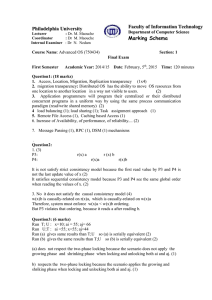

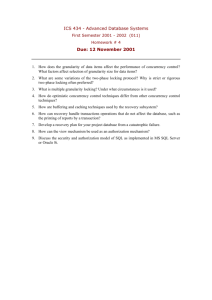

E 12 ® RINGFEDER Locking Assemblies 00 Catalogue RfN 7012 For highly-stressed shaft-hub connections and high machining tolerances RINGFEDER Products are available from MARYLAND METRICS P.O. Box 261 Owings Mills, MD 21117 USA email: sales@mdmetric.com web: http://mdmetric.com phones: (410)358-3130 (800)638-1830 faxes: (410)358-3142 (800)872-9329 Locking Connections RINGFEDER® Locking Assemblies RfN 7012 Please note that our guarantee refers to our products only. Because of the unlimited number of applications and all different types of machines, it is not possible for our engineers to know all factors that may affect or change the technical data or our products. This publication may not be reproduced, either partly or wholly, without the source being quoted. We reserve the right to modify design by way of technical improvement. Locking Connections Certified by DIN EN ISO 9001 and VDA 6.1 RINGFEDER Products are available from MARYLAND METRICS P.O. Box 261 Owings Mills, MD 21117 USA email: sales@mdmetric.com web: http://mdmetric.com phones: (410)358-3130 (800)638-1830 faxes: (410)358-3142 (800)872-9329 Index Page Characteristics ..........................................................................................4 Dimension table for Locking Assemblies RfN 7012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Hub outside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Calculations: Locking Assemblies RfN 7012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Hollow shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Fitting and removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Hints on construction – Typical constructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 The ABC of the Locking Assemblies RfN 7012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Torque wrenches and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Strength values: Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Cast steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 ISO-Table of tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Mounting suggestions, required data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 3 RINGFEDER® Locking Assemblies RfN 7012 For highly-stressed shaft-hub connections The shrink fit is unsurpassable. No other shaft-hub connections can offer anywhere near the same performance regarding fatigue strength under alternating torsional stresses. These fits are nevertheless rare, as they call for involved calculations, extremely close machining tolerances, cause considerable trouble when fitting and removing the parts in question, and give rise to problems during repair work (exchangeability, adjustments, centering, etc.). The locking Assembly RINGFEDER Connections is a shrink fit - a shrink fit of special kind. CHARACTERISTICS Fig. 1 · Locking Assembly RINGFEDER® RfN 7012 TRANSMISSION OF HIGH PERIPHERAL FORCES Several Locking Assemblies RfN 7012 can be used in series. The transmissible torques and axial loads are added (see page 7) OPTIMUM DEPENDABILITY We guarantee the torque/axial load transmission values as given in this publication, regardless of whether the connection is subjected to static, dynamic or impact loads. However, the values given in this catalogue must not be exceeded. SIMPLIFIED MANUFACTURES Locking Assemblies RfN 7012 can bridge large clearances between k 11 and h 11 resp. N 11 and H 11 are possible (cf. Page 7). EASY EXCHANGEABILITY Locking Assemblies RfN 7012 bridge large clearances and need no stops or other mechanical devices of this type. In contrast to all other shafthub connections, close machining tolerances are unnecessary. EASY MOUNTING The temperature difference between shaft and hub for shrinkage fits is eliminated. Locking Assemblies RfN 7012 are tightened using standard screws and standard tools. Machining or fitting work is not required. EASY REMOVAL Release the locking screws, and the Locking Assembly RfN 7012 can be removed. The steep angle of the double tapers (approx. 28∞) prevents selflocking and ensures that the Locking Assembly can be released without difficulty. 4 RINGFEDER® Locking Assemblies RfN 7012 LOW SUSCEPTIBILITY TO CONTAMINATION When the locking screws are tightened down, the contact (functional) surfaces are pressed firmly together, so preventing the ingress of dirt and moisture. UNLIMITED APPLICATION RANGE Locking Assemblies RfN 7012 are most suitable for securing all types of bosses and hubs on shafts and axles. They efficiently replace shrink fits, key and polygon connections, splined shafts, etc. These Locking Assemblies are used for the connection of gearwheels, chain sprockets, levers, cams, cam plates, belt pulleys, brake drums, flywheels, couplings and clutches, shaftmounted gearings, flanges, rope sheaves, track wheels, impellers, ship and aircraft propellers, etc. and are giving every satisfaction in these and countless other applications. EASY ADJUSTABILITY Locking Assemblies RfN 7012 need no stops. Bosses and hubs can therefore be located and locked at any point of the shaft. PERFECT TRUE RUNNING Forming a frictional lock connention, Locking Assemblies RfN 7012 have absolutely no play. FREEDOM FROM WEAR Having no moving parts, Locking Assemblies RfN 7012 can be tightened and released as often as required. The locking screws are standard items and thus readily available. HIGH FATIGUE STRENGTH UNDER ALTERNATING TORSIONAL STRESSES Neither shaft nor hub have keyways. Thus, notch effect is minimized and a high polar section modulus is at the disposal of the designer. OVERLOAD PROTECTION EFFECT When the permissible load is exceeded, Locking Assemblies RfN 7012 will slip. In this way, they can safeguard valuable machine components against damage. However, the Locking Assembly connection is subject to the same laws as all other frictional lock connections, and is not suitable for use as slipping clutches. EASY CALCULATIONS This catalogue lists all interesting data in the form of quickreference tables. 