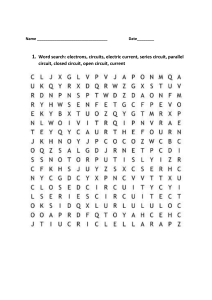

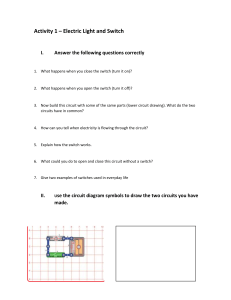

1 CHAPTER ONE INTRODUCTION 1.1 Background of the Study Electricity is dangerous and required proper protection to prevent unwanted voltage from passing through personnel, critical equipment and other nearby metallic objects (Amrapali, 2017). The security and reliability of the electrical energy infrastructure is of vital importance today more than ever, given the degree to which electric-powered technology has become embedded in all human activities. Protecting the electrical power supply system against interruptions due to various faults is researchable (Jay Kumar et al. 2016). One of the components involved in power-system protection is the circuit breaker which is responsible for breaking the system when a fault or anomaly occurs in order to protect the electrical equipment. (Ewesor, 2018) and (Ewesor and Gupta,2005). Circuit breakers are crucial components for power systems operation for detection and removal of faults in the switchgear. (Amrapali, 2017) Moreover, electrical protection for residential, office and commercial buildings is based on a well- design circuit breaker that will trip or fuses being blown when an overload happens. (Stallcup’s, 2005) The current state-of-the-art in this field highlights that the traditional circuit breakers are still widely used today for power-system protection, these devices being usually designed to protect against a single power supply grid fault. (Yuan, Zhao, Zeng, 2014) MCCBs are required to trip above rated current (Oyeleye, 2017) 2 In most buildings, where a number of circuits are to be wired, the distribution fuse board becomes a necessity. Distribution boards are simply an assemblage of parts including one or more fuses or circuit breakers suitably arranged for the distribution of electrical power to final sub circuits. (Oyeleye, 2017). The circuit breakers are on suitable carriers with neutral and earth bars adequately provided inside a metal casing. The metal casing shall be of adequate size and capacity. They are usually iron clad and designed to provide a large space for wiring and splitting the circuits. It consist circuit breakers or fuse inside which can easily remove. The purpose of this study is to verify the proper operation of Distribution Board (DB)and re-design appropriate DB for the business center under consideration to ensure that fault will be isolated at the lowest level. (Marrano and Dilouie,1998), An electrical distribution board is a crucial part of an electrical installation for a commercial building. Its purpose is to distribute the power supply evenly throughout the building by way of different circuits. The incoming power has to be controlled in this manner to prevent any overloads from occurring. Professionals install the distribution board at the point where the main power feed enters the building and hook up feed lines off the various circuits to provide electricity to the numerous consumption points in the building. (Omokhafe and Ambafi, 2011) The standard configuration for this type of board is one main circuit breaker to turn off the entire electrical supply with multiple mini-circuit breakers that control specific areas of the building. The main feeds the other breakers their specific voltage of electricity to send to their allotted places, machinery or appliances. Extensive cabling 3 is necessary for all the circuits to carry out their tasks. (National electrical code, NEC, 2005) On top of the cables and circuits, the electrical distribution board requires fuse links, switches, a bus bar, residual current detector or RCD and bypass equipment. Each component has its unique purpose, but the RCD provides highly effective protection against ground fault shock and fire. Each electrical distribution board is customisable to suit the needs of the commercial property owner. After all, every commercial building has differing electrical load requirements to conduct their daily operations. Often, there also are local regulations as to how these boards are configured. (Marrano and Dilouie, 1998), The importance of ensuring that your electrical distribution board is configured and installed correctly should not be underestimated. Its prime role is to distribute your electricity in the right portions to each area of the building that requires it in a safe, efficient manner. Without this board, you will have constant shorts and overloads, which can lead to electrically caused fires or complete blackouts in severe cases. For optimal performance with this board, you need to hire a professional company that delivers quality electrical work on a regular basis. 