Studies 2.2 Industry Analysis 2.3 Market Potential 2.4 Current Scenario 2.5 Challenges and Solutions 2.6 SWOT Analysis Sample DPR from LoanDPR 3. FINANCIAL DATA & RATIOS 3.1 Summary of Funding Facility 3.2 Projected Balance Sheet 3.3 Projected Operating Statement 3.4 BS Annexure - Fixed Assets Schedule 3.5 P&L Annexure - Indirect Expenses 3.6 Projected Cash Flow Statement 3.7 Synopsis of Balance Sheet 3.8 Debt Service Coverage Ratio Analysis 3.9 Financial Indicators & Ratio 3.10 Current Ratio 3.11 Sensitivity Analysis 3.12 Break Even Analysis 3.13 Security Margin 3.14 Loan Repayment Summary 3.15 CMA Data 3.16 Summary Points 3.17 Notes & Assumptions Sample DPR from LoanDPR 1. EXECUTIVE SUMMARY 1.1 Project Snapshot – Introduction and Overview Name of the Entity – M/S RAJDEEP STEEL Address – Plot 11, Anunagarn, Near Post Office, Gurunagar, Dahod - 389151 Business Description – Manufacturing of M. S. Pipes. (M.S. Pipe is an abbreviation of MILD STEEL PIPE) Name of the Business Owner – Mr. Rakesh Singh Market for the manufactured pipes – Dahod, Ahemdabad, Gandhinagar and other foremost market places in Gujarat Page 4 of 52 Sample DPR from LoanDPR Mild steel pipe are used for conveying water, fluid, gases and liquid as also for structural construction purpose. The importance of M.S. Pipe up to 12 inch Dia for urbanisation and irrigation development programmes of a developing country like India cannot be over emphasical. Applied in general sense, pipe is a term used to designate any long hollow body used for conducting gases or liquid. M/s Rajdeep Steel needs funds for Factory building, Plant & Machinery and other setup costs. Term Loan requested is Rs. 6.00 lakhs and Cash Credit for working capital requested is Rs. 3.00 lakhs. Detailed end use of the funds is covered under Point 1.4. Superior quality MS pipes are highly demanded in the sectors of agriculture, oil and gas, public health, housing, irrigation, engineering etc. Mild steel pipes or MS pipes are used for the purpose of plumbing, firefighting, heating, ventilation and air conditioning. These pipes are perfectly suitable in several industries and various engineering applications. So the demand for the mild steel pipe is high in the market. Page 5 of 52 Sample DPR from LoanDPR 1.2 Profile of Promoters, Business Owners Mr. Rakesh Singh, owner of Rajdeep Steel is having 5 years+ experience in this field of Mild Steel Pipe manufacturing and dealing in the market of steel pipes. The promoter Singh family is also going to invest a considerable sum of money as own contribution for this business because they are confident about the business and revenue. They are having more than enough experience in this field and know the business potential in the locality. The driving force behind every business is increased sales and high profits. Businessmen should be confident about the product they are selling as well as their own ability to successfully, gain the trust, arouse an interest and eventually convince them to try a new product. Singh family is having all such qualities inherently and were able to develop the same during the business course of their other respective businesses. Convincing a prospective customer to buy a product is not an easy task. Selling is an art and requires patience; applicant is skillful in such task & it can be considered as a plus point for an entity. Page 6 of 52 Sample DPR from LoanDPR 1.3 Employment Details One should insist to increase the employment levels of the country. In the light of this, entrepreneurs and business owners help the economy by generating employment in urban and rural areas. In coming years and decades, India is expected to witness significant demographic growth and expansion in the working age population. To absorb such labor force in the future, all the sectors viz. manufacturing, service, trading and agriculture would need to play an important role. Currently manufacturing sector accounts for approximately 11% to 13% of the total employment in the country, which is well below its true potential. Small and medium enterprises (SMEs) and micro small and medium enterprises (MSMEs) account for 90%+ of the total industrial activity in India. Estimates suggests, the SME and MSME sector offers maximum opportunities for self-employment as well as jobs, after the agricultural sector. Also, the labor-capital ratio tends to be higher for SMEs and MSMEs. This cotton ginning & processing unit will help the economy by way of employment generation, as it is going to generate employment to minimum of 7 unskilled and 3 of the skilled people. Total number of employees : 10+ Page 7 of 52 Sample DPR from LoanDPR 1.4 Cost of Project Estimating the cost of a project varies based on the industry, the type and scope of the project undertaken and the time frame for completing the project. While the variables of any given project may change according to circumstances, there are 3 main elements of project costing found in most all project cost estimations. Pre-Planning - Costs related to pre-project planning and preparation vary widely from industry to industry. Typical pre-planning costs include selecting potential project managers and employees, conducting market and project research Material Costs - All materials necessary for a project are included in material costs. Materials are anything the project manager purchases to aid in or conduct the project. Operating Costs - The operating costs of a project include the fees associated with purchasing project supplies, paying rent and associated costs on a facility or location for the project to take place, the cost of permitting, inspections and daily operations. Such costs can further be divided into 2 types viz. capital expenditure and revenue expenditure. For manufacturing industry, setting up the plant, installation of machinery, building/factory set up costs are the major costs. Capital expenditure of about Rs. 8.00 lakhs is required for setup and machinery. The entity is also in need of a working capital requirement of Rs. 3.00 lakhs. Page 8 of 52 Sample DPR from LoanDPR Detailed particulars about the cost have been provided hereunder : Sr. Particulars Amount Rs. (in No. Lacs) 1 Factory Building 2.00 2 Plant & Machinery 6.00 3 Equipments & Electrification -- 4 Furniture & Fixtures -- 5 Land (Industrial) -- 6 Working Capital 4.00 Total Cost in Rs. 12.00 Page 9 of 52 Sample DPR from LoanDPR 1.5 Means of Finance Total requirement of funds for capital investment and for the working capital amounts to Rs. 12.00 lakhs can be arranged in the following manner : MEANS OF FINANCE (Rs. in lakhs) Term Loan 6.00 Cash Credit 3.00 Own Contribution 3.00 Total 12.00 1.6 Existing Obligations The business owners are not having any heavy existing obligations, although, we have provided the documents such as Sanction letters and Bank statements of existing loans (if any), in order to assess the existing banking commitments. Page 10 of 52 Sample DPR from LoanDPR 1.7 Subsidy Government subsidies are monetary grants provided by the government to private institutions or other public entities, in order to stimulate economic activity or promote activities that are in the public good. Subsidies encourage companies to undertake economic activities and business ventures that the government sees as in the public’s best interest. Like indirect taxes, they can alter relative prices and budget constraints and thereby affect decisions concerning production, consumption and allocation of resources. Specific Subsidy for Rajdeep Steel : Credit Linked Capital Subsidy Scheme can be applied to the Rajdeep Steel unit. Units covered under the scheme: a. Existing SSI units registered with the State Directorate of Industries, which upgrade their existing plant and machinery with the state- of -the -art technology, with or without expansion. b. New SSI units which are registered with the State Directorate of Industries and which have set up their facilities only with the appropriate eligible and proven technology duly approved by the GTAB/TSC. Capital Subsidy – Capital subsidy at the revised rate of 15 per cent of the eligible investment in plant and machinery under the Scheme shall be available only for such projects, where terms loans have been sanctioned by the eligible PLI on or after September 29, 2005 . Machinery purchased under Hire Purchase Scheme of the NSIC are also eligible for subsidy under this Scheme . Page 11 of 52 Sample DPR from LoanDPR 2. PROJECT VIABILITY & MARKET STUDIES 2.1 Feasibility Studies A feasibility analysis evaluates the project’s potential for success; therefore, perceived objectivity is an essential factor in the credibility of the study for potential investors and lending institutions. One of the prerequisites for a successful business or unit is to have the technically feasible business model. A technical feasibility evaluates the details of how you propose to deliver a product or service to customers. Think materials, labour, transportation, where your business will be located, and the technology that will be necessary to bring all this together. There are five types of feasibility studies—separate areas that a feasibility study examines. Some major points out of them as explained below. Page 12 of 52 Sample DPR from LoanDPR Technical Feasibility: This assessment focuses on the technical resources available to the organization. It helps organizations determine whether the technical resources meet capacity and whether the technical team is capable of converting the ideas into working systems. Technical feasibility also involves the evaluation of the hardware, software, and other technical requirements of the proposed system. Economic Feasibility: This assessment typically involves a cost/ benefits analysis of the project, helping organizations determine the viability, cost, and benefits associated with a project before financial resources are allocated. It also serves as an independent project assessment and enhances project credibility—helping decisionmakers determine the positive economic benefits to the organization that the proposed project will provide. Operational Feasibility: This assessment involves undertaking a study to analyse and determine whether—and how well—the organization’s needs can be met by completing the project. Operational feasibility studies also examine how a project plan satisfies the requirements identified in the requirements analysis phase of system development. Carrying on aforementioned feasibility studies is an essential part of pre-planning activities. As manufacturing is the process of converting raw materials and/or parts into finished goods that can be sold in wholesale or retail markets or exported for sale in other countries. After considering most of the aforementioned factors and points, a detailed feasibility study viz. Technical, economical and operational – have been carried out by the Page 13 of 52 Sample DPR from LoanDPR promoters / owners of the entity, and based on their personal due diligence and indepth knowledge of the market, the project / company and its business operations are feasible in all the possible ways. The raw material required for the manufacturing the mild steel pipe is easily available to the business owner. Location of the proposed unit is preferably near to the market as well as sources of raw materials. For doing the production activity electricity, fuel, and water are all essential things available in this region. The both skilled & unskilled labour are required for the manufacturing the product which is also available in this region very easily with reasonable price. The financial management of the company financial projection is done by the company management. These products are having domestic as well as national market and still demand is more than supply so manufacturing of these items are feasible. Mild steel pipe manufacturing business, revenue-wise, has very good income potential. So, it would be feasible to setup a unit for the manufacture of mild steel pipe. A detailed financial feasibility study has also been carried out based on the current demand – supply analysis and data & assumption-based projections ; which has been separately presented in the FINANCIAL FEASIBILITY section in (3) Financial Data & Ratios. ‘Sensitivity analysis’ and ‘assessed bank finance’ studies will help in ascertaining the financial viability of the project. Page 14 of 52 Sample DPR from LoanDPR 2.2 Industry Analysis The strong demand of manufacturing products has pushed the Indian manufacturing industry to a new level. It is