5 RINGFEDER® Locking Assemblies RfN 7012 Locking Assembly designation for shaft diameter = 70 mm: Locking Assembly RINGFEDER® 70 x 110 RfN 7012 Surface pressures between Locking Transmissible Assembly and torques axial hub forces shaft Locking Assembly dimensions Ident-No. 6 996 124 990 930 990 957 990 985 990 937 990 981 990 981 7 990 332 991 007 5 996 236 991 015 7 990 359 991 023 7 990 367 991 031 991 040 991 058 991 066 991 074 991 082 991 090 991 104 991 112 991 120 991 139 991 147 991 155 991 163 991 171 991 180 991 198 991 201 991 210 991 228 991 236 991 244 991 252 991 260 991 279 991 287 991 295 991 309 991 317 991 325 991 333 991 341 991 350 991 368 991 376 991 384 991 392 991 406 991 414 991 422 991 430 991 449 991 457 991 465 991 473 991 481 991 490 991 511 991 520 dxD mm 19 20 22 24 25 28 30 32 35 38 40 42 45 48 50 55 60 65 70 75 80 85 90 95 100 110 120 130 140 150 160 170 180 190 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 520 540 560 580 600 620 640 660 680 700 720 740 760 780 800 820 840 860 880 900 920 940 960 980 1000 x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x 47 47 47 50 50 55 55 60 60 65 65 75 75 80 80 85 90 95 110 115 120 125 130 135 145 155 165 180 190 200 210 225 235 250 260 285 305 325 355 375 405 425 455 475 495 515 545 565 585 605 630 650 670 690 710 730 750 770 790 810 830 850 870 890 910 930 950 970 990 1010 1030 1050 1070 1090 1110 L 20 20 20 20 20 20 20 20 20 20 20 24 24 24 24 24 24 24 28 28 28 28 28 28 33 33 33 38 38 38 38 44 44 52 52 56 56 56 66 66 78 78 90 90 90 90 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 102 I mm L1 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 17 27,5 20 33,5 20 33,5 20 33,5 20 33,5 20 33,5 20 33,5 20 33,5 24 39,5 24 39,5 24 39,5 24 39,5 24 39,5 24 39,5 26 47 26 47 26 47 34 52 34 52 34 52 34 52 38 60 38 60 46 68 46 68 50 74 50 74 50 74 60 86,5 60 86,5 72 100,5 72 100,5 84 116 84 116 84 116 84 116 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 96 130 T or Nm 255 270 300 360 380 470 500 630 700 870 920 1500 1610 1700 1770 2270 2470 3040 4600 4900 5200 6300 6600 7900 9600 10500 13100 17600 20900 24200 28000 32800 37800 46500 52500 68000 85500 104000 128000 153000 210000 224000 294000 308000 322000 374000 455000 470000 515000 560000 600000 630000 680000 735000 775000 825000 865000 925000 965000 1030000 1070000 1140000 1210000 1250000 1300000 1370000 1450000 1520000 1590000 1650000 1710000 1790000 1870000 1940000 2000000 Fax kN p 27 27 27 30 30 33 33 40 40 46 46 72 72 71 71 83 83 93 132 131 131 148 147 167 192 191 218 272 298 324 350 386 420 490 525 620 715 800 915 1020 1310 1310 1630 1620 1610 1780 2060 2040 2160 2240 2320 2340 2440 2540 2580 2660 2700 2800 2840 2960 2980 3080 3180 3220 3260 3340 3460 3540 3620 3680 3720 3820 3900 3960 4000 220 210 195 195 190 185 175 192 180 188 180 226 210 196 190 200 180 190 210 195 180 195 180 195 195 180 185 165 165 170 170 160 165 150 150 150 160 165 145 150 150 145 145 135 130 135 130 125 125 125 125 120 120 120 120 120 115 120 115 115 115 115 115 115 115 115 115 115 115 115 110 110 115 110 110 Bold printed types are standard 6 Locking screws DIN EN ISO 4762 (DIN 912) – 12.9 Thread p´ Qty. 90 90 90 95 95 95 95 105 105 110 110 125 125 115 115 130 120 130 130 125 120 130 125 135 135 125 135 115 125 125 130 120 125 115 115 115 125 130 115 120 120 115 115 110 105 110 105 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 8 8 8 9 9 9 9 12 12 15 15 12 12 12 12 14 14 16 14 14 14 16 16 18 14 14 16 20 22 24 26 22 24 28 30 26 30 34 32 36 36 36 36 36 36 40 40 40 42 44 45 45 48 50 50 52 54 56 56 60 60 62 64 65 66 68 70 72 74 75 76 78 80 81 82 dG TA Nm N/mm2 M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M 6 6 6 6 6 6 6 6 6 6 6 8 8 8 8 8 8 8 10 10 10 10 10 10 12 12 12 12 12 12 12 14 14 14 14 16 16 16 18 18 20 20 22 22 22 22 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x Hilfs- Weigh gewinde t 18 18 18 18 18 18 18 18 18 18 18 22 22 22 22 22 22 22 25 25 25 25 25 25 30 30 30 35 35 35 35 40 40 45 45 50 50 50 60 60 70 70 80 80 80 80 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 90 14 14 14 14 14 14 14 14 14 14 14 35 35 35 35 35 35 35 70 70 70 70 70 70 125 125 125 125 125 125 125 190 190 190 190 295 295 295 405 405 580 580 780 780 780 780 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 dD M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M 8 8 8 8 8 8 8 8 8 8 8 10 10 10 10 10 10 10 12 12 12 12 12 12 14 14 14 14 14 14 14 16 16 16 16 20 20 20 22 22 24 24 27 27 27 27 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 ≈ kg 0,24 0,24 0,23 0,26 0,25 0,3 0,29 0,34 0,32 0,36 0,34 0,6 0,57 0,62 0,6 0,63 0,69 0,73 1,26 1,33 1,4 1,49 1,53 1,62 2,01 2,15 2,35 3,51 3,85 4,07 4,3 5,78 6,05 8,25 8,65 11,22 12,2 13,2 19,2 20,5 29,6 31,1 42,2 44 46 50 64,6 67,4 71 72,6 80 82 85 88 91 93 96 99 102 104 107 110 113 116 118 121 124 127 129 132 135 138 140 143 146 Explanations to the opposite table Locking Assemblies RINGFEDER® RfN 7012 are not selfcentering. Consequently, the true running of hubs mounted with these Locking Assemblies is governed by the efficiency of the shaft centering action is governed by the play between the remaining boss or hub bore and the shaft, as well as by the mating length between hub and shaft Fitting Locking Assemblies: The values for T, Fax, p and p´ apply to Locking Assemblies that are lightly oiled prior to being fitted (µ = 0,12). Fig. 2 · Locking Assembly RINGFEDER® RfN 7012 For more details see page 12. d x D, L, l, L1 = Basic dimensions, Locking Assembly not tightened T Surfaces finishes: For shafts and hub bores: Ra 3,2 µm Corresponds to RMS < 125 micro-inches. = Transmissible torque Fax = Transmissible axial force p Tolerances: = Approx. Surface pressure between Locking Assembly and shaft Locking Assemblies RfN 7012 can bridge large deviations from nominal sizes without any torque losses. p´ = Approx. Surface pressure between Locking Assembly and hub We do not stipulate any particular clearances. The following may be taken as guide values: TA = Required tightening torque per locking screw (tighten with torque wrench) Shaft: all fits between k11 and h 11. Hub: all fits between N 11 and H 11. dD = Auxiliary thread in the front thrust ring. The screws at these points are special marked for easy indentification. The Locking Assembly should be located as symmetrically as possible between shaft and hub bore in order to avoid excessive deformations of the relatively thickwalled thrust rings. If the shaft is smaller than nominal d, the bore should exceed nominal D to the same extent and vice versa. The difference between both deviations of the nominal dimensions should not exceed IT 9 (with regard to d). Typical application: Location of several Locking Assemblies RfN 7012: If several Locking Assemblies are to be installed the transmission values of the opposite table can be added in case the Locking Assemblies are located within a distance of 4 L1. Change of screw tightening torques: The Locking Assemblies are generally equipped with screws of the quality 12.9. If required, the transmission values can be increased by increasing the tightening torques of the screws (for quality 12.9 see page 10). A reduction of the surface pressures and the transmission values by diminished tightening of the screws also is possible. The admissible lower limit results from the multiplication of theTA-values of the opposite table by 0,6. There is an approximate linear relationship between TA, T, Fax, p and p´ (Hub and hollow shaft calculation according to the equations on page 11)! Fig. 3 · Hub mounted with Locking Assembly RfN 7012 DN = Diameter of the hub above the Locking Assembly, see pages 8, 9 and 10 (radial load). b L1; L1 table on page 6 7 RINGFEDER® Locking Assemblies RfN 7012 Required hub outside diameter DN when using one Locking Assembly RfN 7012 depending on the yield point of the hub material The values in the table for DN apply to: The use of one Locking Assembly RfN 7012 Width of the hub Depth of the bore B2l b L1 Hub section unweakened (see hub calculation page 11) Cast hubs should be of perfect quality (flawless). Locking