1.2 Statement of the Problem Many things can happen to electrical and electronic circuits after they are in use. Some of the changes in circuits can cause conditions that are dangerous to the circuit itself or to people living or working near the circuits. These potentially dangerous conditions require circuit protection. The conditions that require circuit protection are direct shorts, excessive current and excessive heat. 4 A distribution board is a part of an electrical system that takes electricity from a main source and feeds it through one or more circuits to distribute the electricity throughout a facility. This is often called an electrical panel, panel board, or even a fuse box. Virtually all homes and businesses will have at least one distribution board built in, which is located where the main electrical line enters the structure. The size of the board will depend on the amount of electricity coming in and how many different circuits need to be installed. Distribution boards allow all your electrical equipment to operate safely throughout the entire area. You can, for example, install a small 15-amp circuit breaker into the distribution board to supply one area of the facility with the power it needs. This will only allow up to 15 amps of electricity to pass from the main electrical line into the area where it is used, which means that area can be serviced with smaller and less expensive wire. It will also prevent a surge (of greater than 15 amps) from entering equipment and potentially causing damage. For areas that need more electricity, you would install circuit breakers that allow more electricity through. Having the ability to take one main circuit that provides 100 or more amps of power and distributing it throughout the facility based on how much power is needed in a given place is not only far safer than just having full access to the full amperage at all times, but it is also much more convenient. If, for example, there is a surge in one area, it will only trip the breaker on the distribution board for that one circuit. This prevents an electrical outage to other areas of the home or business. The problem of Direct Short One of the most serious troubles that can occur in a circuit is a Direct Short. Another term used to describe this condition is a Short 5 Circuit. The two terms mean the same thing and, in this chapter, the term direct short will be used. This term is used to describe a situation in which some point in the circuit, where full system voltage is present, comes in direct contact with the ground or return side of the circuit. This establishes a path for current flow that contains only the very small resistance present in the wires carrying the current. There must be a method of protecting people and equipment. Devices have been developed to protect people and electrical circuits from currents and voltages outside their normal operating ranges. 1.3 Objectives of the Study The main objective of this seminar work is to highlight the importance of electrical distribution board in an electrical installation with main emphasis on Commercial building and the specific objectives of this study are as follows: 1. To minimize electrical hazards as fast as possible 2. To reduce service outages to the smallest possible segment of the system 3. To protect the consumers' apparatus 4. To protect the system from unnecessary service interruptions and disturbances 1.4 Significance of the Study A distribution board (also known as panel board, breaker panel, electric panel, DB board or DB box) is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure. A distribution board is the main electrical supply system for any commercial or residential entity. The main cable comes into the distribution board and then by breakers gets distributed in the 6 secondary circuits such as lights and plugs. For optimal performance of every device, it is necessary to maintain a proper power distribution and is crucial for home and appliance safety. Distribution boards are duly fitted with BS bars, DIN rail, and neutral link. Distribution boards are not just a mere enclosure but an overall system in itself having neutral links, earth leakage unit and interconnecting wires for the sole purpose of proper electrical distribution in your house. The standard distribution these days are made in accordance not just with the technical requirements but also as per home décor, so that it can blend easily. 1.5 Definition of Terms Electrical Protective Device: A device used to protect equipment, machinery, components and devices, in electrical and electronic circuit, against short circuit, over current and earth fault, is called as protective devices. Fuse: A fuse is an electrical safety device that has the capability to protect an electric circuit from excessive electric current. Circuit breaker: Circuit breakers are devices that protect circuits from overload current conditions. They do the same job as fuses, but they are not destroyed when activated. Distribution board: A distribution board is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure. 7 CHAPTER TWO Review of Related Literature 2.1 The Generic Configuration of an Electrical Distribution Board The basic configuration of most distribution boards is similar. Just like all boards, the Siemens distribution board consists of various gadgets. This is because the distribution board is an overall system in itself. It consists of neutral links, interconnected wires, and earth leakage units. The main component of the electrical distribution boards is the circuit breaker. This circuit breaker is specially equipped to distribute the total amount of electricity amongst the other miniature circuit breakers (MCB). These electric units are passed from the miniature circuit breakers to the individual power outlets through wires and cables. (Omokhafe and Ambafi, 2011) Often these cables are also attached to the electrical distribution board but are placed opposite the feeder electric cable. FIG 2.1 Generic configuration of an Electrical Distribution Board 2.2 Power Distribution Box When talking about distribution boxes we cannot ignore