expanding to meet the growing demands of the people. According to some economists, manufacturing industry is a wealth-producing sector of an economy. The manufacturing industry in India contributes about 15% of the country’s GDP. Under the National Manufacturing Policy 2015, determined programs are under way to take this figure to 25 percent and the total output from this sector to $1 trillion by upcoming 2 years. Page 15 of 52 Sample DPR from LoanDPR India’s manufactured exports are worth over $180 billion, or 45 percent of the country’s total exports, with the biggest exports being engineering goods, chemicals and related products, and leather goods. Mild steel is a steel with carbon content from about 0.05 up to 3.8 per cent by weight. The term carbon steel may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools and high strength wires. These applications require a much finer microstructure, which improves the toughness. Mild steel pipe are used for conveying water, fluid, gases and liquid as also for structural construction purpose. The importance of M.S. Pipe up to 12 inch Dia for urbanisation and irrigation development programmes of a developing country like India cannot be over emphasical. Applied in general sense, pipe is a term used to designate any long hollow body used for conducting gases or liquid. Mild steel pipe (Welded) upto 12 inch diameter are used for conveying water, gases and liquid as also for structural construction purposes. Fluid handling is one of the most important operation and manufacturing plants, particularly the chemical industry which uses vast quantity of Mild Steel Pipes. These pipes are manufactured using low carbon (less than0.25%) steel and that is the reason why they do not harden and are hassle-free and easy to use. MS pipes can also be welded to various shapes and sizes for the purpose of pipelining and tubing. Page 16 of 52 Sample DPR from LoanDPR These pipes are usually coated with metals, paints, varnish etc. to prevent it from rusting under extreme condition and make them long-lasting and durable. Superior quality MS pipes are highly demanded in the sectors of agriculture, oil and gas, public health, housing, irrigation, engineering etc. Mild steel pipes or MS pipes are used for the purpose of plumbing, firefighting, heating, ventilation and air conditioning. These pipes are perfectly suitable in several industries and various engineering applications. So the demand for the mild steel pipe is high in the market. On the basis various factors related to industry analysis, a detailed scrutiny was carried out by the promoters / business owners and to conclude, based on the SWOT and Porter’s five forces business model, they found the industry very demanding and scope for the business is unrestricted. Page 17 of 52 Sample DPR from LoanDPR 2.3 Market Potential MS steel pipes are made from mild steel they can easily be welded and framed in different shapes and sizes for pipelining and tubing purposes. These are commonly used for fire fighting, drinking water supply I.E. Plumbing, air conditioning yet can likewise be utilized in different other mechanical and designing applications. These MS pipes are usually covered with different metals or paints or varnish and so forth to keep it from rusting however added consideration must to be taken to prevent it under extraordinary conditions. Mild steel pipes are utilized fundamentally in construction sectors, industries where corrosive fluids are in use. Mild steel doesn't corrode. Also, it can withstand up to certain temperature. There are sure weaknesses like hightemperature utilization, high weight or spillages. Due to all these feature demand for the mild steel pipe is rising in the market. Some important features of MS pipes are mild steel pipe tubes have high tensile strength, MS pipes are very stronger, low level of carbon, they can be handily welded, simple to manufacture and accessible promptly, not very exorbitant in contrast with Page 18 of 52 Sample DPR from LoanDPR different metals and long life of 100 years or more. Some of the main applications of mild steel pipes are structural purposes, mechanical reason, general building, residential applications, planning transport body, fencing, construction structure and water steel pipes. So the demand for the mild steel pipe in various sector is rising. Mild steel pipes generally used across construction industries since it is anything but difficult to weld and produce in diverse shapes and sizes to meet the different pipelining and tubing applications. It is a perfect decision for conveying fluids, putting out fires, auxiliary and general building. These pipes otherwise called black pipes. Square mild steel pipes have some significant highlights like high quality, consumption obstruction, high strength and deformability. Round MS pipes is being utilized in a few applications, for example, modern water lines, plant channelling, agribusiness and water system, excited steel fencings, street obstructions, stopping boundaries, brief fencings, steel doors and windows, side of the road railings, basic and creation work, water pipelines, and that's just the beginning. They are also us ed in development to ensure electrical wires. While steel pipes are solid, they can similarly be lightweight. This makes them ideal for use in bike outline produce. MS pipe is widely acclaimed and acknowledged for its construction, durability and corrosion resistance. Mild steel pipe offering has increased tremendous prevalence in the business inferable from its awesome attributes like smooth completion, erosion obstruction, ideal quality and durability. Mild steel pipes, likewise perceived as plaincarbon steel, are right now called the broadest type of steel, for the explanation that its expense is comparatively low, and yet it offers material qualities that are by and large adequate for plenty of uses. These MS pipes have a reasonably low tractable strength, however, it is very not costly and inconvenient allowable to shape, while the surface hardness of the equivalent can be expanded right through carburizing. So the demand for the mild steel pipe in the market is rising. Page 19 of 52 Sample DPR from LoanDPR 2.4 Current Scenario The Global Seamless Steel Pipes Market is projected to grow