Assembly RfN 7012 tightening torqueper dimension screw dxD mm 19 20 22 24 25 28 30 32 35 38 40 42 45 48 50 55 60 65 70 75 80 85 90 95 100 110 120 130 140 150 160 170 180 190 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x 47 47 47 50 50 55 55 60 60 65 65 75 75 80 80 85 90 95 110 115 120 125 130 135 145 155 165 180 190 200 210 225 235 250 260 285 305 325 355 375 405 425 455 475 495 515 545 565 585 605 Required min. hub outside diameter DN (mm) for: yield point Rp0,2 ( N/mm2) 150 180 200 220 270 300 350 400 58 58 58 62 62 68 68 76 76 84 84 100 100 104 104 115 118 128 149 153 158 169 173 185 198 206 225 234 252 266 284 296 313 325 338 370 405 440 462 493 533 553 592 610 630 660 695 715 740 765 57 57 57 61 61 67 67 74 74 81 81 97 97 101 101 111 115 124 144 148 154 164 168 178 192 200 218 228 245 258 275 288 303 316 329 360 394 425 450 480 517 537 575 594 615 650 675 695 715 740 55 55 55 59 59 65 65 72 72 79 79 93 93 98 98 107 111 120 138 143 148 158 162 172 184 193 209 220 237 249 265 278 292 305 317 348 380 410 433 462 500 519 556 576 595 625 655 675 695 720 54 54 54 58 58 64 64 71 71 77 77 91 91 95 95 104 108 116 134 139 144 153 157 166 178 187 203 214 230 242 257 270 284 298 310 339 369 396 423 450 486 506 542 562 585 608 640 660 680 705 DN mm TA Nm 14 14 14 14 14 14 14 14 14 14 14 35 35 35 35 35 35 35 70 70 70 70 70 70 125 125 125 125 125 125 125 190 190 190 190 295 295 295 405 405 580 580 780 780 780 780 1000 1000 1000 1000 250 69 69 69 75 75 82 82 96 96 105 105 130 130 132 132 151 152 169 196 200 203 223 226 247 265 269 302 297 330 347 374 380 408 413 430 470 530 578 585 642 693 700 748 762 790 828 853 865 895 925 65 65 65 70 70 77 77 87 87 96 96 117 117 120 120 136 138 152 176 180 184 199 203 219 236 242 268 270 296 312 335 344 366 375 390 428 475 518 533 572 618 636 680 700 715 758 786 800 825 855 62 62 62 67 67 74 74 84 84 92 92 111 111 114 114 128 131 143 166 171 175 189 193 208 223 230 254 257 282 297 317 328 349 357 372 408 453 490 507 545 590 610 653 670 690 726 755 770 800 825 61 61 61 66 66 72 72 81 81 89 89 107 107 111 111 123 126 138 160 165 169 181 186 199 214 222 243 250 272 286 304 316 336 346 360 395 436 472 492 526 568 588 630 646 665 705 732 750 775 805 8 59 59 59 63 63 69 69 78 78 85 85 103 103 106 106 118 121 132 152 157 161 173 178 189 203 212 231 240 260 273 291 302 321 333 346 379 416 450 472 505 545 564 605 623 640 675 705 725 750 775 RINGFEDER® Locking Assemblies RfN 7012 Required hub outside diameter DN when using two or more Locking Assemblies RfN 7012 depending on the yield point of the hub material The values in the table for DN apply to: The use of two or more Locking Assembly RfN 7012 Width of the hub B L1 · (1+ n) n = number of Locking Assemblies used Hub section unweakened (see hub calculation page 11) Cast hubs should be of perfect quality (flawless). Locking Assembly RfN 7012 tightening torqueper dimension screw dxD mm 19 20 22 24 25 28 30 32 35 38 40 42 45 48 50 55 60 65 70 75 80 85 90 95 100 110 120 130 140 150 160 170 180 190 200 220 240 260 280 300 320 340 360 380 400 420 440 460 480 500 x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x 47 47 47 50 50 55 55 60 60 65 65 75 75 80 80 85 90 95 110 115 120 125 130 135 145 155 165 180 190 200 210 225 235 250 260 285 305 325 355 375 405 425 455 475 495 515 545 565 585 605 Required min. hub outside diameter DN (mm) for: yield point Rp0,2 ( N/mm2) 150 180 200 220 270 300 350 400 62 62 62 67 67 73 73 83 83 91 91 111 111 114 114 128 131 143 165 170 174 188 192 206 221 229 252 257 280 295 315 326 347 357 371 406 450 488 506 544 587 606 649 666 683 722 752 767 794 821 60 60 60 65 65 71 71 80 80 88 88 106 106 110 110 122 125 136 158 163 167 179 184 197 211 219 241 247 269 283 301 313 332 343 357 391 431 467 487 522 564 583 625 643 660 697 727 743 769 795 58 58 58 62 62 69 69 77 77 84 84 101 101 105 105 115 119 129 149 154 159 170 174 186 199 208 227 236 255 268 285 298 315 327 340 373 409 442 465 497 537 556 596 614 632 666 696 713 738 763 56 56 56 61 61 67 67 74 74 81 81 97 97 101 101 111 115 124 144 148 153 163 168 178 191 200 218 227 245 258 274 287 303 316 329 360 394 424 449 479 517 537 575 594 613 644 674 692 716 741 DN mm TA Nm 17 14 14 14 14 14 14 14 14 14 14 35 35 35 35 35 35 35 70 70 70 70 70 70 125 125 125 125 125 125 125 190 190 190 190 295 295 295 405 405 580 580 780 780 780 780 1000 1000 1000 1000 250 79 79 79 87 87 96 96 113 113 127 127 168 168 163 163 200 192 223 258 257 256 294 291 335 359 347 409 368 425 447 493 480 525 511 531 582 682 764 725 800 864 868 929 931 932 1009 1026 1024 1060 1097 72 72 72 78 78 86 86 99 99 111 111 140 140 141 141 164 163 184 213 215 218 242 243 270 290 290 330 316 355 374 406 408 440 440 457 501 571 628 624 680 734 747 800 811 821 879 904 911 943 976 69 69 69 75 75 82 82 94 94 104 104 130 130 132 132 151 152 169 196 199 202 222 225 247 265 268 302 296 329 346 374 380 407 411 428 469 528 578 584 633 683 699 748 762 775 826 853 863 894 924 66 66 66 72 72 79 79 90 90 99 99 122 122 125 125 142 144 159 184 188 192 209 212 231 248 253 282 281 310 327 351 359 384 390 406 445 498 543 554 599 647 664 710 726 740 787 815 827 856 886 9 63 63 63 68 68 75 75 85 85 94 94 115 115 118 118 132 135 148 171 176 180 195 199 214 230 237 262 265 290 306 327 337 359 368 383 419 466 506 522 562 607 625 669 686 702 744 773 787 815 843 RINGFEDER® Locking Assemblies RfN 7012 Calculations Transmissible torques T Resulting torques TR Transmissible axial forces Fax When torque and axial force act simultaneously, one has to check whether the resulting torque TR can be safely transmitted by the Locking Assemblies. A connection made with a Locking Assembly RfN 7012 is similar to a shrink fit. In both cases, transmission of peripheral force Fax or torque T is effected by contact pressures in the joints between inner ring and shaft and outer ring and hub. In the case of shrink fits, the pressure is generated by contraction or expansion (after heating the hub or chilling the shaft), and in the case of the Locking Assembly RfN 7012 by radial deformation of the inner and outer rings following axial displacement of two double tapers. TR = 1) Fax = FN · 2) If the Locking Assemblies RfN 7012 are subject to radial forces, the surface pressure prad generated by them (table on page 6) must be higher than the surface pressure prad resulting from the radial load Fr. Formulae 3 to 5 give due consideration to the special shape of the Locking Assembly (cf. Fig. 4). In formula 3, k is a safety factor governed by the size of the Locking Assembly. Fax = 2 · T d FN = F tan ( + ) = F 0,381 g Radial load Fr d T = FN · · 2 d ·k 2 6) 2 2 g Where: Tg = max. torque to be transmitted Fg = max. axial force to be transmitted d = shaft diameter Formulae 1 and 2 are generally applicable. T = FN · · d T + (F · ) 2 prad = Fr d·l 7) 3) Where d = shaft diameter and I the load-bearing width of the Locking Assembly. The admissible pressure prad is limited. We like to be of assistance. The composed surface pressure(p + prad) must be borne in mind when calculating the hub and the hollow shaft (page 11) 4) Screws, technical data The formulae given above clearly show that the obtainable frictional connection is directly proportional to the sum of screw pre-tension forces Fv. For this reason, the locking screws must always be tightened down using a torque wrench. Information about the torque wrench on page 26. 