Power Distribution Boxes or Power Distribution Units (PDU) or a Distro. A distro safely distributes electricity 8 from the power source to other devices in a circuit. It has one input and multiple outputs. That means several devices are connected to the distro rather than connecting directly to the power source. While ensuring safety, it makes distribution more efficient and convenient. The main advantage is its ability to reduce the chances of blown fuses or dangerous short-outs. (Amrapali, 2017) The shapes, sizes, and construction of power distribution boxes widely vary and can be customized. The possible variables are input and output voltages. Additionally, the number of inputs can also be adjusted, and manufactured with added safety features, such as MCBs and RCBs. Fig. 2.2 Power Distribution Box (Jigupamar, 2011). Power distribution boxes are useful as they eliminate the need to connect each output device directly to the power source. Therefore, there is no need to use more wires than what is necessary. This saves energy, streamlines the circuit, ensures efficiency, and controls power wastage. It creates a safer work zone for staff and visitors, as they have fewer physical wires to deal with. Wires can be a major tripping hazard as they get entangled with other things. (Jigupamar, 2011). 9 2.3 Components of Electrical Distribution Boards Along with these components, there are other pertinent components in an Electrical Distribution Board. These include fuse links, residual current detector (RCD), switches, bus bar, and bypass equipment. Each of these components plays a vital role in providing safety to a building from electrical accidents. For example, the residual current detector (RCD) prevents the infrastructure from issues such as ground fault shock and fire due to a short circuit. The bypass equipment, on the other hand, prevents the board from issues such as power overloading. (Gupta, 2005) The basic structure and technical aspects of electrical distribution boards vary according to places and requirements. A typical electrical distribution box will include: 2.3.1 Fuses Fuse is the safety device and the weakest part of the electrical system. It consists of a small link to the soft metal which melts when excessive current passes through it. (Amrapali, 2017). The fuse wires are usually bare wires and are made of lead and tin. Lead alloy for small current and tinned copper wire is used for large current. However, fuse need no maintenance and it is the cheapest form of protection available. It main disadvantage is wrong rewiring when it cuts and time delay when compare to circuit breaker which leads to damage of the connected equipment to be protected. Due to this, fuse is not used in the design. (Ewesor, 2018) 10 .2.3.2 Circuit Breakers These are automatic electrical switches designed to protect an electrical appliance from damage when drawing current above its rated value (Jigupamar, 2011). It basic function is to detect faults. Unlike fuses, they can be reset (manually or automated) after a break. This existing ability is an advantage over Fuse. (Launches, 2016) i. Main Circuit Breaker: This is the main electromechanical device that can cut off power from the meter cable. ii. Miniature Circuit Breakers (MCB): A miniature circuit breaker controls the supply to various miniature circuits on the main circuit. They switch off if they detect an overcurrent i.e. current that supersedes the circuit’s current rating. They can be single-pole, double-pole, triple-pole, and four-pole, based on the capacity of each circuit and the required energy input of the appliances connected. iii. Residual Current Circuit Breaker (RCCB): Put simply, RCCBs are lifesavers, mandatory in many states’ electrical codes. They can detect if the current is being leaked into a human body or into water (i.e. an earthing fault), and then automatically switch off. They are highly sensitive circuit breakers used in series with MCBs and can detect any slight imbalance between the phase conductors. iv. Molded Case Circuit Breaker (MCCB): These devices have the same function as MCBs, except with a far higher current rating. This means it has more versatility and can interrupt larger current ranges, allowing it to be used in both residential and industrial applications. 11 v. Isolators: These are manually controlled electromechanical devices for isolating a part of the circuit for maintenance. They are often used in series with MCBs for when an MCB fails. Electricians use this to cut off the current in a circuit so that they can repair the circuit without getting shocked. vi. Busbars: Busbars are copper or aluminum conducting strips that carry a large amount of current from the incoming meter line to the various circuit breakers in the distribution board. vii. Switches: These are present on all circuit breakers and automatically switch off in case of any detection in overcurrent and short circuits. vi. Identification Labels: These stickers help name the different miniature circuits based on the rooms they control, so that end users can understand which switch they have to flip to turn off or turn on a specific section of the house/unit. Other components are: a bus bar, switches, bypass equipment, and residual current detector (RCD.). At a broad level these components will aid in: Residential electrical installation The incoming supply circuit breaker or main switch Control and distribution board (consumer unit) Surge protective devices Earth resistance between the electrode and the point of zero potential. Working with the wires and cables in an electrical system must be safe, and the distribution boards must ensure the following: The fuse should block overcurrent through the circuitry. There should be enough space for other wires, fixtures, and cables. 