at a CAGR of 4.1% from USD 71.29 Billion in 2020 to USD 93.96 Billion in 2028. The oil & gas segment led the market in 2020 and accounted for the highest revenue share of over 49.2%. In terms of volume, the chemicals & petrochemicals segment is anticipated to denote a CAGR of 5.1% from 2021 to 2027. Asia Pacific emerged as the leading regional market in 2020 and accounted for a revenue share of over 46.2%. Page 20 of 52 Sample DPR from LoanDPR 2.5 Challenges & Solutions Dependency of raw material Mild Steel pipe manufacturer are heavily depend on the raw steel, so manufacturer should make a contract with supplier to get raw steel on time. Irregular size in the sizing section Sometime due to some issue such as shafts and tooling are not running true, the bearings and bearing blocks are tight, so weld size is not correct according to the setup chart. To overcome this problem manufacturer should focus on machinery set up, check bearing & block to avoid irregular size issue. Solid waste management Mild Steel pipe manufacturing involves the production of large amounts of solid wastes while processing materials through various processes. But what steel manufacturers often overlook is the fact that these solid wastes contain several valuable products which can be reused if recovered economically. Players in the mild steel pipe manufacturing industry need to figure out ways by which they can make the best out of solid waste and reduce wastage of useful resources. Page 21 of 52 Sample DPR from LoanDPR Growth in demand With the increasing focus on infrastructure and development, global mild steel pipe use is expected to rise in the years to come. However, there are some uncertainties in the rate of growth in emergent economies due to unresolved structural problems, political instability, and volatile financial markets. The majority of the increase in demand will be met by existent finished mild steel pipe. But in the future there is scarcity of mild steel pipe. So manufacturer should make a plan to meet the future demand. Specimen geometry The curved shape of pipe faces number of gripping challenges. So manufacturer use jaw which specific jaw faces allow you to quickly grip longitudinal strip curved cut out specimens, without flattening the tab ends. Page 22 of 52 Sample DPR from LoanDPR 2.6 SWOT Analysis A SWOT analysis is an incredibly simple, yet powerful tool to help you develop your business strategy, whether you’re building a start-up or guiding an existing company. SWOT stands for Strengths, Weaknesses, Opportunities, and Threats. SWOT Analysis is a strategic planning method used to evaluate strengths, weaknesses, opportunities, and threats, in a business project or a manufacturing business. These four factors are called SWOT (strengths, weaknesses, opportunities, and threats). This process involves the specific determination and objectives of a manufacturing or business project that identifies internal and external factors SWOT analysis can be applied by analyzing and observing the things that affect the four factors, then apply them in the picture in the SWOT matrix, apply the strengths map to take advantage of the opportunities, how to overcome the weaknesses that prevent the advantages of opportunities are able to deal with the threats that exist, and the last is how to overcome the weaknesses that can make threats become real or create a new threat. Determining the direction of development of a business is strongly influenced by many factors, namely internal and external factors . One may think that they already know everything that they need to do, to succeed, but a SWOT analysis will force them to look at the business in new ways and from new directions. Page 23 of 52 Sample DPR from LoanDPR Strengths Good product prototype and innovation Overall, manufacturing industry is relatively stable. Focus on value creation with leadership in product development leadership and high quality output Strong Research & Development Capabilities High level of Specialization Weakness Employee skills need to be upgraded. Air pollution directly to the community. Lots of levies, unerring costs. Lack of finance Opportunities Lot of scope for innovative products every now and then. Trends in increasing customer purchasing power. Opportunities in the manufacturing industry are in the technology and biotechnology areas. These are growing market segments with higher profit margins. Page 24 of 52 Sample DPR from LoanDPR New market opportunities and consolidation of the industry through Merger & Acquisition activities Threats Regulation of government, regulations on tight industrial business Increasing freight transportation costs Competition from other manufacturing / process units Unnecessary changes in Government policies Geographical disadvantages Page 25 of 52 Sample DPR from LoanDPR SUMMARY OF FUNDING FACILITY COST OF PROJECT Rs in lakhs Particulars Asset Addition Working Capital Requirement Amount Rs. 8.00 4.00 Total SOURCES OF FUND 12.00 Rs in lakhs Particulars Term Loan Cash Credit Own Contribution Amount Rs. 6.00 3.00 3.00 Total Page 26 of 52 12.00 Sample DPR from LoanDPR PROJECTED BALANCE SHEET Particulars I Audited FY 2020 rupees in lakhs Tentative FY 2021 FY 2022 FY 2023 Projected FY 2024 FY 2025 FY 2026 LIABILITIES A DEBT LIABILITIES Secured Loans - - 3.97 2.78 1.46 - - - - - - - - - - - 3.97 2.78 1.46 - - - - - - - - - Total Unsecured Loans - - - - - - - A. Total Outside Liabilities - - 3.97 2.78 1.46 - - Cash Credit / OD / DLOD Sundry Creditors Provisions Short Term Borrowings from Banks/Others (up to 1 year)Advance Payment from Customer/s Creditors for Capital Goods Other Current Liabilities - - 3.00 1.07 - 3.00 1.19 - 3.00 1.32 - 3.00 1.46 - 3.00 - - - 4.07 4.19 4.32 4.46 3.00 - - 8.04 6.97 5.78 4.46 3.00 62.74 4.63 - 67.37 5.31 (1.64) (7.00) 64.04 3.00 5.38 (1.89) - 70.52 6.04 (2.02) - 74.54 6.73 (2.16) - 79.11 7.43 (2.32) - 84.23 8.16 (2.48) - SUB TOTAL 67.37 64.04 70.52 74.54 79.11 84.23 89.92 TOTAL LIABILITIES 67.37 64.04 78.56 81.51 84.89 88.69 92.92 (excluding installments for 1 year) Existing Loans (if any) Total Secured Loans Unsecured Loans B CURRENT LIABILITES B. Total Current Liabilities TOTAL OUTSIDE LIABILITIES(A+B) NET WORTH Capital Balance Opening Balace / Share Capital (incl. Reserves) Own