5) tan = 0,25 tan = = 0,12 The following table contain the most important data on common screw sizes and grades. In the Locking Assemblies RfN 7012 the clamping force F is obtained by screws. F corresponds to the sum of initial clamping forces Fv. Regular thread 1 (metric) 8.8 dG 10 Fv TA 12.9 Fv TA Fv M M M 4 5 6 2,9 6,0 10 3900 6350 9000 4,1 8,5 14 5450 8950 12600 4,9 10 17 6550 10700 15100 (M M (M 7) 8 9) 16 25 36 13200 16500 22000 23 35 51 18500 23200 30900 28 41 61 22200 27900 37100 M 10 M 12 M 14 49 86 135 26200 38300 52500 69 120 190 36900 54000 74000 83 145 230 44300 64500 88500 M 16 M 18 M 20 210 290 410 73000 88000 114000 295 405 580 102000 124000 160000 355 485 690 123000 148000 192000 M 22 M 24 M 27 550 710 1050 141000 164000 215000 780 1000 1500 199000 230000 302000 930 1200 1800 239000 276000 363000 M 30 1450 262000 2000 368000 2400 442000 1) Fig. 4 · Forces acting on the plane Locking Assembly profile. 10.9 TA According to Bauer & Schaurte TA = Tightening torque (Nm) Fv = Initial clamping force (N) (Screws oiled, µtotal = 0,14) RINGFEDER® Locking Assemblies RfN 7012 Hub and hollow shaft calculation because of the differing hub and hollow shaft configurations. Constructions in which Locking Assemblies are intended to be arranged under or above bearings should therefore be avoided as far as possible, or be more closely investigated (e.g. test clamping). Equations for thick-walled cylinders give good service in the estimation of the tangential (tension) stresses occuring in the hub and hollow shaft. Exact determination of the true stresses and deformations (expanding, contraction) is very difficult in view of the wide scatter of the coefficients of friction and Hub calculation Shaft calculation 1) p´ p· d D 1) aW 2) aN = DN D 2) tiW 2 · p · C3 · 3) tiN = p´(aN2 + 1) aN2 – 1 ; B=l 3) taW p · C3 · 4) taN = 2 · p´ aN2 – 1 ; B=l 4) dB 5) tiN = 6) taN = 7) DN d dB d· 2l C3 · p´· 2 aN2 – 1 2l ; B 5) dB d· DN D· aW2 + 1 aW2 – 1 R Rp0,2W – 2 · p · C3 a) R C · p´ Rp0,2N + C3 · p´ R C · p´ Rp0,2N + C3 · p´ R Rp0,2W – 2 · p · C3 – dG b) p0,2W dB · tiW 6) dB a) 7) d b) 8) Rp0,2W p c) 9) pzul. Rp0,2W 1 – EW p · d · (m – 1) + dG c) EW · m p0,2N – 3 8) aW2 aW2 – 1 p0,2W C3 · p´(aN2 + 1) ; B aN2 – 1 D· = c) p0,2N – 3 9) 10) DN p´zul. DN · taN EN Rp0,2N C3 · DN2 – D2 DN2 + D2 d dB 2 a) C3 · 2 a) a) cross section of the hollow shaft below the Locking Assembly, unweakened and hollow shaft longer than 2 l (generally the case. Hollow shafts 2 l are very rare). C3 = 0,6 for one Locking Assembly C3 = 0,8 for two or more Locking Assemblies a) cross section of the hub above the Locking Assembly, unweakened. C3 = 0,6 for one Locking Assembly and B 2 l C3 = 0,8 for two or more Locking Assemblies and B L1 · (1 + n); n = number of Locking Assemblies C3 = 1 for one or more Locking Assemblies and B = l bzw. B = L1 · n b) if bores or threads (dG) in the hollow shaft. C3 = 0,8 b) if bores or threads(dG) in the hub. C3 = 0,8 if B 2 l or B L1 · (1 + n) C3 = 1 if B = l or B = L1 · n c) for solid shafts for steel: E = 210000 N/mm2 m = 10/3 c) approximated value. A higher scatter range is possible, as the value depends on the actual coefficient of friction and the shape of the hub. Fig. 5 Sketch for hub and hollow shaft calculation 11 RINGFEDER® Locking Assemblies RfN 7012 Installation and removal instructions* Installation Removal Since the force is transmitted by contact pressure and friction between functional surfaces, condition of contact surfaces and proper tightening of the locking screws are of great importance (see point 1). Locking Assemblies RINGFEDER® RfN 7012 are not selflocking. The taper of the individual rings is such that the inner and outer rings spring apart. On the last screw being loosened. The washers under the special marked screws protect the auxiliary (removal) threads against damage; these washers must be replaced after having been used several times. 1. All contact surfaces, including screw threads and screw head bearing surfaces, must be clean and slightly oiled. In this condition, the shaft, hub and Locking Assemblies are to be assembled. (Do not use Molybdenum Disulphide!) If relatively high forces are needed to to extract a Locking Assembly that has already been loosened (e.g. if the Locking Assembly has to be pushed against the weight of a heavy boss or hub), any type of removal device may be used, but the screws must only be slackened and not screwed out too far. As long as this instruction is followed, there is no objection against the use of a removal device, provided the forces applied are kept low. 2. Tighten locking screws lightly and align hub. 3. Tighten screws evenly in diametrically opposite sequence and do this in two or three stages up to the indicated tightening torque TA. 4. Re-check tightening torque by applying it to all screws all the way around. When no screw will turn any more, the assembly is completed. The auxiliary threads have only abour 3-5 effective courses and are not cut right through. Do not use these holes for jack screws. Information about the torque wrench on page 26. Dirty or used Locking Assemblies must be disassembled and cleaned before fitting. For reassembly the sequence as per fig. 6 is recommended. The special marked screws are fitted with washers in order to protect the auxiliary threads in the front thrust ring. In all other respects they have the same function as the other screws and serve only to identify the position of the auxiliary threads. Fig. 7 If the rear thrust ring is not automatically released, the screws have to be turned out by a few threads. Light tapping against the screw heads causes the rear thrust ring to spring backwards. 1 2 3 4 5 6 rear thrust ring outer ring inner ring front thrust ring washer locking screw Fig. 8 Should the front thrust ring jam, it is released in a similar way. The special marked screws are removed to expose the auxiliary threads of the front thrust ring. The front thrust ring can be released and a Locking Assembly which is located deeply in the hub bore can be removed by corresponding screws. Fig. 6 ·Locking Assembly RINGFEDER® RfN 7012. Designation of components. 12 RINGFEDER® Locking Assemblies RfN 7012 Constructions hints Fig. 9 · Locking Assembly RINGFEDER®. Connection. Design, designations Fig. 10 · Locking Assembly RINGFEDER® RfN 7012 Fig. 11 · Track wheel mounted using one Locking Assembly RfN 7012. The Locking Assembly must transmit above all the torque. The minor bore of the hub should be as long as possible and have close clearances in order to improve true running and to absorb stresses resulting from the axial force acting off-centre on the rim. Fig. 12 · Coupling half mounted with one Locking Assembly RfN 7012. In this arrangement, the shaft is stepped to permit the largest possible hub crosssection. 