Electrical Panel Installation Method Statement - Kuwait University

advertisement

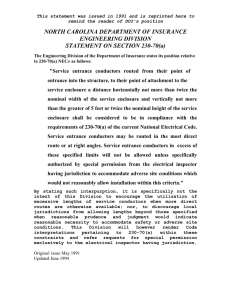

TABLE OF CONTENTS 1 Purpose......................................................................................... 4 2 Scope of Work................................................................................ 4 3 Responsible Personnel on Site........................................................ 4 4 Storage......................................................................................... 4 5 Pre-Installation.............................................................................. 4 6 Installation.................................................................................... 5 7 Reference Documents................................................................... 6 8 Safety.......................................................................................... 7 STATE OF KUWAIT KUWAIT UNIVERSITY ELECTRICAL METHOD STATEMENT TENDER NO. KU/KUCP/C0251/10-11 Page 3 of 7 1. Purpose This method of statement covers the in-site installations of Electrical Panels as defined in the General Specification. 2. Scope of Work This procedure will define the method to be used to ensure that the Electrical Panels installations, on-site assembly, final connection and workmanship are acceptable, correct, and safe and conforms the Contract Documents and Specification. 3. Responsible Personnel on Site 3.1. Construction Manager 3.2. Electrical Field Engineers 3.3. Safety Officer 3.4. QA/QC Engineer 3.5. Electrical Supervisors 4. Storage 4.1 Unload the Electrical panels to the designated unloading area. Use fork lift or mobile crane to unload self standing panels. 4.2 Ensure that the Panels are stored in dry and clean locations. 4.3 Make sure that the storage area is safe. 5. Pre-Installation 5.1 All materials and documentation relevant to this particular section of works shall be checked prior to installation. 5.2 Ensure that the location wherein the panels were installed is accessible, clean and free of debris and foreign materials and suitable for installations. STATE OF KUWAIT KUWAIT UNIVERSITY ELECTRICAL METHOD STATEMENT TENDER NO. KU/KUCP/C0251/10-11 Page 4 of 7 6. Installation 6.1 Check the size of panel enclosure knockouts to be the same size of the incoming / outgoing conduits. 6.2 remove the knockouts prior to mounting the enclosure. On multiple ring knockouts remove the center section by striking at the point furthest from the tie. Bend the knockout back and forth to break the tie. 6.3 use knockout punches where possible to prevent burrs. 6.4 use a small magnet to remove any metals shavings from the enclosure. 6.5 If a larger opening is required, remove each additional ring one at a time by prying with a screwdriver and bending back and forth with pliers as shown in the following figure. 6.6 install the panel enclosure as required by specs , standards and codes. 6.7 use Approved cable clamps ( lock nuts) or conduit hubs in the holes to secure the pipe to the panel enclosure and protect the cable and conductors. 6.8 carefully , install the conductors into the raceway to prevent nicks and other damage to insulation. 6.9 replace conductors if the insulation is damaged. 6.10 assemble the panel interior components and tight the screws and bolts properly. 6.11 separate the phases conductors to two categories as one will be terminated from left side breakers and the other will be terminated to the right side breakers. 6.12 separate also the neutral conductors for all circuits which will be terminated to the neutral bus. 6.13 separate also the ground conductors for all circuits which will be terminated to the ground bus. 6.14 tie each group of phases conductors with cable ties till the first bottom branch circuit breakers. 6.15 tie each group of neutral conductors and ground conductors with cable ties till the neutral and ground bars. 6.16 adjust the length of each conductor to be able to reach its corresponding circuit breaker , neutral bar or ground bar. 6.17 label each conductor as per panel schedule and as per specs. STATE OF KUWAIT KUWAIT UNIVERSITY ELECTRICAL METHOD STATEMENT TENDER NO. KU/KUCP/C0251/10-11 Page 5 of 7 6.18 strip the insulation from the end of each conductors by using approved tools. 6.19 don't allow loose strands of conductors to stick out from terminations. 6.20 connect the main conductors to the mechanical lugs of the main circuit breakers. 6.21 don't install more than one conductor under a mechanical lug or termination. 6.22 Connect the branch circuit conductors to the mechanical lugs of its corresponding branch circuit breakers. 6.23 connect the neutral conductors and the ground conductors to the neutral bar and ground bar respectively. 6.24 Assemble the dead front , the trim and access door of the panel board and securely tight the screws and bolts. 6.25 provide circuit directory to the door for listing which breaker provides service for each room or appliance. 6.26 Raise Request for Inspection for Panel installation. 7. Reference Documents 7.1 Approved Electrical Shop Drawings 7.2 Approved Material Submittals for Panels 7.3 Approved QA/QC Installation and Test Plan 7.4 Factory Test Certificates of the said equipments 7.5 Operation and Maintenance Manuals for Panels 7.6 Approved Material Inspection Report 7.7 Approved Safety Plan STATE OF KUWAIT KUWAIT UNIVERSITY ELECTRICAL METHOD STATEMENT TENDER NO. KU/KUCP/C0251/10-11 Page 6 of 7 8. Safety 8.1 All safety precautions shall be followed as per approved safety plan & procedure. Ensure all involved persons are aware of the same. 8.2 Ensure that tradesman will keep their working places clean, tidy and free from rubbish. ------------------------ Procedure End---------------------- STATE OF KUWAIT KUWAIT UNIVERSITY ELECTRICAL METHOD STATEMENT TENDER NO. KU/KUCP/C0251/10-11 Page 7 of 7