Contribution for Business Surplus (+) or deficit (-) in P&L Account Drawings Any other item (+)/(-) Page 27 of 52 Sample DPR from LoanDPR PROJECTED BALANCE SHEET Particulars Audited FY 2020 rupees in lakhs Tentative FY 2021 FY 2022 FY 2023 Projected FY 2024 FY 2025 FY 2026 II ASSETS CURRENT ASSETS (0.00) (0.00) (0.00) (0.00) (0.00) Cash & Bank Stock in hand Sundry Debtors & Receivables Advances to Staff or Creditors Deposits Security Deposit & TDS, Taxes (Advance, etc.) Export & Other Receivables Other Current Assets 0.49 8.38 1.72 3.25 8.76 0.28 0.45 15.80 0.40 1.92 2.00 16.12 0.45 1.84 2.40 16.44 0.74 3.94 2.88 16.77 0.47 5.42 3.46 17.10 TOTAL CURRENT ASSETS 8.87 13.73 16.53 20.43 21.12 24.32 26.45 0.17 - 0.18 - 5.00 - 5.00 - 8.50 - 9.80 - 12.50 - 68.62 58.33 50.13 57.03 56.09 55.27 54.57 - - 8.00 - - - - 10.29 8.20 1.10 0.95 0.81 0.70 0.60 58.33 50.13 57.03 56.09 55.27 54.57 53.97 67.37 64.04 78.56 81.51 84.90 88.70 92.92 - 0.00 0.00 0.00 0.00 0.00 0.00 - 0.00 0.00 0.00 0.00 0.00 0.00 INVESTMENTS OTHER NON-CURRENT ASSETS FIXED ASSETS GROSS BLOCK Addition : Less : Depreciation NET BLOCK TOTAL ASSETS Page 28 of 52 Sample DPR from LoanDPR PROJECTED OPERATING STATEMENT Audited FY 2020 Particulars Tentative FY 2021 rupees in lakhs FY 2022 FY 2023 Projected FY 2024 FY 2025 FY 2026 1. GROSS INCOME Domestic Revenue Export Revenue Less : GST / Other Duties / Return 9.91 - 12.86 - 16.60 - 17.93 - 19.18 - 20.53 - 21.96 - SUB TOTAL 9.91 12.86 16.60 17.93 19.18 20.53 21.96 - - - - - - - 4.25 0.02 - 5.47 0.50 - 7.06 0.46 - 7.62 0.54 - 8.15 0.58 - 8.72 0.62 - 9.33 0.66 - 4.27 5.97 7.52 8.16 8.73 9.34 9.99 56.91% 53.61% 54.70% 54.50% 54.50% 54.50% 54.50% 3. INDIRECT COSTS 1.01 1.51 1.61 1.73 1.80 1.90 2.02 OPERATING PROFIT 4.63 5.38 7.47 8.04 8.66 9.28 9.95 - - - - - - - - - - - 0.32 0.58 - 0.32 0.48 - 0.32 0.36 - 0.32 0.23 - 0.32 0.08 - - - 1.10 0.95 0.81 0.70 0.60 4.63 5.38 5.47 6.30 7.17 8.04 8.95 46.72% 41.87% 32.96% 35.15% 37.37% 39.17% 40.77% Provision for Income Tax - 0.08 0.09 0.26 0.43 0.61 0.79 PROFIT AFTER TAX (PAT) 4.63 5.31 5.38 6.04 6.73 7.43 8.16 2. COST OF SALES Opening Stock Purchases Direct Labour (Wages) Power & Fuel Other prime costs Closing Stock (+) (+) (+) (+) (-) SUB TOTAL Gross Profit % Non Operating Income Interest and Financial Charges Cash Credit Term Loan Any Existing Funding Facility (TL) Any Existing Funding Facility (other than TL) Depreciation NET PROFIT BEFORE TAX Net Profit % Page 29 of 52 Sample DPR from LoanDPR FIXED ASSETS ANNEXURE 1 Computers Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance Rate Of Depreciation Additions During the Year Before Oct. After Oct. 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 2 Plant & Machinery Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance 6.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 3 Plant Shed Construction Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 4 Furniture & Fixtures Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Depreciation 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Deletions Total 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Deletions Depreciation 6.00 5.10 4.34 3.68 3.13 2.66 2.26 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Deletions 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Page 30 of 52 0.90 0.77 0.65 0.55 0.47 0.40 0.34 Depreciation 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Rate Of Depreciation Additions During the Year Before Oct. After Oct. 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Closing Balance 5.10 4.34 3.68 3.13 2.66 2.26 1.92 10% Total 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Closing Balance 15% Rate Of Depreciation Additions During the Year Before Oct. After Oct. 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Total Rate Of Depreciation Additions During the Year Before Oct. After Oct. 0.00 5.10 4.34 3.68 3.13 2.66 2.26 Deletions 40% 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Closing Balance 0.00 0.00 0.00 0.00 0.00 0.00 0.00 10% Total Depreciation 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Closing Balance 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Sample DPR from LoanDPR FIXED ASSETS ANNEXURE 5 Plots & Land Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance Rate Of Depreciation Additions During the Year Before Oct. After Oct. 50.13 50.13 50.13 50.13 50.13 50.13 50.13 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 6 Building & Civil Works Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance 0.00 1.80 1.62 1.46 1.31 1.18 1.06 Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Total 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Depreciation 50.13 50.13 50.13 50.13 50.13 50.13 50.13 Rate Of Depreciation Additions During the Year Before Oct. After Oct. 2.00 0.00 0.00 0.00 0.00 0.00 0.00 Total 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Deletions 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Closing Balance 50.13 50.13 50.13 50.13 50.13 50.13 50.13 10% Depreciation 2.00 1.80 1.62 1.46 1.31 1.18 1.06 Rate Of Depreciation Additions During the Year Before Oct. After Oct. 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Deletions 0.00 0.00 0.00 0.00 0.00 0.00 0.00 7 Transport Vehicles & Other Assets Year Deletions 0% 0.20 0.18 0.16 0.15 0.13 0.12 0.11 Closing Balance 1.80 1.62 1.46 1.31 1.18 1.06 0.96 15% Total 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Depreciation 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Closing Balance 0.00 0.00 0.00 0.00 0.00 0.00 0.00 SUMMARY Year Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7 Opening Balance 50.13 57.03 56.09 55.27 54.57 53.97 53.46 Additions During the Year Before Oct. After Oct. 8.