13 RINGFEDER® Locking Assemblies RfN 7012 Constructions hints Fig. 13 · Connection of two shafts using one Locking Assembly RfN 7012 per shaft. The hub bore need not be stepped; if a through-bore hub is used, it is recommended that a centering ring be fitted to improve trueness of running. Fig. 14 · Lever mounted using one Locking Assembly RfN 7012. Frictional-connection Locking Assembly permits stepless movement of the lever to any degree of accuracy required. Fig. 15 · Flywheel mounted using one Locking Assembly RfN 7012. Fig. 16 · Bevel gear mounted using one Locking Assembly RfN 7012. In this case the Locking Assembly transmits both the torque and the tooth pressure axial component. 14 RINGFEDER® Locking Assemblies RfN 7012 Constructions hints Fig. 17 · Shaft-mounted gearing secured using 3 Locking Assemblies RfN 7012. Belt drum mounted using 2 Locking Assemblies RfN 7012. 1/2000 to 1/3000 as related to the bearing spacing (recommended empirical value as quoted by the relevant industry). The drum-shaft connection on the drive side must be calculated for the full torque to be transmitted. Fig. 18 · Belt drum mounted with Locking Assemblies RfN 7012. With this and similar constructions, it must be ensured that the shaft deflections are kept within permissible limits. For practical purposes, the shaft deflection of 15 RINGFEDER® Locking Assemblies RfN 7012 Constructions examples Fig. 19 · Cable drum of a 400 kN foundry crane. The drum is mountedusing Locking Assemblies RfN 7012 Messrs. Koninklijke Nederlandsche Grofsmederij, Leiden, Netherlands, works photograph Fig. 20 · Ossberger turbine The rotor is mounted using 2 Locking Assemblies RfN 7012. Messrs. Ossberger Turbinenfabrik, Weissenburg, works photograph Fig. 21 · Precision stamping press. Gearwheels mounted using Locking Assemblies RfN 7012. Messrs. Osterwalder AG, Lyss/Switzerland, works photograph Fig. 22 · Primary crusher, Type 2 -1001. Vee-belt pulley and disc-type flywheel mounted with Locking Assemblies RfN 7012. Messrs. A. M¸ller, Rottweil, works photograph 16 RINGFEDER® Locking Assemblies RfN 7012 Constructions examples Fig. 23 · ANKER (R) Screw-type automatic injection moulding machine. Locking Assemblies RfN 7012 are used for securing the cranks actuating the clamping plate. Messrs. Ankerwerk Gebr. Goller, N¸rnberg, works photograph Fig. 24 · Details of the injection moulding machine shown in Fig. 23, with the cranks, Locking Assemblies RfN 7012, and plate. Messrs. Ankerwerk Gebr. Goller, N¸rnberg, works photograph Fig. 25 · Crank press. Gearwheel mounted with Locking Assemblies RfN 7012. Messrs. Hatebur, works photograph Fig. 26 · Bucket wheel excavator. Locking Assemblies RfN 7012 used in bucket wheel, the bucket wheel drive, travelling gear drive, the belt drums, etc. Messrs. Krupp, works photograph 17 RINGFEDER® Locking Assemblies RfN 7012 Constructions examples Fig. 27 · Bucket-wheel excavator. Locking Assemblies RfN 7012 used in the bucket-wheel, slewing and travelling drives. Messrs. DEMAG-Lauchhammer, works photograph Fig. 28 · Shaft couplings. Fitted with Locking Assemblies RfN 7012. Messrs. B. Willy Lein, Hilden, works photograph Fig. 29 · Automatic thread rolling machine. Cam disc mounted using one Locking Assembly RfN 7012. Messrs. Reed Rolled Thread Die Co., Holden/USA, works photograph Fig. 30 · Single-column eccentric press. Gearwheels mounted on the crankshaft with Locking Assemblies RfN 7012. Messrs. A. Richter, Kassel-Lohfelden, works photograph 18 RINGFEDER® Locking Assemblies RfN 7012 Constructions hints Fig. 31 · Ship propeller. Mounted with 2 Locking Assemblies RfN 7012. Fig. 32 · Ship propeller being fitted-fig. 31. Deutsche Werft, works photograph Fig. 33 · Cam actuator. For the Ossberger turbine, cams mounted using Locking Assemblies RfN 7012. Messrs. Ossberger Turbinenfabrik, Weissenburg, works photograph Fig. 34 · Lever mountings. These levers are used in a hydraulic welding press; they are mounted using Locking Assemblies RfN 7012. Messrs. Keller & Knappich GmbH, Augsburg, works photograph 19 RINGFEDER® Locking Assemblies RfN 7012 Constructions examples Fig. 35 · Bogiflex Drive TSP. Locking Assemblies RfN 7012 in the pinion support. Messrs. Tool Steel Gear & Pinion Co., Cincinnati/USA Fig. 36 · Conveying belt drums. Mounted on the drum shaft using Locking Assemblies RfN 7012. Messrs. Italsider Co./Italy Fig. 37 · Textile machine. A Locking Assembly 55 x 85 RfN 7012 is used for mounting the cam. Messrs. Tsudakoma Industrial Co., Ltd., Kanazawa/Japan SACAM, Mulhouse / France Fig. 38 · Medical betatron ray machine for cancer treatment. Positioning for radial guide with Locking Assemblies 70 x 110 RfN 7012. Messrs. Shimazu Seisakusho, Kyoto/Japan 20 RINGFEDER® Locking Assemblies RfN 7012 Constructions examples Fig. 39 · DEMAG standard-gauge Diesel-driven crane. Bevel gears mounted with Locking Assemblies RfN 7012. Waggonfabrik Uerdingen AG, works photograph Fig. 40 · Ore transporter. Locking Assemblies RfN 7012 used in belt drums and shaft mounted gearings. Pohlig-Heckel-Bleichert AG, Rohrbach, works photograph Fig. 41 · Saw frame. Connecting rod mounted with Locking Assembly RfN 7012. Esterer AG, Altˆtting, works photograph Fig. 42 · Pipe cutting mill. Locking Assemblies RfN 7012 used in vee-belt pulleys. Messrs. Pallman, Zweibrücken 21 RINGFEDER® Locking Assemblies RfN 7012 Constructions examples Fig. 43 · Winder machine. Lever mounted with Locking Assemblies 300 x 375 RfN 7012. Messrs. Nishimura Co. Ltd., Japan Fig. 44 · Bolt forming machine. Pinion mounted with Locking Assembly 120 x 165 RfN 7012. Messrs. Sakamura Machine Mfg. Co. Ltd., Japan Fig. 45 · Bolt forming machine. Locking Assemblies RfN 7012 used in levers, can discs and vee-belt pulleys. Messrs. Sakamura Machine Mfg. Co. Ltd. Japan Fig. 46 · Chain conveyor. Sprockets mounted with Locking Assemblies 70 x 110 RfN 7012. Messrs. Hitachi Zosen Co. Ltd., Japan 22 The ABC of Locking Assemblies RINGFEDER® RfN 7012 Adjustability Fatigue strength under alternating torsion stresses The friction-lock connection by means of Locking Assemblies RfN 7012 is infinitely variable and can be adjusted with a high degree of accuracy. The greatest variable stress component oscillating about the mean stress zero a specimen can resist an unlimited number of times without fracture or inadmissible deformation (see DIN 50100). This value is influenced by shape and surface finish. The ratio between the fatigue strength of the unnotched and polished specimen is referred to a notch factor . varies from material to material and decreases in value as the static tensile strength value increases. Axial force Fax The axial thrust that can be transmitted by Locking Assemblies RfN 7012, regardless of the type of load encountered (static, increasing, alternating or impact). Fax can be calculated by dividing the torque by the shaft radius (Fax = 2 x T/d). In comparison with these theoretical values, substantially higher values have been established in practical operations. (values for Fax see table on page 6.) When Locking Assemblies RINGFEDER® RfN 7012 are used, both