Bioactive Glass Scaffolds for Bone Tissue Engineering

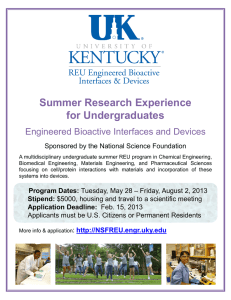

advertisement