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Deletions 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Page 31 of 52 Total 58.13 57.03 56.09 55.27 54.57 53.97 53.46 Depreciation 1.10 0.95 0.81 0.70 0.60 0.52 0.45 Closing Balance 57.03 56.09 55.27 54.57 53.97 53.46 53.01 Sample DPR from LoanDPR INDIRECT EXPENSES ANNEXURE rupees in lakhs Sn. Particulars 1 2 3 4 5 6 7 8 9 10 Accounting & Audit Bank Charges Electricity Expenses Rent Telephone Expenses Printing & Stationery Professional Fees Salaries Fuel & Travelling Expenses Repairs & Maintenance TOTAL FY 2022 0.12 0.21 0.54 0.17 0.57 1.61 FY 2023 Projected FY 2024 FY 2025 FY 2026 0.13 0.22 0.59 0.18 0.61 - 0.13 0.24 0.59 0.19 0.65 - 0.14 0.25 0.62 0.20 0.70 - 0.15 0.27 0.65 0.21 0.75 - 1.73 1.80 1.90 2.02 Page 32 of 52 Sample DPR from LoanDPR PROJECTED CASH FLOW STATEMENT rupees in lakhs Sr No A Particulars FY 2022 Projections FY 2024 FY 2025 FY 2026 CASH FLOW FROM OPERATING ACTIVITIES Net Profit Before Tax Adjustments for: Depreciation Interest & Finance Charges debited to Profit & Loss Account Operating Profit before Working Capital Changes B FY 2023 5.47 6.30 7.17 8.04 8.95 1.10 0.90 7.47 0.95 0.79 8.04 0.81 0.68 8.66 0.70 0.54 9.28 0.60 0.40 9.95 Adjustments for: Decrease/(Increase) in Receivables Decrease/(Increase) in Inventories 2.80 - (1.46) - 0.08 - (2.10) - (1.48) - Decrease/(Increase) in Other asset Decrease/(Increase) in Other receivables Decrease/(Increase) in Advance Tax Payments Increase/(Decrease) in Payables Increase/(Decrease) in Short Term Borrowings Increase/(Decrease) in Capital Goods creditors & others (7.04) 1.07 - (2.00) (0.32) 0.12 - (0.40) (0.32) 0.13 - (0.48) (0.33) 0.15 - (0.58) (0.34) (1.46) - Cash generated from operations Income Tax paid Net Cash flow from Operating activities 4.29 (0.09) 4.20 4.38 (0.26) 4.12 8.14 (0.43) 7.71 6.52 (0.61) 5.91 6.10 (0.79) 5.31 CASH FLOW FROM INVESTING ACTIVITIES Cash Credit Own Contribution for Business Purchase of Assets Loan and Advances Investments & Other Assets Net Cash used in Investing activities 3.00 3.00 (8.00) (4.82) (6.82) - - - - (3.50) (3.50) (1.30) (1.30) (2.70) (2.70) Page 33 of 52 Sample DPR from LoanDPR PROJECTED CASH FLOW STATEMENT rupees in lakhs Sr No C Particulars FY 2022 FY 2023 Projections FY 2024 FY 2025 FY 2026 CASH FLOW FROM FINANCING ACTIVITIES Loan Disbursement / Repayment Drawings by Propritor Interest paid for Cash Credit Limit Interest paid for Term Loan Limit Increase/(Decrease) in Capital Account Items Increase/(Decrease) in Contingent Liabilities Unsecured Loans & Quasi Capital Net Cash used in Financing Activities 3.97 (1.89) (0.32) (0.58) 1.18 (1.19) (2.02) (0.32) (0.48) (4.00) (1.32) (2.16) (0.32) (0.36) (4.16) (1.46) (2.32) (0.32) (0.23) (4.32) (2.48) (0.32) (0.08) (2.88) Net increase in cash & Cash Equivalents (1.44) 0.12 0.05 0.29 (0.27) Cash and Cash equivalents as at the beginning of the year Cash and Cash equivalents as at the end of the year Net increase in cash & Cash Equivalents 1.72 0.28 (1.44) 0.28 0.40 0.12 0.40 0.45 0.05 0.45 0.74 0.29 0.74 0.47 (0.27) Page 34 of 52 Sample DPR from LoanDPR SYNOPSIS OF BALANCE SHEET rupees in lakhs Particulars Source of Funds Share capital Reserves & surplus / any other item Secured loans : Short term : Long term Unsecured loans Other liabilities Total Uses of Funds Fixed assets (Gross Block) Less : Depreciation Net block Investments & Other Assets Inventories Sundry Debtors Cash & Bank balances Loans & advances to others Other Current Assets (Less current liabilities) (Less provisions) NET CURRENT ASSETS Misc. expenditure (to the extent not written off or adjusted Total FY 2022 70.52 FY 2023 Projected FY 2024 FY 2025 FY 2026 3.00 3.97 - 74.54 3.00 2.78 - 79.11 3.00 1.46 - 84.23 3.00 - 89.92 3.00 - 77.49 80.32 83.58 87.23 92.92 58.13 1.10 57.03 5.00 0.45 0.28 15.80 (1.07) 20.46 57.03 0.95 56.09 5.00 1.92 0.40 18.12 (1.19) 24.24 56.09 0.81 55.27 8.50 1.84 0.45 18.84 (1.32) 28.31 55.27 0.70 54.57 9.80 3.94 0.74 19.65 (1.46) 32.66 54.57 0.60 53.97 12.50 5.42 0.47 20.56 38.95 - - - - - 77.49 80.33 83.58 87.23 92.92 Page 35 of 52 Sample DPR from LoanDPR DEBT SERVICE COVERAGE RATIO ANALYSIS PARTICULARS Projections FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 Net Profit After Interest & Tax (+) Depriciation (+) Bank Interest 5.38 1.10 6.04 0.95 6.73 0.81 7.43 0.70 8.16 0.60 0.58 0.48 0.36 0.23 0.08 Net Cash Inflow 7.06 7.46 7.91 8.36 8.85 Bank Interest Principal Repayment of Installment 0.58 0.96 0.48 1.07 0.36 1.19 0.23 1.32 0.08 1.46 Net Cash Outflow 1.55 1.55 1.55 1.55 1.55 Debt Service Coverage Ratio 4.56 4.82 5.11 5.40 5.72 Page 36 of 52 Sample DPR from LoanDPR FINANCIALS INDICATORS Sr. No. PARTICULARS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 SALES(a) OTHER INCOME(b) TOTAL INCOME (a+b) OPERATING PROFIT NET PROFIT CASH PROFIT OPEARATING PROFIT MARGIN(%) NET PROFIT MARGIN (%) CASH PROFIT TO SALES QUASSI CAPITAL (UNSECURED LOANS) CAPITAL NET WORTH TOTAL OUTSIDE LIABILITIES CURRENT RATIO QUICK RATIO DEBTORS TURNOVER RATIO CREDITORS TURNOVER RATIO FIXED ASSET TURNOVER RATIO SALES TO CAPITAL EMPLOYED FIXED ASSETS TO NET WORTH CREDITORS NO. OF DAYS PURCHASES RECEIVABLES NO. OF DAYS SALES STOCK NO. OF DAYS SALES TOL/TNW DEBT MANAGEMENT RATIO INTEREST COVERAGE PROPRIETARY RATIO CASH FLOW YIELD 29 CASH FLOW TO ASSETS Projections FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 16.60 0.00 16.60 7.47 5.38 6.48 45.00% 32.39% 39.02% 0.00 70.52 70.52 3.00 4.06 4.06 36.50 N.A. 0.29 1.33 0.81 10.00 0.04 5.05% 7.08 0.90 76.64% 17.93 0.00 17.93 8.04 6.04 6.99 44.84% 33.70% 38.97% 0.00 74.54 74.54 3.00 4.88 4.88 9.36 N.A. 0.32 1.10 0.75 39.00 0.04 3.41% 8.94 0.91 127.58% 19.18 0.00 19.18 8.66 6.73 7.55 45.13% 35.11% 39.34% 0.00 79.11 79.11 3.00 4.89 4.89 10.43 N.A. 0.35 1.14 0.70 35.00 0.04 1.72% 11.61 0.93 87.82% 20.53 0.00 20.53 9.28 7.43 8.13 45.23% 36.21% 39.61% 0.00 84.23 84.23 3.00 5.45 5.45 5.21 N.A. 0.38 1.03 0.65 70.00 0.04 0.00% 15.76 0.95 71.45% 21.96 0.00 21.96 9.95 8.16 8.76 45.32% 37.17% 39.90% 0.00 89.92 89.92 3.00 8.82 8.82 4.06 N.A. 0.41 0.94 0.60 90.00 0.03 0.00% 23.41 0.97 150.74% 5.24% 9.46% 6.97% 5.99% 13.24% Page 37 of 52 Sample DPR from LoanDPR CURRENT RATIO PARTICULARS Projections FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 CURRENT ASSETS Cash & Bank Stock in hand Sundry Debtors Advances Deposits Security Deposit & TDS, Taxes (Advance, etc.) 0.28 0.45 - 0.40 1.92 2.00 - 0.45 1.84 2.40 - 0.74 3.94 2.88 - 0.47 5.42 3.46 - Other Current Assets 15.80 16.12 16.44 16.77 17.10 TOTAL CURRENT ASSETS 16.53 20.43 21.12 24.32 26.45 3.00 3.00 3.00 3.00 3.00 Sundry Creditors - - - - - Provisions - - - - - Other Current Liabilities 1.07 1.19 1.32 1.46 - TOTAL CURRENT LIABILITIES 4.07 4.19 4.32 4.46 3.00 4.06 4.88 4.89 5.45 8.82 CURRENT LIABILITIES Cash Credit CURRENT RATIO Page 38 of 52 Sample DPR from LoanDPR SENSITIVITY ANALYSIS rupees in