12 Should not be prone to corrosion. Best-quality wiring should be used to ensure safety. 2.4 Functions of the component of electrical distribution board Their main functions are to: Break up the power supply into sub-circuits depending on the purpose for it. Ensure that everyone and everything is safe against short circuits. Distribute power to different areas from the main power source. Different types of distribution boards available serve specific distribution requirements, and some are also customizable. 2.5 Importance of Electrical Distribution Board 1. Delivering the Correct Amount of Voltage and Ensuring Building Safely The importance of the electrical distribution board is such that it constantly needs to be checked and old devices needed to be replaced with new ones. But this can be a tricky job. Before doing so, it is important to get these devices tested and approved by a professional electrician. Moreover, it is strictly not advisable for any person to handle these devices without prior experience or assistance. Due to the high distribution board price, most people do not consider setting it up in their residential or commercial buildings. However, to attain maximum performance, efficiency, and safety is it immensely important to set up a reliable electrical distribution board in your commercial building. Nevertheless, you will need to ensure that you use all switches and circuit breakers that are compatible with the main system. 13 2. The distribution box serves as the load centre and Distributor of Electrical Power. A distribution box ensures that electrical supply is distributed in the building, also known as a distribution board, panel board, breaker panel, or electric panel. It is the central electrical supply system of any building or property. As a component of an electrical system: it divides electrical power into subsidiary circuits and provides a protective fuse or circuit breaker for each circuit. (Jim. and Sandi, 1996); A distribution box houses all the contact breakers, earth leakage units, doorbells, and timers. The cable is connected to the distribution board and the power is distributed through the breakers in the secondary circuits (lights and plugs). 2.6 Type of Distribution Boxes 1. Main Breaker Pane: The most commonly used type is the main breaker panel and is important to have in any property as it: 1) Protects the circuits and controls the amperage capacity. 2) Protects the circuits from getting overheated. 3) Protects a power supply by shutting down (including the circuit breaker) in case of a short circuit. 2. Sub Panel: Subpanels are suitable when multiple circuits are required within the same area. Subpanels are easy to install, safe, and efficient for residential homes. These are connected to the main panel through a circuit. They draw power from the main panel and adjust the distribution around an area or property. Being smaller, Sub Panels can 14 distribute power to a specific part of a house or area on the property and work as satellite circuit breaker panels for the area. However, they do not have disconnection. 3. Main Lug Panel: They are generally used as a distribution box during a main upstream breaker. Line wires are connected to these lugs, and the main lug panel can be used as a sub-panel when connected to a breaker from the main panel. The separate disconnection in the meter can be used during a fire or emergency. This will serve as the main breaker and discontinue the power supply even before it enters the property/building. 4. Transfer Switch: A transfer switch (a type of subpanel) is used when a power-load needs to be shifted from one electrical source to another. For example – a normal supply to the generator and vice versa.. Transfer switches are convenient to use as backup power generators where weather is unstable and unpredictable. In case of disruption of power supply, the transfer switch converts generator power to electrical power seamlessly through the breaker panel. There are two types of transfer switches: 1) Manual Transfer Switches: Used when one manually operates the switch to generate the electrical load to the backup power. 2) Automatic Transfer Switches: This is used to get temporary electrical power during a power supply disruption from a generator. It is seamless and easy to use, preferred by homeowners. 5. Unitized Panel: It is an exclusive one as this electronic meter displays the electrical parameters. Unitized panels are used in power centres to supply and deliver a low voltage of 15 power from a medium-voltage line. These panels are used in industrial and commercial establishments 6. Panel Fuse Bank: Serves as the load centre of a distribution system. It provides electrical safety protection of an over the current electrical circuit. A panel fuse bank is ideal for distributing electrical power from a solar panel. The power first gets stored on the solar panels and then goes directly to the fuse box before being distributed to the entire house. 