shaft and hung retain their full crosssections, i.e. are not grooved. Consequently, the stress states at the connection point are virtually identical with those of a smooth shaft, i.e. the material is utilized by almost 100%. Calculations Locking Assemblies RfN 7012: Hubs: Hollow shafts: see page 10 see page 11 see page 11 Fitting see page 12 Fretting / Galling Centering action Damage to or destruction of shaft, hub bore or Locking Assembly surfaces as a result of overloading followed by → Slip. Fretting can always be avoided by correct dimensioning of the connection. Guiding action of the shaft in the minor bore of the hub. The clearance between shaft and hub bore and the length of the minor bore have the greatest effect on True running of the mounted hub. Fretting corrosion Corrosion between the contact surfaces of ferrous metals. Even the smallest relative movements favour and accelerate fretting corrosion; lubricants can delay the process, but not stop it altogether. Longterm prevention of fretting corrosion can be achieved only by designing the connection in such a way that relative movement is impossible. Locking Assemblies RfN 7012 greatly facilitate the solving of this problem. Locking screws – securing of Screws subjected to static loads need not be secured against slackening (in some cases, lock washers, etc. can even be harmful). The screws used in conjunction with Locking Assemblies are normally subjected to static loads only; consequently, they need not be secured against loosening. Tightening down to the specified torque value is quite adequate. Fig. 47 · Locking Assembly RINGFEDER® Principle sketch. Clearances see page 7 Coefficient of friction Molykote The catalogue values (table page 6) apply to = 0,12. Surfaces of the Locking Assemblies, shaft and hub bore slightly oiled with lubricants which do not contain → Molykote. Trade name of a lubricant containing molybdenum disulphide (MoS2). As MoS2 reduces the Coefficient of friction, it is used for frictional connections between shafts and hubs in exceptional cases only. We urgently recommend that our advice be sought if it is intended that lubricants containing MoS2 be used in conjunction with Locking Assemblies. Contact pressure p, p’ p = contact pressure between inner ring and shaft. p’ = contact pressure between outer ring and hub p and p’ – together with the → Coefficient of friction – determine the frictional connection value. In order to avoid deformation in the plastic range, the following values must obtain: p p´ Rp0,2W and Rp0,2N Deformations see page 11 Exchangeability see page 4 23 The ABC of Locking Assemblies RINGFEDER® RfN 7012 Continuation Notch factor k Safety → Fatigue strength under alternating torsion stresses. The frictional connection values given in the tables are achieved or even exceeded if designing is correct and the connection properly made. The theoretical values are higher. Frictional connections of all types – including shrink fits and press fits – must be designed in such a way that the load peaks vary so greatly from case to case that we are unable to give any recommendations as regards specific safety factors. Locking Assembly connections are insensitive to impact loads (see fig. 48). Notch impact strength figure k Produkt of the → Shape factor k (governed by material configuration) and the → Notch factor k (governed by material properties): Formel.......... k - 1 k = k - 1 values for Approximate k 0,4...0,8 – light metals and c-steels 0,6...1 – heat-treatable steels. Overload protection see page 5 Play, freedom from Connections with Locking Assemblies RfN 7012 are absolutely free of play. Like other frictional connections there is no danger of lateral oscillation. Fig. 48 Polar section modulus Wp Shape factor k In the case of circular cross sections, Wp is defined thus: Wp = d3 /16 Proportionally factor covering stress conditions at bores, crosssection transitions, clamping points, grooves, etc. The following applies: The value of Wp is significantly reduced by keyways, grooves for Woodruff and feather keys, etc. When using Locking Assemblies RfN 7012, the full cross-section of the shaft is available (see Shape factor k). max Höchstspannung Formel...... k = = n Nennspannung (use smallest cross-sections and/or resistance moments when determining n). For smooth shafts k = 1 Radial load, admissible Locking Assemblies RINGFEDER® RfN 7012 can also absorb radial loads. It must be considered, however, that the surface pressure resulting from the radial load with respect to the projected surface of the locking Assembly, is smaller than the surface pressure generated by the clamping (see also calculation on page 10). Releasability Locking Assemblies RfN 7012 are not self-locking. The angel of the tapered rings is such that releasability is guaranteed even after prolonged heavy loading. Extractors are not required. Removal see page 12 Rust Because of the relatively high pressures per unit of area, rusting cannot take place between the effective surfaces of a Locking Assembly as well as shaft and hub Because of their split inner and outer rings the Locking Assemblies RfN 7012 cannot hermetically seal the clamping point. In this case we advise to use corrosion inhibitors, seals, etc. in order to protect the Locking Assemblies (locking screws) against corrosion. r grooved – t = 0,5 r grooved – = 0,2 t e. g. r = 2,5 mm k = 2,1 W’p = 6 cm3 e. g. r = 1 mm k = 3,4 W’p = 3,7 cm3 r grooved – = 0,1 t e. g. r = 0,5 mm k = 5,4 W’p = 2,32 cm3 Fig. · 49 · Influence of the groove shape on shape factor k and thus on the →Polar moment of resistance; extract from the work of Prof. Thum. 40 mm (Wp = 12,56 cm3). For smooth shafts k = 1. 24 Spannsätze RINGFEDER® RfN 7012 Slip All shrink fits slip on overloading taking place. → Fretting of the contact (slipping) surfaces normally unavoidable. Locking Assemblies subjected to high pressures per unit of area and rotating at high peripheral speeds can be completely destroyed. Under normal circumstances, the degree and type of destruction do not indicate the cause of slipping. Slipping clutch Fig. 52 · Due to the relatively close fit between shaft and hub, the heat is dissipated readily and no significant difference in temperature occurs. The contact pressure and thus the transmissible torque remain constant. Locking Assemblies RINGFEDER® RfN 7012 are not suitable for use as a slipping clutch. With their overload protection effect they can only safeguard valuable machine components against damage (see also page 5). Tightening torque TA Controlled torque per locking screw generated by the torque wrench (see page 6, 7 and 10). Surface finish Surface condition of shaft and hub bore. When using Locking Assemblies RfN 7012, Rt 16 µm. (RMS 125 micro-inches). Torque wrench Standard tool indicating the tightening torque exerted on the screw heads. As the friction lock of the Locking Assemblies RINGFEDER® RfN 7012 is proportional to the srew tightening torque, it is advised to use a torque wrench (see page 26). Tangential stresses Tensile stress in the hub bore or compression stress in