lakhs I. REVENUE GROWTH OF 5% PARTICULARS Projected revenue % Change Growth Change FY 2022 FY 2023 16.60 5% FY 2024 17.93 5% FY 2025 19.18 5% FY 2026 20.53 5% 21.96 5% 0.83 0.90 0.96 1.03 1.10 Cost of Goods sold Indirect Costs Interest, Depreciation 7.52 1.61 2.00 8.16 1.73 1.74 8.73 1.80 1.49 9.34 1.90 1.24 9.99 2.02 1.00 EBT 5.47 6.30 7.17 8.04 8.95 Updated EBT Impact on EBT 6.30 0.83 6.35 0.05 7.22 0.05 8.09 0.05 9.00 0.05 FY 2022 16.60 5% 15.77 FY 2023 17.93 5% 17.03 FY 2024 19.18 5% 18.22 FY 2025 20.53 5% 19.50 FY 2026 21.96 5% 20.86 7.52 1.61 2.00 8.16 1.73 1.74 8.73 1.80 1.49 9.34 1.90 1.24 9.99 2.02 1.00 5.47 4.64 (0.83) 6.30 5.40 (0.90) 7.17 6.21 (0.96) 8.04 7.01 (1.03) 8.95 7.86 (1.10) II. REVENUE REDUCTION OF (-)5% PARTICULARS Projected revenue % Change Updated Revenue Change Cost of Goods sold Indirect Costs Interest, Depreciation EBT Updated EBT Impact on EBT Page 39 of 52 Sample DPR from LoanDPR III. INCREASE IN COGS BY 5% PARTICULARS Projected revenue Cost of Goods sold % Change Increase Updated COGS Indirect Costs Interest, Depreciation EBT Updated EBT Impact on EBT rupees in lakhs FY 2022 16.60 FY 2023 17.93 7.52 5% FY 2024 19.18 8.16 5% FY 2025 20.53 8.73 5% FY 2026 21.96 9.34 5% 9.99 5% 0.38 7.90 0.41 8.57 0.44 9.16 0.47 9.81 0.50 10.49 1.61 2.00 1.73 1.74 1.80 1.49 1.90 1.24 2.02 1.00 5.47 5.09 (0.38) 6.30 5.89 (0.41) 7.17 6.73 (0.44) 8.04 7.57 (0.47) 8.95 8.45 (0.50) Page 40 of 52 Sample DPR from LoanDPR BREAK EVEN ANALYSIS rupees in lakhs Sr. Particulars No. Weightage (A) Gross Revenue FY 2021 FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 12.86 16.60 17.93 19.18 20.53 21.96 5.47 0.38 0.00 0.00 0.00 7.06 0.35 0.00 0.00 0.00 7.62 0.40 0.00 0.00 0.00 8.15 0.43 0.00 0.00 0.00 8.72 0.46 0.00 0.00 0.00 9.33 0.49 0.00 0.00 0.00 5.84 5.97 7.02 7.40 8.02 8.58 9.19 9.83 9.20 9.91 10.60 11.34 12.13 54.58% 55.40% 55.25% 55.25% 55.25% 55.25% 0.00 0.00 0.00 0.00 0.00 0.08 0.54 0.21 0.00 0.00 0.09 0.59 0.22 0.00 0.00 0.09 0.59 0.24 0.00 0.00 0.10 0.62 0.25 0.00 0.00 0.10 0.65 0.27 0.00 0.00 Total Fixed & Semi-fixed Expenses 0.00 0.83 0.90 0.92 0.97 1.02 (E) Operating profit 7.02 8.36 9.00 9.68 10.37 11.12 (F) Break-even point 0.00% 9.07% 9.13% 8.67% 8.53% 8.39% (B) Variable Expenses Purchases Direct Labour (Wages) Power & Fuel Other prime costs Difference in Stock 100% 75% 65% 60% 100% Total Variable expenses (C) Contribution Contribution (A - B) (%) (D) Fixed & Semi-fixed Expenses Administration Costs Rent Insurance Property Taxes Other Fixed Costs (C - D) 70% 100% 100% 100% Page 41 of 52 Sample DPR from LoanDPR SECURITY MARGIN Sr. PARTICULARS No. A B C WDV OF FIXED ASSETS AGGREGATE TL OUTSTANDINGS SECURITY MARGIN PERCENTAGE OF MARGIN FY 2021 FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 50.13 0.00 50.13 57.03 3.97 53.06 56.09 2.78 53.30 55.27 1.46 53.81 54.57 0.00 54.57 53.97 0.00 53.97 100.00% 93.04% 95.04% 97.35% 100.00% 100.00% Page 42 of 52 Sample DPR from LoanDPR SUMMARY OF LOAN REPAYMENT SCHDULE Interest Rate Particulars 10.50% p.a FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 Principal at the begining of the year 0.00 5.04 3.97 2.78 1.46 Add :- Disbursement 6.00 0.00 0.00 0.00 0.00 Add :- Interest 0.58 0.48 0.36 0.23 0.08 Less :- Repayment During the year 1.55 1.55 1.55 1.55 1.55 Principal at the end of the year 5.04 3.97 2.78 1.46 0.00 Page 43 of 52 Sample DPR from LoanDPR Detailed working of Term Loan from Bank rupees in lakhs Month Opening Disburse- Monthly Monthly Closing Balance ment Interest Installement Balance REPAYMENT Year I - Month 1 Month 2 Month 3 Month 4 Month 5 Month 6 Month 7 Month 8 Month 9 Month 10 Month 11 Month 12 5.92 5.85 5.77 5.69 5.61 5.53 5.45 5.37 5.29 5.20 5.12 Year II - Month 1 Month 2 Month 3 Month 4 Month 5 Month 6 Month 7 Month 8 Month 9 Month 10 Month 11 Month 12 5.04 4.95 4.87 4.78 4.69 4.61 4.52 4.43 4.34 4.25 4.15 4.06 6.00 6.00 - Year III - Month 1 Month 2 Month 3 Month 4 Month 5 Month 6 Month 7 Month 8 Month 9 Month 10 Month 11 Month 12 3.97 3.87 3.78 3.68 3.59 3.49 3.39 3.29 3.19 3.09 2.99 2.88 - Page 44 of 52 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.04 0.58 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.48 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.36 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 1.55 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 1.55 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 1.55 5.92 5.85 5.77 5.69 5.61 5.53 5.45 5.37 5.29 5.20 5.12 5.04 4.95 4.87 4.78 4.69 4.61 4.52 4.43 4.34 4.25 4.15 4.06 3.97 3.87 3.78 3.68 3.59 3.49 3.39 3.29 3.19 3.09 2.99 2.88 2.78 Sample DPR from LoanDPR Year IV - Month 1 Month 2 Month 3 Month 4 Month 5 Month 6 Month 7 Month 8 Month 9 Month 10 Month 11 Month 12 2.78 2.68 2.57 2.46 2.36 2.25 2.14 2.03 1.92 1.81 1.69 1.58 - Year V - Month 1 Month 2 Month 3 Month 4 Month 5 Month 6 Month 7 Month 8 Month 9 Month 10 Month 11 Month 12 1.46 1.35 1.23 1.11 0.99 0.87 0.75 0.63 0.50 0.38 0.25 0.13 - Page 45 of 52 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.01 0.01 0.23 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.00 0.00 0.00 0.00 0.08 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 1.55 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 1.55 2.68 2.57 2.46 2.36 2.25 2.14 2.03 1.92 1.81 1.69 1.58 1.46 1.35 1.23 1.11 0.99 0.87 0.75 0.63 0.50 0.38 0.25 0.13 (0.00) Sample DPR from LoanDPR Credit Monitoring Arrangement (CMA) rupees in lakhs LIABILITIES FY 2022 Projected 70.52 70.52 FY 2023 Projected 74.54 74.54 FY 2024 Projected 79.11 79.11 FY 2025 Projected 84.23 84.23 FY 2026 Projected 89.92 89.92 Term Loans Unsecured Loans Other Term Liabilities Total Term Liabilities 3.97 0.00 0.00 3.97 2.78 0.00 0.00 2.78 1.46 0.00 0.00 1.46 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Sundry Creditors Bank Borrowings-CC Provision Other Current Liabilities other advances Total Current Liabilities Total Outside Liabilities 0.00 3.00 0.00 1.07 0.00 4.07 8.04 0.00 3.00 0.00 1.19 0.00 4.19 6.97 0.00 3.00 0.00 1.32 0.00 4.32 5.78 0.00 3.00 0.00 1.46 0.00 4.46 4.46 0.00 3.00 0.00 0.00 0.00 3.00 3.00 78.56 81.51 84.89 88.69 92.92 Capital Net Worth Total Liabilities Page 46 of 52 Sample DPR from LoanDPR ASSETS Fixed Assets Depreciation Net Block FY 2022 FY 2023 FY 2024 FY 2025 FY 2026 Projected Projected Projected Projected