7. Industrial Lighting Panel: They reduce the energy consumption in industrial establishments by programming the lights to turns-off during an idle period Distribution of Metallic Case The metallic enclosure shall be dust and weather proof and have a mounting arrangement on a wall. This closure will have an earthling terminal and it will be interlocked with the actuating lever to prevent access to the interior whilst the lever is in the on position. Fixed contacts and other metal parts shall be nickel plated or tinned where it is desirable. MCCB Cable Sizing In selecting the proper size conductors for supplying power in circuit from the source to the load. It is most important that the designer apply the appropriate standards. In the case of power service the electrician usually selects the cable size to corresponding capacity of the circuit breaker at the distribution board. However, 16 voltage drop should be considered because it affect the cable sizing especially the MCCB cable. (Jim. and Sandi, 1996). The overcurrent protection conductors and equipment shall be sized in such a way to open the circuit if the currents research a value that causes excessive or dangerous temperature in conductors (Jigupamar, 2011) The conductors allowable ampacity according NEC are based on four determine factors which are ambient temperature, Heat generated internally, Dissipation into ambient medium and adjacent load carry conductors (Kennedy, 2000). However, conductor shall be sized to carry the load current without deteriorating the insulation. i. Derating Factor This is a factor that consider reduction in actual rating capacity of the cable. The actual rating of the cable is reduce by a certain factor if it is more than one running in parallel. It is a factor that consider safe heating of the cable when more than one cable in parallel. ii. Voltage Drop Cables have resistance which oppose the flow of currents through them, which leads to voltage drop. The voltage at the load is lower than the supply voltage by the amount of the voltage drop across the cable which depends on the length of the cables. These losses normally result in heating of the cables and at the same time cause temperature rise to such degree that can damage or completely destroy the cable insulation. However the rate at which heat in the cable take place depend on conductor material, surface area and thickness of the insulation. (Kennedy, 2000) 17 Most manufacturers recommends that voltage drop should be 1% however NEC limits the voltage drop to 3% in a branch circuit to avoid power quality problem in a branch circuit. (Launches, 2016) Multiply Factor The multiplying factor considered in this research in sizing of cable is based on the NEC code as presented in Table 1. Design considerations Design consideration in this research are namely: 1. Location of the panel 2. Load rated value 3. Phase requirement 4. Future expansion of the DB Applicable Design Standards The applicable design codes from international organization and reliable literature are summed up in Table1. Table I: Design Code for Sizing a Distribution Board (Jigupamar, 2011). S/N Elements Code(Multiplying Factor 1 Miniature circuit breaker 1.25 2 Mould case circuit breaker 1.25 3 Cable/conductor 1.25 4 Load future expansion 18 2.7 Uses of Distribution Boards i. Electrical Distribution: It is from where you can distribute and control the electrical supply to different sections of your house. It arranges the electrical distribution into a subsidiary or miniature circuits. ii. Electrical Security: A circuit breaker or fuse will protect each miniature circuit. Fuses are now out of use, due to their lack of reusability. 2.9 Types of Distribution Boards Based on usage, location, and amperage, there are several types of distribution boards available today. They are used based on the electrical code in the state or district. (Huang GM, Ma, Geng, 2011) and (Huang GM, Ma, Geng, Oyeleye 2019) i. Main Breaker Panel: This type is either used for one whole commercial or residential unit. They are downstream to the supply from the meter cable. They contain the main circuit breaker that can cut off all supplies to the unit. They also indicate the amperage rating i.e. the entire electrical current the circuit can safely take. ii. Main Lug Panel: This type is used when there is a main breaker panel upstream. They have a separate disconnector that can help disconnect it during fires and other calamities. iii. Sub-panel: Like main lug panels, they take the supply from the main breaker panel and split it into smaller circuits for specialized appliances and sections of the house. They, however, do not have separate disconnects. iv. Transfer Switches: This is a variant of a subpanel, which is used in series with backup power generators, to switch from the main supply. These are especially useful in stormy regions when power cuts are frequent. (Geng, 2011). 