the bore of hollow shafts as a result of the → Contact pressures between outer locking ring and hub and/or inner locking ring and hollow shaft. See page 11 for calculation. True running The relatively narrow Locking Assembly RINGFEDER® RfN 7012 serve mainly to transmit high torques and axial forces. They are not self-centering. True running of the hub/boss is thus governed by the → Centering action and the care taken during → Fitting. Fig. 50 · Tangential stresses in shrink fits. Temperature, influence of Shrink fits – and thus Locking Assembly RfN 7012 connections, too – give perfect service as long as the contact pressure in the joint does not drop below a certain minimum value. Consequently, contact pressure in the joint at operating temperature must be the subject of close attention. Please contact us for advice. Fig. 53 · Pre-centering by selection of correct fit between shaft and hub. Wear Fig. 51 · The air cushion between shaft and hub/boss has an insulating effect; consequently, heat transmission is poor. The result is a difference in temperature between shaft and hub. If both hub and shaft have the same linear expansion coefficients, the hub undergoes a higher degree of expansion than the shaft; the diminishing contact pressure reduces the frictional connection value. 25 see page 5 Torque Wrenches For controlled tightening of locking screws of Locking Assemblies RINGFEDER®, we offer suitable torque wrenches and attachments. These tools facilitate the installation of our Locking Assemblies RfN 7012 particularly on straight through shafts. They can be used, of course, also for mounting of Locking Assemblies RINGFEDER® RfN 7013, 7014, 7015 and Locking Elements RINGFEDER® RfN 8006 and other screwed or bolted connections. The rigid square drives SSD and hex bit sockets exhibit compact over-all dimensions and can be combined with commercially available axtensions. The SSD-drives fit with all MCCM torque handles. Square drives and hex bit sockets drives required for any given Locking Assembly size are listed in following table. Locking Assemblies RfN 7012 Size from to d d 19 40 Recommended Tools Hex bit Sockets Square Drives 1/4– 5 Torque Wrench Handles MCCM - 20 Nm SSD– 1/4 42 65 1/4– 6 70 95 3/8– 8 100 160 3/8–10 170 200 1/2–12 220 300 1/2–14 MCCM - 100 Nm SSD– 3/8 MCCM - 200 Nm SSD– 1/2 MCCM - 600 Nm Torque wrenches for larger Locking Assemblies are readily available Description and operation When preset torque is reached, you hear a click and feel the breakover. No disadvantages are caused by dials and indicators. Torque setting is achieved by turning the adjustable micrometer torque habdle. Every setting point is felt by a distinct stop. Torque setting cannot accidentally change while wrench is in use. By turning the lock screw located at the end of handle counter-clockwise (“Lock”), the adjustable handle is locked. By turning it clockwise (“Unlock”), the handle is unlocked. Frictionless adjustment mechanism permits high torque accuracy even after prolonged use. Slim design and light weight for better accessibility to fasteners and minimum operator fatigue. Required attachments slide on easy onto the dovetailed and pin locked torque handle. For release of attachments, the spring loaded lock pin can be easily depressed by a pin or screw driver. 26 ...and accessories Torque Wrench Handles MCCM - 20 Nm MCCM - 100 Nm MCCM - 200Nm MCCM - 600 Nm Calibration in Nm Nm Nm Nm Torque range 4 – 20 Designation Graduation 20 – 100 50 – 200 100 - 600 0,2 1 1 0,5 Weight kg 0,32 0,5 0,64 3,9 A max. mm 235 330 406 915 A min. mm 216 303 384 903 B mm 78 107 107 254 C mm 51 102 118 660 F mm 25 25 25 51 Square Drives Designation Square Drive size A B C D SSD – 4 4" 44 14 19 19 SSD – s s" 46 20 22 25 SSD – 2 2" 48 22 25 28 mm Hex bit Sockets Designation 27 Square Drive size S L mm D 4 –5 4" 5 55 11 4 –6 4" 6 55 11 s –8 s" 8 52 18 s – 10 s" 10 52 18 2 – 12 2" 12 60 24 2 – 14 2" 14 60 24 Material standards – selection Hints for material specifications and according values of yield strength replaced by DIN DIN EN designation aproximate range of yield point* N/mm2 1629 seamless tubes for special requirements 215 up to 355 1681 cast steel for common use 200 up to 300 Beibl. 1 1691 cast iron 1692 malleable cast iron 200 up to 530 1693 spheroidal graphite cast iron 250 up to 500 1705 copper - tin and copper - tin - zinc - alloys 90 up to 180 98 up to 228 (0,1 – limit of elongation) 1725 575 aluminium alloys 70 up to 380 17100 10025 structural and constructural steels 175 up to 365 17200 10083 heat-treatable steel 300 up to 560 17245 ferritic creep resistant cast steel 125 up to 540 17440 stainless steels 185 up to 600 * dependent on quality, kind of product and intended use 28 ISO-tolerances for shafts and bores Allowances in µm (1 µm = 39.37 µin) Nominal diameter of shaft (mm) d 11 e8 e7 f8 f7 g6 h 11 h9 h8 h7 above to upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower 3 6 10 6 10 18 – 30 – 40 – 50 – 105 – 130 – 160 – 20 – 25 – 32 – 38 – 47 – 59 – 20 – 25 – 32 – 32 – 40 – 50 – 10 – 13 – 16 – 28 – 35 – 43 – 10 – 13 – 16 – 22 – 28 – 34 – – – 4 5 6 – 12 – 14 – 17 0 0 0 – 75 – 90 – 110 0 0 0 – 30 – 36 – 43 0 0 0 – 18 – 22 – 27 0 0 0 – 12 – 15 – 18 18 30 50 30 50 80 – 65 – 80 – 100 – 195 – 240 – 290 – 40 – 50 – 60 – 73 – 89 – 106 – 40 – 50 – 60 – 61 – 75 – 90 – 20 – 25 – 30 – 53 – 64 – 76 – 20 – 25 – 30 – 41 – 50 – 60 – 7 – 9 – 10 – 20 – 25 – 29 0 0 0 – 130 – 160 – 190 0 0 0 – 52 – 62 – 74 0 0 0 – 33 – 39 – 46 0 0 0 – 21 – 25 – 30 80 120 180 120 180 250 – 120 – 145 – 170 – 340 – 395 – 460 – 72 – 85 – 100 – 126 – 148 – 172 – 72 – 85 – 100 – 107 – 125 – 146 – 36 – 43 – 50 – 90 – 106 – 122 – 36 – 43 – 50 – 71 – 83 – 96 – 12 – 14 – 15 – 34 – 39 – 44 0 0 0 – 220 – 250 – 290 0 0 0 – 87 – 100 – 115 0 0 0 – 54 – 63 – 72 0 0 0 – 35 – 40 – 46 250 315 400 315 400 500 – 190 – 210 – 230 – 510 – 570 – 630 – 110 – 125 – 135 – 191 – 214 – 232 – 110 – 125 – 135 – 162 – 182 – 198 – 56 – 62 – 68 – 137 – 151 – 165 – 56 – 62 – 68 – 108 – 119 – 131 – 17 – 18 – 20 – 49 – 54 – 60 0 0 0 – 320 – 360 – 400 0 0 0 – 130 – 140 – 155 0 0 0 – 81 – 89 – 97 0 0 0 – 52 – 57 – 63 Nominal diameter of shaft (mm) above to h6 h5 j6 k6 k5 m6 m5 n6 p6 upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower 3 6 10 6 10 18 0 0 0 – 8 – 9 – 11 0 0 0 – 5 – 6 – 8 + 7 + 7 + 8 – 1 – 2 – 3 – + 10 + 12 – + 1 + 1 – + 7 + 9 – + 1 + 1 + 12 + 15 + 18 + + + 4 6 7 + 9 + 12 + 15 + 4 + 6 + 7 + 16 + 19 + 23 + 8 + 10 + 12 + 20 + 24 + 29 + 12 + 15 + 18 18 30 50 30 50 80 0 0 0 – 13 – 16 – 19 0 0 0 – 9 – 11 – 13 + 9 + 11 + 12 – 4 – 5 – 7 + 15 + 18 + 21 + 2 + 2 + 2 + 11 + 13 + 15 + 2 + 2 + 2 + 21 + 25 + 30 + 8 + 9 + 11 + 17 + 20 + 24 + 8 + 9 + 11 + 28 + 33 + 39 + 15 + 17 + 20 + 35 + 42 + 51 + 22 + 26 + 32 80 120 180 120 180 250 0 0 0 – 22 – 25 – 29 0 0 0 – 15 – 18 – 20 + 13 + 14 + 16 – 9 – 11 – 13 + 25 + 28 + 33 + 3 + 3 + 4 + 18 + 21 + 24 + 3 + 3 + 4 + 35 + 40 + 46 + 13 + 15 + 17 + 28 + 33 + 37 + 13 + 15 + 17 + 45 + 52 + 60 + 23 + 27 + 31 + 59 + 68 + 79 + 37 + 43 + 50 250 315 400 315 400 500 0 0 0 – 32 – 36 – 40 0 0 0 – 23 – 25 – 27 + 16 + 18 + 20 – 16 – 18 – 20 + 