Projected 58.13 57.03 56.09 55.27 54.57 1.10 0.95 0.81 0.70 0.60 57.03 56.09 55.27 54.57 53.97 Cash & Bank Balance advances to suppliers Othr current assets stock investments Receivables 0.28 0.00 15.80 0.00 0.00 0.45 0.40 0.00 18.12 0.00 0.00 1.92 0.45 0.00 18.84 0.00 0.00 1.84 0.74 0.00 19.65 0.00 0.00 3.94 0.47 0.00 20.56 0.00 0.00 5.42 Total Current Assets 16.53 20.43 21.12 24.32 26.45 Investments Other Non Current Assets Total Non Current Assets 5.00 0.00 5.00 5.00 0.00 5.00 8.50 0.00 8.50 9.80 0.00 9.80 12.50 0.00 12.50 Accumulated Losses Other Intangible Assets Total Intangible Assets 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 78.56 0.00 81.51 0.00 84.90 0.00 88.70 0.00 92.92 0.00 Total Assets control total Page 47 of 52 Sample DPR from LoanDPR WORKING CAPITAL CALCULATIONS PARTICULARS Capital Other Reserves P/L Account unsecured loans Term Loans Term Deposits Other Term Liabilities Long Term Sources Net Fixed Assets Investments Other Non Current Assets Adv to Suppliers of Cap Goods Intangible Assets Long Term Uses Net Working Capital CA-CL control total NWC as % to TCA FY 2022 Projected FY 2023 Projected FY 2024 Projected FY 2025 Projected FY 2026 Projected 70.52 74.54 79.11 84.23 89.92 0.00 3.97 0.00 0.00 74.49 0.00 2.78 0.00 0.00 77.32 0.00 1.46 0.00 0.00 80.58 0.00 0.00 0.00 0.00 84.23 0.00 0.00 0.00 0.00 89.92 57.03 5.00 0.00 56.09 5.00 0.00 55.27 8.50 0.00 54.57 9.80 0.00 53.97 12.50 0.00 0.00 62.03 12.46 12.46 0.00 75.37 0.00 61.09 16.24 16.24 0.00 79.49 0.00 63.77 16.80 16.81 0.00 79.55 0.00 64.37 19.86 19.86 0.00 81.64 0.00 66.47 23.44 23.45 0.00 88.65 Page 48 of 52 Sample DPR from LoanDPR KEY FINANCIAL INDICATORS PARTICULARS FY 2022 Projected 16.60 29.08 5.38 32.39 6.48 70.52 0.11 12.46 4.06 16.60 5.38 1.10 FY 2023 Projected 17.93 8.00 6.04 33.70 6.99 74.54 0.09 16.24 4.88 17.93 6.04 0.95 FY 2024 Projected 19.18 7.00 6.73 35.11 7.55 79.11 0.07 16.80 4.89 19.18 6.73 0.81 FY 2025 Projected 20.53 7.00 7.43 36.21 8.13 84.23 0.05 19.86 5.45 20.53 7.43 0.70 FY 2026 Projected 21.96 7.00 8.16 37.17 8.76 89.92 0.03 23.44 8.82 21.96 8.16 0.60 FY 2022 Projected Net Sales 16.60 Purchases 7.06 Sundry Creditors 0.00 CREDITORS NO. OF DAYS PURCHASES 0.00 Receivables 0.45 RECEIVABLES NO. OF DAYS SALES 10.00 Stock 0.00 STOCK NO. OF DAYS SALES 0.00 FY 2023 Projected 17.93 7.62 0.00 0.00 1.92 39.00 0.00 0.00 FY 2024 Projected 19.18 8.15 0.00 0.00 1.84 35.00 0.00 0.00 FY 2025 Projected 20.53 8.72 0.00 0.00 3.94 70.00 0.00 0.00 FY 2026 Projected 21.96 9.33 0.00 0.00 5.42 90.00 0.00 0.00 Net Sales % increase Net Profit after Tax % to Sales Cash Accruals TNW TOL/TNW NWC Current Ratio Net Sales Net Profit Depreciation PARTICULARS Page 49 of 52 Sample DPR from LoanDPR Working Capital - Assessment BASED ON TONDAN COMMITTEE - I Method I (WCG) 1. Total Current Assets 2. Other Current Liabilities 3. WCG 4. 25 % Margin 5. MPBF as per method I FY 2022 Projected 16.53 1.07 15.46 3.87 11.60 FY 2023 Projected 20.43 1.19 19.24 4.81 14.43 FY 2024 Projected 21.12 1.32 19.81 4.95 14.85 FY 2025 Projected 24.32 1.46 22.86 5.71 17.14 FY 2026 Projected 26.45 0.00 26.45 6.61 19.83 FY 2023 Projected 20.43 1.19 19.24 5.11 14.13 FY 2024 Projected 21.12 1.32 19.81 5.28 14.53 FY 2025 Projected 24.32 1.46 22.86 6.08 16.78 FY 2026 Projected 26.45 0.00 26.45 6.61 19.83 FY 2023 Projected 17.93 4.48 0.90 3.59 FY 2024 Projected 19.18 4.80 0.96 3.84 FY 2025 Projected 20.53 5.13 1.03 4.11 FY 2026 Projected 21.96 5.49 1.10 4.39 0.90 16.24 0.96 16.80 1.03 19.86 1.10 23.44 BASED ON TONDAN COMMITTEE - II Method II (TCA) 1. Total Current Assets 2. Other Current Liabilities 3. WCG 4. 25 % Margin (TCA*25%) 5. MPBF as per method II FY 2022 Projected 16.53 1.07 15.46 4.13 11.33 NAYAK COMMITTEE NORMS - TURNOVER METHOD Turnover Method FY 2022 Projected 1. Actual / Projected Sales 16.60 2. WCG - 25 % of sales 4.15 3. 5 % of sales as margin 0.83 4. Minimum permissible finance 3.32 (20% of turnover) 5. Margin Money by Borrower 0.83 6. Actual/Projected NWC 12.46 Page 50 of 52 Sample DPR from LoanDPR Particulars Stock (Days cost of production) Receivables (Days sales) Other Current assets % to Total Current Assets Loans and advances holding period Cash & bank balances % to total Current Assets Total Current Assets Sundry Creditors Days purchases OCL – Provisions % to TCL Total Current Liabilities FY 2022 Projected 0.00 0 0.45 10 15.80 95.56 0.00 0 0.28 1.69 16.53 0.00 0 1.07 N.A. 1.07 FY 2023 Projected 0.00 0 1.92 39 18.12 88.68 0.00 0 0.40 1.94 20.43 0.00 0 1.19 N.A. 1.19 FY 2024 Projected 0.00 0 1.84 35 18.84 89.18 0.00 0 0.45 2.11 21.12 0.00 0 1.32 N.A. 1.32 Page 51 of 52 FY 2025 Projected 0.00 0 3.94 70 19.65 80.78 0.00 0 0.74 3.03 24.32 0.00 0 1.46 N.A. 1.46 FY 2026 Projected 0.00 0 5.42 90 20.56 77.74 0.00 0 0.47 1.78 26.45 0.00 0 0.00 N.A. 0.00 Sample DPR from LoanDPR Notes to the Project Report a. Depreciation is calculated as per the rate priscribed in the Income Tax Act and Seperate Depreciation schedule has been attatched for calculation purpose. b. Data such as Sensativity Analysis & Balance Sheet synopsis has been prepared based on the standard financial assumptions and calculations. c. It has been presumed that there will be no change in the Government policies & rules with respect to the business of the loan applicant. Also, no abnormal events will take place during the life of the project / business, d. Provision for Income Tax has been made on the Rules and Regulations which are applicable for current scenario. e. Standard assumption of Year end at March has been presumed f. Indirect Expenses, Break Even Analysis and Security margin calculation have been shown in the separate Annexures. g. All the data related to revenue from business, asset addition, existing obligations, etc. have been provided based on the information given by the client. h. This Projected data is a future-oriented financial information prepared using assumptions to the best judgment of applicants as to the most probable set of economic conditions and should not be treated as a forecast. i. All the information related to business entity, owner's profile, employment along with the feasibility studies, Industry analysis, market potential, current scenario and challenges-solutions is based on the discussions and inputs from the loan applicant. Page 52 of 52