19 2.9 Safety Precaution When Using Distribution Boards i. Covering: The distribution board must always be covered when not being manually handled. This is to prevent corrosion in the wires and fixtures from moisture, humidity, dust, etc. The unoccupied openings of distribution boards must be covered with a blanking plate. ii. Location: Do not install the distribution board in an area where there can be contact with water. Some basements are disqualified because of this. Many electrical codes deem that they must not be placed at an inconvenient height of 2200 mm above the floor. It is preferable to install it in an out-of-the-way location where children cannot reach it and where interior aesthetics are not disturbed. Also, these boards should not be installed near a fixed cooking appliance, due to fire hazards. iii. Warning Indication: Place a warning sign on the doors of the concealed metal box which houses the distribution board. This will prevent people from carelessly touching hazardous components. iv. Dangerous Symptoms: If you detect a burning smell at the distribution panel, it is a serious fire hazard to your house. Turn off the power and contact a professional electrician. Also, if circuit breakers keep tripping despite you turning off appliances, this could indicate that your circuitry or board is damaged and faulty. You will need to replace it. If you want to understand and purchase this electrician amenity for your properties and buildings, you can always contact Precision Electricals for affordable options. We have had considerable experience supplying them to the Indian B2B market for electrical components and look forward to aiding you in your venture. 20 CHAPTER THREE Summary, Conclusion and Recommendations 3.1 Summary The primary purpose of an electricity distribution system is to meet the customer’s demands for energy after receiving the bulk electrical energy from transmission or subtransmission substation. Electrical distribution boards are an essential part of any building; residential or commercial. These systems aid in the smooth flow of electricity throughout the infrastructure. The distribution board is responsible for supplying varying voltages to different consumption points in the building. 3.2 Conclusion A distribution board (also known as panel board, breaker panel, or electric panel) is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure. Normally, a main switch, and in recent boards, one or more residual-current devices (RCDs) or residual current breakers with over current protection (RCBOs) may also incorporated Where electricity is to be sub-billed between relevant parties in commercial and industrial applications, the meters must meet the requirements of Annex B of MID. For full billing, the meters must comply with Annex B and Annex F. To achieve the accuracy of a meter that requires the use of CT’s, the cable resistance should not exceed a certain value depending on the power capability of the CT provision of more metering and energy efficient solutions through the use of control devices or 21 linking to building management systems. This is to enable electricity supply system divides an electrical power feed into subsidiary circuits while providing a protective fuse or circuit breaker for each circuit in a common enclosure. 3.3 Recommendations 1. It is recommended that over current protective device (CB) must conform to international standard of 25% multiplying factor in order to adequately protect the intending load. This is necessary to reduce cost of maintenance and or otherwise procurement of new one. 2. It is also necessary to avoid disruption of work or service. 22 REFERENCES Amrapali.D. and Warsha, k. (2017).Electronic Circuit Breaker. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056 Volume: 04 Issue: 07 | July - www.irjet.net Ewesor, P.O. (2018). Practical Electrical systems installation, work and practice.Frankue partners technical and Engineering Company published by Ambik press ltd, Benin city pp.318., Gupta.J.B (2005).A course in Electrical Installation Estimating and Costing 8th edition.Publisher S.K Kataria and Sons, 6, Guru Nanak Market Naisarak Delhi 110006.pg. 497. Jay Kumar et al. Password Based Circuit Breaker. International Journal of Recent Research Aspects. Issue 1, March 2016, pp 80-88. Jigupamar.(2011). Difference between MCB, MCCB, ELCB and RCCB, Electrical Engineering Portal October, https://electricalengineering- portal.com. Jim P. and Sandi Y. (1996); Sizing a Circuit Breaker https://www.ecmweb.com/basics/sizing-circuit-breaker, Kennedy, B. (2000). Power quality primer publisher McGraw-Hill Inc, London, pg 361. Launches E. (2016). Arc Fault Detection Device to Reduce Electrical Safety Risk, Eaton Company Press Release; Liu J, Huang GM, Ma Z, Geng Y. (2011). A novel smart high-voltage circuit breaker for smart grid applications. IEEE Transactions on Smart Grid.;2(2):254–264. M. O. Oyeleye (2019). Design of 11/0.415 kV substation using applicable international codes.journal of multidisciplinary engineering science studies. Marrano J. S. and Dilouie C.E.M. (1998), Electrical system design and specification handbook for industrial facilities. Publisher The Fairmont press, 700 indian Trail Lilburn, GA 30047, pp 437 National electrical code, NEC.(2005). International series, pp. 711. Omokhafe J. T, and Ambafi G. J. (2011). Innovations in Science and Engineering, Vol.1, PP.104-114, www.woaj.org/ISE Oyeleye, M.O. (2017). Evaluation and planning of lightening protection efficacy on Nigerian high voltage installations.Ikorodu 11 kV-132 kV system as case study.Phd thesis Federal university of Technology Akure, Nigeria, pp.122-125 pg 192. Stallcup’s, J. (2005), Electrical design book published by Jones and Bartlett London, pp 9- 30. Yuan W, Zhao L, Zeng B. (2014). Optimal power grid protection through a defender– attacker–defender model.Reliability Engineering & System Safety. 121:83–89.