36 + 40 + 45 + 4 + 4 + 5 + 27 + 29 + 32 + 4 + 4 + 5 + 52 + 57 + 63 + 20 + 21 + 23 + 43 + 46 + 50 + 20 + 21 + 23 + 66 + 73 + 80 + 34 + 37 + 40 + 88 + 98 + 108 + 56 + 62 + 68 Nominal diameter of bore (mm) D 11 E8 E7 F8 F7 G7 H 11 H9 H8 H7 above to upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper lower upper 3 6 10 6 10 18 + 105 + 130 + 160 + 30 + 40 + 50 + 38 + 47 + 59 + 20 + 25 + 32 + 32 + 40 + 50 + 20 + 25 + 32 + 28 + 35 + 43 + 10 + 13 + 16 + 22 + 28 + 34 + 10 + 13 + 16 + 16 + 20 + 24 + + + 4 5 6 + 75 + 90 + 110 0 0 0 + 30 + 36 + 43 0 0 0 + 18 + 22 + 27 0 0 0 + 12 + 15 + 18 0 0 0 18 30 50 30 50 80 + 195 + 240 + 290 + 65 + 80 + 100 + 73 + 89 + 106 + 40 + 50 + 60 + 61 + 75 + 90 + 40 + 50 + 60 + 53 + 64 + 76 + 20 + 25 + 30 + 41 + 50 + 60 + 20 + 25 + 30 + 28 + 34 + 40 + 7 + 9 + 10 + 130 + 160 + 190 0 0 0 + 52 + 62 + 74 0 0 0 + 33 + 39 + 46 0 0 0 + 21 + 25 + 30 0 0 0 80 120 180 120 180 250 + 340 + 395 + 460 + 120 + 145 + 170 + 126 + 148 + 172 + 72 + 85 + 100 + 107 + 125 + 146 + 72 + 85 + 100 + 90 + 106 + 122 + 36 + 43 + 50 + 71 + 83 + 96 + 36 + 43 + 50 + 47 + 54 + 61 + 12 + 14 + 15 + 220 + 250 + 290 0 0 0 + 87 + 100 + 115 0 0 0 + 54 + 63 + 72 0 0 0 + 35 + 40 + 46 0 0 0 250 315 400 315 400 500 + 510 + 570 + 630 + 190 + 210 + 230 + 191 + 214 + 232 + 110 + 125 + 135 + 162 + 182 + 198 + 110 + 125 + 135 + 137 + 151 + 165 + 56 + 62 + 68 + 108 + 119 + 131 + 56 + 62 + 68 + 69 + 75 + 83 + 17 + 18 + 20 + 320 + 360 + 400 0 0 0 + 130 + 140 + 155 0 0 0 + 81 + 89 + 97 0 0 0 + 52 + 57 + 63 0 0 0 Nominal diameter of bore (mm) H6 J7 above to upper lower 3 6 10 6 10 18 + 8 + 9 + 11 18 30 50 30 50 80 80 120 180 250 315 400 J6 K7 K6 upper lower upper lower upper lower upper 0 0 0 + 5 + 8 + 10 – – – 7 7 8 + 4 + 5 + 6 – 4 – 4 – 5 – + 5 + 6 – – 10 – 12 – + 2 + 2 – – + 13 + 16 + 19 0 0 0 + 12 + 14 + 18 – 9 – 11 – 12 + 8 + 10 + 13 – 5 – 6 – 6 + 6 + 7 + 9 – 15 – 18 – 21 120 180 250 + 22 + 25 + 29 0 0 0 + 22 + 26 + 30 – 13 – 14 – 16 + 16 + 18 + 22 – 6 – 7 – 7 + 10 + 12 + 13 315 400 500 + 32 + 36 + 40 0 0 0 + 36 + 39 + 43 – 16 – 18 – 20 + 25 + 29 + 33 – 7 – 7 – 7 + 16 + 17 + 18 M7 M6 N7 N6 lower P7 lower upper lower upper lower upper lower upper lower upper lower – 7 9 0 0 0 – 12 – 15 – 18 – – – 1 3 4 – 9 – 12 – 15 – – – 4 4 5 – 16 – 19 – 23 – – – 5 7 9 – 13 – 16 – 20 – 8 – 9 – 11 – 20 – 24 – 29 + 2 + 3 + 4 – 11 – 13 – 15 0 0 0 – 21 – 25 – 30 – – – 4 4 5 – 17 – 20 – 24 – – – 7 8 9 – 28 – 33 – 39 – 11 – 12 – 14 – 24 – 28 – 33 – 14 – 17 – 21 – 35 – 42 – 51 – 25 – 28 – 33 + 4 + 4 + 5 – 18 – 21 – 24 0 0 0 – 35 – 40 – 46 – – – 6 8 8 – 28 – 33 – 37 – 10 – 12 – 14 – 45 – 52 – 60 – 16 – 20 – 22 – 38 – 45 – 51 – 24 – 28 – 33 – 59 – 68 – 79 – 36 – 40 – 45 + 5 + 7 + 8 – 27 – 29 – 32 0 0 0 – 52 – 57 – 63 – 9 – 10 – 10 – 41 – 46 – 50 – 14 – 16 – 17 – 66 – 73 – 80 – 25 – 26 – 27 – 57 – 62 – 67 – 36 – 41 – 45 – 88 – 98 – 108 29 Technical service Based on your technical drawings and data we are ready to execute installation proposals to solve your specific problems. Many years of experience and modern calculation methods open extraordinary possibilities of assistance. VDA 6.1 Type approvals by: Fax enquiry (410)358-3142 (800)872-9329 Maryland Metrics For technical assistance To: RINGFEDER VBG GMBH, department KM From: Messrs.: .................................................................. .................................................................................. .................................................................................. address: ................................................................ .................................................................................. .................................................................................. contact: ................................................................... phone: .................................................................. department: ............................................................ fax: ......................................................................... To make it easier for our technical staff and to avoid errors or mistakes your enquiry should include the following information: Information for technical service Expected maximum loads: Max. torque Max. bending moment Max. axiall load Max. radial load Tg Mg Fg Fr max. max. max. max. = = = = ……………………… Nm ……………………… Nm ……………………… kN ……………………… kN = = = = = = = = ……………………… mm ……………………… mm ……………………… 1/min ……………………… mm ……………………… mm ……………………… N/mm2 ……………………… N/mm2 ……………………… °C Dimensionens, materials: shaft diameter In case of hollow shaft, internal diameter Speed/revolutions Hub outside diameter Hub width Hub material/yield strength Shaft material/yield strength Temperature at the connection dW dB n DN B Rp0,2N Rp0,2W Temp. Additional information: ................................................................................. ................................................................................. ................................................................................. ................................................................................. Please send a drawing or sketch together with your enquiry! RINGFEDER Products are available from MARYLAND METRICS P.O. Box 261 Owings Mills, MD 21117 USA email: sales@mdmetric.com web: http://mdmetric.com phones: (410)358-3130 (800)638-1830 faxes: (410)358-3142 (800)872-9329 For shaft-hub connections we supply: RINGFEDER® Shrink Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . for external clamping RfN 4071 / 4091 / 4051 / 4073 / 4171 RINGFEDER® Shaft Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . for an absolutely rigid connection of shafts and high accuracy of alignment Special designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . on request Torque wrenches and accessories . . . . . . . . . . . . . . . . . . . . . . . . . for correct tightening conditions S. 119.1. 31.1.01 RINGFEDER® Locking Assemblies RfN 7012 . . . . . . . . . . . . . . . . . for highly stressed shaft-hub connections and big machining tolerances RINGFEDER® Locking Assemblies RfN 7012-IN . . . . . . . . . . . . . . . for shafts with inch-dimensions RINGFEDER® Locking Assemblies RfN 7013 . . . . . . . . . . . . . . . . . for higher demands to concentricity RINGFEDER® Locking Assemblies RfN 7013-IN . . . . . . . . . . . . . . . for shafts with inch-dimensions RINGFEDER® Locking Assemblies RfN 7014 . . . . . . . . . . . . . . . . . for extremely stressed shaft-hub connections RINGFEDER® Locking Assemblies RfN 7015 . . . . . . . . . . . . . . . . . self-centering, for highest transmission values as well as for the use in belt drums RINGFEDER® Locking Elements RfN 8006 . . . . . . . . . . . . . . . . . . . adaptable design for special requirements RINGFEDER® Locking Assemblies RfN 7110 . . . . . . . . . . . . . . . . . compact dimensions, excellent centering ability Locking Connections RINGFEDER Products are available from MARYLAND METRICS P.O. Box 261 Owings Mills, MD 21117 USA email: sales@mdmetric.com web: http://mdmetric.com phones: (410)358-3130 (800)638-1830 faxes: (410)358-3142 (800)872-9329